Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Increase rolling capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing technology and device for improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller

ActiveCN105401059AEasy feedingOvercome the defect of prone to tissue segregationFurnace typesProcess efficiency improvementManufacturing technologyFerrosilicon

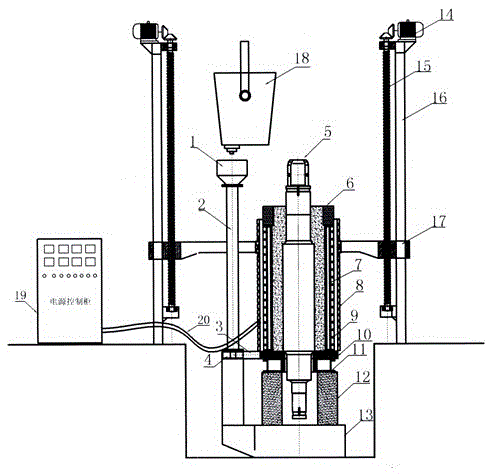

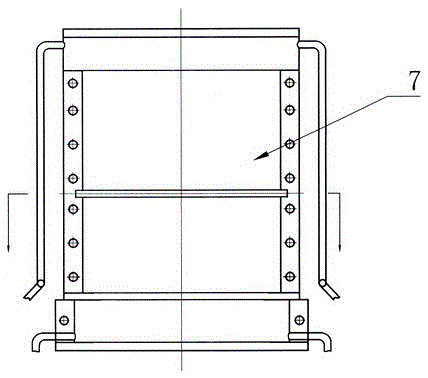

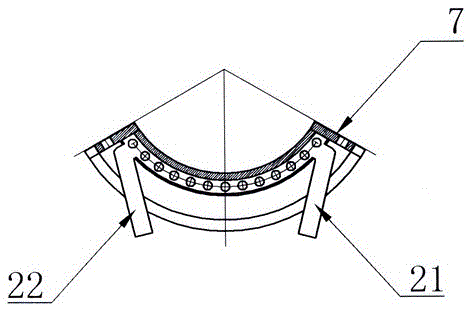

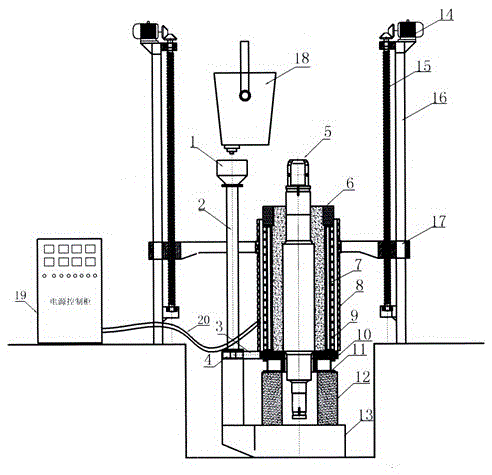

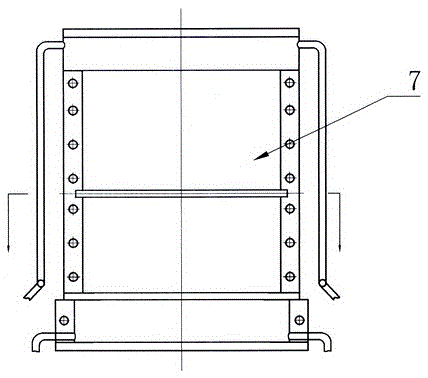

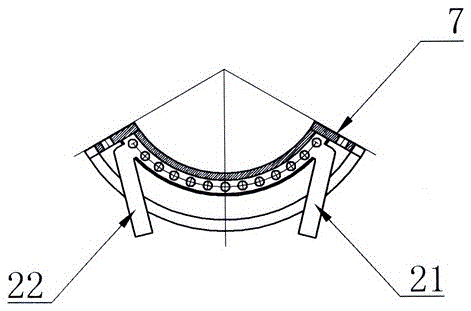

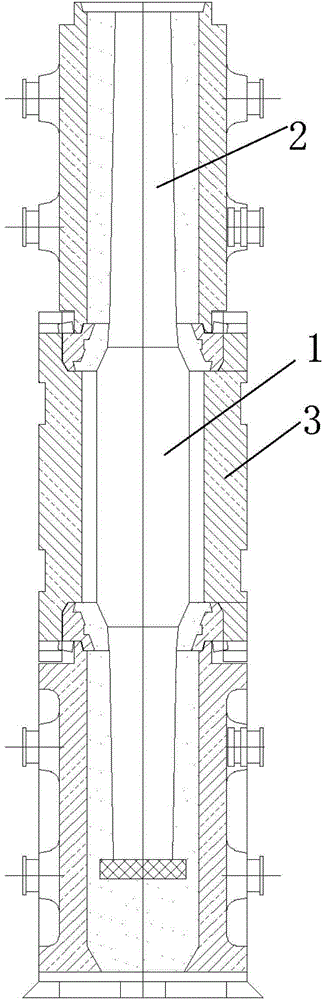

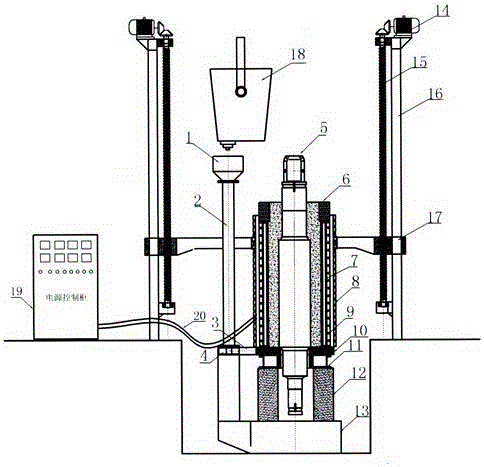

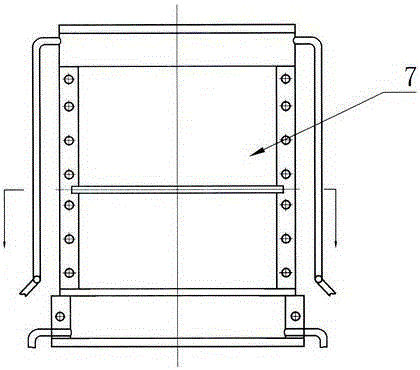

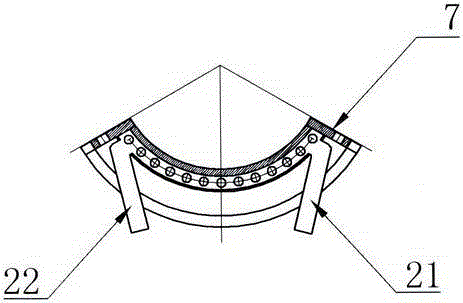

The invention discloses a manufacturing technology and device for an improved forged steel roller neck high nickel chrome molybdenum alloy cast composite roller. The roller comprises, by mass percent, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% of Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, not larger than 0.05% of P, not larger than 0.03% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE and the balance Fe and inevitable micro elements. Yttrium base rare-earth nodulizing and Ba, Ca, and silicon iron composite inoculation are adopted, Nb, Ti, V, B and Sb are added for modification, and the mechanical performance of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved, an induction heater is adopted to carry out in-mold whole heating casting on a core stick, a water cooled crystallizer is molded, a composite layer interface can be dynamically controlled, the technology is simple, the efficiency is high, power consumption is small, the cost is low, no composition segregation exists, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

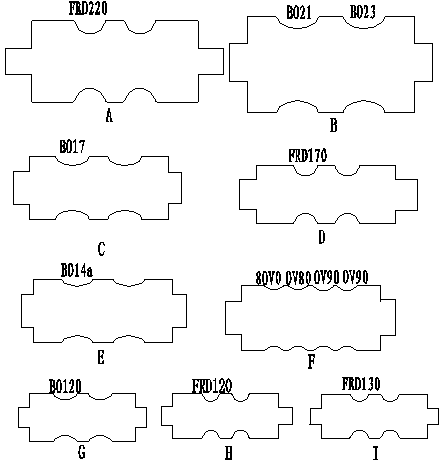

Method of manufacturing oriented silicon steel strip in razor-thin

InactiveCN1562511AIncrease rolling capacityReduce rolling pressureLiquid surface applicatorsWork treatment devicesSteel platesAcid washing

A process for preparing the very-thin oriented silicon steel band with high and stable magnetic property includes such steps as acid washing of recrystallized and oriented silicon steel plate, cold rolling to make its thickness reach 0.06-0.1 mm, heat treating at 700-980 deg.C in protective atmosphere, coating and annealing.

Owner:NORTHEASTERN UNIV

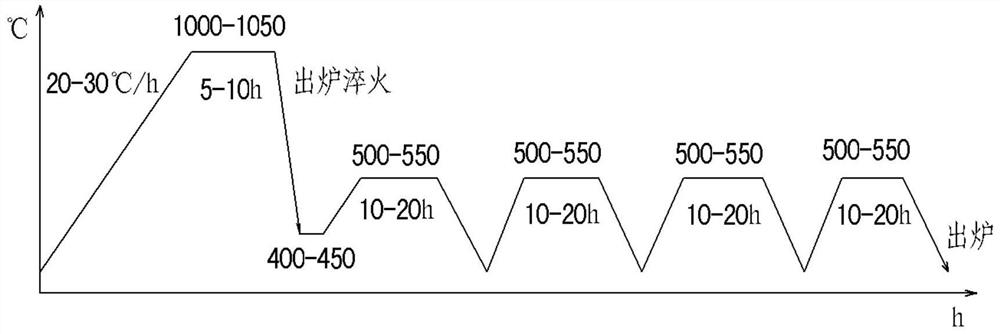

Heat treatment method for one-piece casting hot-rolled strip supporting roller

InactiveCN104561504AFine grainImprove wear resistanceFurnace typesHeat treatment furnacesTemperature treatmentMicrostructure

The invention discloses a heat treatment method for a one-piece casting hot-rolled strip supporting roller and belongs to the technical field of roller heat treatment methods. The heat treatment method is used for carrying out heat treatment on the one-piece casting hot-rolled strip supporting roller. According to the technical scheme, the heat treatment method comprises the following steps of entirely heating the roller to a certain temperature by virtue of a resistance furnace, then transferring the roller to a differential temperature furnace for further heating the surface layer of a roller body to a higher temperature, carrying out heat preservation for enough time, tapping, and carrying out spray quenching and tempering treatment so that the microstructure of the roller body is changed into bainite and the microstructures of a roller neck are sorbite and pearlite. By the differential temperature treatment method, the one-piece casting hot-rolled strip supporting roller exhibits excellent wear resistance and comprehensive mechanical properties, so that the wear resistance, thermal cracking resistance and accident resistance of the roller body are improved. By innovating the heat treatment method for the one-piece casting hot-rolled strip supporting roller, the problem that no heat treatment method is suitable for the one-piece casting hot-rolled strip supporting roller in a long term is solved, the quality of the roller is significantly improved, and user requirements in use and enterprise economy benefits are met.

