Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104results about How to "Flexible splicing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

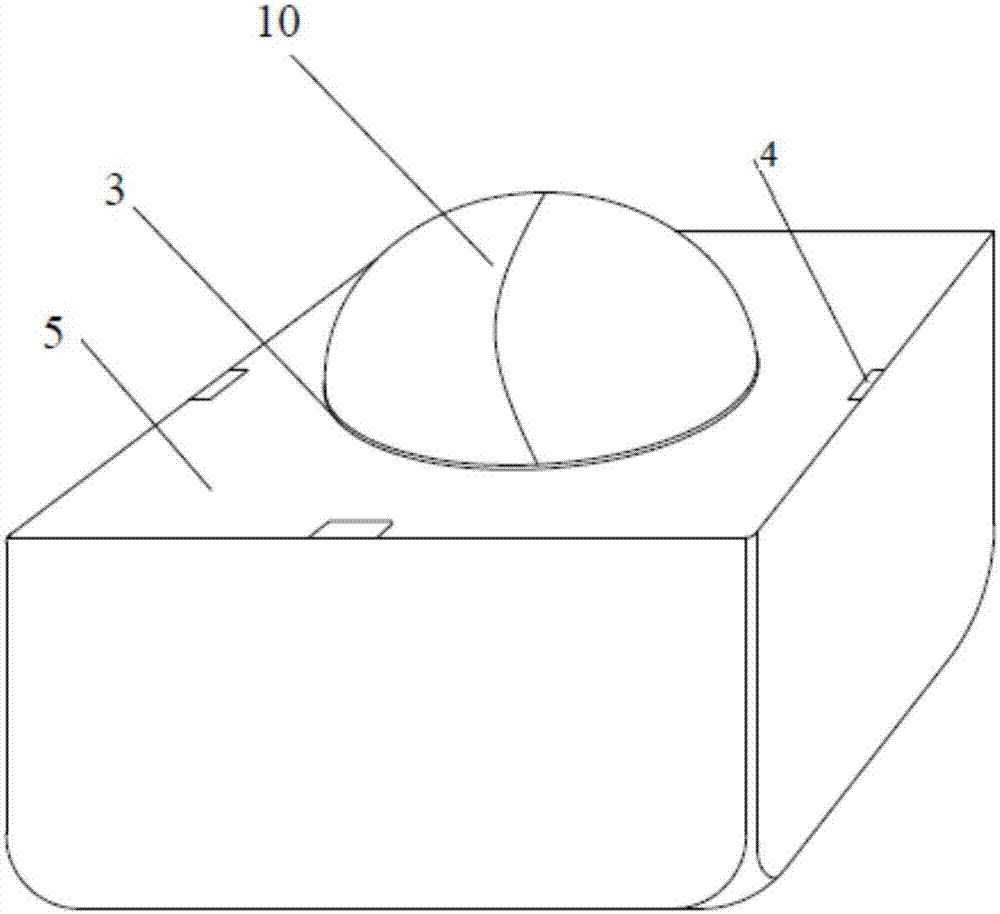

Airship airbag with shape-control frames

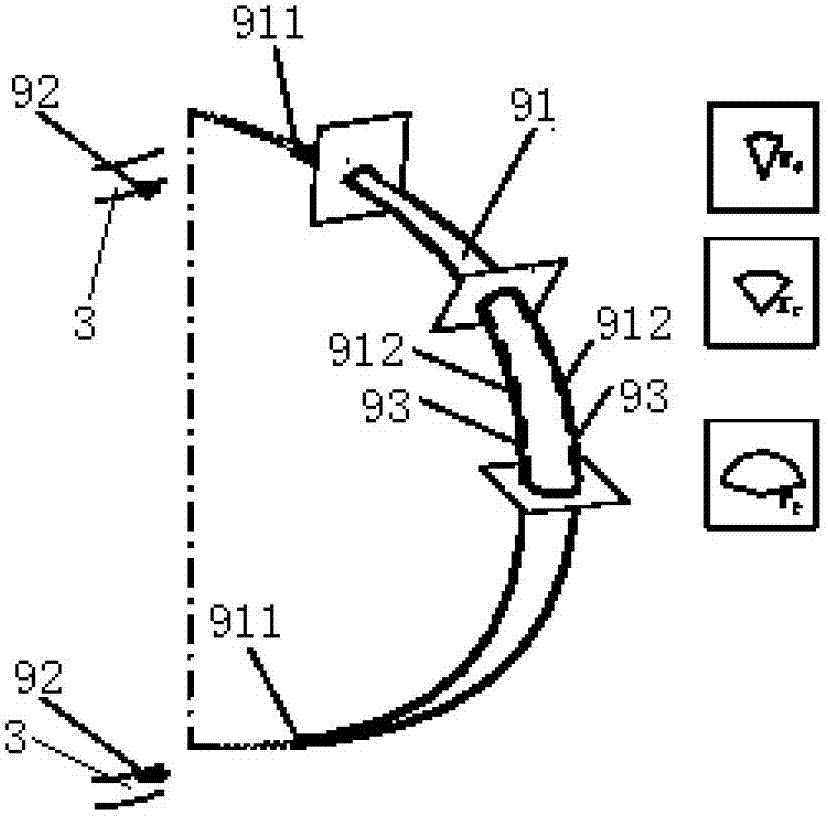

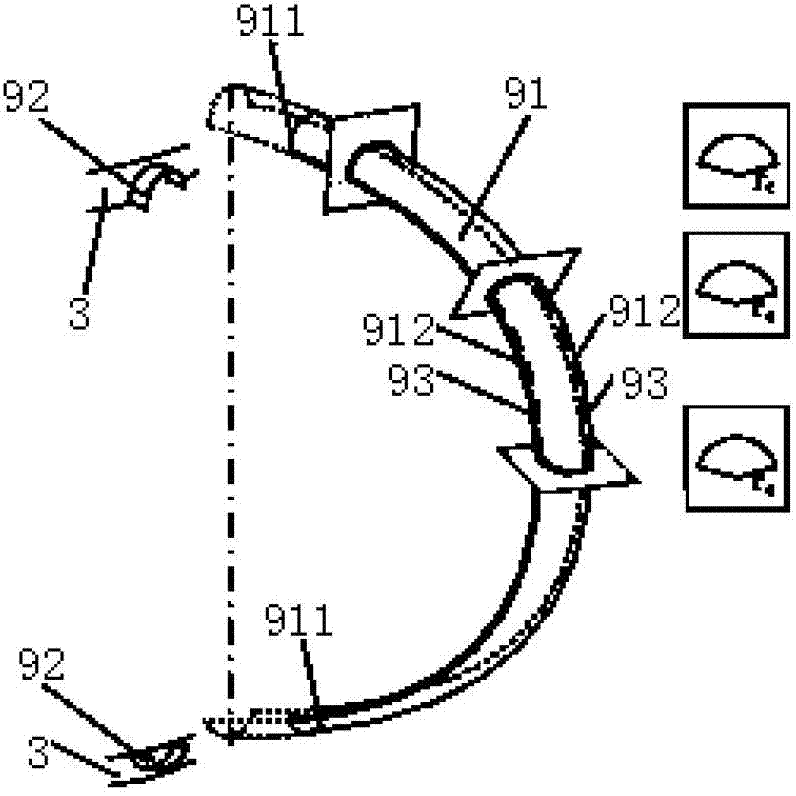

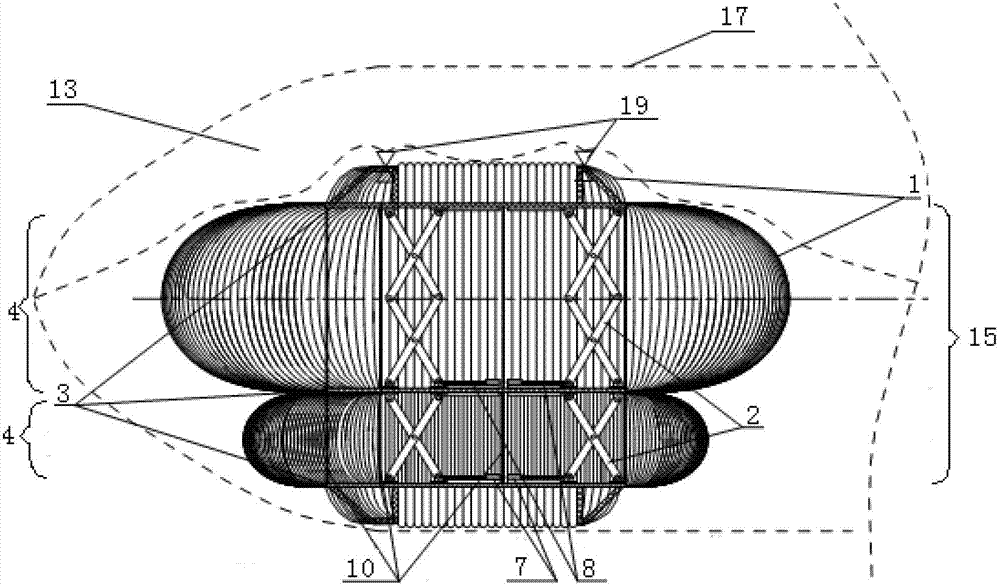

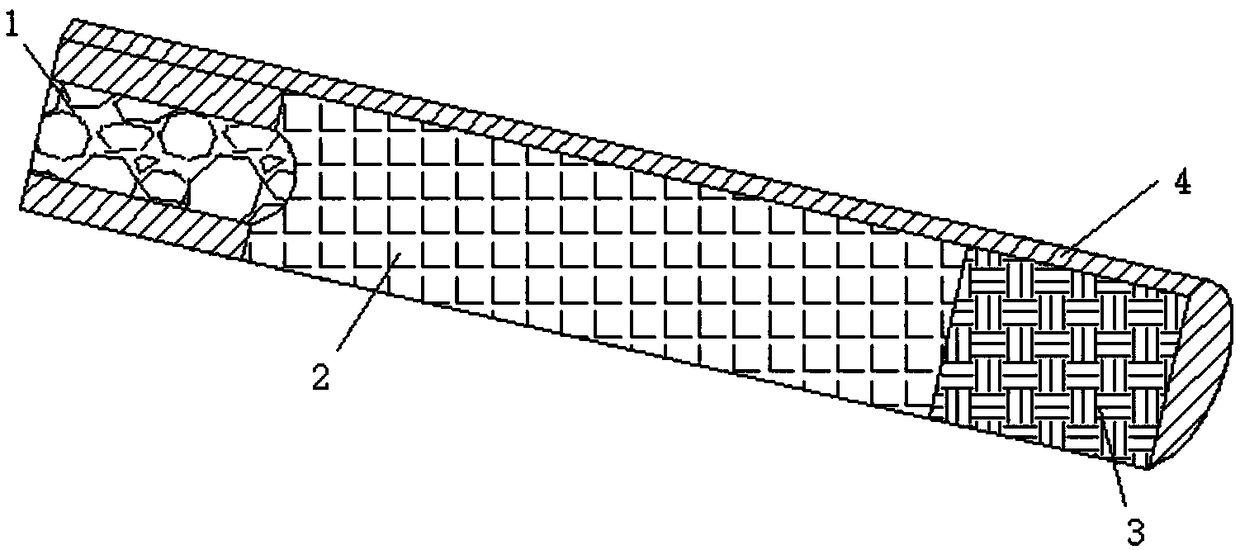

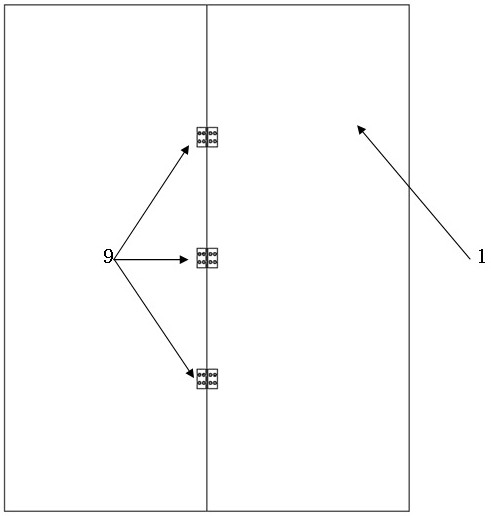

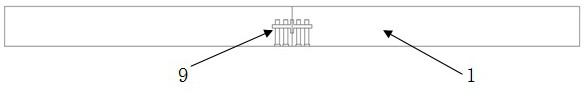

