Cathode material of lithium ion battery and preparation method and application of cathode material

A technology for lithium-ion batteries and positive electrode materials, applied in the field of lithium-ion battery positive electrode materials and their preparation, can solve problems affecting commercial applications, poor electrochemical performance stability, etc., to suppress dissolution, improve lattice stability, and improve The effect of the discharge voltage plateau

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

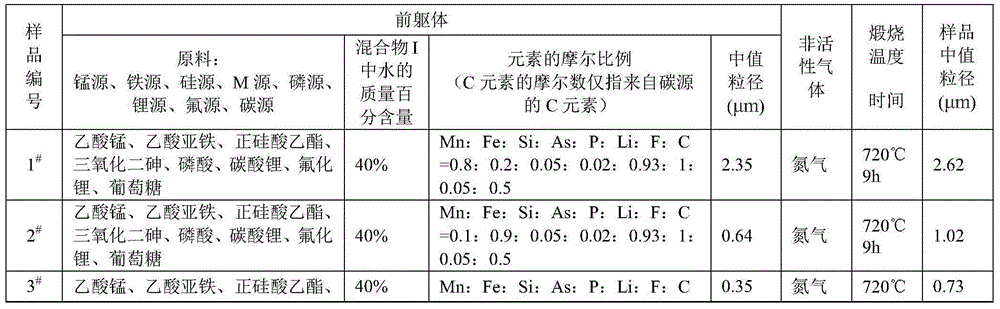

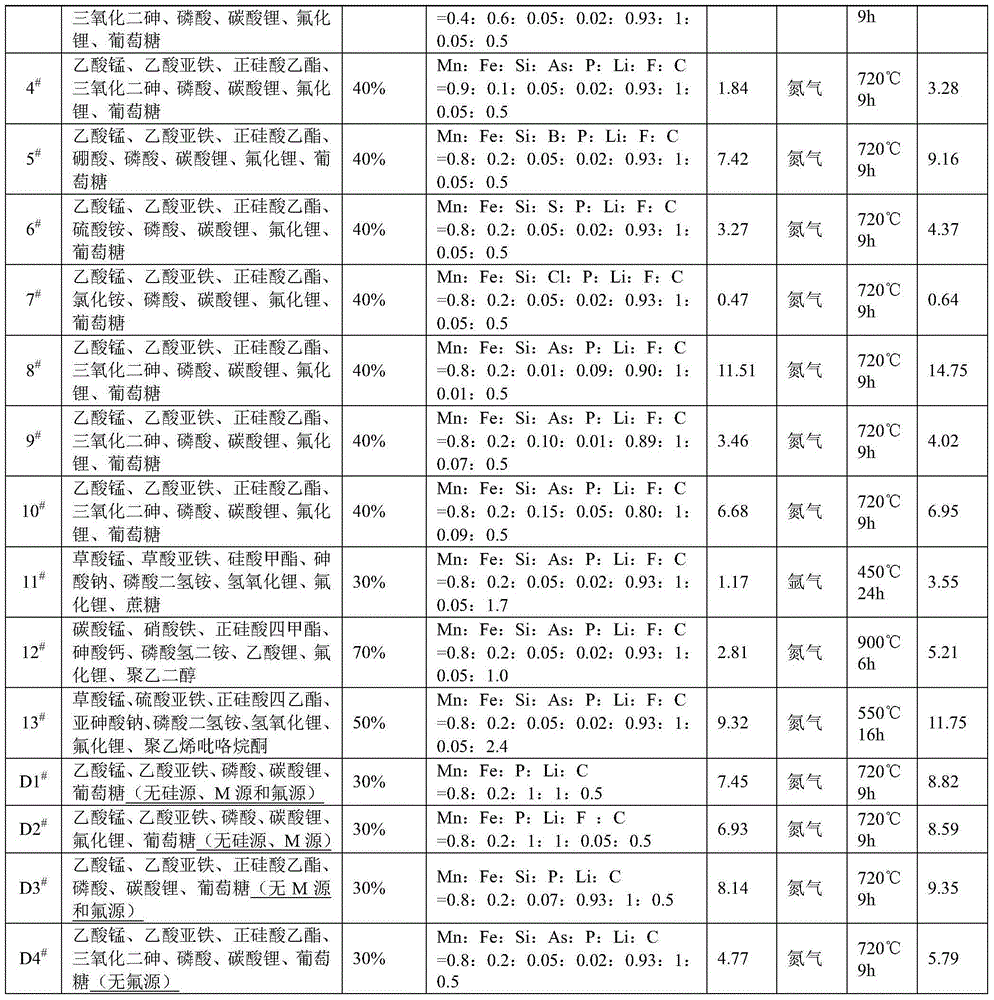

[0060] Example 1 Sample 1 # ~13 # preparation of

[0061] The specific preparation process of the cathode material sample is as follows:

[0062] Mix manganese source, iron source, silicon source, M source with water to obtain mixture I; add phosphorus source to mixture I while stirring, keep stirring evenly, and dry at 80°C for 24 hours to obtain mixture II. Put the mixture II, lithium source, lithium fluoride and carbon source into the ball mill tank of the ball mill for ball milling with alcohol as the medium, and dry at 60°C for 4 hours after ball milling to obtain the precursor. The precursor is placed in a tube furnace and calcined after passing through a dynamic inactive gas. The space velocity of the inactive gas passing through the precursor is 0.1h -1 (mass of inactive gas passing through unit mass of precursor per unit time); after calcination, cool to room temperature, and pulverize the obtained solid by airflow crushing method to obtain the positive electrode m...

Embodiment 2

[0075] The particle size test of embodiment 2 sample

[0076] To embodiment 1 gained sample 1 # ~13 # And comparative sample D1 obtained in comparative examples 1-4 # ~D4 # The particle size of its precursor and its precursor were analyzed, and the results are shown in Table 1.

Embodiment 3

[0077] The element composition and structure test of embodiment 3 samples

[0078] Determination of sample 1 by ICP-OES # ~13 # and comparative sample D1 # ~D4 # Among them, the composition of elements with atomic number greater than 9, the results are shown in Table 2.

[0079] Sample 1 was analyzed on the Shanghai Dekai HCS-140 high-frequency infrared carbon and sulfur analyzer # ~13 # and comparative sample D1 # ~D4 # The carbon content was analyzed, and the results are shown in Table 2.

[0080] Adopt transmission electron microscope TEM to embodiment 1 gained sample 1 # ~13 # And comparative sample D1 obtained in comparative examples 1-4 # ~D4 # Observe and record the thickness range of the carbon coating, the results are shown in Table 2.

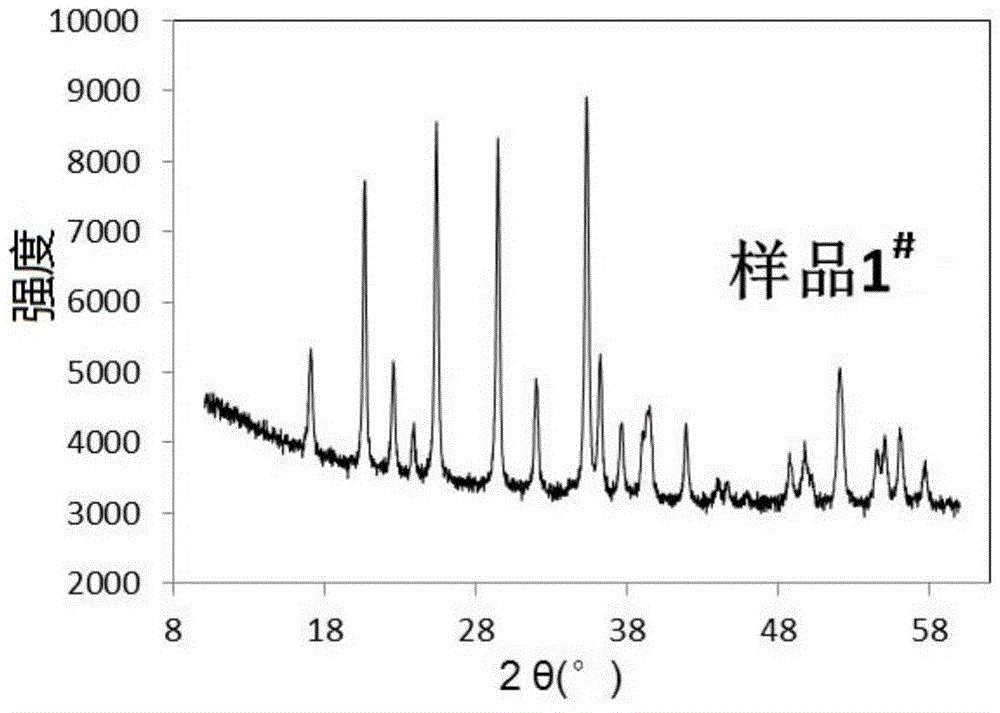

[0081] For sample 1 # ~13 # and D1 # ~D4 # Do XRD analysis, the results show that they all have the same crystal structure as the orthorhombic olivine-type lithium iron phosphate. Typical Representative Sample 1 # Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com