Owner:TANGSHAN IRON & STEEL GROUP

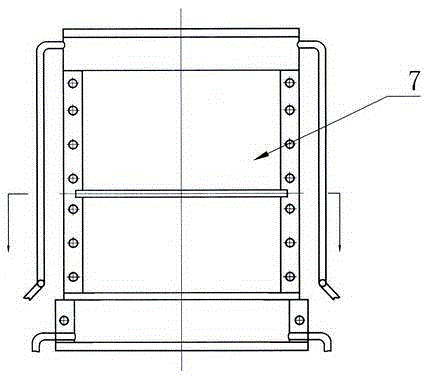

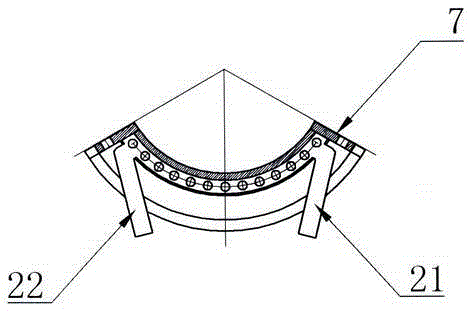

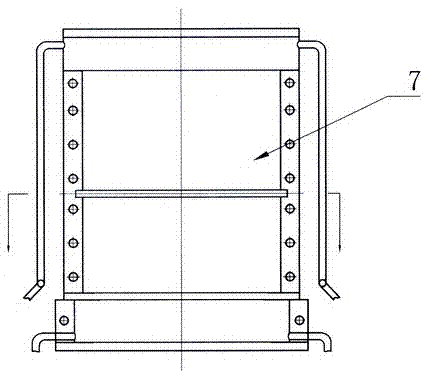

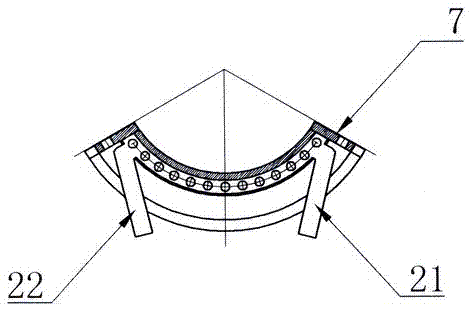

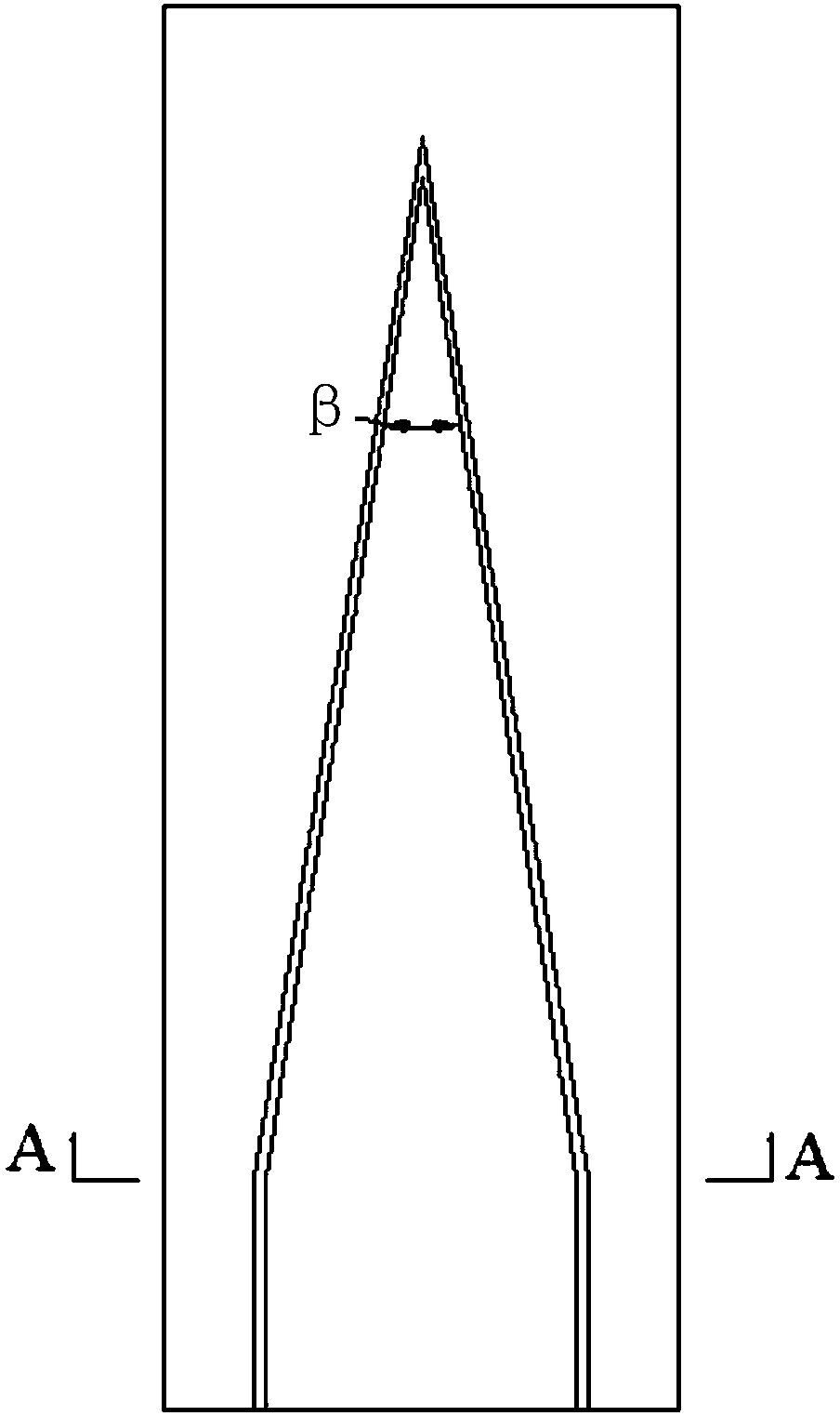

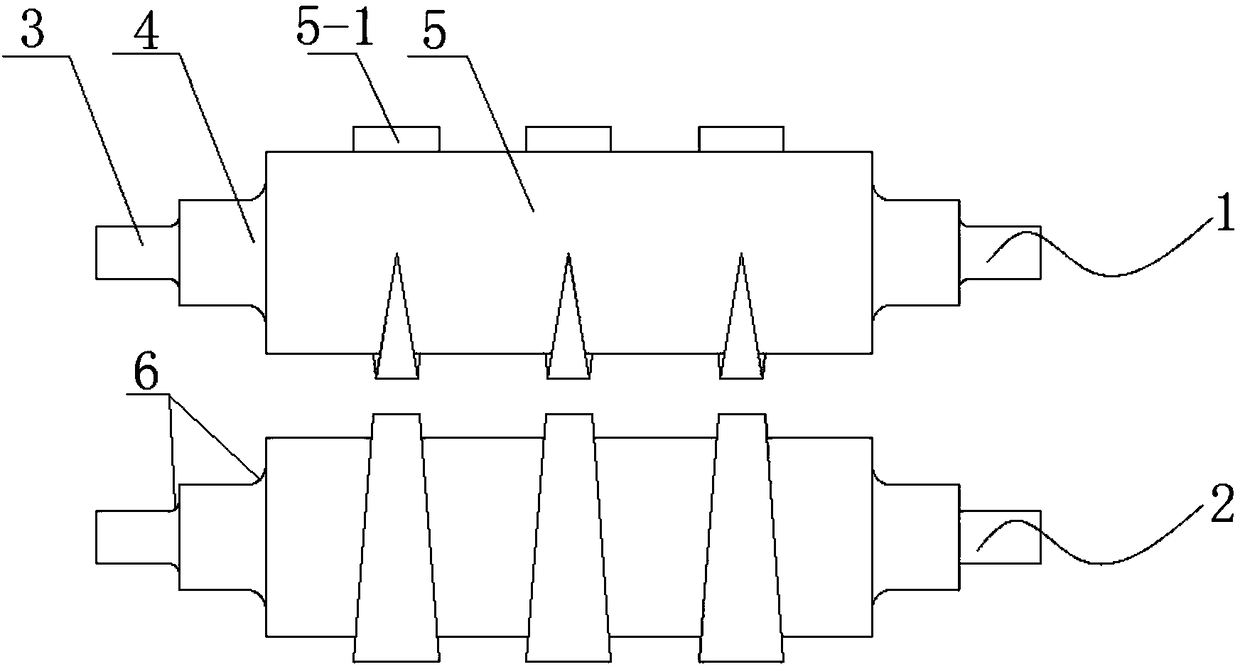

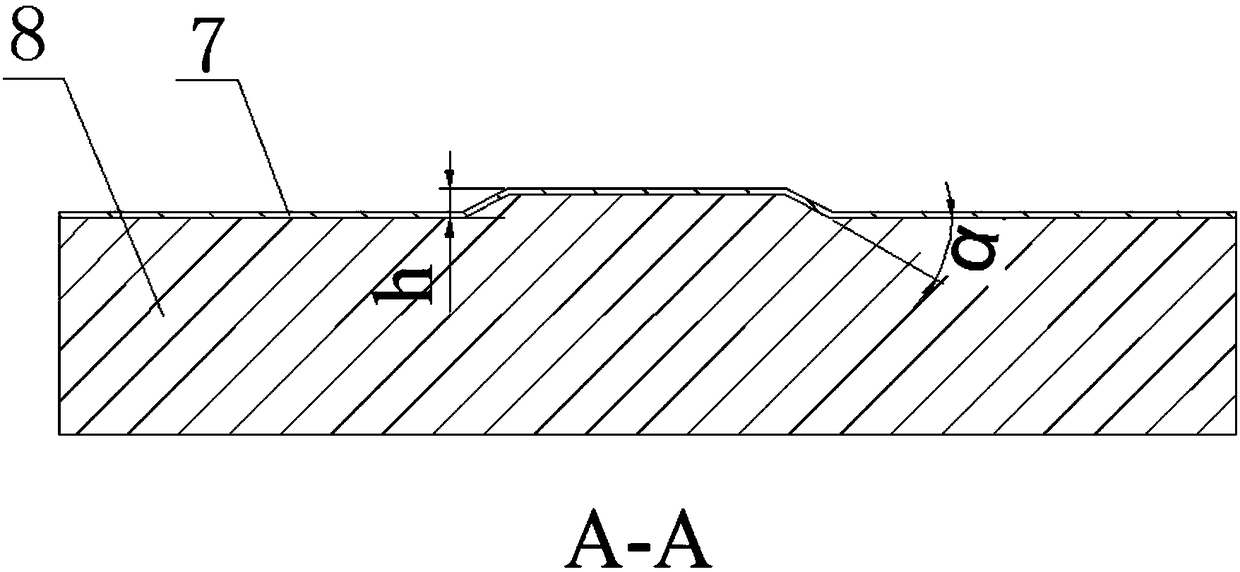

Manufacturing technique and device for improved bainite nodular cast iron composite roller provided with forged steel roller neck

