Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Increase discharge voltage platform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cathode material used for lithium sulfur battery, preparation and application thereof

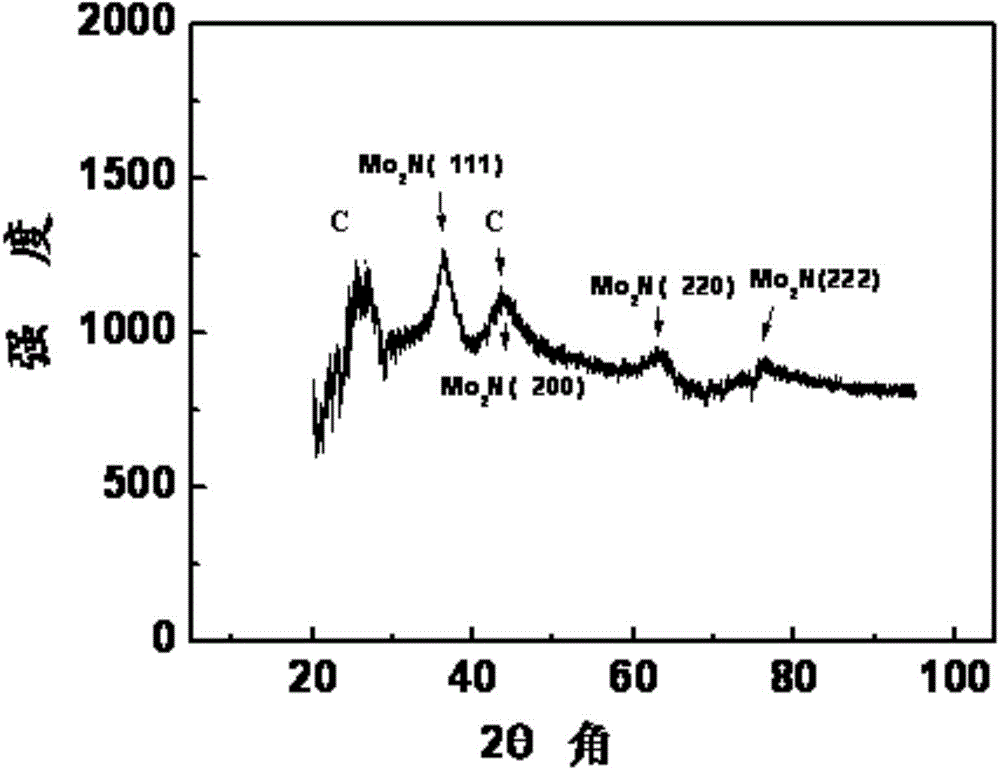

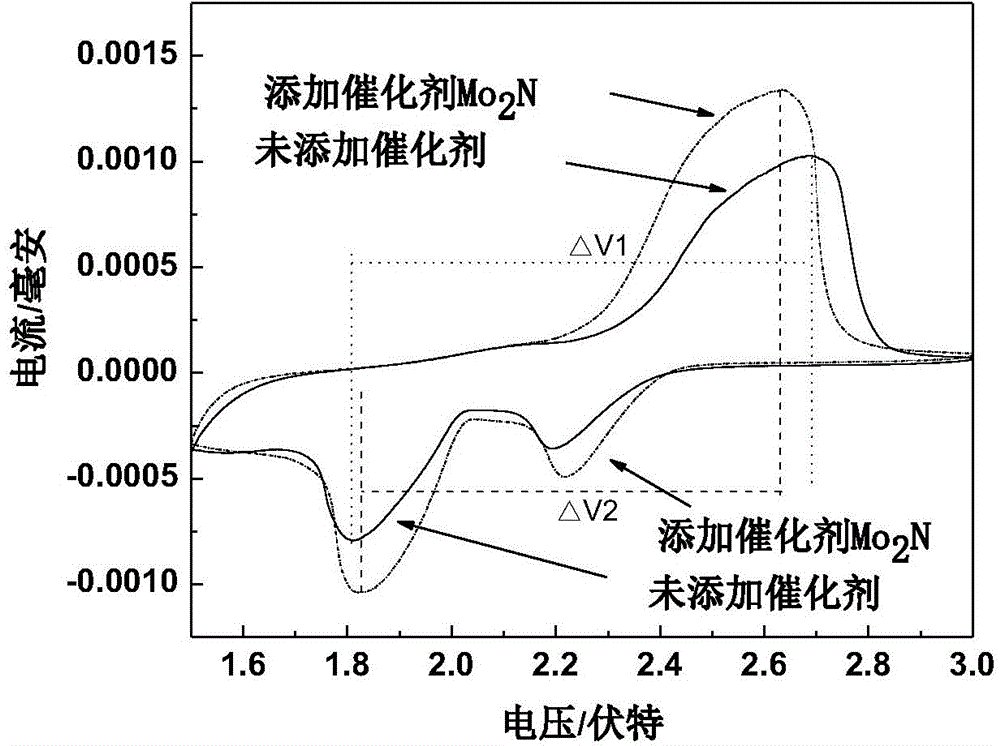

The invention relates to a cathode material used for a lithium sulfur battery, preparation and an application thereof. The cathode material employs one or more than two carbides or nitrides of metal elements from transition metal as a catalytic component and employs elementary sulfur as an active component. The catalytic component is supported on a carrier firstly and then the active component is supported on the carrier on which the catalytic component is supported. The content of the catalytic component is 2-30% of the total weight of the cathode material and the content of the sulfur is 30-80% of total weight of the cathode material, and the balanced is the carrier. The cathode material, when being used as a cathode in the lithium sulfur battery, has excellent selectivity on reduction of elementary sulfur and reduces reaction energy barrier required for sulfur reduction, reduces reaction polarization and increases discharge voltage platform. The cathode material is environment-friendly, is low in cost and is abundant in resources.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