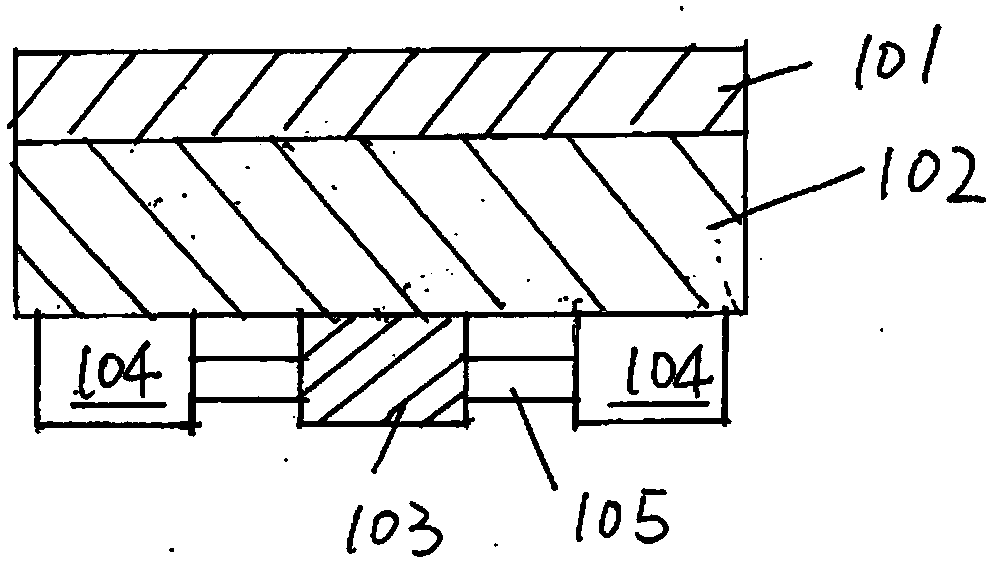

The invention relates to an airship airbag with shape-control frames. The airship airbag with the shape-control frames comprises an airbag casing (1) and the shape-control frames; the airtight flexible airbag casing (1) is arranged on the outer layer of the air bag, is of a laminated structure on the whole and consists of a plurality of layered structures; the inside of every layered structure is fixedly connected with the shape-control frames which comprises a plurality of pairs of vertically-arranged folding frames (2) and two pairs of shaping frames (3) respectively hinged to two ends of the folding frames (2); the airbag casing (1) of every layered structure (4) is formed by splicing the airtight film covering pieces (91) of a plurality of convex curved surface unit (9), and every convex curved surface unit (9) not only comprises one elongated airtight film covering piece (91) but also comprises a pair of end-edge fixing parts (92) on the shaping frames (3) and a pair of pulling-resistant straps (93). The airship airbag with the shape-control frames can make full use of the space inside an airship, is good in regularity of expansion and shrinkage deformation and good in repeatability and stability, and can bear relative large overpressure when being inflated and expanded fully.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