The invention discloses a manufacturing technique and device for an improved bainite nodular cast iron composite roller provided with a forged steel roller neck. The improved bainite nodular cast iron composite roller provided with the forged steel roller neck is prepared from, by mass, 3.0%-3.6% of C, 0.60%-1.20% of Si, 0.30%-1.20% of Mn, 3.0%-5.0% of Ni, 1.0%-2.0% of Cr, 0.40%-1.2% f Mo, 0.1%-2% of W, 0.5%-1.0% of Cu, 0-0.05% of P, 0-0.30% of S, 0.04%-0.06% of Mg, 0.1%-0.3% of Nb, 0.1%-0.30% of Ti, 0.2%-0.6% of V, 0.05%-0.2% of B, 1.5%-2.5% of Ba, 1%-2% of Ca, 1%-3% of Sb, 0.02%-0.18% of N, 1.0%-2.0% of Y / RE, and the balance Fe and inevitable trace elements. According to the manufacturing technique and device for the improved bainite nodular cast iron composite roller provided with the forged steel roller neck, yttrium-based rare earth is used for nodularization, Ba, Ca and silicon iron are used for combined inoculation, Nb, Ti, V, B and Sb are added for modification treatment, and thus the mechanical property of the roller is improved; by the adoption of the forged steel roller neck, the strength of the roller is improved; integral in-mold heating and casting of a core rod are conducted through an induction heater, and a water-cooling crystallizer is used for formation; the interface of a composite layer can be controlled dynamically, the technique is simple, power consumption is low, the cost is low, composition segregation is avoided, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Centrifugal metal roll ring and manufacturing process thereof

ActiveCN105463308AImprove surface qualityEnhanced and improved surface qualityFurnace typesHeat treatment furnacesChemical compositionCrack resistance

The invention discloses a centrifugal metal roll ring and a manufacturing process thereof. The centrifugal metal roll ring comprises an inner layer and an outer layer which are made of different materials. The inner layer comprises 0.80%-1.2% of C, 1.00%-2.00% of Si, 0.50%-1.50% of Mn, not larger than 0.03 of P, 0.20%-1.00% of Ni, not larger than 0.20% of Mo, not smaller than 0.04% of Mg and the balance Fe. The outer layer comprises 2.00%-3.00% of C, 0.50%-1.50% of Si, 0.80%-1.50% of Mn, not larger than 0.10% of P, not larger than 0.03% of S, 12.00%-18.00% of Cr, not smaller than 0.50% of Ni, 0.20%-1.50% of Mo and the balance Fe. Compared with high-chromium cast iron and a high-carbon semi-steel roll ring which are obtained through inblock casting and centrifugal casting, by the adoption of the centrifugal metal roll ring, precious metal is saved, production cost is lowered by 18% to 22%, the roll ring is easy to cut, and the matrix organization, impact toughness, wear resistance and heat crack resistance can be improved greatly.

Owner:江苏凯达重工股份有限公司

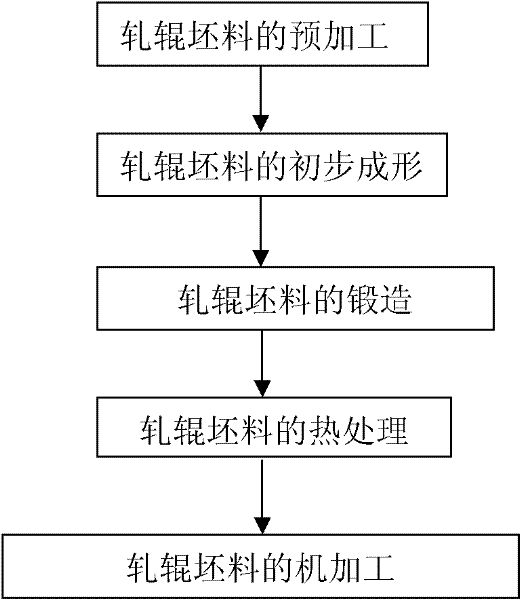

Manufacture method of cold-rolled roller

InactiveCN102528382AQuality improvementImprove pass rateSoldering apparatusCarbidePulp and paper industry

The invention discloses a manufacture method of a cold-rolled roller, which includes the following steps of: 1 preprocessing of roller blanks, 2 preliminary forming of the roller blanks, 3 forging of the roller blanks, 4 thermal treatment of the roller blanks and 5 machining of the roller blanks. The manufacture method 'changes passive removal to active control', does not adopt passive removal mode but researches the mechanism of forming and growing of carbides, controls the carbides after the carbides are formed but no grow up during forging, leads the carbides to constantly maintain in an acceptable level range, and therefore many links in a later segment are reduced, the purpose is achieved and energy consumption is reduced. The effect of the manufacture method can reach above 97%.

Owner:SHANGHAI HEAVY MACHINERY PLANT

Hypoeutectic high-chromium white cast iron roller and preparation method thereof

The invention provides a hypoeutectic high-chromium white cast iron roller and a preparation method thereof. The roller is characterized by comprising a roller sleeve and a mandrel. The roller sleeve is composed of a roller body made of hypoeutectic high-chromium white cast iron and a seamless steel pipe lining, wherein the roller body comprises the following chemical components by mass: C 2.1 to 2.4%, Si 0.5 to 0.8%, Mn 0.3 to 0.5%, Cr 21 to 23%, Mo 1.2 to 1.5%, Ni 1.5 to 1.8%, B 0.3 to 0.6%, Ti 0.1 to 0.2%, W 0.2 to 0.3%, Nb 0.1 to 0.2%, V 0.2 to 0.3%, yttrium-based rare earth 0.3 to 0.5%, S <= 0.03% and P <= 0.03%, with the balance being Fe. The hypoeutectic high-chromium white cast iron roller provided by the invention has the advantages of good heat crack resistance, small hardness drop, good toughness and good wear resistance, and the rolling capacity of the roller is improved by 3 to 4 times compared with the rolling capacity of a centrifugal bainite composite roller.

Owner:邢台正锟机械轧辊有限公司

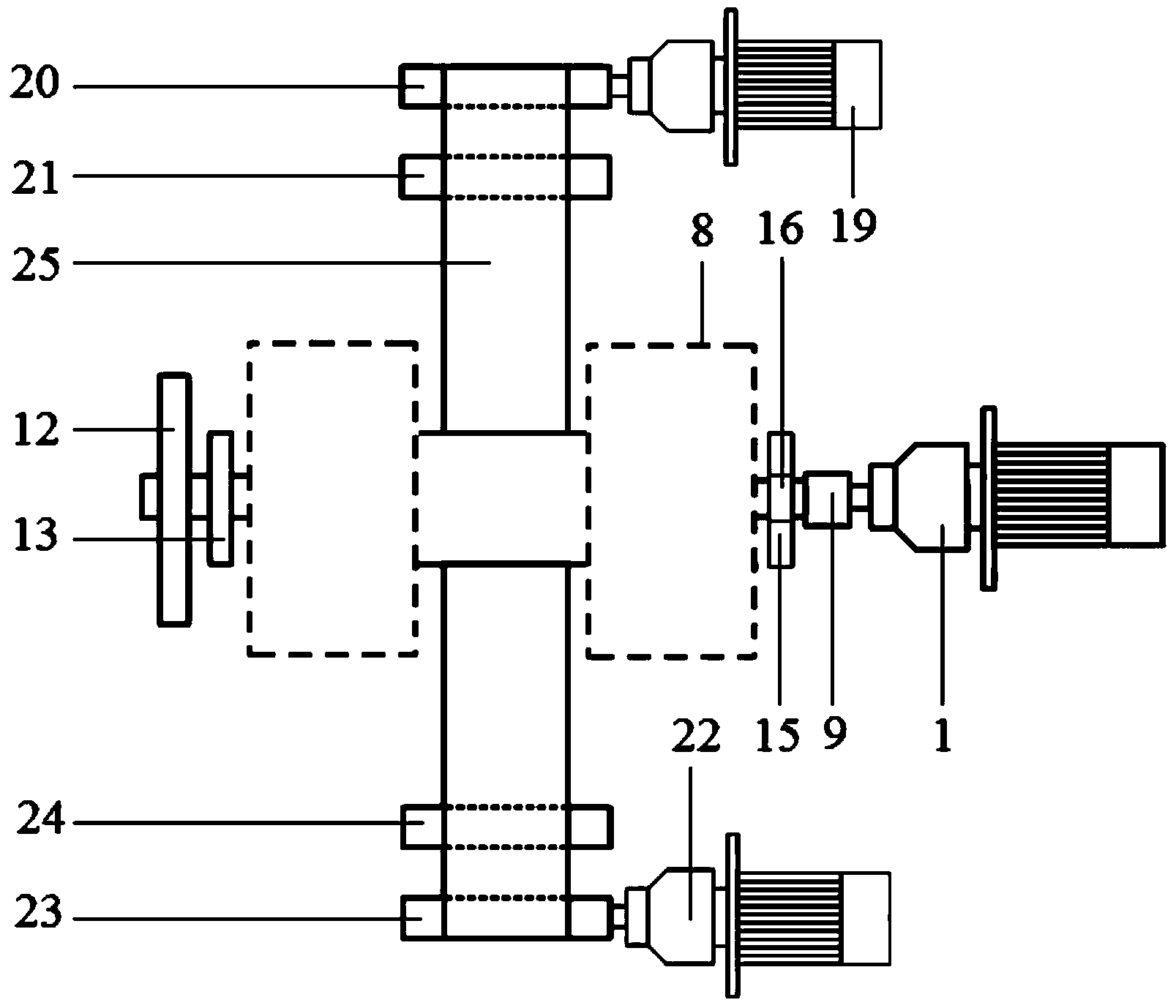

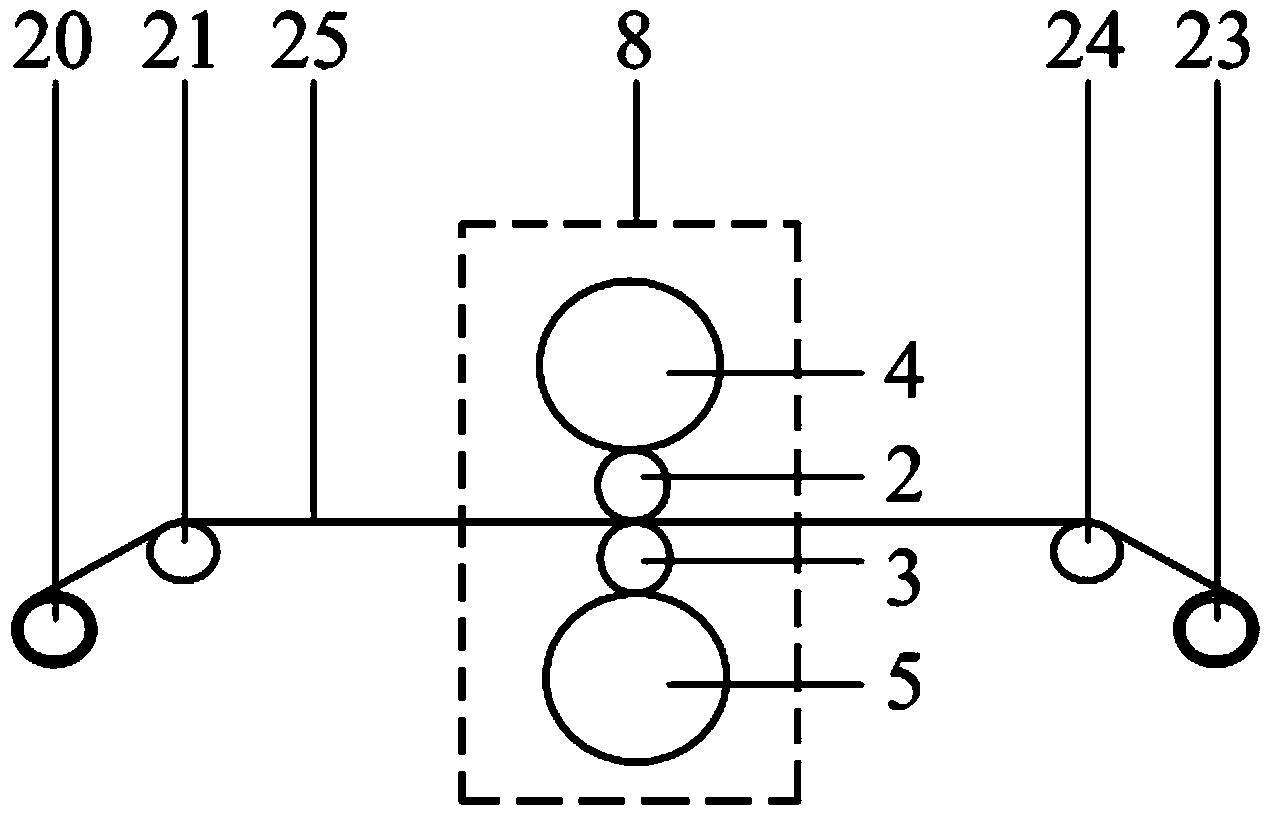

Ultrathin strip rolling mill adopting support roller transmission and rolling method of ultrathin strip rolling mill