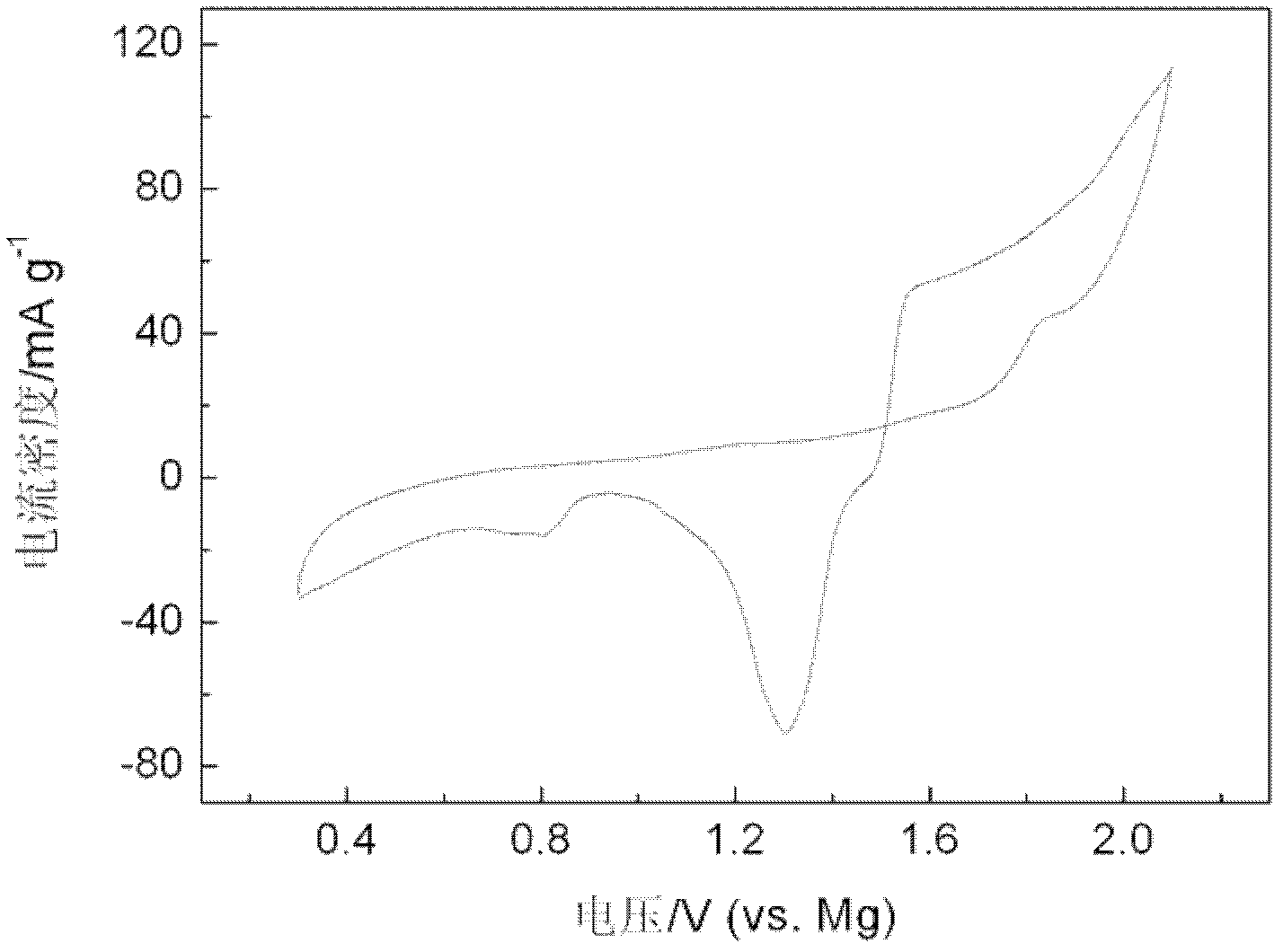

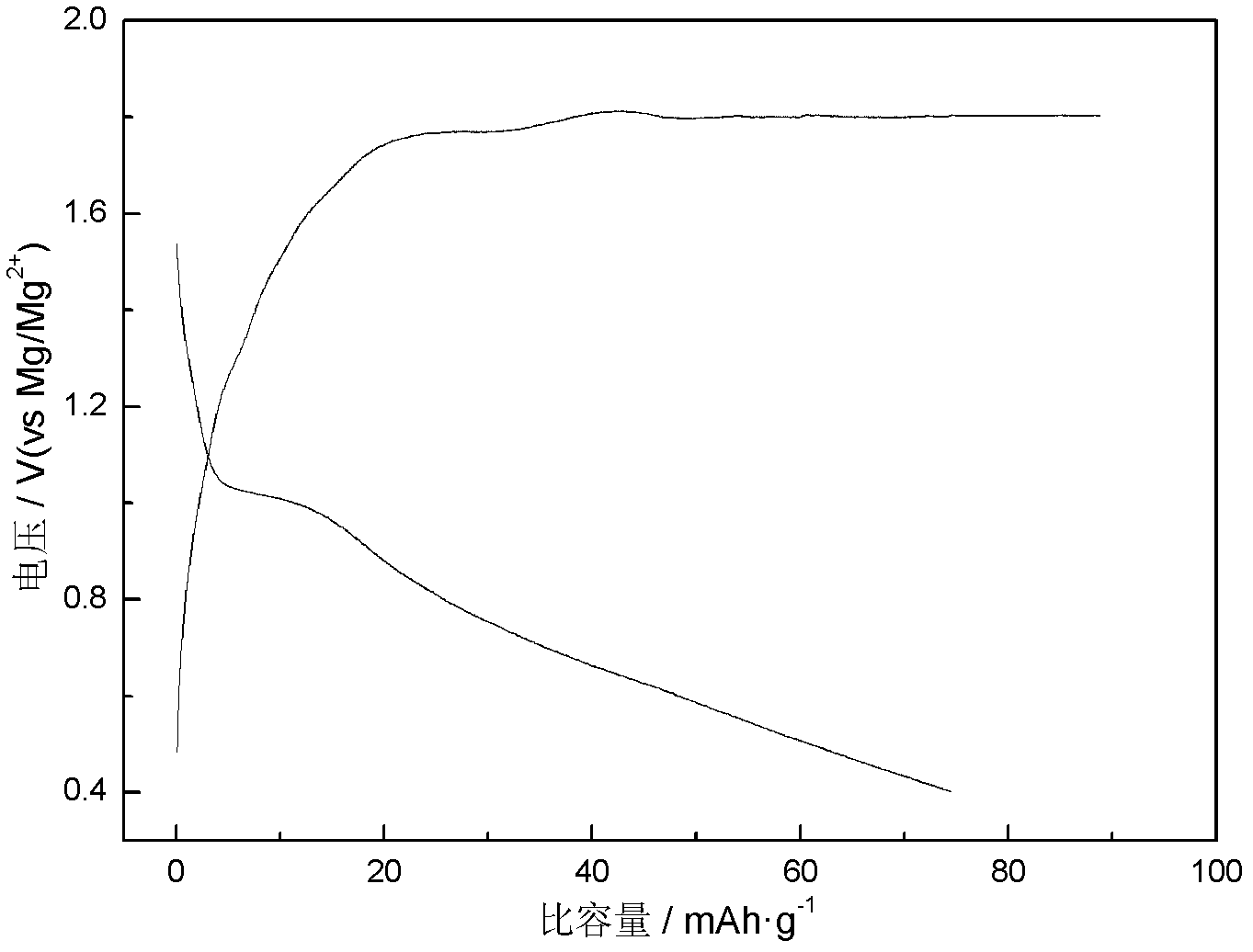

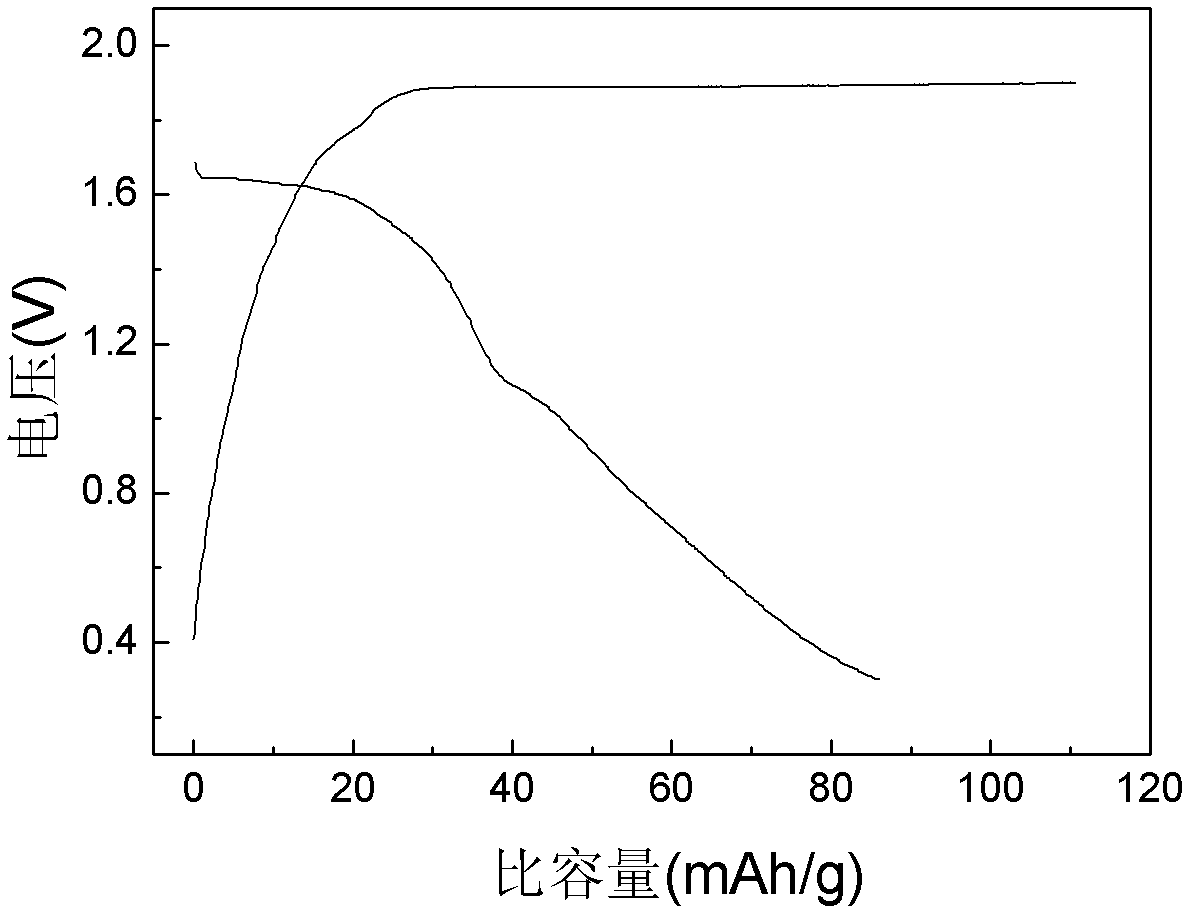

Rechargeable magnesium battery taking oxygen-containing organic matter as cathode material, and preparation method thereof

InactiveCN102683744AEasy to manufactureIncrease discharge voltage platformCell electrodesSecondary cellsQuinoneOrganic matter

The invention discloses a rechargeable magnesium battery taking oxygen-containing organic matter as a cathode material, and a preparation method of the rechargeable magnesium battery, wherein the oxygen-containing organic matter comprises the components of quinones, phenols, anhydrides derivatives and a compound containing nitro and oxygen radical. The battery and the method have the advantages of being simple in preparation technology, easy to process, environment-friendly and high in regeneration. The rechargeable magnesium battery prepared by the invention has the advantages of being relatively good in structural stability and circulation stability, rich in raw materials, safe in system and the like.

Owner:SHANGHAI JIAO TONG UNIV

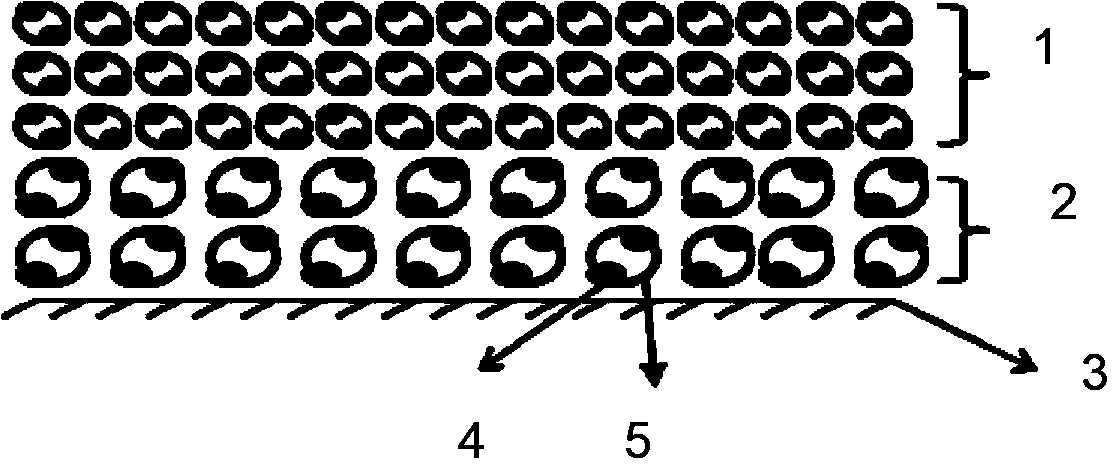

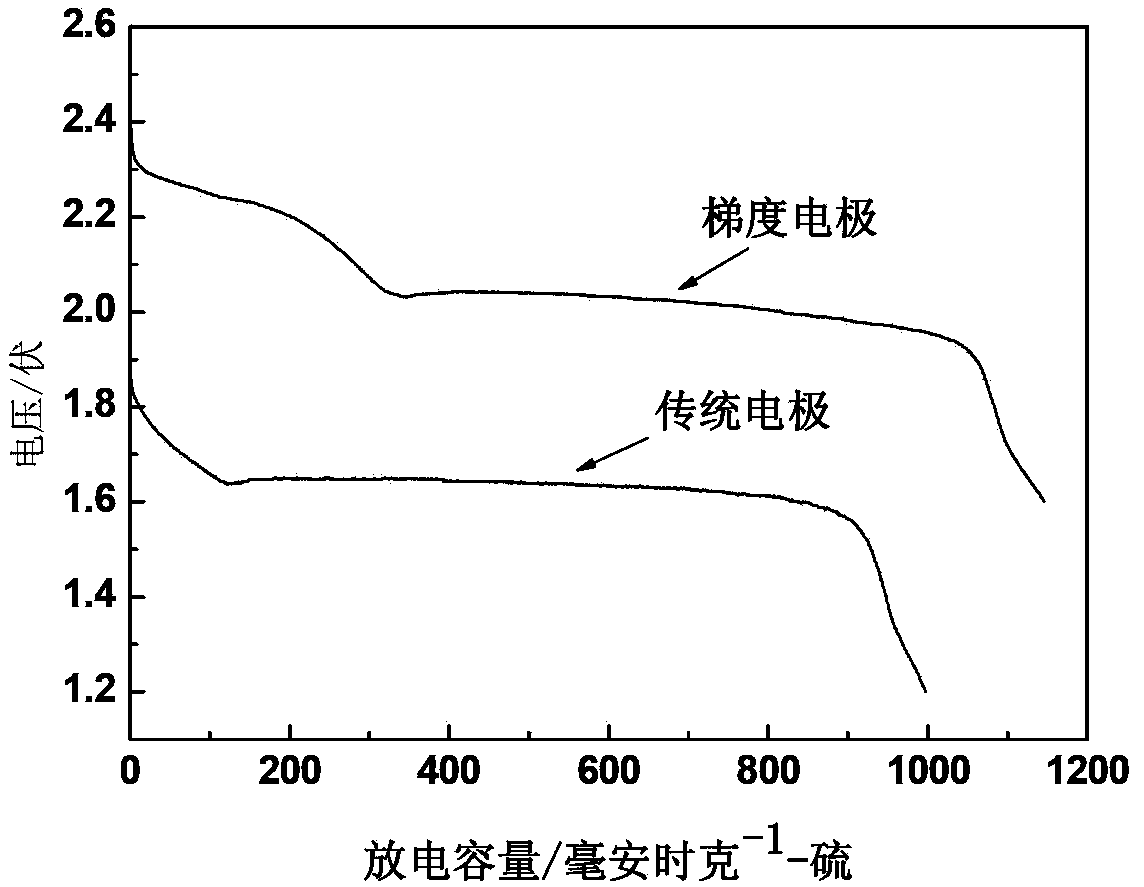

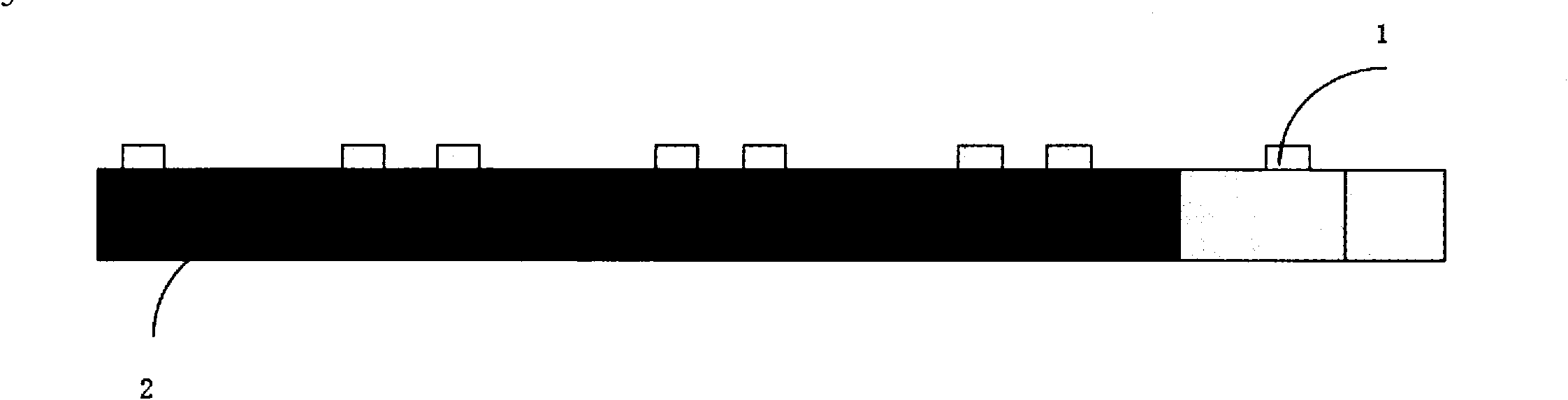

Lithium-sulfur battery positive electrode structure and preparation method thereof

ActiveCN103840125AEasy transferImprove discharge ratePositive electrodesElectrode collector coatingSulfurLithium–sulfur battery

The present invention relates to a lithium-sulfur battery positive electrode structure and a preparation method thereof. According to the lithium-sulfur battery positive electrode structure, a current collector is adopted as a substrate, two carbon-sulfur complex layers with different pore sizes are attached onto the substrate, the structure sequentially comprises the current collector, the large pore size carbon-sulfur complex layer and the small pore size carbon-sulfur complex layer, the thickness of the large pore size carbon-sulfur complex layer is 50-500 mum, the thickness of the small pore size carbon-sulfur complex layer is 10-200 mum, the large pore size carbon material is a carbon material with a pore size of greater than 100 nm and less than 1 mum and a pore volume accounting for 50-90% of the total pore volume, and the small pore size carbon material is a carbon material with a pore size of 0.5-100 nm and a pore volume accounting for more than 50-90% of the total pore volume. With the lithium-sulfur battery positive electrode structure, the mass transfer curvature of the lithium ions in the electrode is effectively increased, the lithium ion transmission path is prolonged, provision of the capacity of the high supporting capacity active substance is easily achieved, and the energy density of the battery is increased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

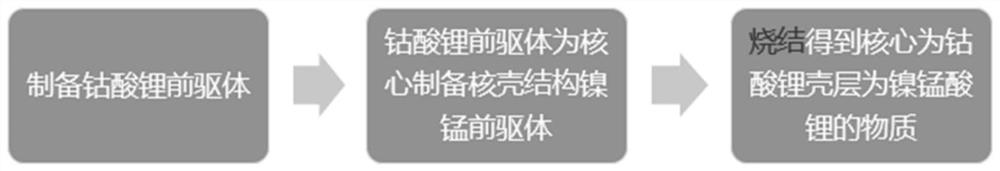

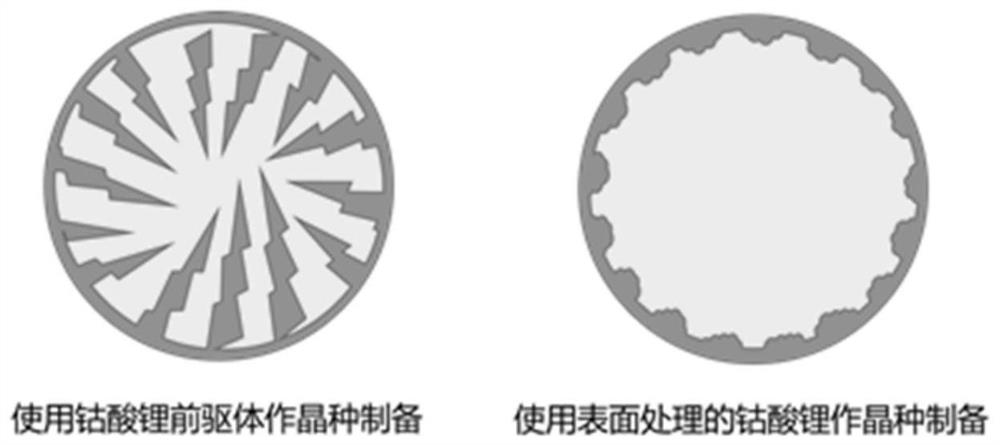

Anode material, preparation method of anode material and lithium ion battery comprising anode material

ActiveCN103137961AGood lithium ion conductivityEffective gram capacityElectrode thermal treatmentLi-accumulatorsGramLithium electrode

The invention belongs to the technical field of lithium ion batteries, and particularly relates to anode material. The anode material is formed by bulk phase material and surface material in a fusion mode, wherein the surface material is located on the surface of the bulk phase material, the bulk phase material is lithium cobalt oxide, the surface material is fusing granules which are composed of layered nickel lithium manganate, and the surface material accounts for 0.1-10% of the anode material by a mass percentage. Compared with the prior art, the anode material which is formed by the layered nickel lithium manganate is coated on the surface of the lithium cobalt oxide, due to the fact that the coating layer has good lithium-ion conduction performance, not only is a discharge voltage platform of the anode material not reduced and is the discharge voltage platform of the anode material increased on the contrary, but also the coating layer can play effective gram volume under high voltage, increase structural stability of base body material and accordingly improve the discharge capacity of the anode material under the high voltage and prolong the cycle life of the anode material significantly. In addition, the invention further discloses a preparation method of the anode material and a lithium ion battery comprising the anode material.

