Longitudinal, transverse and vertical force integrated control optimization method for electric vehicles driven by hub

An electric vehicle, wheel hub drive technology, applied in the field of electric vehicle control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

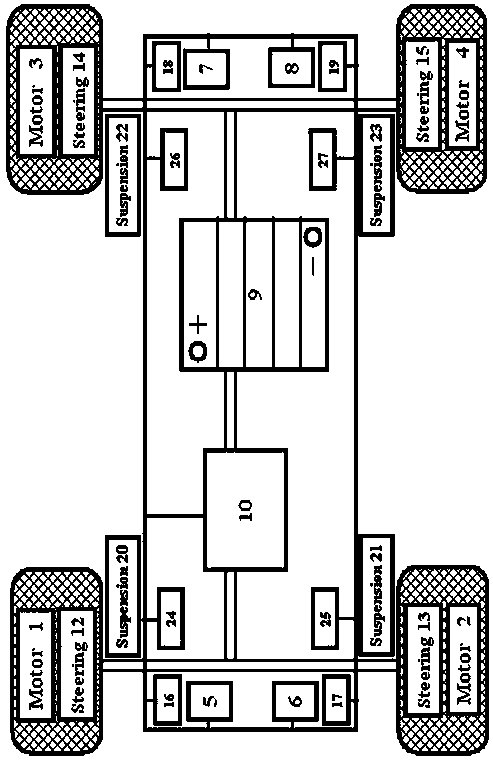

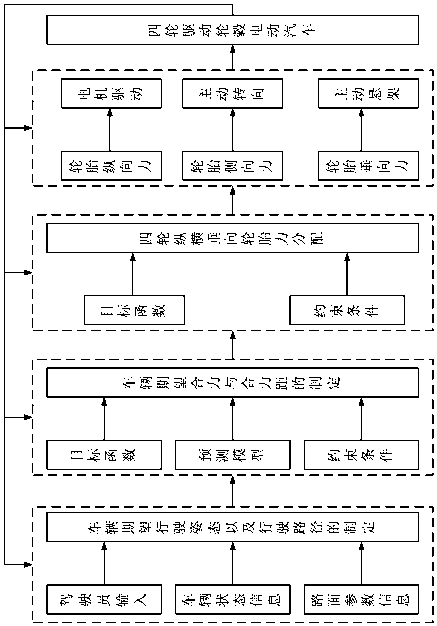

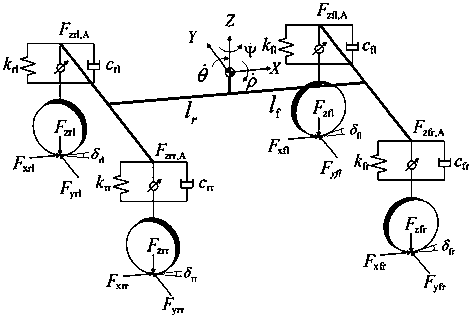

[0083] The invention relates to a control method belonging to the field of integrated optimization control of the chassis of a four-wheel hub-driven electric vehicle. The optimized distribution and cooperative control method of vector force integration can improve the maneuverability, stability and comfort of the vehicle. The electric vehicle longitudinal-lateral-vertical force integrated control system based on model predictive control designed by the present invention can well solve the above four problems. The invention adopts a layered cooperative control structure to control the chassis integrated control system. Specifically divided into three layers, the upper layer includes the driver control layer and the motion control layer, the middle tire force distribution layer and the lower actuator control layer. The present invention uses measurable quantities such as torque and speed information of four wheels, gives control instructions through the driver control layer, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com