ActiveCN104043648AMin limit thicknessStrong rolling capacityMetal rolling stand detailsMetal rolling arrangementsCouplingStrip mill

An ultrathin strip rolling mill adopting support roller transmission and a rolling method of the ultrathin strip rolling mill belong to the technical field of plate and strip rolling. A main transmission motor of the ultrathin strip rolling mill directly drives a support roller by a coupler; the support rollers are driven by first opening gear banks; work rollers and the support rollers are driven by a second opening gear bank and a third opening gear bank; tension motors are positioned at front and rear sides of the rolling mill; a rolled piece penetrates through roller seams and is connected with a reel; the rolling method comprises the steps of preparing two types of first opening gear banks, wherein multiple sets of first type of gear banks are arranged, all sets of the first type of gear banks are different in gear ratio and are used for asynchronous rolling, and the second type of gear banks are same in tooth number and are used for synchronous rolling; selecting one type of gear banks for mounting according to process needs, and applying a rolling force by a pressing device, applying a tension by the tension motors, and starting the main transmission motor, thus finishing the first rolling process rolling. The proper first opening gear banks can be replaced and mounted by multiple times according to the process needs, and the next rolling process rolling is performed till the rolled piece achieves a target thickness.

Owner:NORTHEASTERN UNIV

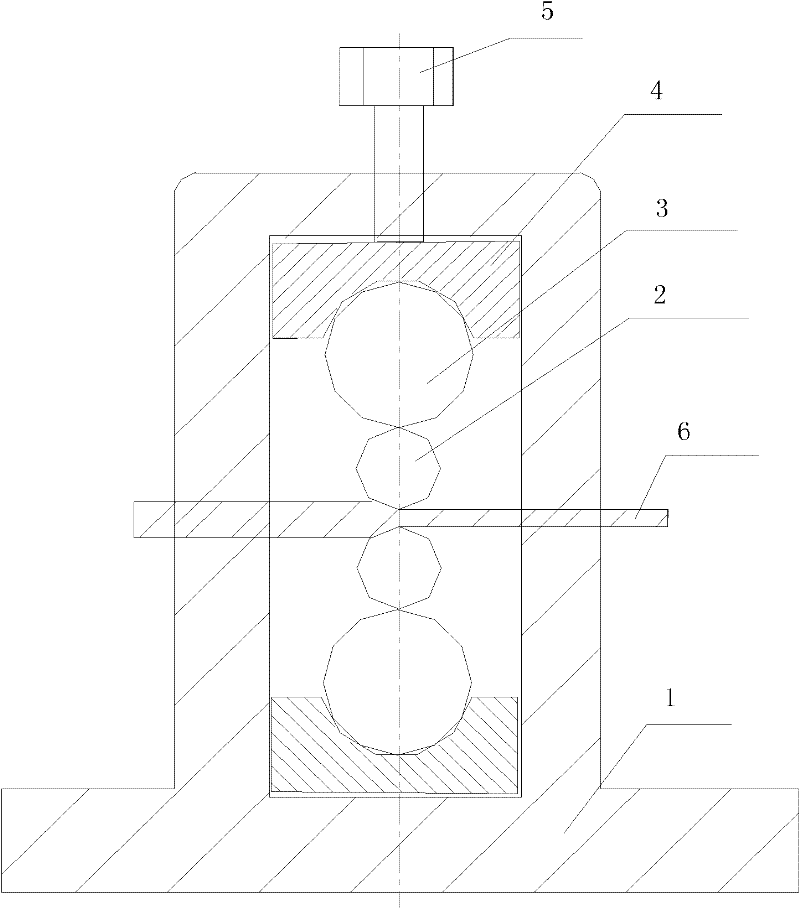

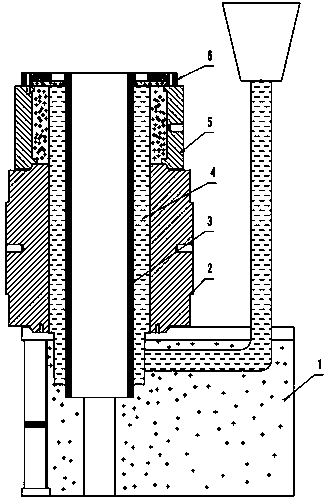

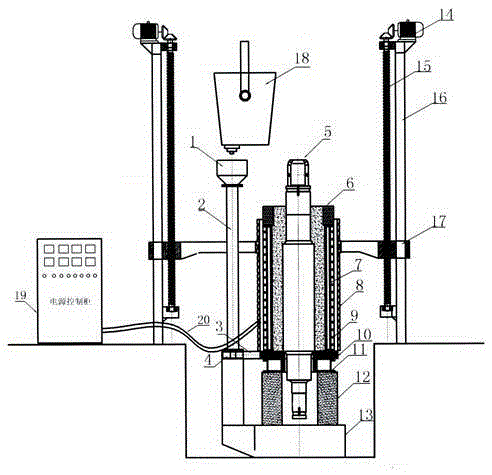

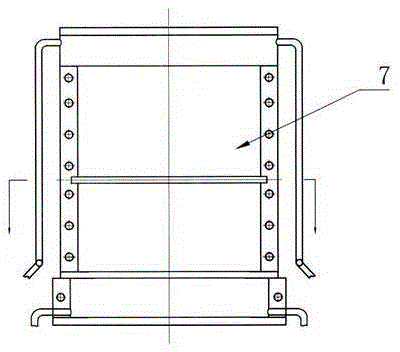

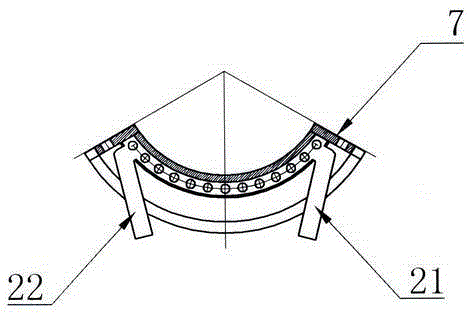

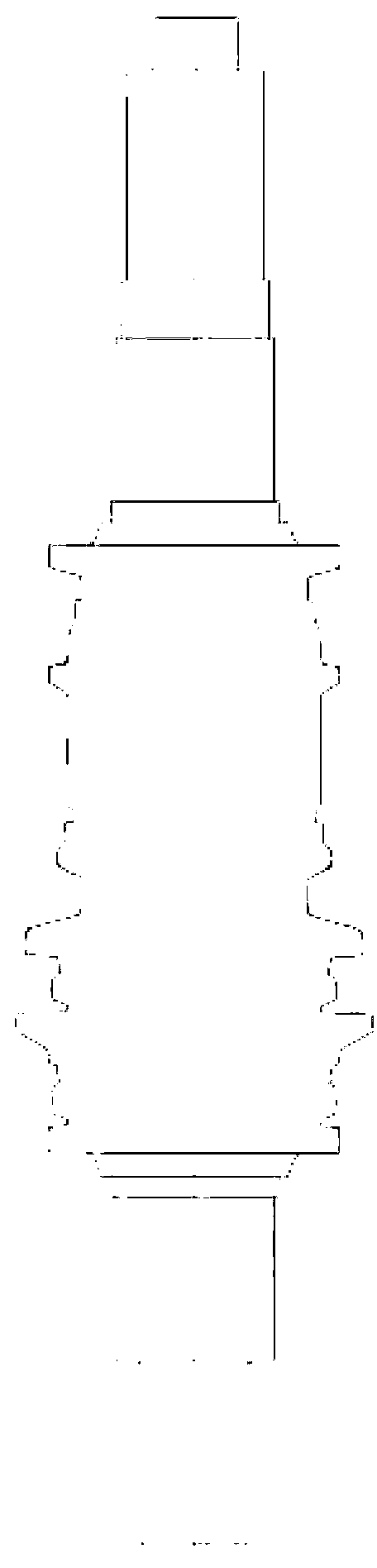

Manufacturing technology and device of forged steel roller neck alloy nodular cast iron composite roller

ActiveCN105397067AEasy feedingOvercome the defect of prone to tissue segregationManufacturing technologyFerrosilicon

The invention discloses a manufacturing technology and device of a forged steel roller neck alloy nodular cast iron composite roller. The forged steel roller neck alloy nodular cast iron composite roller comprises, by mass percent, 3.2%-3.9% of C, 1.6%-2.1% of Si, 0.4%-0.8% of Mn, not larger than 0.05% of P, not larger than 0.03% of S, 0.2%-0.5% of Cr, 0.3%-0.7% of Mo, 1.4%-2.0% of Ni, 0.04%-0.06% of Mg, 0.06%-0.2% of Nb, 0.1%-0.25% of Ti, 0.2%-0.5% of V, 1.5%-2.5% of Ba, 1%-2% of Ca, 1.0%-2.0% of RE and the balance Fe. Rare-earth nodulizing and Ba, Ca and silicon iron compound inoculation are adopted, and Nb, Ti and V are added for modification, so that the mechanical property of the roller is improved, a forged steel roller neck is adopted to improve the strength of the roller, and an induction heater is adopted to carry out in-mold whole heating casting on a forged steel or cast steel core stick; and a combined type water cooled crystallizer is molded, a lifting device lifts the heater upwards at a certain speed to form area directional solidification, a composite layer interface is dynamically controlled, the technology is simple, the efficiency is high, the electric consumption is small, the cost is low, no composition segregation exists in the composite layer, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

Tungsten carbide roller

InactiveCN102069093AOptimize raw material compositionImprove the ratio of ingredientsRollsMetal rolling arrangementsChromium carbideTitanium carbide

The invention relates to a tungsten carbide roller. The tungsten carbide roller comprises the following components of: 84.5 to 85.5 percent of WC, 6.8 to 7.5 percent of Co, 6.8 to 7.5 percent of Ni, 0.2 to 0.5 percent of TiC, 0.2 to 0.5 percent of CrC, and 0.1 to 0.3 percent of VC. The mixed raw material powder is molded by an isostatic pressing process, and a roller blank is subjected to vacuum sintering treatment at the temperature of between 1,390 and 1,490 DEG C. Because a mixture of cobalt and nickel elements, titanium carbide, chrome carbide and vanadium carbide of hard alloy phase with extremely good bonding performance is added, the composition of the tungsten carbide roller is improved, and a reasonable internal tissue structure is formed. By reasonably selecting the sintering temperature in the vacuum state, defects of under sintering, over sintering and deformation are avoided, the tungsten carbide roller with good comprehensive performance is obtained, the rolling quantity of single-roll single rolling rings is improved by over two times, workload and expenditure of roller replacement are reduced, the work efficiency of the roller is improved, and the quality of wire products is ensured.