Owner:DONGGUAN AMPEREX TECH

High-voltage lithium ion battery anode, lithium ion battery using same and preparation method of high-voltage lithium ion battery anode

ActiveCN102088086AIncrease discharge voltage platformIncrease specific energyCell electrodesSecondary cellsElectrical batteryCurrent collector

The invention relates to a high-voltage lithium ion battery anode, a lithium ion battery using the same and a preparation method of the high-voltage lithium ion battery anode. The high-voltage lithium ion battery anode comprises a current collector, an anode active substance material, a conduction agent and a binder, wherein 85-95wt% of anode active substance material, 2.5-7.5wt% of conduction agent and 2.5-7.5wt% of binder are prepared into a sizing agent; and the sizing agent is coated on the current collector. The lithium ion battery anode in the invention and the lithium ion battery usingthe anode have the advantages of high discharging voltage platform, high specific energy and low cost and are easy for large-scale industrial production.

Owner:CHERY AUTOMOBILE CO LTD

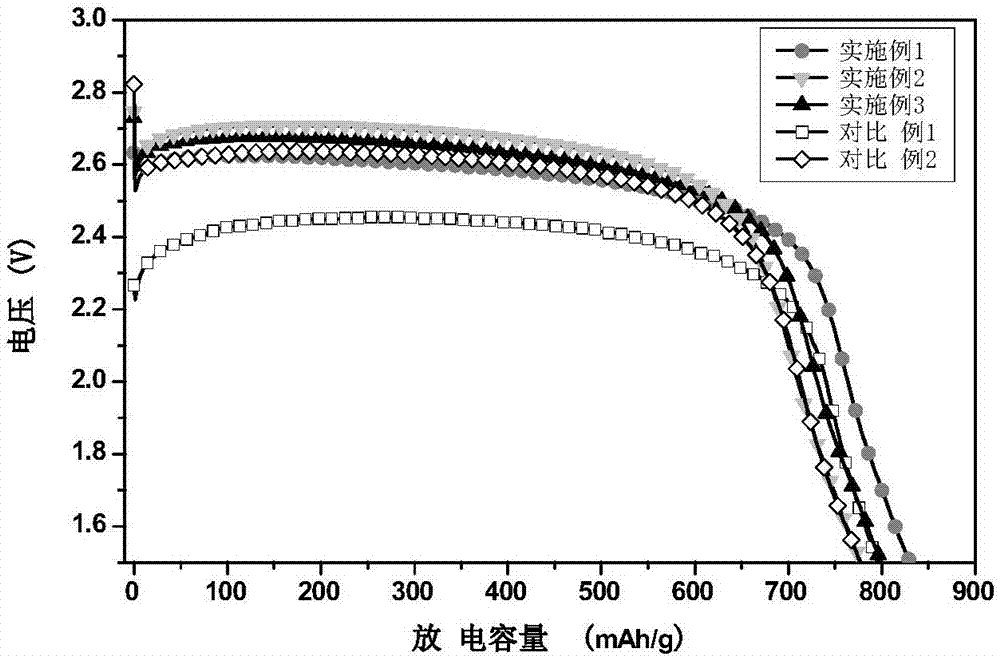

Cathode material of lithium ion battery and preparation method and application of cathode material

InactiveCN104577115AImprove cycle performanceExtend your lifeSecondary cellsPositive electrodesHigh temperature storageElectrical battery

The application discloses a cathode material of a lithium ion battery and a preparation method and application of the cathode material. Through the use of the cathode material, the change rate of the relative volume of the cathode material can be reduced under the conditions of the embedding of a lithium ion and the extraction of the lithium ion, and besides the dissolution of Mn in the cathode material is effectively restrained in a charging process and a discharging process, so that the stability of a crystal structure of the cathode material in the operating condition is improved. The lithium ion battery made from the cathode material has an excellent cycle property, an excellent safety property and an excellent high temperature storage property.

Owner:QINGHAI CONTEMPORARY AMPEREX TECH

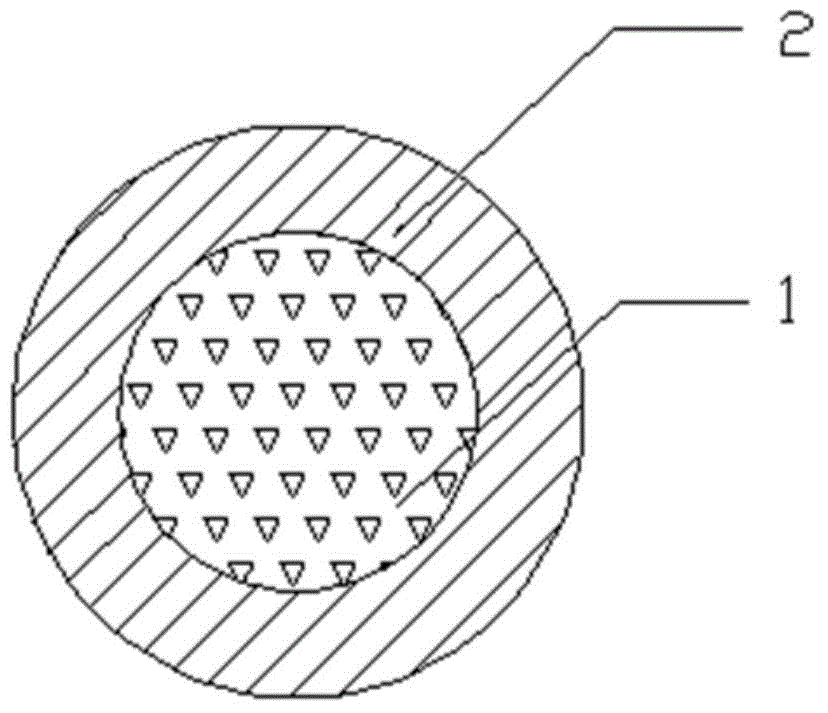

High-voltage anode material for lithium ion battery and lithium ion battery comprising same

ActiveCN103066282AImprove cycle performanceImprove securityCell electrodesSecondary cellsElectrical batterySodium-ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a high-voltage anode material for a lithium ion battery. The anode material comprises a material A and a material B, wherein the material A has a core-shell structure, a core layer material is lithium cobalt oxide particles formed by primary particles, the median particle diameters D50 of the lithium cobalt oxide particles are 15-25 microns, and the structure formula of a core-shell material is LixNiyMnzPO4; the material B has a core-shell structure, the core layer material is the lithium cobalt oxide particles formed by secondary particles, and the median particle diameters D50 of the lithium cobalt oxide particles are is 3-9 microns; and the structure formula of the core-shell material is LiwAlpZrqO2, and the mass ratio of the material A to the material B is (0.1-10) to 1. Compared with the prior art, the high-voltage anode material for the lithium ion battery provided by the invention has the advantages that the large and small lithium cobalt oxide particles are combined reasonably, different core layer materials can be arranged on the surfaces of the lithium cobalt oxide particles, and the secondary particles are selected as the small lithium cobalt oxide particles, so that the cycle performance and the safety performance of the anode material under high voltage are notably improved.

Owner:DONGGUAN AMPEREX TECH

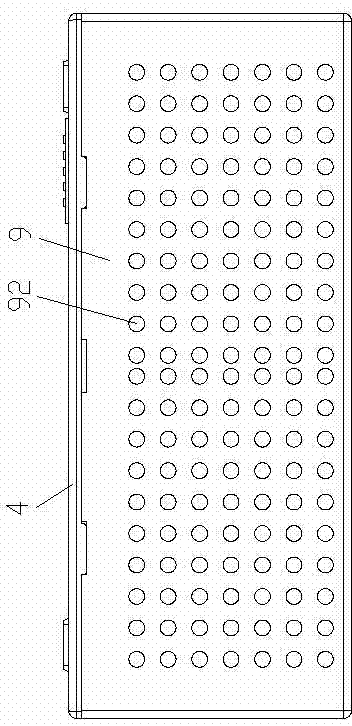

Power lithium-ion battery with heat dissipation performance

InactiveCN101867069ALower internal resistanceIncrease output currentElectrode carriers/collectorsSecondary cellsInternal resistancePole piece

The invention discloses a power lithium-ion battery with heat dissipation performance, comprising a positive electrode pole piece, a negative electrode pole piece and an isolating membrane, wherein the positive electrode pole piece and the negative electrode pole piece comprise a current collector and an active material membrane coated on the current collector; the current collector is provided with a plurality of extending parts in an extending manner in the width direction; when the positive and negative electrode pole pieces and the isolation membrane coil to form battery cells, the extending parts arranged on the current collectors of the positive and negative electrodes are fixed together to respectively form positive and negative electrode tabs; the above battery cells are connected with the external circuit electrically through the positive and negative electrode tabs. In the lithium-ion battery with the above structure, the positive and negative electrode pole pieces are provided with tabs constituted by the plurality of the extending parts, thus greatly increasing the distributary capability during charge-discharge of great current of current collector tabs, and lowering internal resistance of the battery. When the battery emits heat, heat dissipation can be carried out through multiple extending parts of current collectors.

