Preparation method and application of copper-coated chromium oxide positive electrode

A technology of chromium oxide and copper coating, applied in the direction of positive electrode, active material electrode, battery electrode, etc., to achieve the effect of good dispersion, high crystallinity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0023] Specific implementation mode 1: This implementation mode records a method for preparing a copper-coated chromium oxide positive electrode, and the steps of the method are as follows:

[0024] Step 1: Calcining chromium trioxide at high temperature, ball milling, and washing with water to prepare a positive electrode of chromium oxide with high specific capacity;

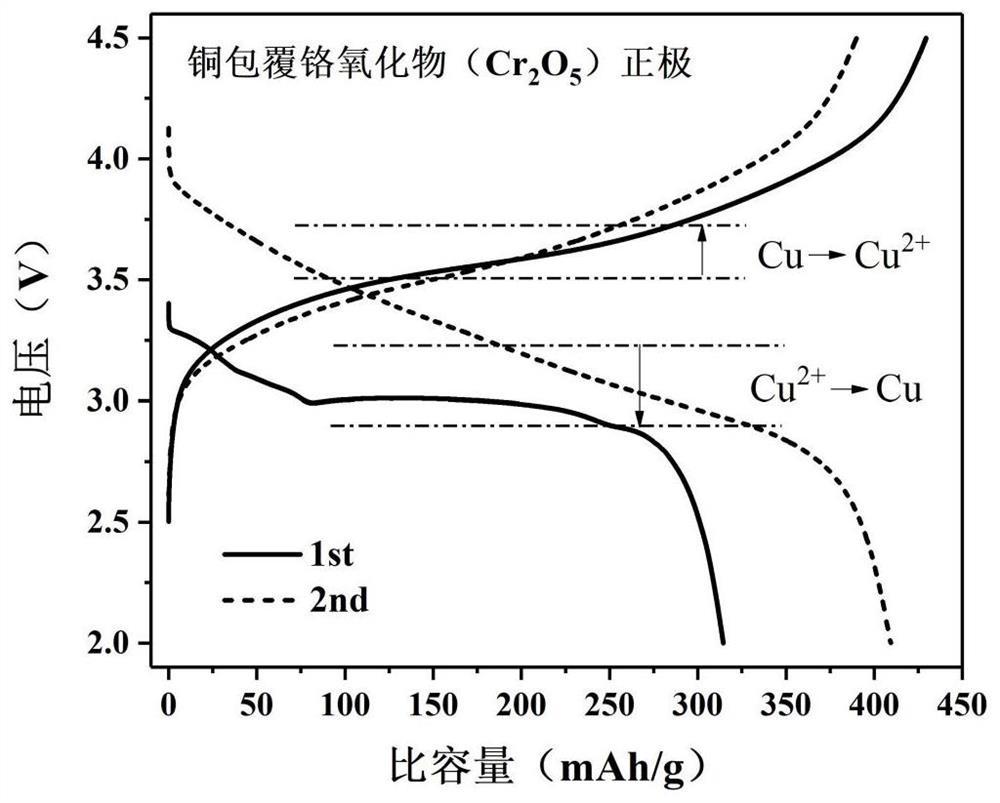

[0025] Step 2: Coating copper on the surface of the chromium oxide positive electrode in Step 1. The copper-coated chromium oxide prepared in this step has high charge / discharge specific capacity, first-time Coulombic efficiency and discharge voltage platform.

specific Embodiment approach 2

[0026] Specific embodiment two: the preparation method of a copper-coated chromium oxide positive electrode described in specific embodiment one, in step one, the temperature of the high-temperature calcination is 250-450 ° C, the time is 1-5 hours, and the heating rate is 1-10°C / min. Calcination conditions of chromium oxide have great influence on its composition.

specific Embodiment approach 3

[0027] Specific embodiment three: the preparation method of a copper-coated chromium oxide positive electrode described in specific embodiment one, in step two, the coating method is magnetron sputtering, atomic layer deposition, molecular layer deposition, evaporation One of plating or chemical deposition methods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com