Owner:ANGANG STEEL CO LTD +1

Tungsten carbide roll collar formula

InactiveCN101994051AOptimize raw material compositionImprove the ratio of ingredientsMotor ticsRolling mill

The invention discloses a tungsten carbide roll collar formula being capable of effectively solving the problems of low combination property and low rolling amount of the traditional tungsten carbide roll collar. The tungsten carbide roll collar formula comprises the following components in weight percentage: 93-98 percent of WC, 1.5-5 percent of Co, 0-4 percent of Ni, 0.2-0.3 percent of TiC, 0.2-0.3 percent of CrC, 0.05-0.3 percent of VC and 0.05-0.1 percent of Y. The invention has the advantages that the raw material composition and the component proportion of a tungsten carbide roll are improved so that the tungsten carbide roll has the internal condition formed by an internal organization structure meeting the service performance requirement, and moreover, the roll collar has small abrasion loss, smooth surface and long service period, cannot be broken and has low roll replacing frequency, and thus, the roll replacing work load is reduced, the cost is reduced, the operating rate of a rolling mill and the product quality are improved and the inherent quality and the surface quality of produced wire rod products are ensured.

Owner:ZHEJIANG HENGCHENG CEMENTED CARBIDE

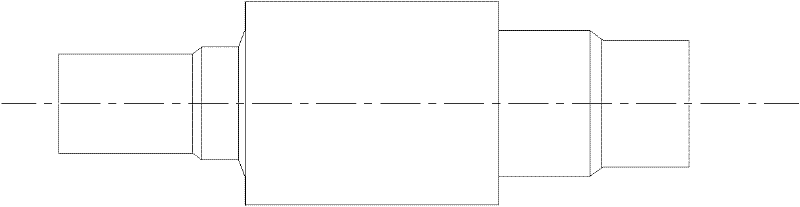

Intermediate roll of multi-roll mill and manufacturing method thereof

The invention discloses an intermediate roll of a multi-roll mill and a manufacturing method thereof. The intermediate roll of the multi-roll mill comprises the following chemical components in percentage by weight: 0.80-0.90 percent of carbon, 0.60-1.00 percent of silicon, 0.40-0.60 percent of manganese, 7.00-8.00 percent of chromium, 1.80-2.20 percent of molybdenum, 0.40-0.70 percent of vanadium, less than or equal to 0.025 percent of phosphorus, less than or equal to 0.010 percent of sulfur and the balance of iron and inevitable impurities. The manufacturing method of the intermediate roll of the multi-roll mill comprises the steps of smelting and forging of a roll blank, pre-heat treatment and final heat treatment, wherein the pre-heat treatment adopts tempering and quenching treatment at the temperature of 960-980 DEG C and tempering treatment at the temperature of 600-630 DEG C; the final heat treatment adopts overall quenching treatment at the temperature of 1,020-1,070 DEG C, cold treatment at the temperature of minus 75 DEG C and tempering treatment at the temperature of 500-550 DEG C. The intermediate roll of the multi-roll mill has better wear resistance performance and better accident resistance performance, and the requirements of a Sendzimir mill can be met.

Owner:BAOSTEEL ROLL SCI & TECH

Roller applicable to cross wedge rolling shaft type parts and production technology

The invention relates to a roller and a production technology, in particular to a roller applicable to cross wedge rolling shaft type parts and a production technology. The roller is prepared from chemical ingredients comprising 1.8-2.2% of C, 0.4-0.60% of Si, 0.8-1.2% of Mn, 0.03% or less of P, 0.025% or less of S, 1.2-1.6% of Cr, 1.6-2.0% of Ni, 0.6-0.8% of Mo, 0.2-0.4% of V, 0.2-0.4% of Nb andthe balance Fe and a small amount of residual elements, then, two-furnace smelting is carried out, yttrium-based rare earth alterant is added, and a special heat treatment technology is carried out, so that the roller is obtained. The phenomenon that carbide exists in a discontinuous (granular) state is changed by optimally allocating the chemical ingredients, particularly adding niobium and vanadium, and the microscopic structure of the roller is improved. Meanwhile, by adding the yttrium-based heavy rare earth alterant for purifying molten steel in the steel melting process, the purity is improved, the comprehensive mechanical property of the roller is improved, the yield and quality of rolled products are improved, the service life of the roller is prolonged, and the purposes of cost decreasing and benefit increasing for enterprises are achieved.

Owner:湖州中杭轧辊有限公司

High-nitrogen high-speed steel centrifugal composite roller and preparation process thereof

ActiveCN112743064AImprove wear resistanceExcellent thermal fatigue crack resistanceFurnace typesProcess efficiency improvementThermal fatigueCrack resistance

The invention relates to the technical field of rollers, and provides a high-nitrogen high-speed steel centrifugal composite roller. The high-nitrogen high-speed steel centrifugal composite roller comprises an outer layer and a core part. The outer layer is made of high-nitrogen high-speed steel and is prepared from the following components in percentage by weight: 0.8-1.8% of C, 0.3-1.0% of Si, 0.4-1.0% of Mn, less than or equal to 0.030% of P, less than or equal to 0.025% of S, 5.0-15.0% of Cr, 0.5-4.0% of Mo, less than or equal to 2.0% of Ni, less than or equal to 5.0% of V, less than or equal to 3.0% of Nb, less than or equal to 5.0% of W, 60-300ppm of [N] and the balance of Fe. The core part is made of high-strength nodular cast iron and comprises the following components in percentage by weight: 2.5-3.5% of C, 2.0-3.0% of Si 2, 0.3-0.8% of Mn, less than or equal to 0.10% of P, less than or equal to 0.03% of S, less than or equal to 0.5% of Mo, less than or equal to 0.5% of Cr, more than or equal to 0.04% of Mg and the balance of Fe. Through the technical scheme, the problems of poor toughness, wear resistance and thermal fatigue crack resistance of the outer layer in the prior art are solved.

Owner:TANGSHAN XIANLONG ROLL INDAL

Technique and equipment for forged steel roll neck high-chrome cast iron composite roller

The invention discloses a technique and equipment for a forged steel roll neck high-chrome cast iron composite roller. Materials comprise, by mass, 2.4-3.3% of C, 0.60-1.0% of Si, 0.50-1.20% of Mn, 0.8-1.2% of Ni, 15-20.0% of Cr, 0.80-2.2% of Mo, 0.5-1% of W, 0-0.05% of P, 0-0.03% of S, 1-3% of Sb, 0.02-0.18% of N, 0.1-0.3% of Y, and the balance Fe and inevitable trace elements. The rare earth Y and silicon iron are adopted for composite inoculation; grain refinement treatment is conducted by adding the Sb and the N, so that the mechanical properties of the roller are improved; the strength of the roller is improved by the adoption of a forged steel roll neck; integral in-mold heating and casting are conducted on a mandril through an induction heater, and a water-cooling crystallizer is used for formation. The interface of a composite layer can be dynamically controlled, the technique is simple, the cost is low, composition segregation is avoided, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

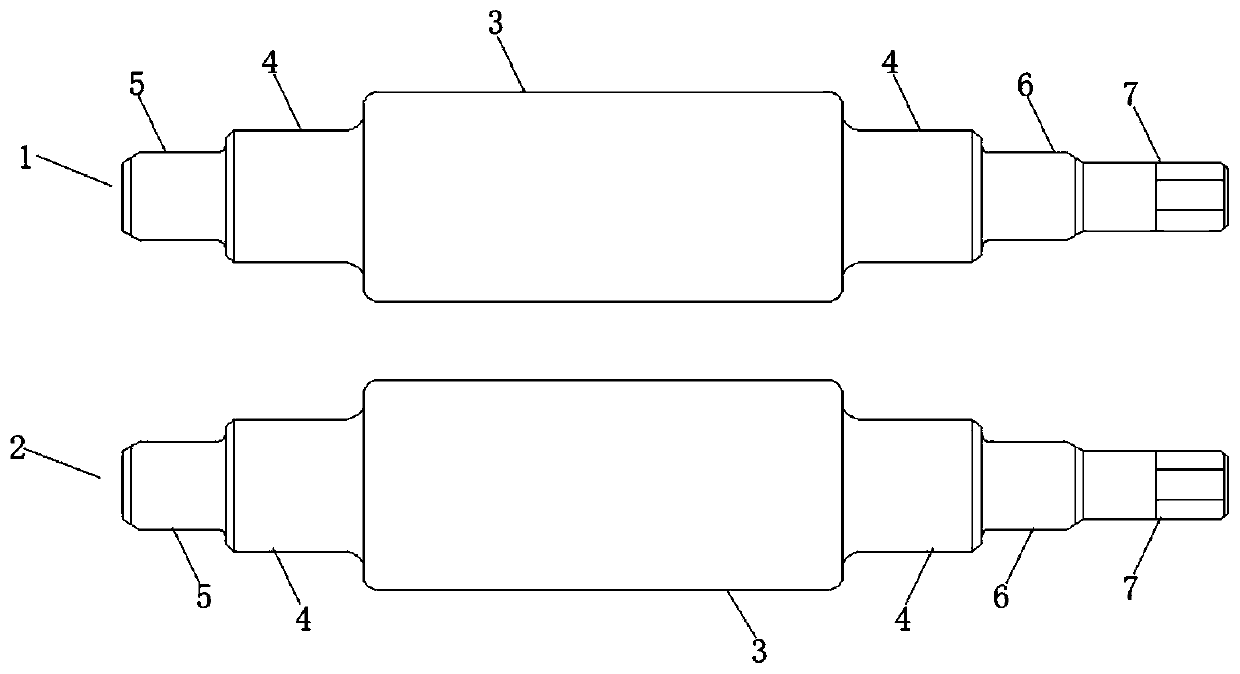

Graphite steel roller used by ribbon steel reversible roughing mill and manufacturing process thereof

PendingCN110218944AImprove wear resistanceLubricant, anti-oxidation, anti-thermal cracking performanceFurnace typesRollsStrip steelGraphite

The invention relates to the technical field of rollers, in particular to a graphite steel roller used by a ribbon steel reversible roughing mill and a manufacturing process thereof. The defect that the use requirement cannot be met in the prior art is overcome; the graphite steel roller includes an upper roller and a lower roller, the upper roller and the lower roller are symmetrically arranged and each comprise a roller body, bearing guards are fixedly arranged on the both sides of each roller body, the other sides of the bearing guards are fixedly provided with first roller necks and secondroller necks, and the other side of each second roller neck is fixedly provided with a transmission part. According to the graphite steel roller used by the ribbon steel reversible roughing mill, molten steel is spheroidized and inoculated by a spheroidizing agent and an inoculant correspondingly, an electromagnetic vibration centrifugal casting manner is used in cooperation, the microstructure of solidification crystallization of the steel industry can be improved, the structure loose area is eliminated, when the roller is used for rolling weathering resistant steel class strip steel, the rolling amount is 1-2 times that of a traditional roller, and the graphite steel roller very popular with users.