Owner:DONGGUAN AMPEREX TECH

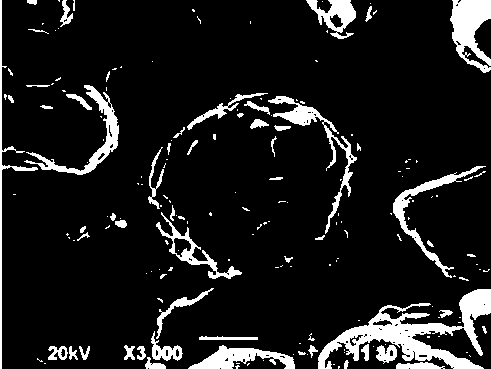

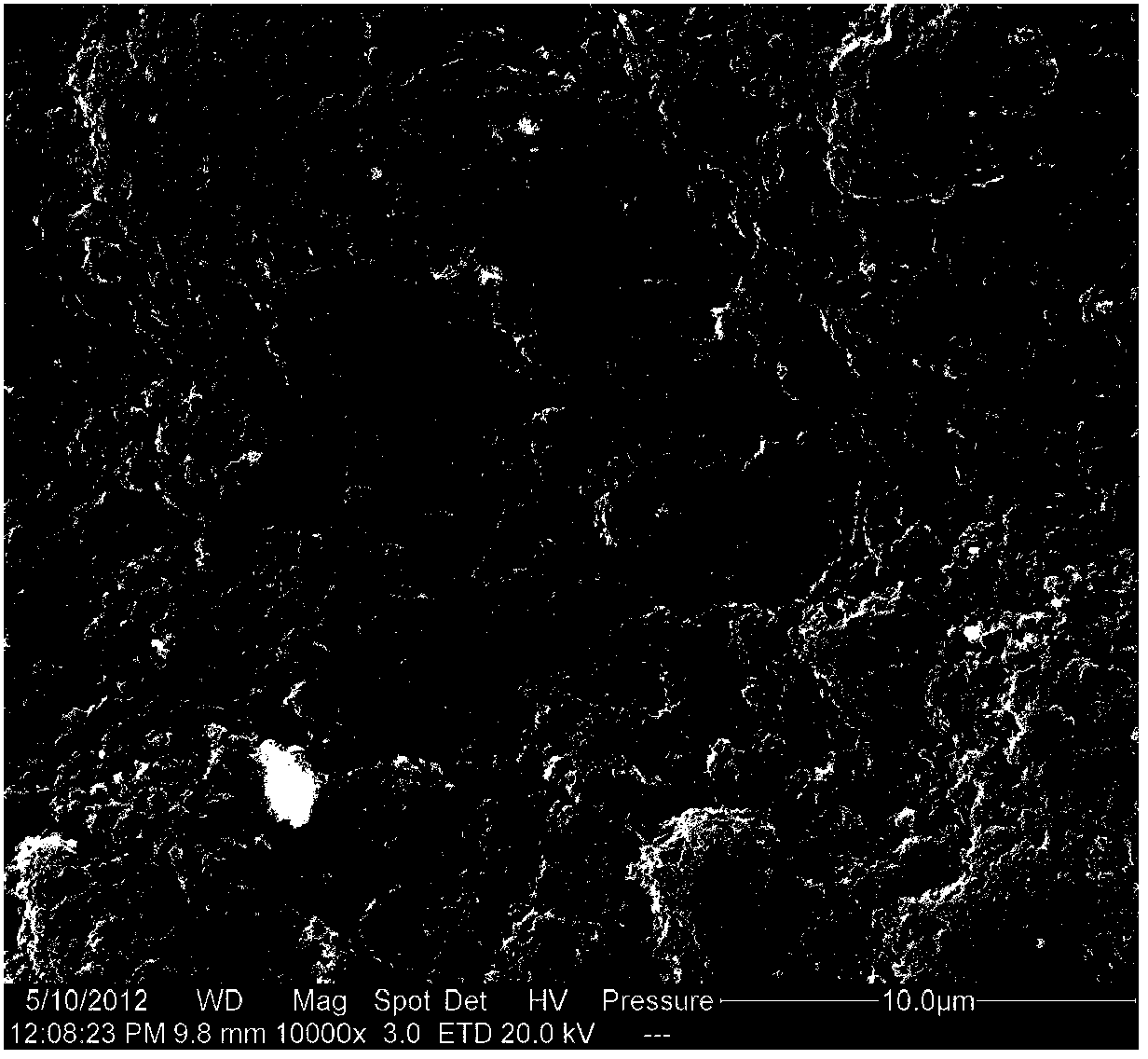

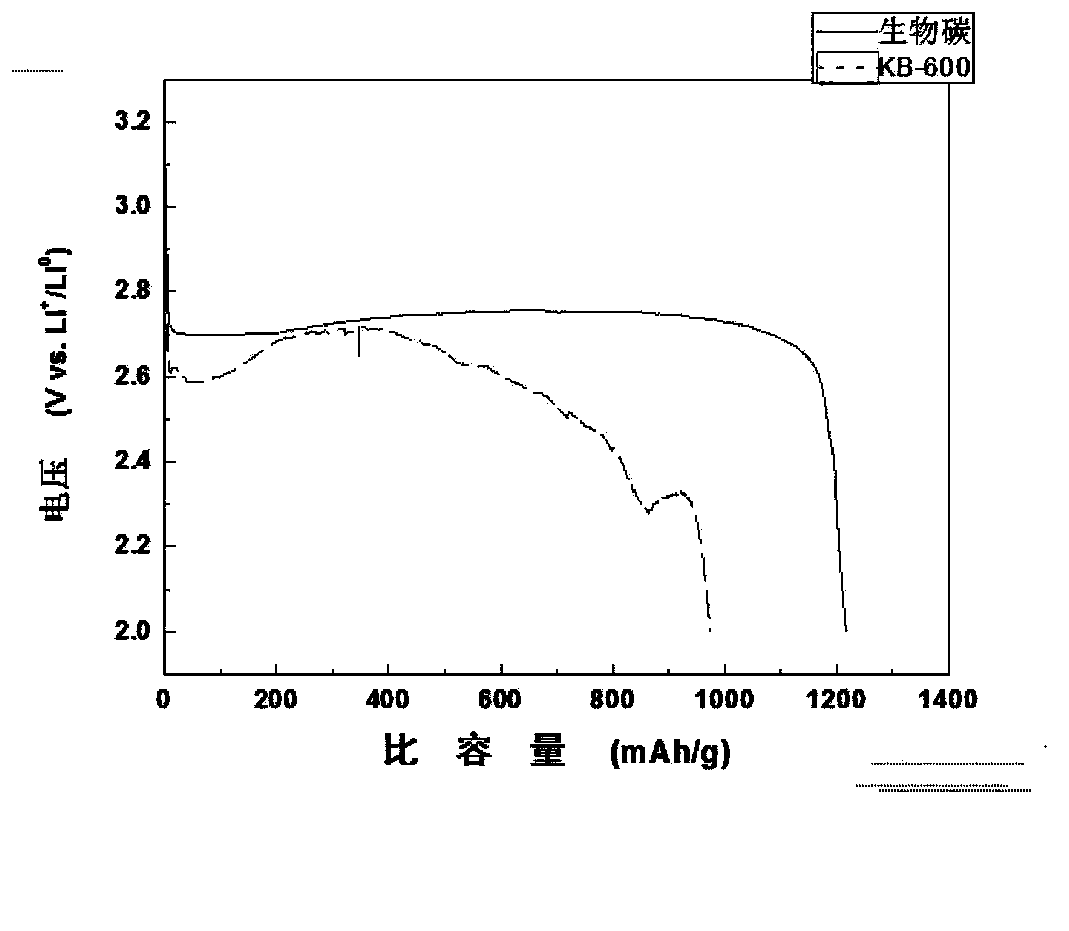

Anode material for lithium-air battery and preparation method thereof

InactiveCN103579640ARich sourcesLow priceFuel and secondary cellsCell electrodesAlkaline activationLithium–air battery

The invention relates to an anode material for a lithium-air battery and a preparation method thereof. Through alkaline activation and catalytic activation, the anode material is prepared from a biomass carbon material. The anode material has a specific surface area of 800-2000m<2>.g<-1>, total pore volume of 0.8-2cm<3>.g<-1> and a ratio of mesoporous volume to total pore volume of 30-90%. The lithium-air battery prepared from the anode material has good discharge performances and has the advantages of simple processes, good technology repeatability, low cost and environmental friendliness.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

High-voltage composite spinel-coated positive electrode material and preparation method thereof

ActiveCN112736230AImprove lithium ion conductivityDoes not reduce the discharge voltage platformPositive electrodesSecondary cells servicing/maintenanceSolid state electrolyteManganese oxide

The invention provides a high-voltage composite spinel-coated positive electrode material and a preparation method thereof. The positive electrode material comprises a lithium cobalt oxide core, a spinel-type lithium nickel manganese oxide middle layer and a solid electrolyte surface layer. The invention provides a positive electrode material with a composite coating layer on the surface, and the coating layer has good lithium ion conductivity, so that the positive electrode material is high in discharge capacity and excellent in cycle life under a high voltage without influencing a discharge platform, the volume energy density of a lithium ion battery is improved, and the corrosion of HF to the surface layer of the material can be reduced; and the high-temperature cycle life of the material is prolonged, so that the defects of unstable use structure of the positive electrode material under high charging cut-off voltage or poor cycle performance and low discharge capacity even if the structure is stable in the prior art are overcome, the high-temperature cycle performance is improved, and the material is more suitable for the actual use working condition of the material.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

Accumulator and its preparing method

InactiveCN1722506ALower internal resistanceImprove discharge capacityElectrode manufacturing processesFinal product manufactureEngineeringVoltage

This invention relates to an accumulator, comprising the following steps: joining the positive plate, baffle plate, negative plate and electrolytic solution in the cell housing, wherein, the positive and negative plates is formed by coating active material on both sides of the metallic base, and one lateral side of at least one of the positive and negative plates is located with metallic net embedded in the lateral side of the plate. The invention has the advantages of simple structure of accumulator plate, lower essential resistance, higher discharge capacity and simple preparing method.

Owner:SHANGHAI BYD

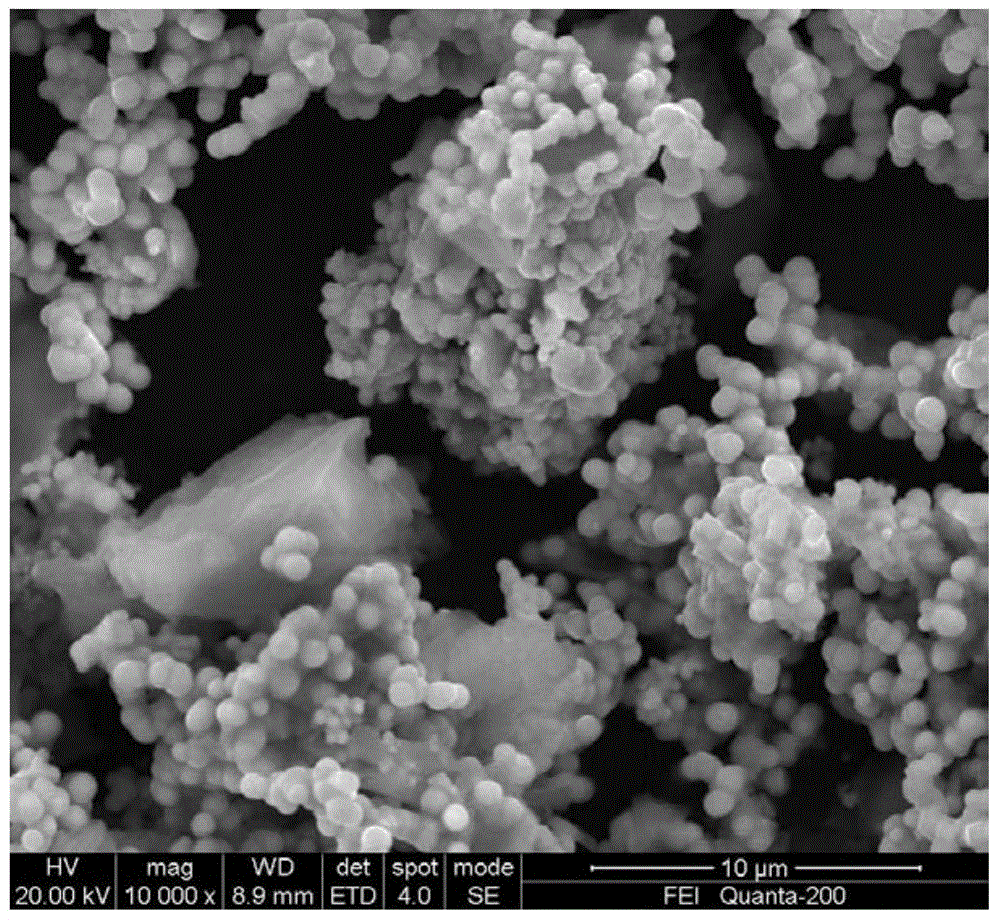

Nickel coated carbon fluoride positive electrode material and preparation method thereof

The invention discloses a nickel coated carbon fluoride positive electrode material and a preparation method of the nickel coated carbon fluoride positive electrode material. The positive electrode material is prepared by coating the surface of carbon fluoride particles with a nickel-plating layer. The preparation method comprises the steps that the carbon fluoride particles are sequentially sensitized, activated and reduced under a function of dispersing agents and the nickel-plating layer is plated; the carbon fluoride particles coated with the nickel-plating layer are subjected to thermal treatment to obtain the nickel coated carbon fluoride positive electrode material. The preparation method is easy to operate, mild in process conditions and low in cost; the prepared nickel coated carbon fluoride positive electrode material is uniform in coating of nickel-plating layer, stable in structure, and can be used for preparing a lithium carbon fluoride battery with high conductivity, high specific capacity and high power density.

Owner:XIANGTAN UNIV

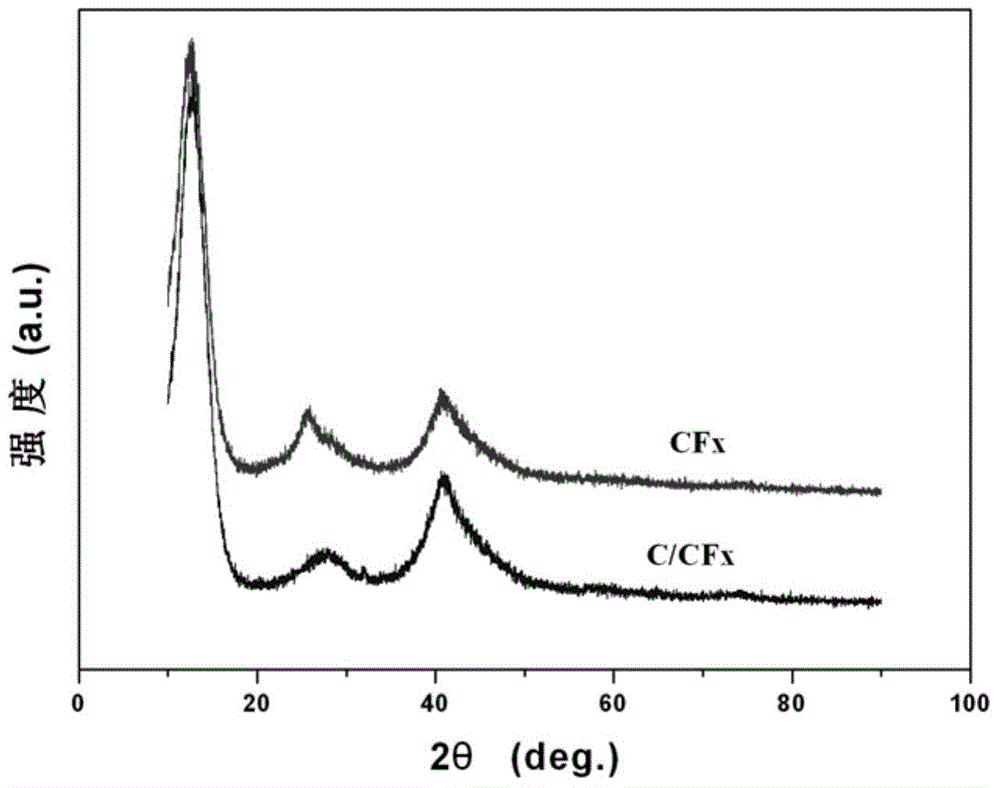

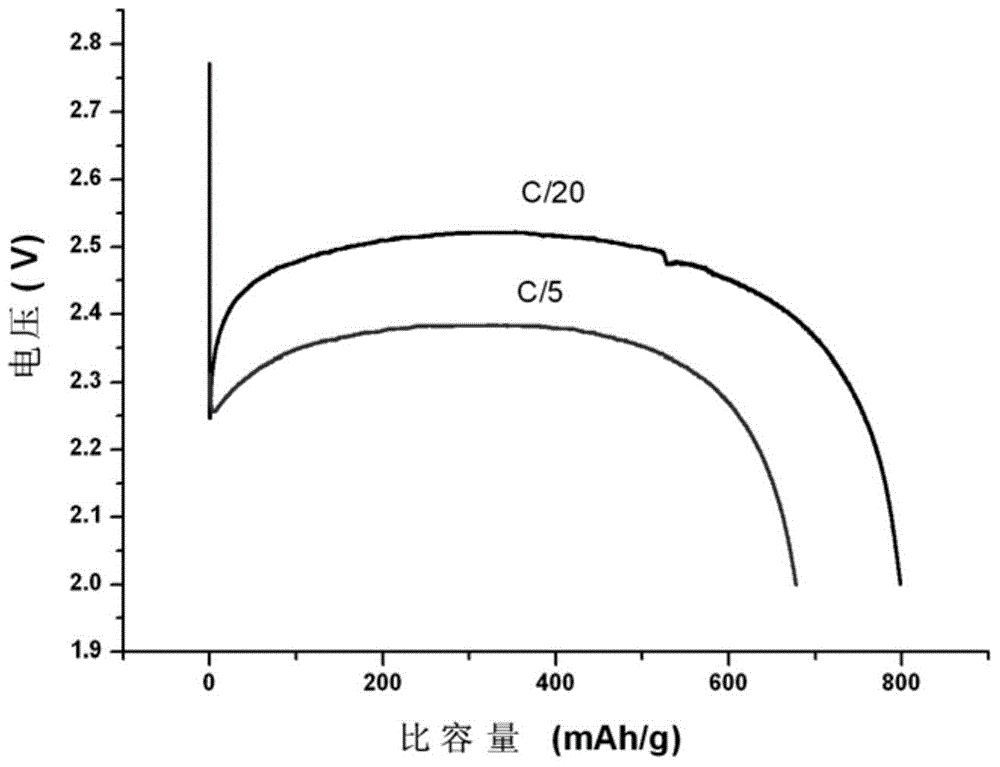

Pitch carbon coated fluorocarbon cathode material and preparation method thereof

ActiveCN107482187AHigh specific capacityHigh magnificationCell electrodesOrganic electrolyte cellsCarbon sourceFluorocarbon

The invention discloses a pitch carbon coated fluorocarbon cathode material and a preparation method thereof. The preparation method comprises the following steps: mixing fluorocarbon with pitch, performing heat treatment on the obtained mixture and sieving the mixture to obtain the pitch carbon coated fluorocarbon cathode material. According to the method, fluorocarbon is coated with pitch carbon, and by improving binding force between the fluorocarbon surface and a carbon source, the electric conductivity of the material is improved to a greater extent, so that the discharge voltage plateau, specific capacity and high-current discharge performance of the material are improved substantially. The method has the advantages of low cost, simple equipment, simple and easily controllable process conditions, high yield and the like and is quite suitable for large-scale industrial production.

