Making method of function-enhanced fermented soybean leisure food

A technology for a snack food and a production method, which is applied in the directions of food ingredients, functions of food ingredients, food science, etc., can solve the problems of many preparation steps, complicated processes, shortened production cycle, etc., and achieves rich nutrition, increased soluble protein content, The effect of suppressing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

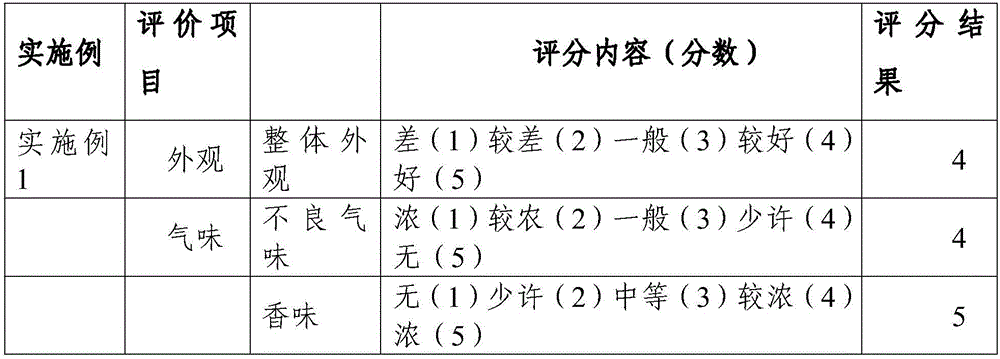

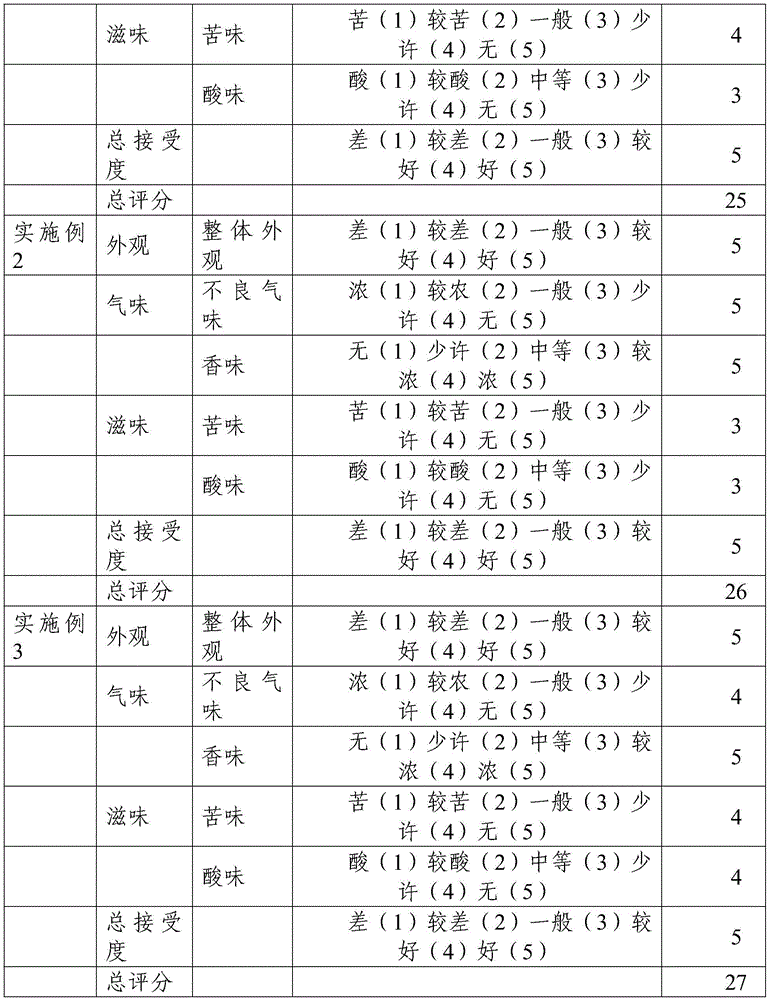

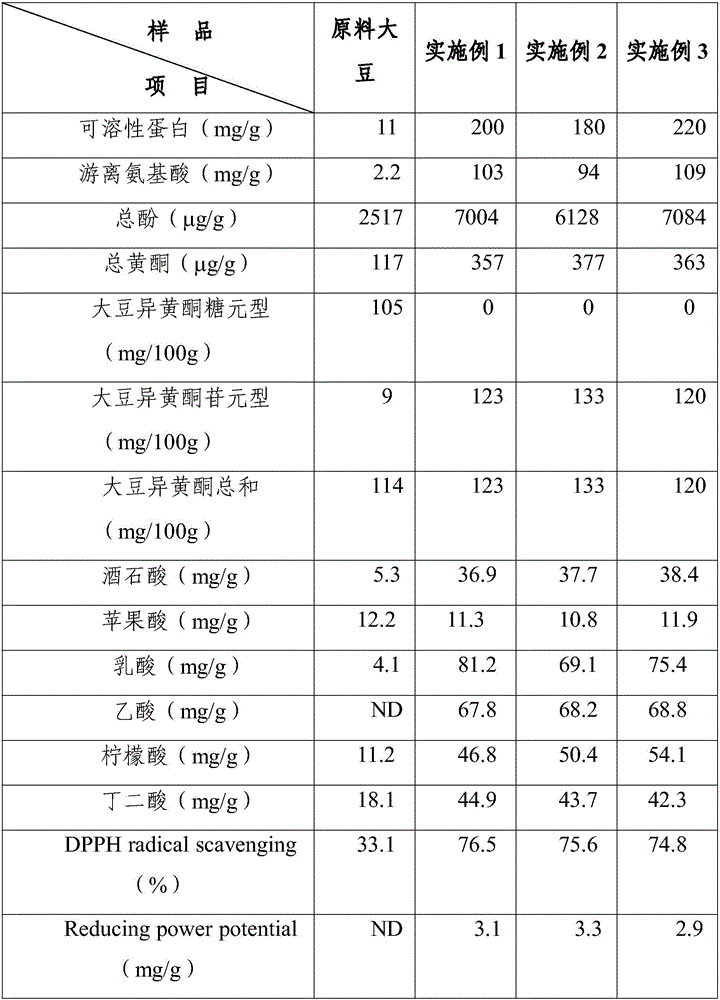

Examples

Embodiment 1

[0021] Preparation of each composite bacterial suspension:

[0022] (1) Preparation of compound bacillus suspension: take out each bacillus preservation strain from the -80°C freezer, and the bacillus includes: Bacillus natto, Bacillus subtilis, Bacillus amyloliquefaciens, Bacillus licheniformis, Bacillus pumilus For Bacillus coagulans and Bacillus coagulans, thaw each preserved strain of Bacillus on ice, inoculate 20μl into 10ml sterilized LB culture medium, shake and culture at 250rpm37℃ until the bacterial concentration is 109cfu / ml; 1:1 (bacteria number ratio) mixed, inoculated with 2% inoculum amount into 200ml freshly sterilized LB medium, shake cultured at 200rpm at 37°C for 6-12h to obtain a composite Bacillus suspension.

[0023] (2) Preparation of compound lactic acid bacteria suspension: take out each preserved strain of lactic acid bacteria from the -80°C freezer, and the lactic acid bacteria include: Lactobacillus rhamnosus, Lactobacillus plantarum, Lactobacillus ...

Embodiment 2

[0033] The preparation of each composite bacterial suspension is the same as in Example 1.

[0034] Preparation of Aspergillus oryzae compound enzyme solution:

[0035]Put Aspergillus oryzae in the PDA solid medium and cultivate it for about 7 days to activate it. After the Aspergillus oryzae is full, add sterile water to wash the Aspergillus oryzae spores to obtain a spore suspension, and then add the spore suspension to the prepared enzyme-producing medium In the medium, aerobic culture at 28°C for 7 days, adding PBS buffer solution for low-temperature extraction for 18 hours, taking it out, centrifuging, and selecting the supernatant to obtain the Aspergillus oryzae complex enzyme solution.

[0036] The preparation method of the enzyme-producing medium is as follows: add wheat bran, bean cake powder, and phosphate in a conical flask, add water, mix well, and sterilize at 121° C. for 30 minutes.

[0037] A method for preparing a function-enhanced fermented soybean snack foo...

Embodiment 3

[0042] The preparation of each composite bacterial suspension is the same as in Example 1.

[0043] Preparation of Aspergillus oryzae compound enzyme solution:

[0044] Put Aspergillus oryzae in the PDA solid medium and cultivate it for about 7 days to activate it. After the Aspergillus oryzae is full, add sterile water to wash the Aspergillus oryzae spores to obtain a spore suspension, and then add the spore suspension to the prepared enzyme-producing medium In 26°C, aerobic culture was carried out for 7 days, and PBS buffer solution was added to extract at low temperature for 16 hours. After taking it out, it was centrifuged, and the supernatant was selected to obtain the complex enzyme solution of Aspergillus oryzae.

[0045] The preparation method of the enzyme-producing medium is as follows: add wheat bran, soybean meal, and phosphate into an Erlenmeyer flask, add water, mix well, and sterilize at 121° C. for 30 minutes.

[0046] A method for preparing a function-enhance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com