Owner:常州市中宇合金轧辊厂

Forged steel roll journal indefinite chill high nickel-chromium-molybdenum composite roll process and equipment

ActiveCN105562647AAchieve regulationMeet manufacturingFurnace typesProcess efficiency improvementTrace elementInduction heater

The invention discloses a forged steel roll journal indefinite chill high nickel-chromium-molybdenum composite roll process and equipment. A material comprises the following components in percentages by mass: 3.1-3.5% of C, 0.70-1.20% of Si, 0.40-1.20% of Mn, 3.0-4.8% of Ni, 1.0-2.0% of Cr, 0.40-1.1% of Mo, 0.1-2% of W, 0.5-1.0% of Cu, less than or equal to 0.05% of P, less than or equal to 0.03% of S, 1-3% of Sb, 0.02-0.18% of N, 0.1-0.3% of Ce, and the balance Fe and inevitable trace elements; rare earth Ce and silicon iron are subjected to compound inoculation, Sb and N are added to carry out grain refinement, mechanical properties of a roll are improved, the strength of the roll is improved by a forced steel roll journal, a mandrel is subjected to internal integral heating fusion casting by an induction heater, forming is implemented by a water-cooled crystallizer, an interface of a composite layer can be controlled dynamically, the process is simple, the cost is low, composition segregation is avoided, and the service life of the roll is long.

Owner:丹阳恒庆复合材料科技有限公司

High-strength low-hardness ferritic nodular cast iron roller ring and manufacturing method thereof

ActiveCN105316565AExtended service lifeImprove wear resistanceFoundry mouldsFoundry coresChemical compositionThermal fatigue

The invention discloses a high-strength low-hardness ferritic nodular cast iron roller ring and a manufacturing method thereof. The roller ring comprises the following chemical components: 3.00-3.10 percent of C, 1.90-2.10 percent of Si, 0.50-0.60 percent of Mn, at most 0.10 percent of Cr, 2.00-2.10 percent of Ni, 0.60-0.70 percent of Mo, at most 0.08 percent of P, at most 0.03 percent of S, 0.04-0.06 percent of Mg and the rest of Fe. The high-strength low-hardness ferritic nodular cast iron roller ring can be strongly extruded for a long term at high temperature so not to be cracked and has good abrasive resistance, extruding toughness and thermal fatigue resistance. The on-machine operation time is prolonged, and the service life of the roller ring is prolonged. Compared with the traditional roller ring, the production cost can be reduced by 22 percent, and the rolling quantity is improved by more than 80 percent.

Owner:江苏凯达重工股份有限公司

High-chromium-steel supporting roller and preparing method thereof

ActiveCN104561817AUniform hardnessImprove wear resistanceCounter-pressure devicesFurnace typesMaterials preparationPressure casting

The invention discloses a high-chromium-steel supporting roller and a preparing method thereof. The method includes: a first step of material preparation, namely a step of preparing outer layer high-chromium molten steel of the supporting roller and center globular graphite molten iron of the supporting roller; a step of centrifugal pressure casting, namely a step of performing centrifugal pressure casting by adoption of a centrifugal roller mold, with the inner diameter of the centrifugal roller mold being 560-900 mm, maintaining the temperature (for a period of time), and unpacking to obtain a supporting roller workblank; and a step of subjecting the supporting roller workblank to thermal processing. By addition of V and Nb which are alloy elements to the outer layer casting molten steel, surface hardness of the supporting roller is uniform (not more than 1.0 / 1.5 degree), and can reach 50-65 HSD according to demands of users. By adding a BaCa nucleating agent improving the balling degree into the center globular graphite molten iron, the tensile strength of a roller neck is not less than 550 MPa. Accordingly, the high-chromium-steel supporting roller is extremely high in abrasion resistance and high in toughness and thermal fatigue resistance, and the accidents of fatigue cracks, peeling and falling on both sides of the roller body during operation of the supporting roller are almost avoided.

Owner:江苏凯达重工股份有限公司

Roller for rolling large profile steel and manufacturing technology of roller

ActiveCN103341492AActs as a lubricantSolve the sticky steel problemRollsMetal rolling arrangementsManufacturing technologyCarbide

The invention discloses a roller for rolling large profile steel and a manufacturing technology of the roller. A base body of the roller for rolling the large profile steel contains evenly-distributed spheroidal graphite, and the base body is composed of granulous carbide, tempered sorbite and pearlite. When the roller for rolling the large profile steel rolls the large profile steel, the small graphite is crashed under the effect of squeezing, heating and the like, the effect of lubricant can be achieved during rolling material hole punching, the problem of steel sticking is solved, and the surface of a rolled piece is bright and clean.

Owner:江苏凯达重工股份有限公司

Wear-resistant high holding precision rolling rear working roller and production method thereof

The invention discloses a wear-resistant high holding precision rolling rear working roller which is applied to working roller at precision rolling rear section of hot belt continuous mill in rolling industry. The working layer material thereof comprises a roller body of alloy cast iron and a roller core made of ductile cast iron; the working layer comprises the following alloy components according to percentages by weight: 3.00-3.50% of C, 0.40-1.20% of Si, 0.50-1.20% of Mn, not more than 0.10% of P, not more than 0.05% of S, 1.30-2.50% of Cr, 3.20-4.50% of Ni, 0.20-1.00% of Mo, 0.50-1.00% of W, 1.5-2.0% of V, and Fe and unavoidable impurities as the rest. The casting method thereof comprises the following steps: using a horizontal centrifuging machine to cast working layer of roller; statically casting core portion and roller neck portion after condensation of the working layer; then annealing the roller for 28-30h at 420-430 DEG C and annealing the roller for 28-30h at 490-510 DEG C. The working roller prepared in the invention has high wearing resistance and excellent roller holding ability, and is capable of completely meeting quality requirement of rolling high-grade plate.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Asynchronous cold rolling forming process of aluminum alloy stainless steel composite plate

ActiveCN110883093AIncrease rolling capacityImprove rolling precisionTemperature control deviceWork cooling devicesComposite plateLine heating

The invention discloses an asynchronous cold rolling forming process of an aluminum alloy stainless steel composite plate. The process comprises the following process steps: 1, rolling and compoundinga stainless steel plate and an aluminum alloy plate in an asynchronous rolling mode, and 2, after asynchronous rolling, diffusing and annealing the composite plate, specifically, in the step 1, online heating is carried out on the opposite surface of the composite plate surface of the stainless steel plate, online cooling is carried out on the opposite surface of the composite plate surface of the aluminum alloy plate online, and the heating temperature is 350 DEG C-850 DEG C; the temperature of the composite plate surface of the stainless steel plate from which the composite plate is rolledis lower than 650 DEG C, and the temperature of the composite plate surface of the aluminum alloy plate from which the composite plate is rolled is lower than 300 DEG C; the rolling reduction rate is20%-90%; the different speed ratio of a roller for asynchronous cold rolling is 1.05-1.50; the thickness ratio of the aluminum alloy plate to the stainless steel plate is 1.5-4.0; and in the step 2, the annealing temperature is 250 DEG C-500 DEG C and the annealing time is 15-120 min. The single-side online heating process for rolling the composite plate is creatively provided so as to improve theinterface bonding strength of the composite plate and realize rolling compounding in an interface semi-melting state.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

Roll allocation method and device for optimization of roll pass system

InactiveCN103586284AReduce in quantityReduce occupancyGuiding/positioning/aligning arrangementsWork treatment devicesEngineeringWorkload

The invention provides a technical scheme of a roll allocation method and device for optimization of a roll pass system. The scheme comprises three types of rolls with the specifications of phi 610*760, phi 770*1000 and phi 860*1200, a guide mechanism used for guiding steel materials and a cooling mechanism used for cooling the steel materials. The roll allocation method and device for optimization of the roll pass system are characterized in that the three specifications of rolls are semi-steel rolls with the carbon content of 1.6%, each of the three specifications of rolls is additionally provided with a roll groove on the premise that the safety factor of roll rings is 0.6-0.9, and the section area of each roll groove is smaller than or equal to the section area of original roll grooves of the three specifications of rolls. Meanwhile, in order to adapt to the variation of the roll grooves of the rolls, the guide mechanism and the cooling mechanism are modified, the single-groove rolling amount of the rolls is largely improved, and the problems of low work efficiency and heavy workloads on technical personnel caused by frequent replacement of the rolls are avoided.