Owner:TIANJIN B&M SCI & TECH

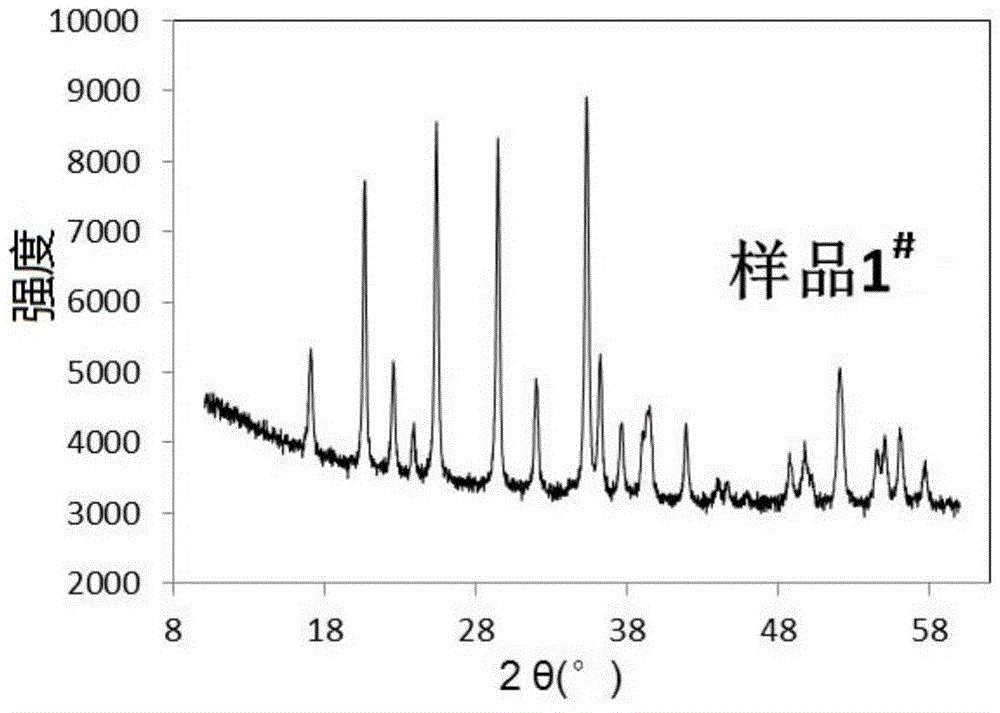

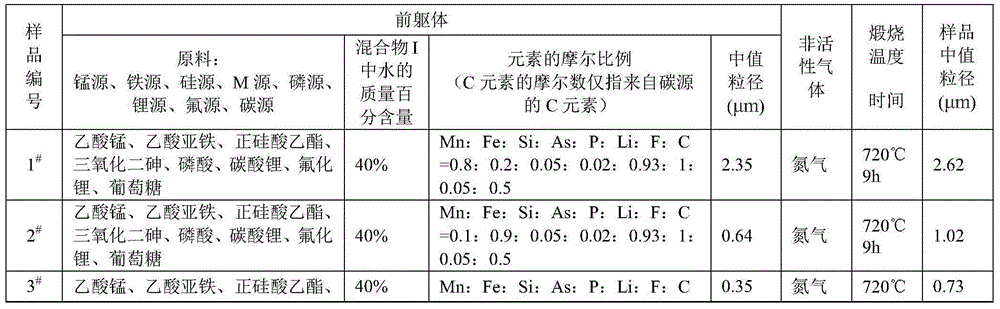

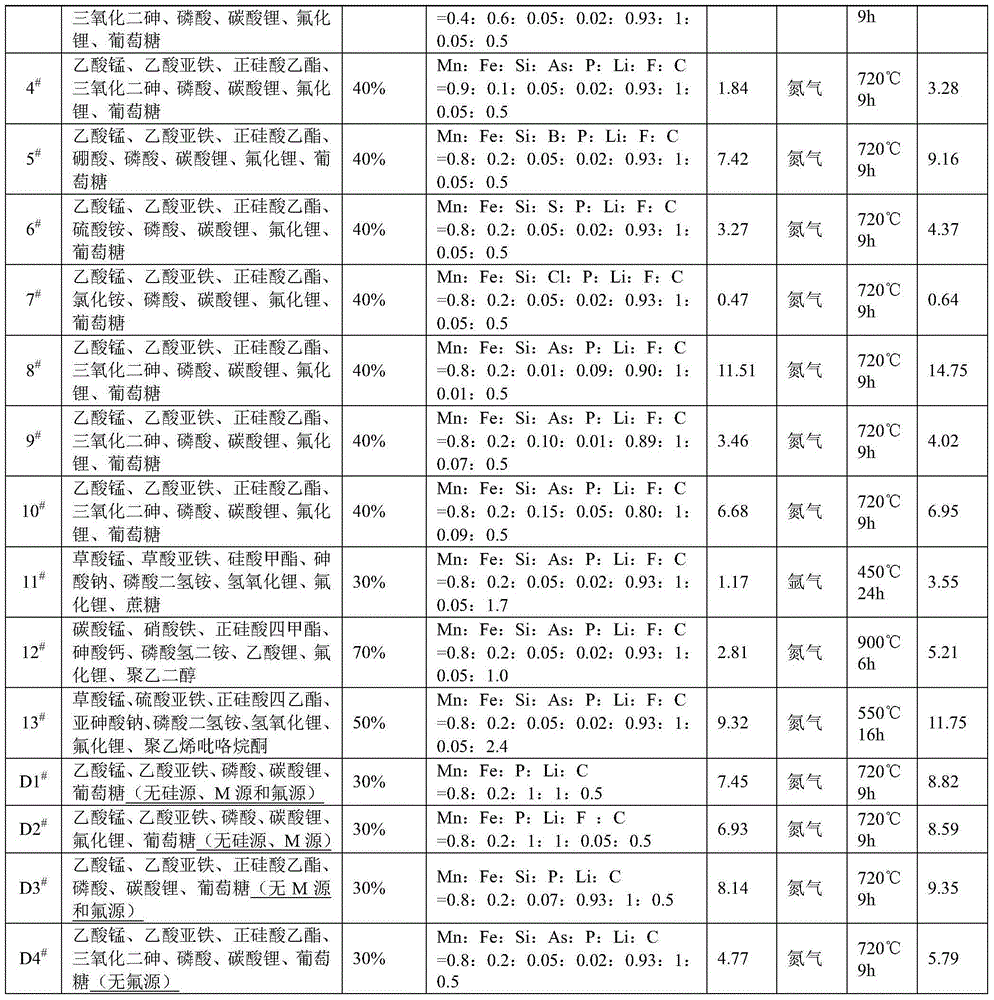

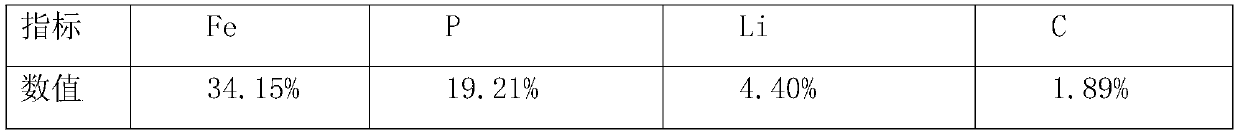

Lithium ion battery anode material manganese lithium iron phosphate and preparation method thereof

ActiveCN103956491AImprove electronic conductivityIncrease discharge voltage platformCell electrodesSecondary cellsElectrical batteryManganese

The invention relates to lithium ion battery anode material manganese lithium iron phosphate and a preparation method thereof. The preparation method comprises the following steps of firstly weighing a certain amount of lithium source, iron source and phosphorus source according to the molar ratio of (1.0-1.2) to 1 to 1, adding a carbon source the mass fraction of which is 5%-13%, uniformly mixing, placing a mixture in an inert gas atmosphere at 250-400DEG C, and carrying out heat treatment for 2-5 hours and furnace cooling treatment on the mixture; taking a half of the prepared mixture to add in a manganese source according to the iron / manganese molar ratio at 1 to 1, meanwhile, weighing the lithium source, and the phosphorus source according to the manganese source / lithium source / phosphorus source molar ratio of 1 to (1.0-1.2) to 1, adding 3% of the carbon source, and uniformly mixing; placing a manganese lithium iron phosphate precursor after uniformly mixing in a chemical combination furnace, carrying out chemical combination treatment on the manganese lithium iron phosphate precursor for 2-20 minutes, and calcining the manganese lithium iron phosphate precursor; and finally, controlling the heating rate at 5-12DEG C / min, carrying out calcination treatment on a precursor powder material for 3-12 h after chemical combination treatment under inert gas atmosphere protection at 550-750DEG C, and carrying out furnace cooling on the precursor powder material to indoor temperature so as to obtain a carbon-coated manganese lithium iron phosphate anode material. The lithium ion battery anode material manganese lithium iron phosphate and the preparation method provided by the invention have the advantages that a lithium manganese phosphate structure is stable, the electronic conductivity of the lithium manganese phosphate is improved, and the manganese lithium iron phosphate anode material has the good electrochemical property.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

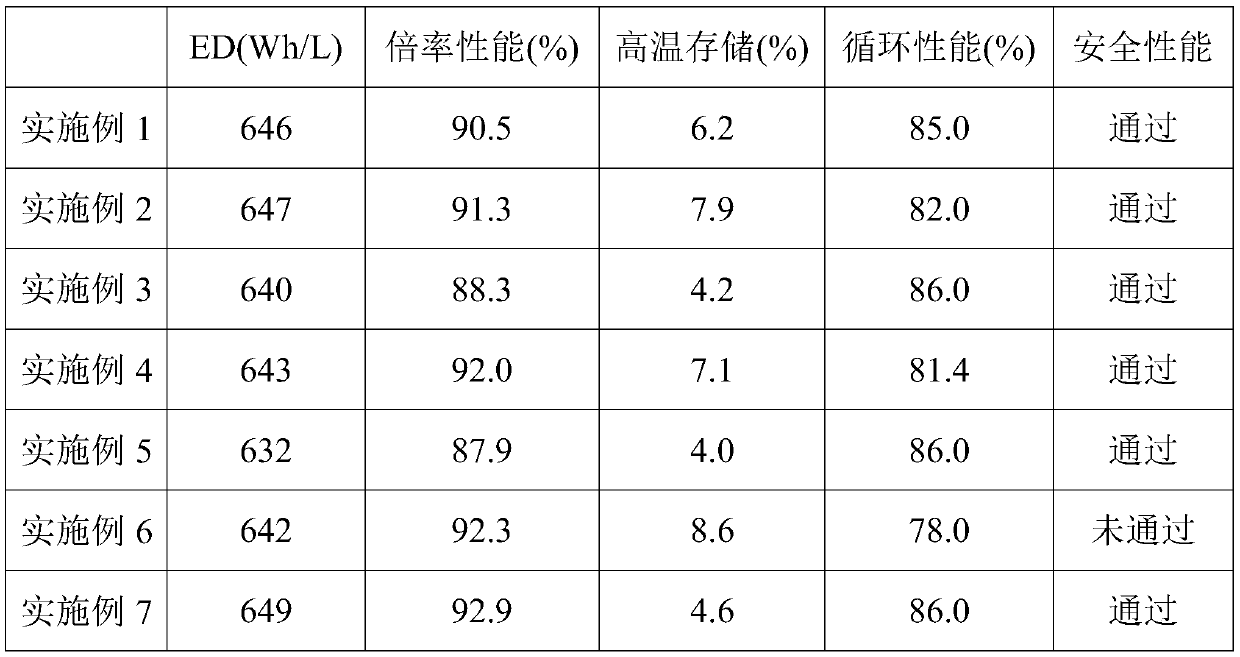

Positive electrode material and preparation method and application thereof

InactiveCN110112393AIncrease energy densityImproved magnification performanceCell electrodesSecondary cellsState of artDecomposition

The invention relates to a positive electrode material and a preparation method and application thereof. The surfaces of a core layer material A composed of secondary spherical particles and a singlecrystal particle core layer material B composed of the secondary spherical particles are coated with a shell layer material to form a material A and a material B respectively, and then the material Aand the material B are mixed, so that the energy density, the rate capability, the high-temperature cycle and the safety performance of the positive electrode material are remarkably improved. The core layer material is coated with the shell layer material, so that the residual alkali of the positive electrode material can be remarkably reduced, the oxidative decomposition of the positive electrode material on the electrolyte is reduced, and the high-temperature cycle and safety performance of the positive electrode material are improved. Compared with the prior art, a lithium ion battery obtained by the invention can achieve very good energy density, cycle performance and safety performance under higher voltage (greater than or equal to 4.2V vs (Li + / Li)). Due to the fact that the charging cut-off voltage is increased, the battery has high energy density, and the requirement of people for thinness of the lithium ion battery can be met.

Owner:东莞维科电池有限公司

Preparation method of titanium-doped lithium iron phosphate

InactiveCN111498825AIncrease compaction densityImprove electronic conductivityCell electrodesPhosphorus compoundsLithium carbonateTitanium tetrachloride

The invention discloses a preparation method of titanium-doped lithium iron phosphate. The method includes introducing titanium tetrachloride into a phosphoric acid solution, then putting the reactionslurry into a sealed reaction kettle, and carrying out reduced pressure evaporation until water is completely evaporated to dryness; pouring out the evaporated powder, mixing lithium carbonate through jet milling, mixing, slurrying, levigating, spraying and calcining to obtain a primary calcined material; adding the primary calcined material into a polyethylene glycol solution, stirring and slurrying to obtain a slurried material, then adding a ferrous sulfate solution, a phosphoric acid solution and an ammonia water solution into the slurried material together, and filtering, washing and drying the reaction material to obtain an iron-titanium mixture; and mixing the iron-titanium mixture with lithium carbonate and a carbon source, slurrying, grinding, spraying and calcining to obtain a material, carrying out jet milling, screening and iron removal on the material to obtain the titanium-doped lithium iron phosphate. According to the invention, the uniformly titanium-doped lithium ironphosphate can be obtained, the discharge voltage platform is high, the compaction density is high, and the energy density is high.

