Asynchronous cold rolling forming process of aluminum alloy stainless steel composite plate

A technology of aluminum alloy plate and stainless steel plate, applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of low efficiency, reduce the number of intermediate annealing times, reduce equipment weight and investment, and eliminate internal defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

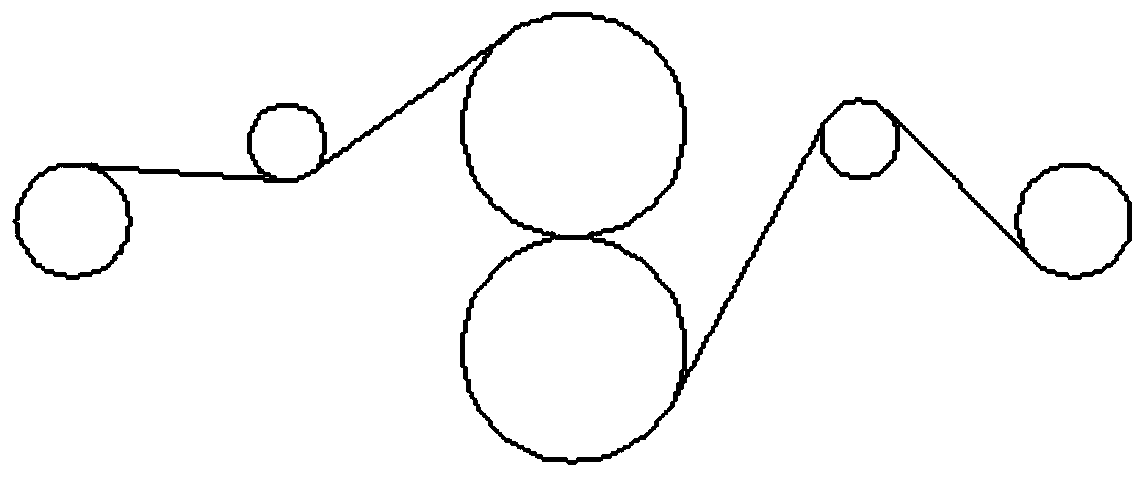

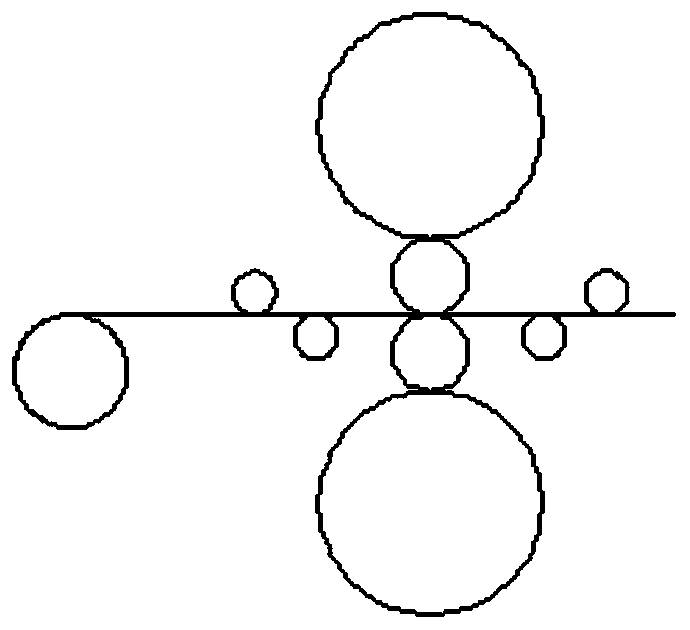

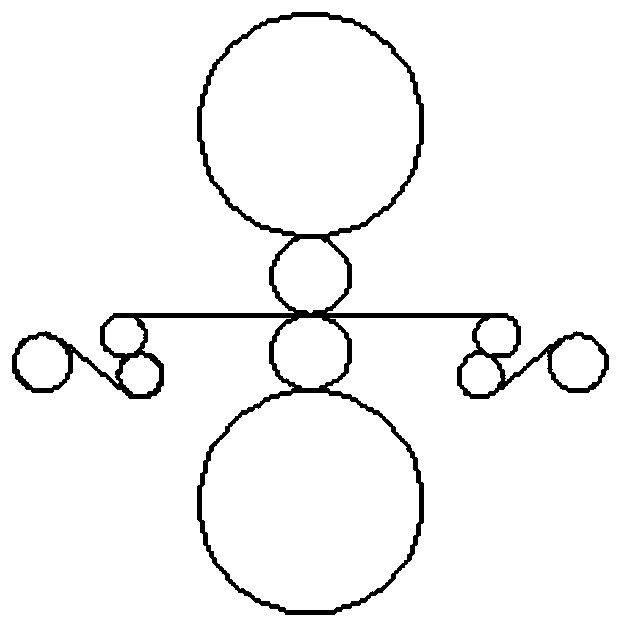

[0027] Such as figure 2 , Figure 5 , Figure 7 As shown, the present invention is an asynchronous cold rolling forming process of aluminum alloy stainless steel clad plate, comprising the following process steps:

[0028] S1: The stainless steel plate 1 and the aluminum alloy plate 2 are rolled and compounded by asynchronous rolling;

[0029] S2: After asynchronous rolling, diffusion annealing is performed on the clad plate 3;

[0030] In the S1 step, the stainless steel plate 1 is heated on-line on the opposite surface of the composite plate 3, and the aluminum alloy plate 2 is cooled on-line on the opposite surface of the composite plate 3, and the heating temperature is 350°C; The temperature of the 3 sides of the composite plate 3 of the stainless steel plate 1 rolled out of the clad plate 3 is lower than 650°C, and the temperature of the 3 faces of the aluminum alloy plate 2 of the rolled clad plate 3 is lower than 300°C; the rolling reduction rate is 20% ; The spee...

Embodiment 2

[0033] The difference from Example 1 is that the specification of 316L stainless steel is 200mmx30mmx5mm; The asynchronously rolled clad plate with a reduction rate of 70% was placed in a vacuum SX-4-10 resistance furnace for annealing at a temperature of 500°C and annealing time of 120 minutes.

Embodiment 3

[0035] The difference from Example 2 is that the specification of 316L stainless steel is 200mm×30mm×4 mm; . The annealing temperature is 300°C and the annealing time is 120min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com