Owner:SHANDONG XIWANG SPECIAL STEEL

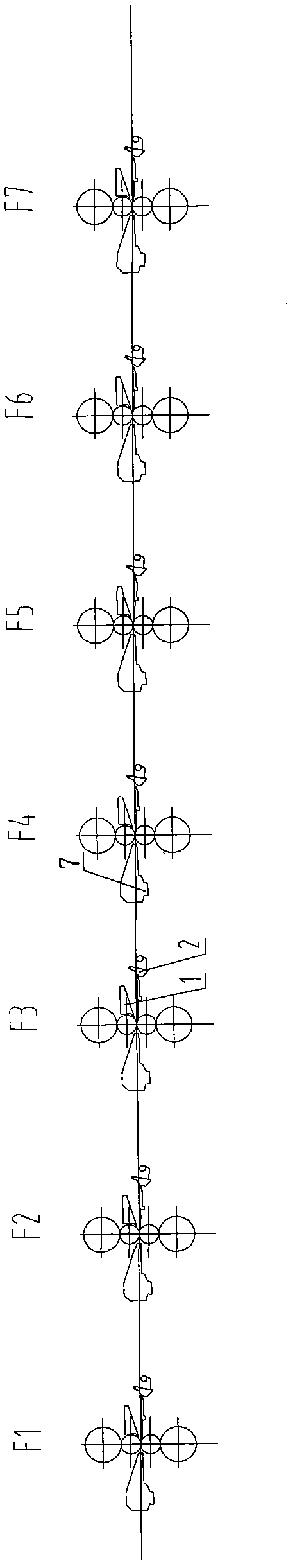

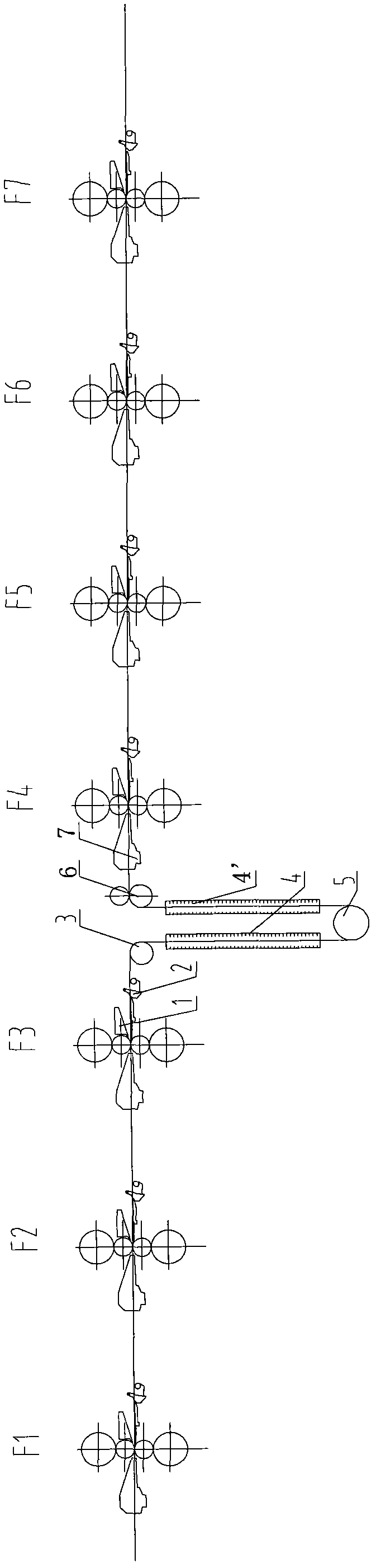

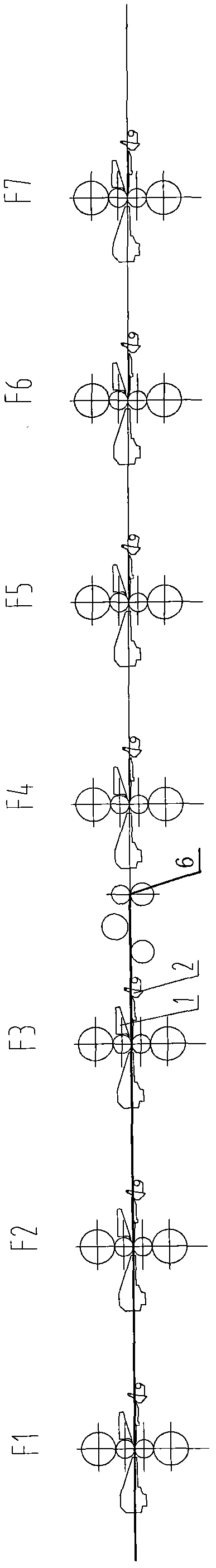

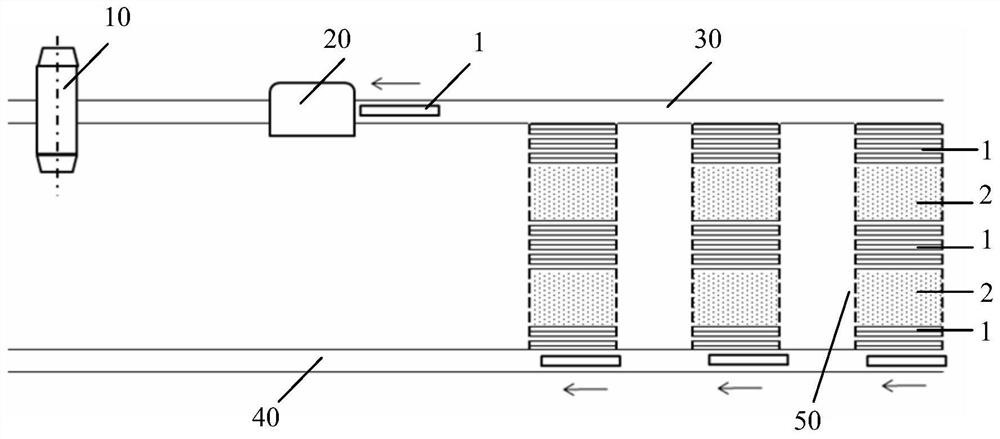

Intermediate additional cooling equipment and method for hot continuous rolling plate band

ActiveCN102303052AIncrease rolling capacityWide thickness rangeWork treatment devicesMetal rolling arrangementsTransmission lineEngineering

The invention discloses intermediate additional cooling equipment and method used for a hot continuous rolling plate band. The intermediate additional cooling equipment arranged between two adjacent racks in a series of hot continuous rolling racks comprises a steering roller (3), at least one cooling device (4, 4'), a long-stroke looper roller (5) and a pinch roller (6), wherein the steering roller (3) and the pinch roller (6) are forward and backward arranged along a plate band transmission line; the at least one cooling device (4,4') and the long-stroke looper roller (5) are arranged between the steering roller (3) and the pinch roller (6); and the work process of the intermediate additional cooling equipment mainly comprises the steps of head part wearing, building a loop, cooling, receiving the loop and drifting. According to the equipment and method provided by the invention, thickness and width ranges of a rolled product are greatly expanded on a basis of no yield reduction, a greater increase of the additional value of the rolled product is obtained, and a greater application value in an actual production is realized.

Owner:BERIS ENG & RES CORP

Anti-wrinkling cold rolling method for 443 ultra-pure ferritic stainless steel

PendingCN114082782AIncreasing the thicknessEliminate and Improve Rolling Wrinkle DefectsTemperature control deviceMetal rolling arrangementsSS - Stainless steelSurface wrinkling

The invention provides an anti-wrinkling cold rolling method for 443 ultra-pure ferritic stainless steel. The method comprises the following steps of molding molten iron into a plate blank, rolling the plate blank into an NO1 plate, pickling and annealing the NO1 plate, rolling the NO1 plate into a cold-rolled hard steel coil by adopting a low pressure reduction rate and fewer passes, and finally slitting and packaging the steel coil. Compared with an existing 443 stainless steel rolling method, the anti-wrinkling cold rolling method has the effects that the rolling reduction rate is low, the total deformation amount is small, the surface wrinkling phenomenon of the plate is effectively reduced, and meanwhile the production efficiency is effectively improved due to the fact that the rolling reduction rate is low and the number of passes is small.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Manufacturing process and equipment for nickel-chromium-molybdenum alloy cast iron composite roller in forged steel roller neck

ActiveCN105328168AEasy feedingOvercome the defect of prone to tissue segregationFerrosiliconDirectional solidification

The invention discloses a manufacturing process and equipment for a nickel-chromium-molybdenum alloy cast iron composite roller in a forged steel roller neck. The nickel-chromium-molybdenum alloy cast iron composite roller is composed of, by mass, 3.3-3.8% of C, 0.6-1.2% of Si, 0.4-1.2% of Mn, 0.6-1.2% of Cr, 0.3-1.0% of Mo, 2.0-3.0% of Ni, 0.6-1.1% of Cu, 0-0.05% of P, 0-0.03% of S, 0.04-0.06% of Mg, 1.5-2.5% of Ba, 1-2% of Ca, 1.0-2.0% of RE and the balance Fe. Rare earth globularization and Ba, Ca and silicon iron composite inoculation are adopted, and the mechanical properties of the roller are improved; the strength of the roller is improved by the adoption of the forged steel roller neck; in-mold integral heating and casting are conducted on a core rod through a sensing heater, forming is conducted through a combined water-cooling crystallizer, a lifting device lifts a heater upwards at a certain speed to form local directional freezing, the interface of a composite layer can be controlled dynamically, the process is simple, the efficiency is high, the electric losses are small, the cost is low, composition segregation of the composite layer is avoided, and the service life of the roller is long.

Owner:丹阳恒庆复合材料科技有限公司

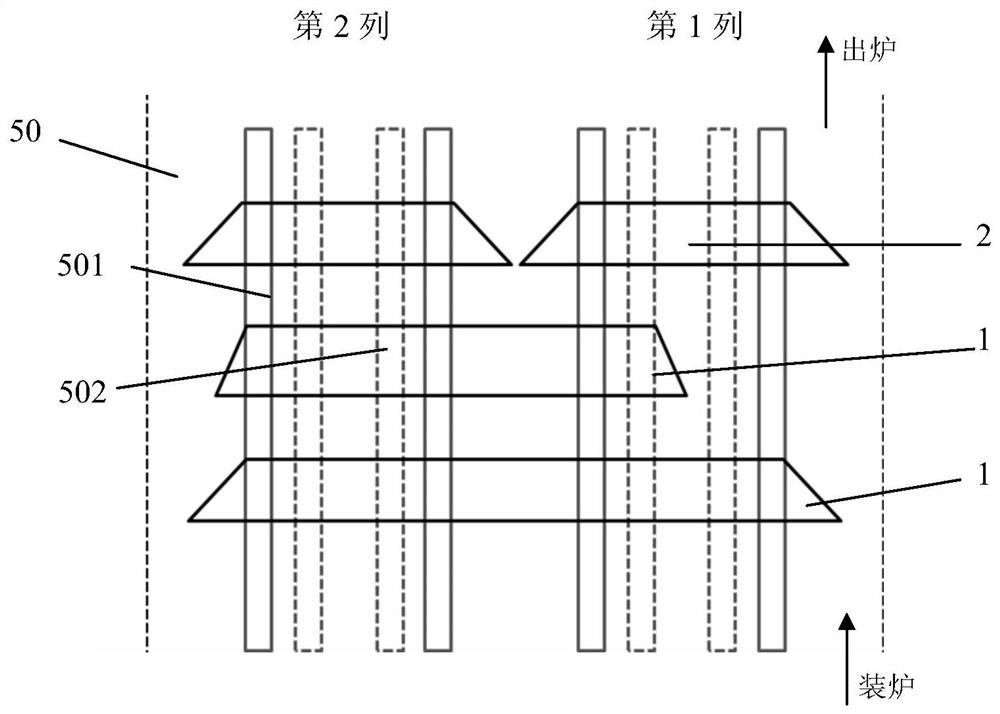

Continuous heating furnace arrangement mode for thick plate production and steel pumping method through same

PendingCN112575176AIncrease rolling capacityProduction efficiency optimizationFurnace typesWork heating devicesThick plateProcess engineering

The invention discloses a continuous heating furnace arrangement mode for thick plate production and a steel pumping method through the same. According to the continuous heating furnace arrangement mode, three walking beam continuous heating furnaces are arranged side by side, and each walking beam continuous heating furnace sequentially comprises a heat recovery section, a preheating section, a first heating section, a second heating section and a soaking section from the furnace tail to the furnace end in the furnace length direction; and a double-discharging mode is adopted for discharging,that is, each heating furnace is provided with two rows of discharging, the bottom of each heating furnace is provided with two sets of walking beam mechanisms, and the two sets of walking beam mechanisms form walking beam synchronous action by arranging a connecting frame. According to the continuous heating furnace arrangement mode, starting from furnace body walking beam synchronism guaranteeand overall optimization of the steel pumping and charging process, the efficiency of the fixed-length blank and long blank combined production process is ensured, finally, the requirement of a user for longitudinal rolled materials is met at the highest speed in batches, and meanwhile the operation cost is reduced; and moreover, efficient supply of long blanks required by longitudinal rolled materials can be achieved alternately in the operation process of a traditional thick plate rolling mode, the rolling efficiency is improved, and the cost is saved.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

High-strength and low-hardness ferritic nodular cast iron roll ring and manufacturing method thereof

ActiveCN105316565BExtended service lifeImprove wear resistanceFoundry mouldsFoundry coresThermal fatigueDuctile iron

The invention discloses a high-strength low-hardness ferritic nodular cast iron roller ring and a manufacturing method thereof. The roller ring comprises the following chemical components: 3.00-3.10 percent of C, 1.90-2.10 percent of Si, 0.50-0.60 percent of Mn, at most 0.10 percent of Cr, 2.00-2.10 percent of Ni, 0.60-0.70 percent of Mo, at most 0.08 percent of P, at most 0.03 percent of S, 0.04-0.06 percent of Mg and the rest of Fe. The high-strength low-hardness ferritic nodular cast iron roller ring can be strongly extruded for a long term at high temperature so not to be cracked and has good abrasive resistance, extruding toughness and thermal fatigue resistance. The on-machine operation time is prolonged, and the service life of the roller ring is prolonged. Compared with the traditional roller ring, the production cost can be reduced by 22 percent, and the rolling quantity is improved by more than 80 percent.