Owner:蒋央芳

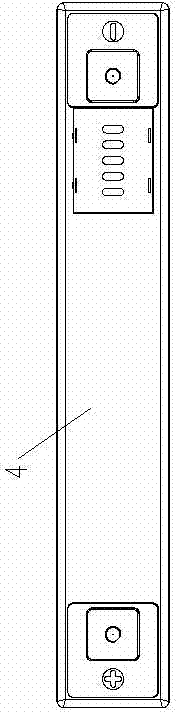

Lithium ion battery for automobile

ActiveCN102956852AGuaranteed aestheticsReduce weightFinal product manufactureCell component detailsHeat conductingElectrical battery

The invention relates to a lithium ion battery for an automobile. At present, no lithium ion battery with reasonable structural design and stable performance for the automobile exists. The lithium ion battery comprises a battery core, an upper cover, an anode terminal, a cathode terminal and a shell, and is characterized by further comprising an anode conductive metal plate, a cathode conductive metal plate, an anode cover plate, a cathode cover plate, a temperature detection guard plate and a metal isolation groove, wherein the anode terminal comprises an anode terminal body, an anode boss and an anode temperature measuring head; the anode conductive metal plate is fixed on the battery core anode plug of the battery core; the anode terminal body is fixed on the anode conductive metal plate; the cathode terminal comprises a cathode terminal body, a cathode boss and a cathode temperature measuring head; tThe cathode conductive metal plate is fixed on the battery core cathode lug of the battery core; the cathode terminal body is fixed on the cathode conductive metal plate; the wall faces of the shell are provided with multiple rows of heat-dissipating holes; and the inner walls of the wall faces, provided with the heat-dissipating holes, of the shell are provided with multiple heat-conducting grooves. The lithium ion battery for the automobile has the advantages of reasonable structural design, good heat dissipation and stable performance.

Owner:湖州天丰电源有限公司

Method for preparing reduction carbon nano tube coated lithium iron phosphate cathode material

The invention relates to a method for preparing a reduction carbon nano tube coated lithium iron phosphate cathode material, which is characterized by comprising the following preparation process of: heating citric acid and ethylene glycol to perform polymerization reaction, then carrying out air isolation presintering, cooling and grinding and sintering at a temperature of 400 DEG C in the air atmosphere to obtain a carbon compound; mixing the prepared carbon compound and a mixture of reducing agents to obtain a reduction carbon compound; carrying out mixing and ball milling on the reduction carbon compound, a lithium source compound, a ferrous source compound, a phosphoric acid source compound and a wet grinding medium and carrying out vacuum drying to obtain dry powder; and placing the dry powder in the inert atmosphere or the weakly reducing atmosphere, cooling, grinding and sieving the dry powder after sintering the dry powder at a temperature of 300 DEG C, placing the obtained powder in the inert atmosphere or the weakly reducing atmosphere again and obtaining the reduction carbon nano tube coated lithium iron phosphate cathode material by adopting a two-phase sintering method. The electrode material prepared by the method disclosed by the invention has uniform composition and has excellent discharge performance, particularly excellent discharge circulating performance under the condition of large current.

Owner:贵州唯特高新能源科技有限公司

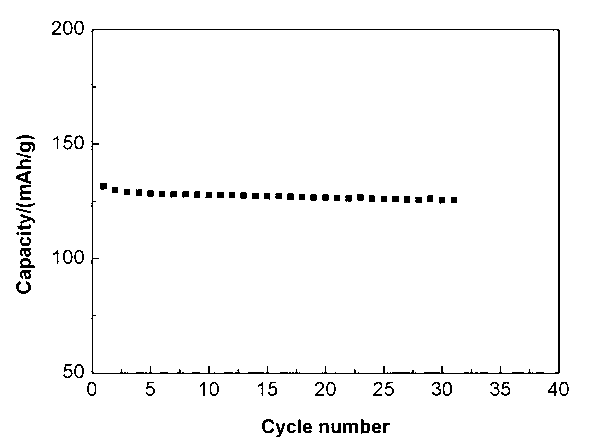

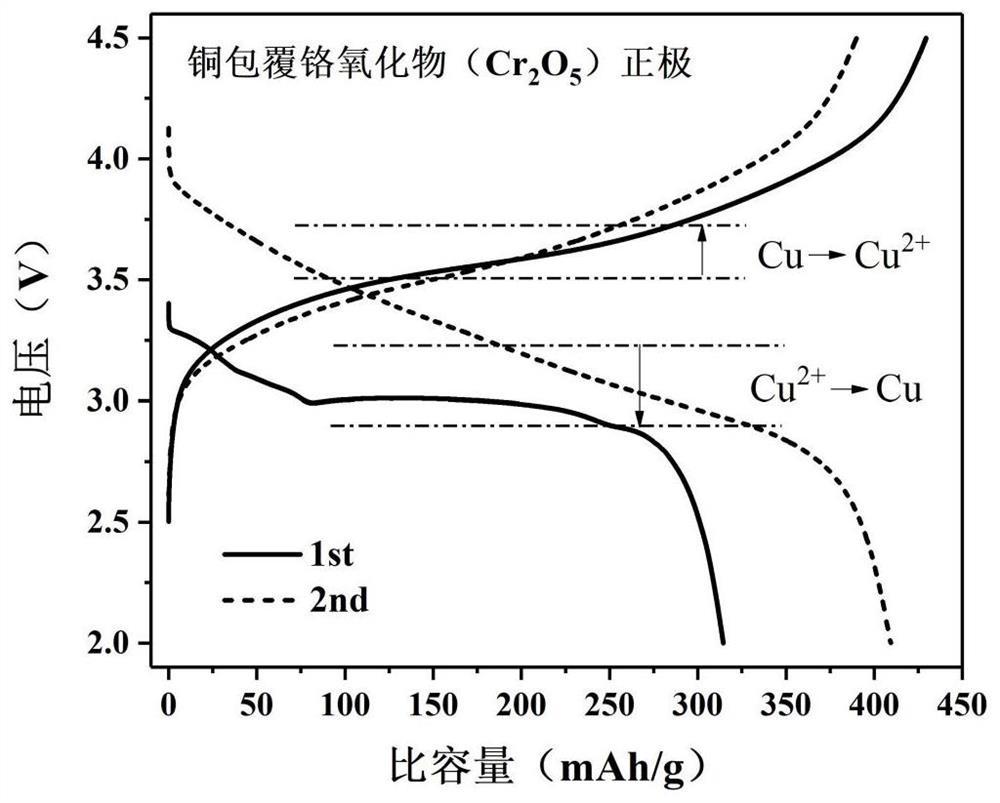

Preparation method and application of copper-coated chromium oxide positive electrode

ActiveCN112201773AImprove dynamic performanceImprove discharge capacitySecondary cellsPositive electrodesElectrochemical responseChromium trioxide

The invention discloses a preparation method and application of a copper-coated chromium oxide positive electrode, and belongs to the technical field of lithium ion batteries. In order to further improve the discharge (electric) specific capacity, the dynamic process and the rate capability of the chromium oxide positive electrode material, the method comprises the following steps: carrying out high-temperature calcination, ball milling and water washing treatment on chromium trioxide to prepare a chromium oxide positive electrode; and coating the surface of the chromium oxide positive electrode with copper. According to the invention, the battery is assembled by adopting a copper-coated chromium oxide positive electrode, a single lithium ion selective diaphragm, a lithium-containing negative electrode and an ether or ester electrolytic solution; and the special electrochemical behavior of copper on one side of the positive electrode of the lithium ion battery is utilized, the Cu-Cu<2+> electrochemical reaction has a relatively high discharge voltage platform and specific capacity, and the dynamic process, the discharge capacity and the voltage platform of the positive electrode material of the battery can be remarkably improved.

Owner:HARBIN INST OF TECH

Microencapsulated carbon-coated carbon fluoride cathode material and preparation method thereof

InactiveCN105161681AImprove conductivityNot easy to reuniteCell electrodesPrimary cellsCarbonizationOrganic matter

The invention discloses a microencapsulated carbon-coated carbon fluoride cathode material and a preparation method thereof. The cathode material is formed by coating the surfaces of carbon fluoride particles with a layer of carbon. The preparation method comprises the following steps: firstly coating the surfaces of carbon fluoride particles with a layer of an organic matter to prepare carbon fluoride microcapsule particles by microencapsulation technologies such as an interfacial polymerization method and a complex coacervation method; and then preparing the carbon-coated carbon fluoride cathode material by a high-temperature carbonization or concentrated sulfuric acid carbonization technology. The carbon-coated carbon fluoride cathode material prepared by the method is uniform in particles and good in conductivity; particle agglomeration can be avoided; the battery discharge voltage can be improved; and the rate discharge property is improved.

Owner:XIANGTAN UNIV

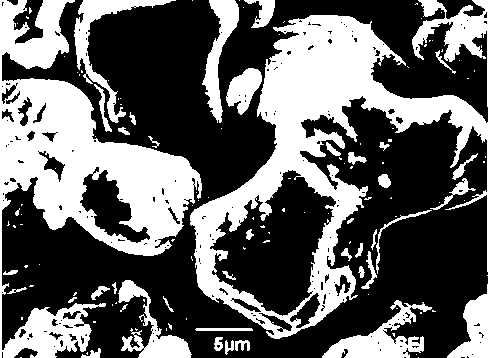

A lithium-ion battery positive electrode material iron manganese magnesium lithium phosphate and preparation method thereof

ActiveCN104319368BImprove electrochemical performanceIncrease discharge voltage platformCell electrodesMagnesium phosphateMagnesium orthophosphate

A lithium-ion battery positive electrode material iron manganese magnesium magnesium phosphate and its preparation method, the chemical general formula of iron manganese magnesium magnesium lithium phosphate is LiFe0.5Mn0.45Mg0.05PO4, the molar ratio is 1.0-1.2:0.5:0.45:0.05:1 Get lithium source, iron source, manganese source, magnesium source, phosphorus source in the ball mill tank, add carbon source, use distilled water as dispersant, place ball mill in ball mill, make iron manganese magnesium magnesium lithium precursor; Put it into a microwave oven, dry it with microwave treatment for 2~20 minutes, and then leave it for calcination; the precursor powder after microwave treatment is controlled at a heating rate of 5~12°C / min under the protection of an inert gas atmosphere, at 500~850 Calcining at ℃ for 3~15h, and finally cooling to room temperature with the furnace, the doped carbon-coated iron, manganese, magnesium, and lithium cathode materials can be obtained.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

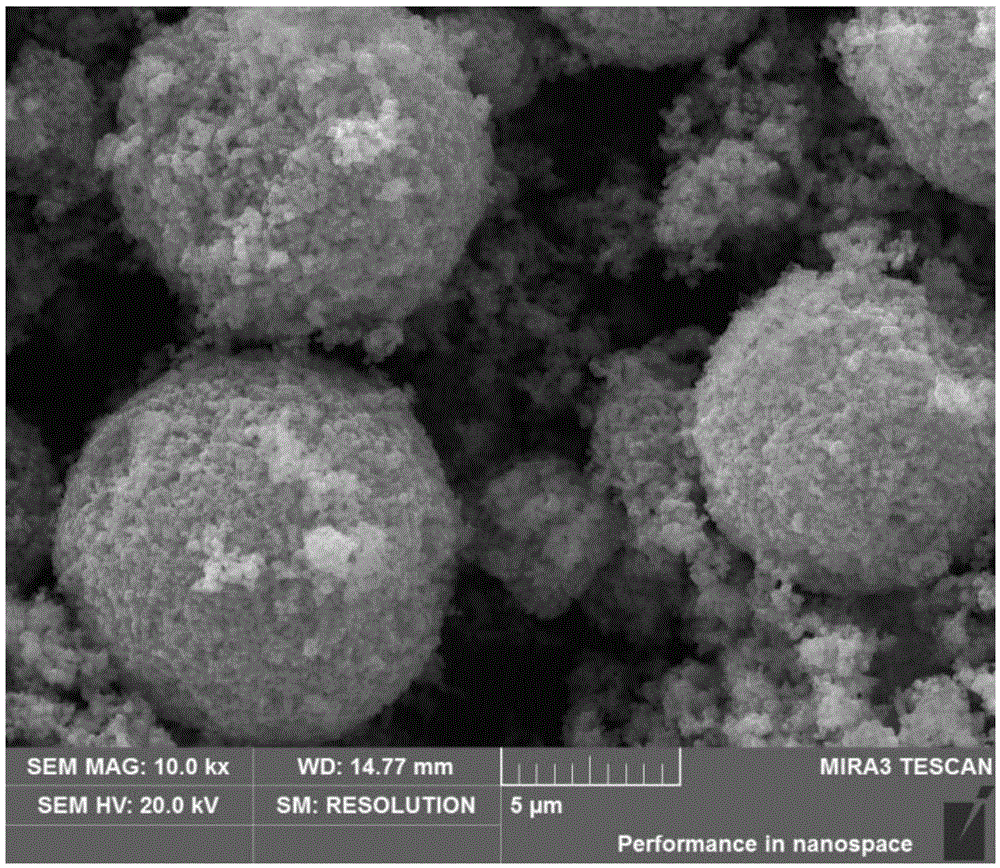

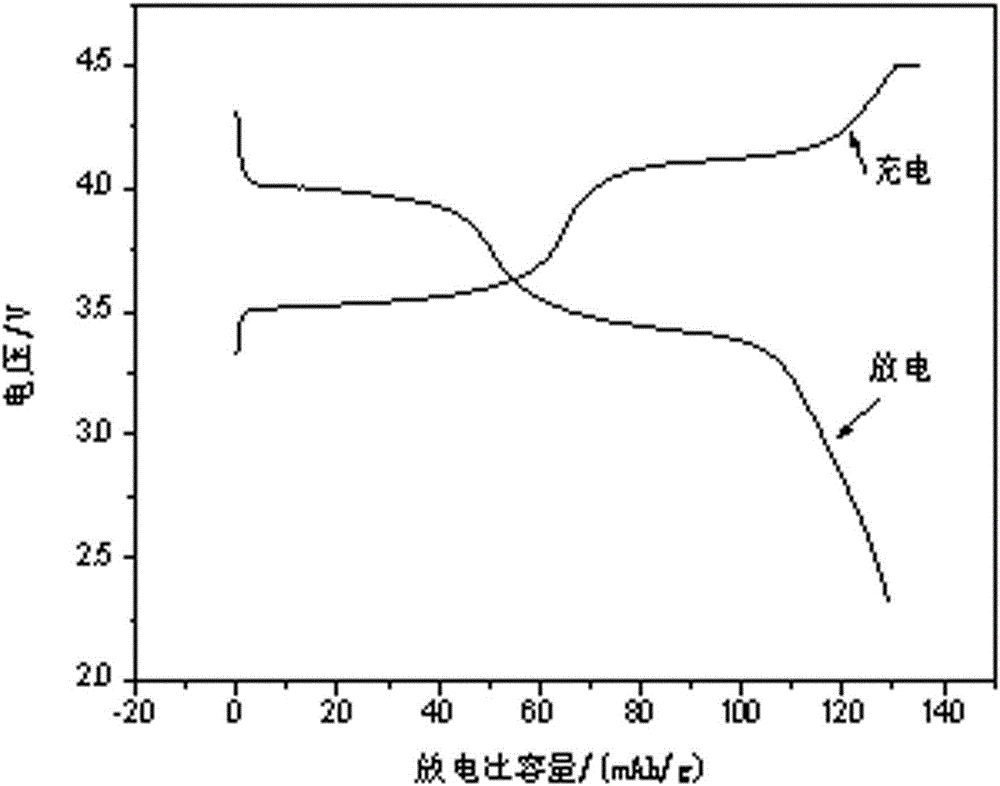

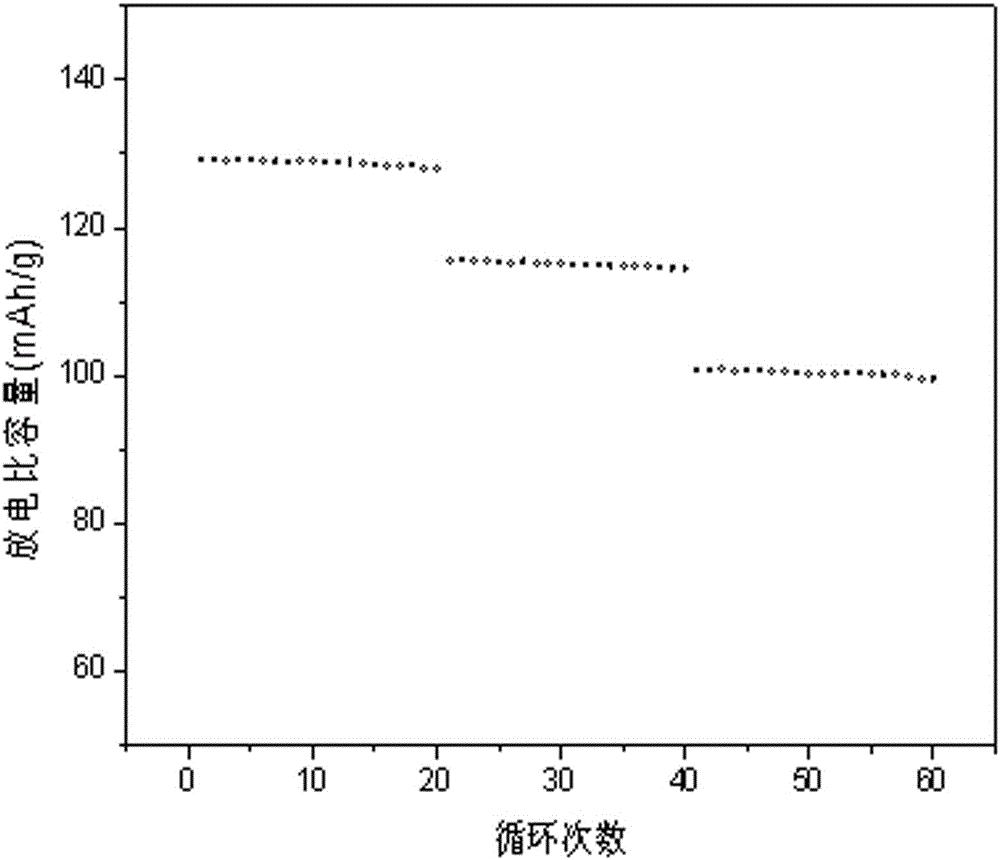

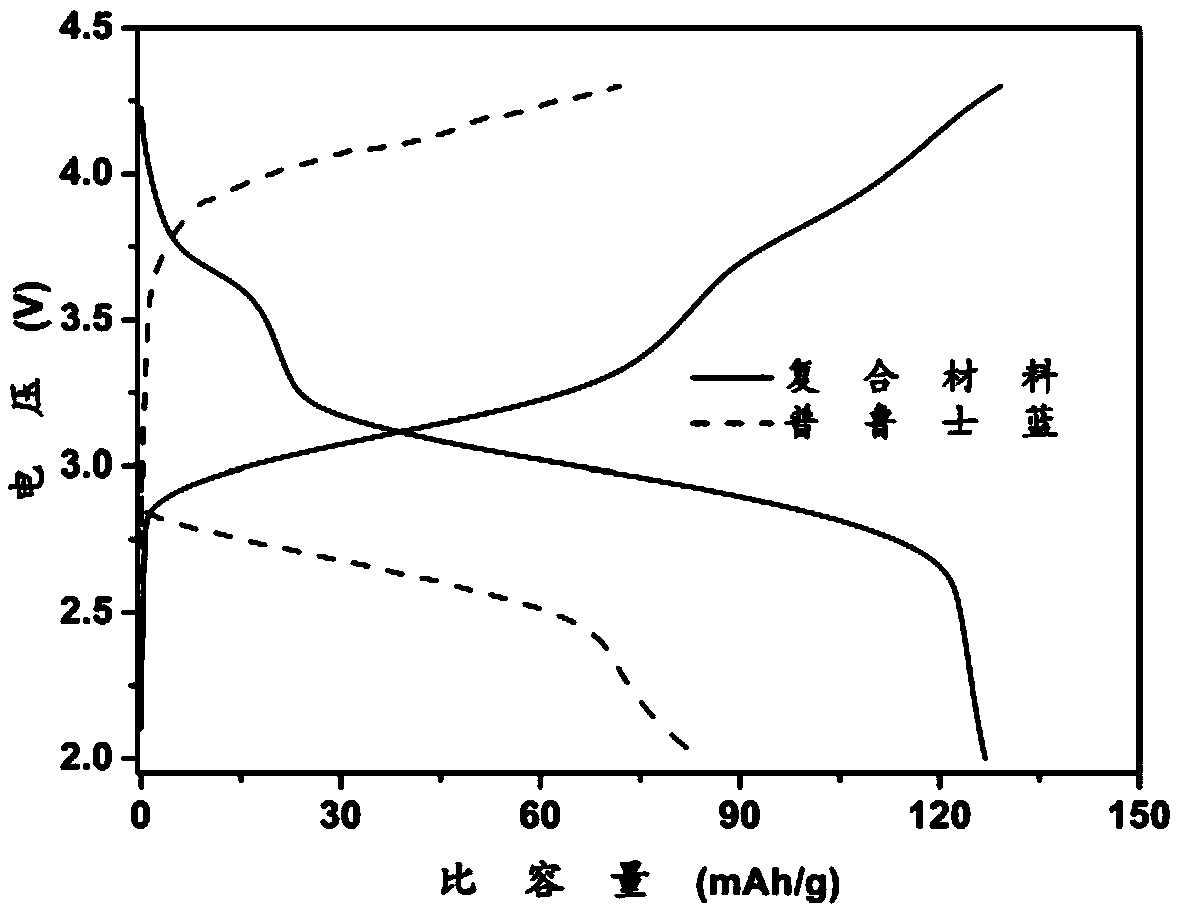

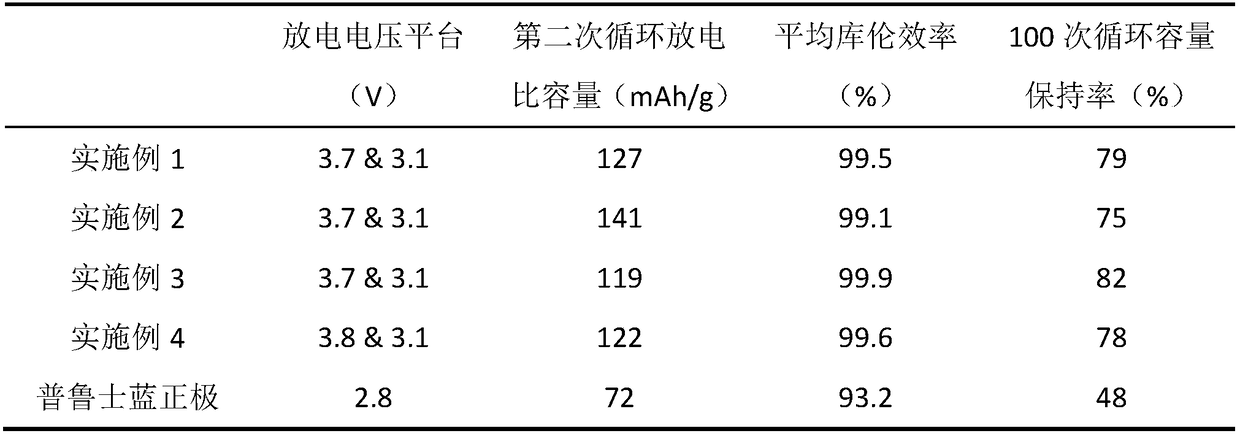

High-performance Prussian blue @ graphite lithium battery composite cathode material and preparation method thereof

InactiveCN109216674ARich pore structureImprove electrochemical activityGraphiteCell electrodesSolventIon

The invention discloses a high-performance Prussian blue @ graphite lithium battery composite cathode material and a preparation method thereof. The preparation method comprises uniformly dispersing natural graphite powder in deionized water, dissolving ferrocyanide salt and ferric chloride in the dispersion, vigorously stirring the mixture at 60-65 DEG C for 4-6h, centrifuging, washing and vacuumdrying to obtain a composite material of Prussian blue and graphite; Mixing the obtained composite material with a binder, adding a solvent and stirring to form a coating slurry; The slurry was evenly coated on aluminum foil by coating method, dried, sliced and used as cathode material of lithium battery. The preparation method has the advantages of simple process, cheap raw materials, environmental protection, high structural stability and excellent electrochemical performance of the Prussian blue @ graphite composite material, and has good application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of lithium ion battery which contains modified lithium-manganese group-enriched anode active material and application thereof

InactiveCN103779553AEasy to prepareImprove cycle performanceCell electrodesSecondary cells manufacturePhysical chemistrySodium-ion battery

The invention provides a preparation method of lithium ion battery which contains modified lithium-manganese group-enriched anode active material and application thereof, and relates to the field of lithium ion battery technology, and the lithium ion battery cathode material containing the modified lithium-manganese group-enriched anode active material comprises the following components by mass: 86-95% of modified lithium-manganese group-enriched anode active materials, 3-6% of binders and 2-8% of conductive agents. The preparation method of the lithium-manganese group-enriched anode material is simple, and lithium ion battery employing the cathode material has the advantages of good cycle performance, non-attenuation capacity at high temperature, good low temperature performance, high discharge voltage platform, etc.

Owner:深圳市艾利奇科技有限公司

Positive electrode of nickel-hydrogen secondary battery added with carbon gas gel

InactiveCN1933216ALower internal resistanceNo pollution in the processAlkaline accumulator electrodesHigh rateHydrogen

This invention relates to the positive of a NiH secondary cell added with carbon gel in the following components and weight content: carbon gel: 0.1-1%, cobaltous oxide: 3-12%, Zn: 2.1-6.5%, Teflon: 1.0-4.5%, carboxymethylcellulose sodium: 0.1-1.2% and spherical beta-Ni(OH)2, which can be widely used in high rate, high capacitance and high temperature NiH sealing alkali secondary cells.