Owner:江苏凯达重工股份有限公司

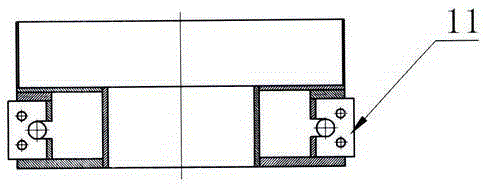

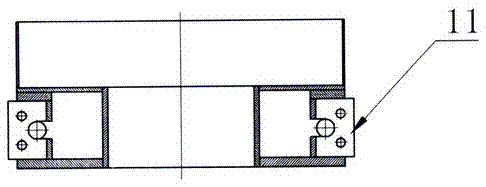

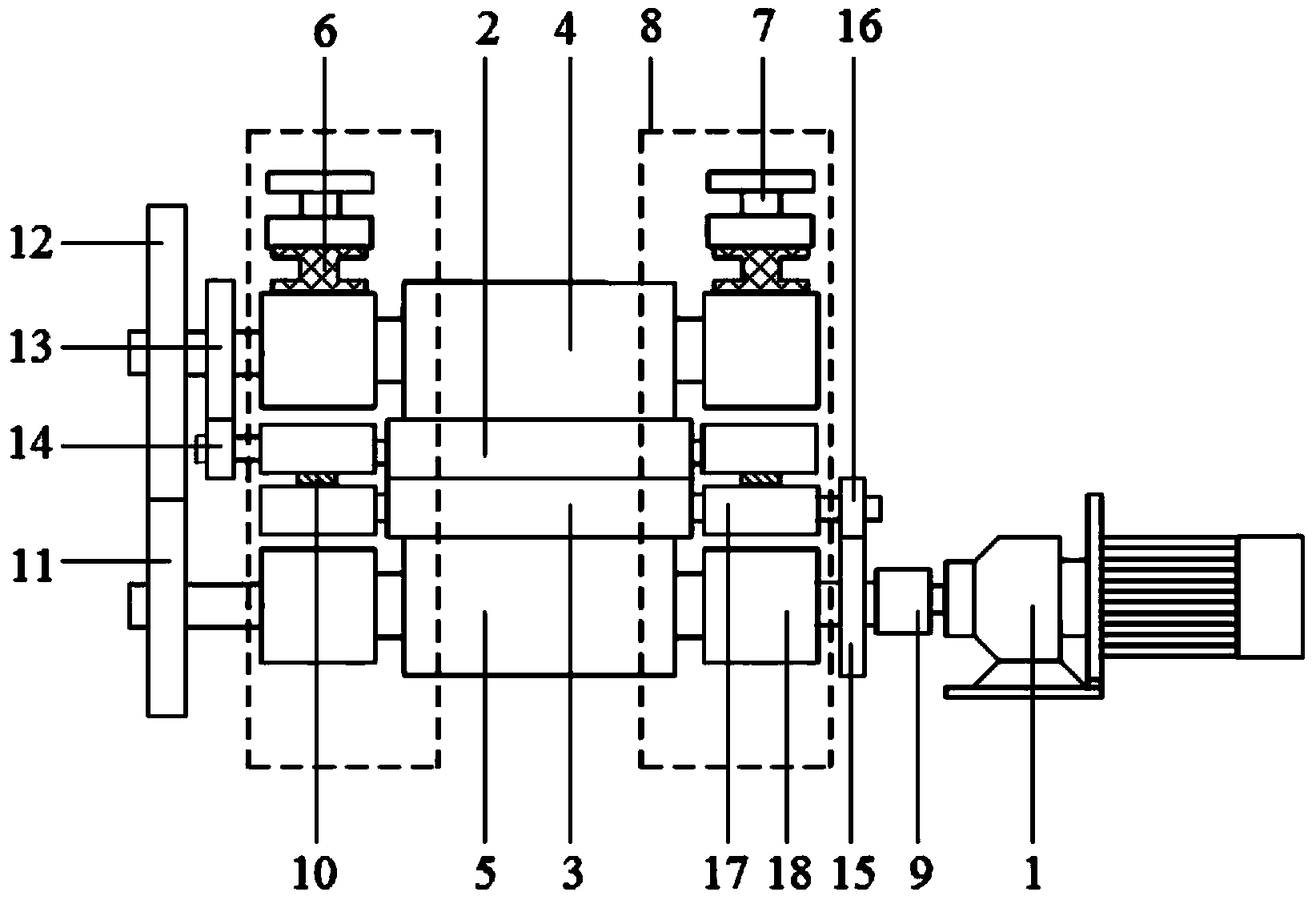

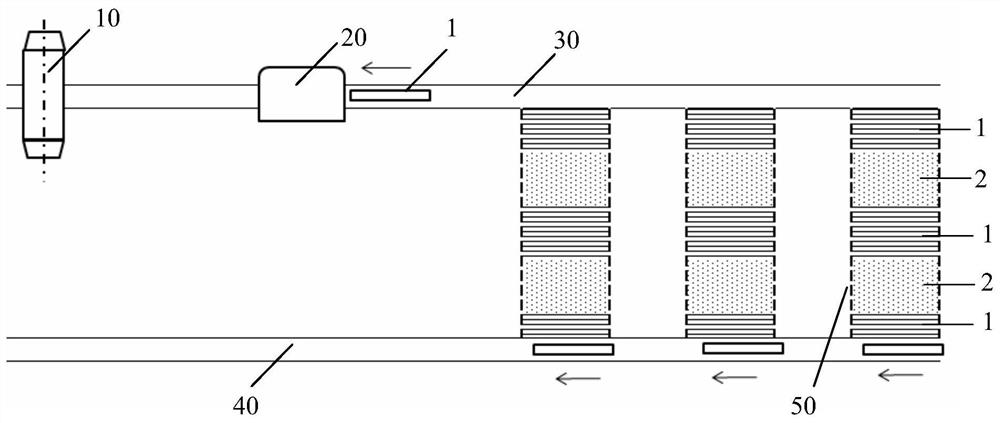

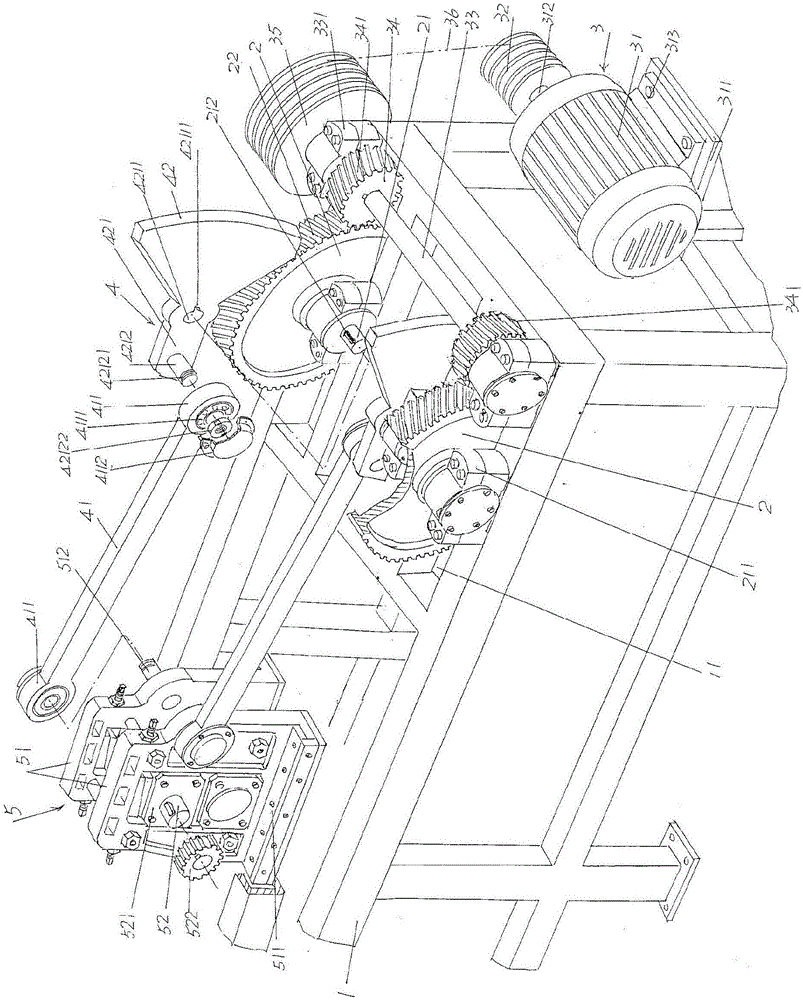

Roller support reciprocated driving device for high-speed cold pilger mill

ActiveCN105834222AMove fastIncrease rolling capacityRolling mill drivesMetal rolling arrangementsGear driveEngineering

The invention relates to a roller support reciprocated driving device for a high-speed cold pilger mill, and belongs to the technical field of steel tube rolling machines. The roller support reciprocated driving device comprises a rack, a pair of large gears, a large gear driving mechanism and a pair of connecting rod mechanisms; the pair of large gears are supported to the right end of the rack through large gear axle shafts in the mutually-corresponding manner; the large gear driving mechanism is arranged at the position, corresponding to the right sides of the pair of large gears, on the rack and is in transmission fit with the pair of large gears; and the pair of connecting rod mechanisms are connected with the large gear axle shafts of the pair of large gears and are connected with a roller support movably arranged at the upper portion of the left end of the rack. The roller support reciprocated driving device is characterized in that each of the pair of connecting rod mechanism comprises a connecting rod and a balance hammer, each balance hammer and the corresponding large gear axle shaft are fixed, the left end of each connecting rod is connected with the roller support, and the right end of each connecting rod is connected with the corresponding balance hammer. The motion speed of the pair of connecting rods can be increased, and the steel tube rolling capacity within unit time can be better improved remarkably.

Owner:CHANGSHU MEILI MACHINERY MFG

Improved nickel chromium molybdenum inlimited cold hard cast-iron for roller and its compound roller

ActiveCN1327022CChange wear resistanceChange in thermal crack resistanceCrack resistanceMetal machining

This invention relates to an improvement of NiCrMo infinite cooling hard cast iron used in roll materials of metal machining hot rolling and cold rolling plate, especially relates to a kind of NiCrMo infinite cold hard cast iron used in roll with excellent wear resistance and thermal crack resistance property, long longevity, the character is adding 0.03-0.1%(WT) B and 0.2-1.5% Nb in the component of NiCrMo infinite cold hard cast iron. As well as the composite roll made from this materials. Because of the addition of B and Nb, the wear resistance and thermal crack resistance property are remarkably improved, which overcomes the disadvantage of raw materials. The operating life of composite roll whose working layers are made from this materials is enormously improved compared with original life. The plate band rolling amount increases more than 20%; the improvement of thermal crack resistance property.

Owner:JIANGSU GONGCHANG ROLL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com