Owner:SHANGHAI JIAO TONG UNIV

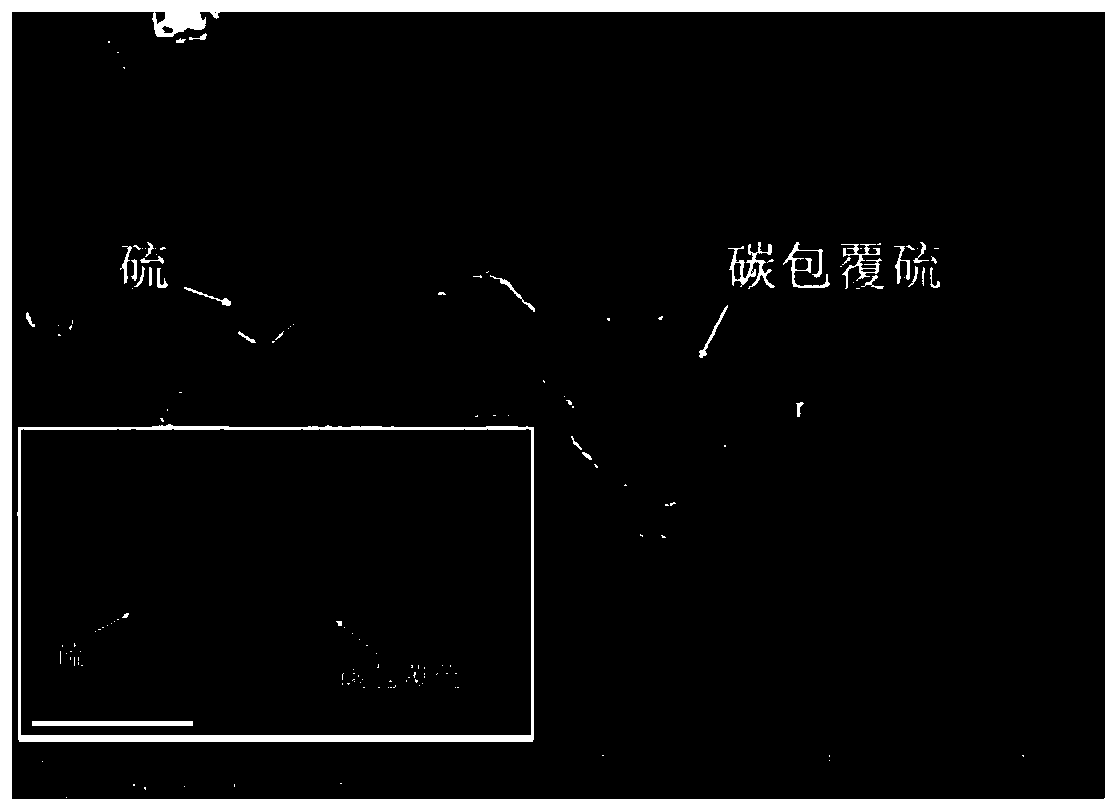

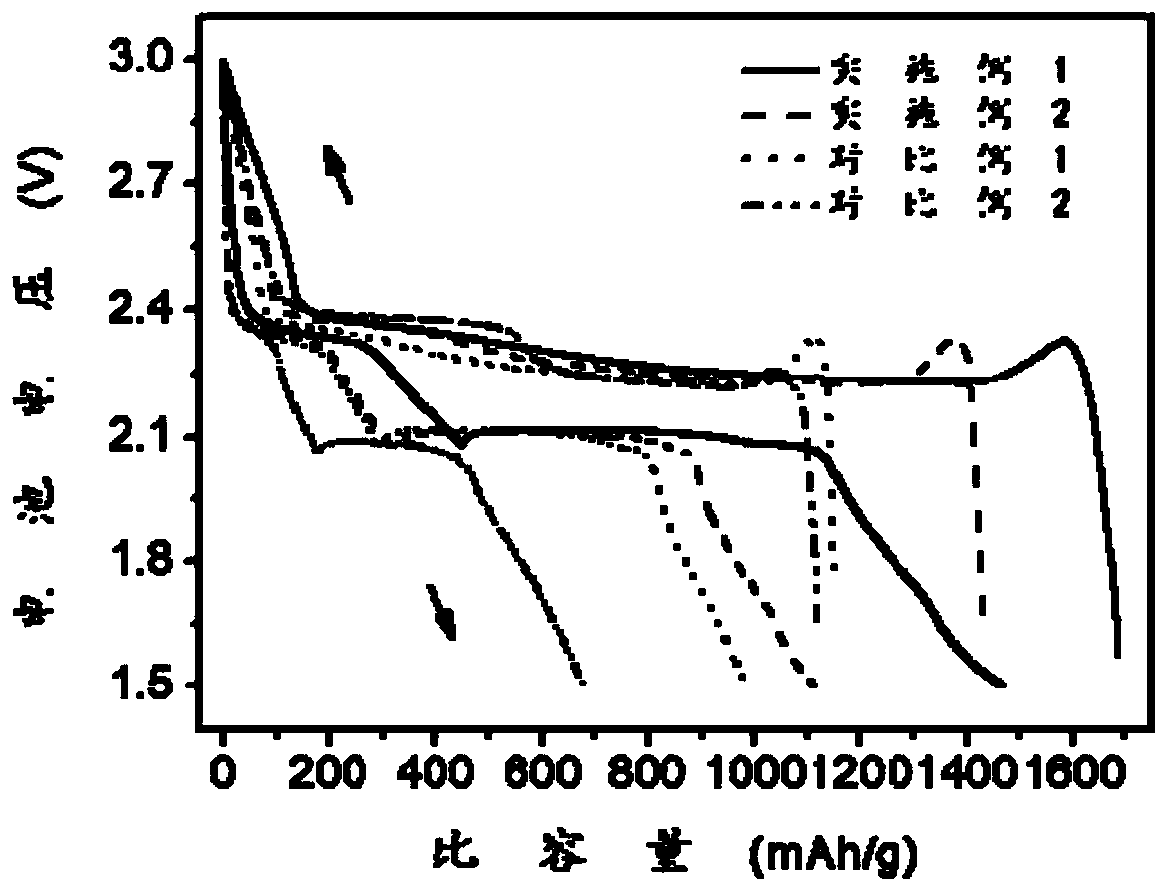

Preparation method of high-stability composite positive electrode material for lithium-sulfur battery

ActiveCN110380014AExtend your lifeHigh energyPositive electrodesLi-accumulatorsLithium–sulfur batterySulfur

The invention provides a preparation method of a high-stability composite positive electrode material for a lithium-sulfur battery, and the method employs carbon-coated carbon fluoride as a functionalcarrier of sulfur, so that the cycling stability, the rate capability, the first discharge capacity and the discharge voltage platform of the composite positive electrode material can be remarkably improved; the utilization rate of the active material in the positive electrode material is improved, and the important significance is realized on prolonging the service life, energy and power performance of the lithium-sulfur battery. By adopting the preparation method disclosed by the invention, two solid-phase products with coated structures can be subjected to ball milling and then are meltedand diffused to enable sulfur to be melted and permeated into two phases, so that the positive electrode material is prepared through combination. The process has the technical advantages that after sulfur is coated with carbon, the sulfur can be more uniformly dispersed in the prepared positive electrode material through ball milling and melting diffusion, thereby reducing the agglomeration of the sulfur; and the coating size can reach the nanoscale. However, conventional mixing of elemental sulfur and a conductive agent cannot effectively coat sulfur, and the sulfur agglomeration phenomenonis serious.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Preparation method for lithium ferrous phosphate anode material coated by directly reduced nanocarbon

ActiveCN102856548BLow costWide variety of sourcesMaterial nanotechnologyCell electrodesPhosphateVacuum drying

The invention relates to a preparation method for a lithium ferrous phosphate anode material coated by directly reduced nanocarbon, which comprises the steps: mixing a reducer and water; then adding nanocarbon into the mixture of the reducer and water; obtaining the directly reduced nanocarbon by heating, ultrasonication, filtering and drying and the like; mixing the directly reduced nanocarbon with a lithium source compound, a ferrous source compound, a phosphorus source compound and a wet grinding medium, and vacuum drying to obtain dry powder; placing the dry powder in an inertial atmosphere or a reducing atmosphere, and preparing the lithium ferrous phosphate anode material coated by directly reduced nanocarbon by a two sectional sintering method. The electrode material prepared by the invention is uniform in component and excellent in discharge performance, and in particular optimal circulating performance under large current.

Owner:贵州唯特高新能源科技有限公司

Preparation method for lithium ferrous phosphate anode material coated by directly reduced nanocarbon

ActiveCN102856548ALow costWide variety of sourcesMaterial nanotechnologyCell electrodesPhosphateVacuum drying

The invention relates to a preparation method for a lithium ferrous phosphate anode material coated by directly reduced nanocarbon, which comprises the steps: mixing a reducer and water; then adding nanocarbon into the mixture of the reducer and water; obtaining the directly reduced nanocarbon by heating, ultrasonication, filtering and drying and the like; mixing the directly reduced nanocarbon with a lithium source compound, a ferrous source compound, a phosphorus source compound and a wet grinding medium, and vacuum drying to obtain dry powder; placing the dry powder in an inertial atmosphere or a reducing atmosphere, and preparing the lithium ferrous phosphate anode material coated by directly reduced nanocarbon by a two sectional sintering method. The electrode material prepared by the invention is uniform in component and excellent in discharge performance, and in particular optimal circulating performance under large current.

Owner:贵州唯特高新能源科技有限公司

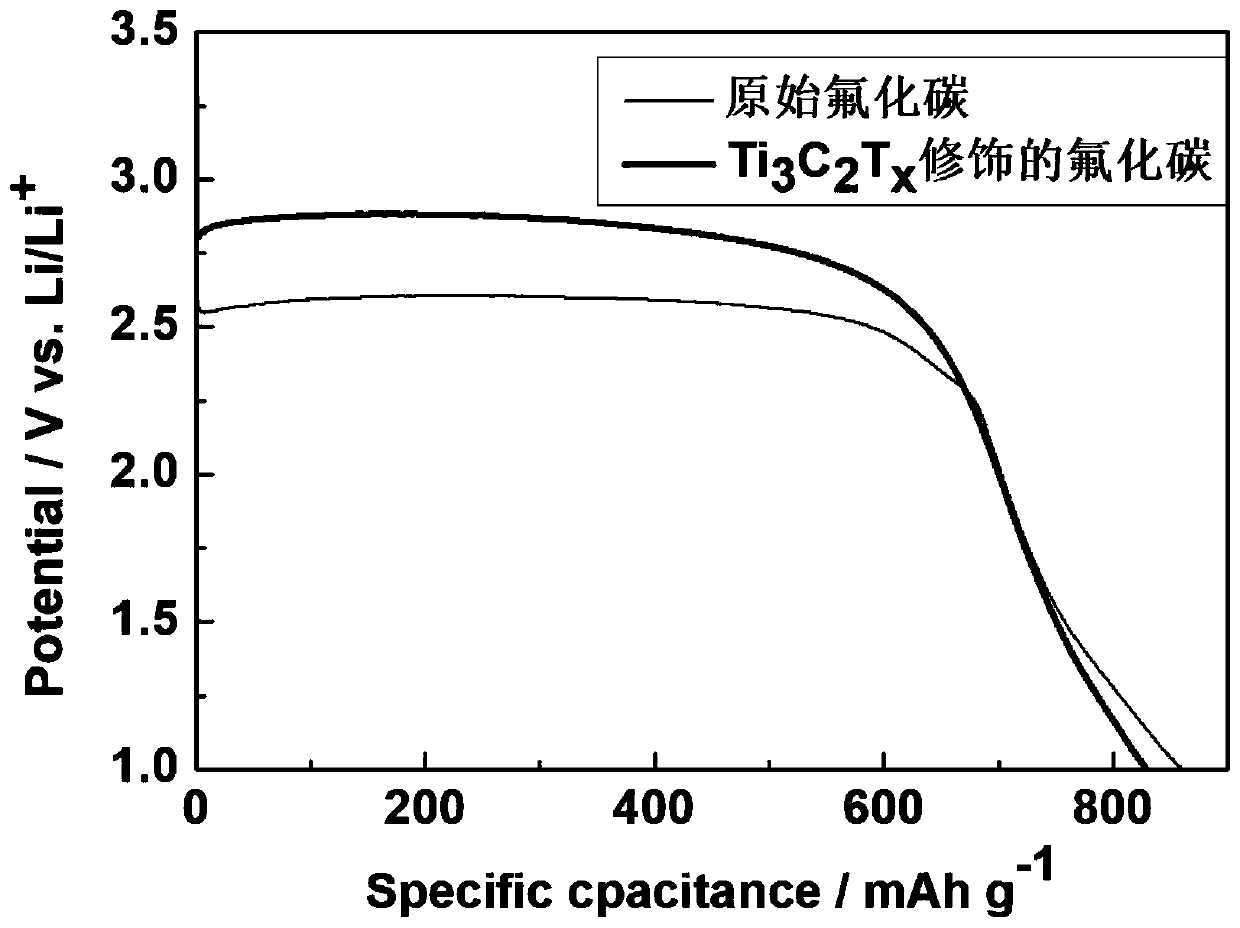

Preparation method and application of two-dimensional Ti3C2Tx modified carbon fluoride composite positive electrode material

ActiveCN111430715AIncrease discharge voltage platformImprove conductivityNon-aqueous electrolyte cellsPositive electrodesElectrical batteryModified carbon

The invention relates to a preparation method and application of a two-dimensional Ti3C2Tx modified carbon fluoride (CFx) composite positive electrode material, belongs to a battery positive electrodematerial, and particularly relates to the technical field of primary battery positive electrode materials. The preparation method comprises the following steps of uniformly dispersing a CFx materialinto a mixed solution of deionized water and ethanol; adding the two-dimensional Ti3C2Tx into the CFx suspension according to a certain proportion, and carrying out ultrasonic stirring to fully mix the two-dimensional Ti3C2Tx and the CFx suspension; filtering the mixed suspension, and washing with deionized water for multiple times to obtain a mixture; freezing and drying the mixture to obtain a composite material; and putting the composite material into a tubular furnace in an inert atmosphere, carrying out high-temperature treatment, and cooling to room temperature to obtain the two-dimensional Ti3C2Tx modified carbon fluoride material. According to the preparation method, the Ti3C2Tx is successfully modified among the particles of the carbon fluoride material, so that the specific surface area and the conductivity of the carbon fluoride material are remarkably improved. When the material is used as a positive electrode material of a lithium carbon fluoride battery, the discharge voltage platform and specific capacity are greatly improved, and the voltage lag is reduced.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

Room temperature sodium-sulfur battery positive electrode material and preparation method and application thereof

PendingCN110098390AAvoid reunionAvoid stickingMaterial nanotechnologySecondary cellsElectrochemical responseChemical reaction

The invention relates to a room temperature sodium-sulfur battery positive electrode material and a preparation method and an application thereof. The preparation method comprises the steps of S1, blending polyacrylonitrile and sulfur powder, ball milling and calcining to obtain a sulfurized polyacrylonitrile precursor material; S2, polymerizing pyrrole monomers on the precursor material in situ to obtain a polypyrrole (PPy) nanolayer; S3, annealing the material obtained in the step S2 to obtain the room temperature sodium-sulfur battery positive electrode material. The surface of sulfurized polyacrylonitrile is coated with an N-doped carbon layer, thereby being capable of well playing a role of protecting and stabilizing the electrode. Meanwhile, the doping of the element N can acceleratethe kinetic process of the electrochemical reaction, reduce the polarization in the electrochemical reaction process, improve the discharge voltage platform of the battery and thus improve the energydensity of the battery. Furthermore, the positive electrode material is carbonized at a low temperature, thereby avoiding the loss of sulfur; and the obtained positive electrode material has excellent cycle performance, stable Coulomb efficiency, high specific capacity and excellent electrochemical performance.

Owner:GUANGDONG UNIV OF TECH

Method for coating CFx

The invention relates to a method for coating CFx. The method comprises the following steps: step 1, preparation of a carbon precursor: (1) adding humic acid or sulfonated asphalt into a LiOH solution to obtain an alkali solution free of solids; (2) adjusting the alkali solution with diluted hydrochloric acid to separate out solids to obtain solid weak-acid water-solubility nano carbon precursor ACM or SCP; and (3) preparing ACM or SCP and the LiOH solution into an ACM or SCP alkali aqueous solution; and step 2, the coating process of CFx powder: mixing the ACM or SCP alkali aqueous solution with CFx suspension to obtain mixed liquid, evaporating to obtain mixed solids, drying, cooling, sieving and carbonizing, thus finishing the coating process of CFx. According to the method, since a cheap water-solubility nano carbon material is used as a precursor, the uniformity of a carbon layer in the coating process can be ensured, the problem of voltage delay can be eliminated, and the conductivity, discharge voltage platform and rate performance of CFx can be improved.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com