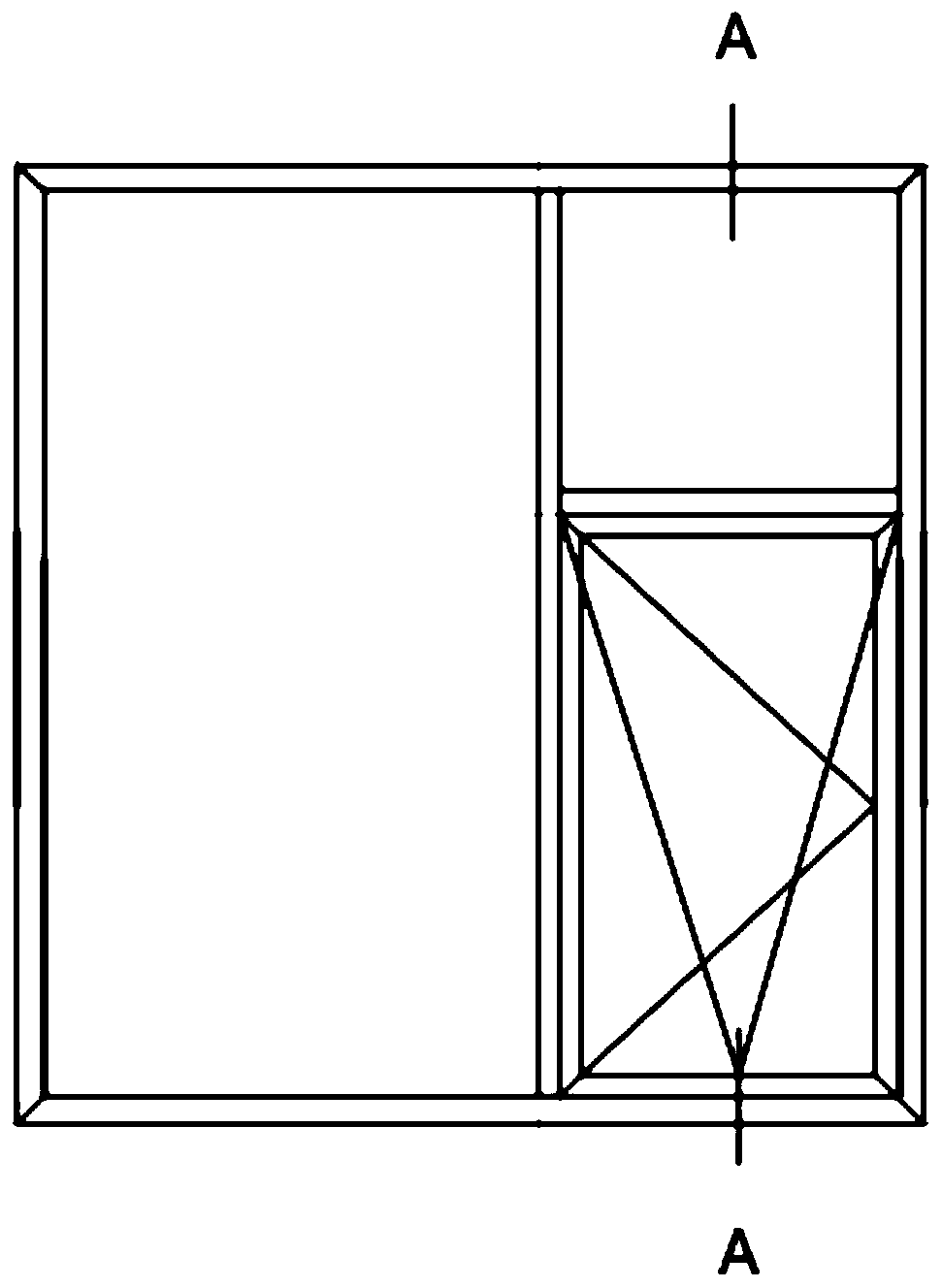

Three-dimensional geometrical measurement method and three-dimensional geometrical measurement system based on LED tag tracking

InactiveCN104976968AFlexible block measurementConvenient block measurementUsing optical meansThree dimensional measurement3d scanning

The invention provides a three-dimensional geometrical measurement method and a three-dimensional geometrical measurement system based on LED tag tracking. A three-dimensional scanner is arranged such that the three-dimensional scanner can move along a track and is close to an object to be measured, and blocked local measurement is flexibly and conveniently carried out on a large-scale object by a structured light method to obtain a high-resolution local image. Meanwhile, as the light of an LED tag is bright enough, even when the distance between a stereoscopic tracker and the LED tag increases, the stereoscopic tracker can quickly and accurately track the LED tag to ensure that a server can precisely locate the center position of the LED tag and the position of the LED tag in the coordinate system of the three-dimensional scanner, precisely obtain the LED tag relationship between two local measurements, accurately evaluate the attitude change of the three-dimensional scanner and realize precise stitching of local measurement results. Moreover, three-dimensional measurement of the whole contour of a large-scale object can be completed conveniently, stably and accurately without the need for tedious switching between multiple projectors.

Owner:JIANGSU UNIV OF SCI & TECH

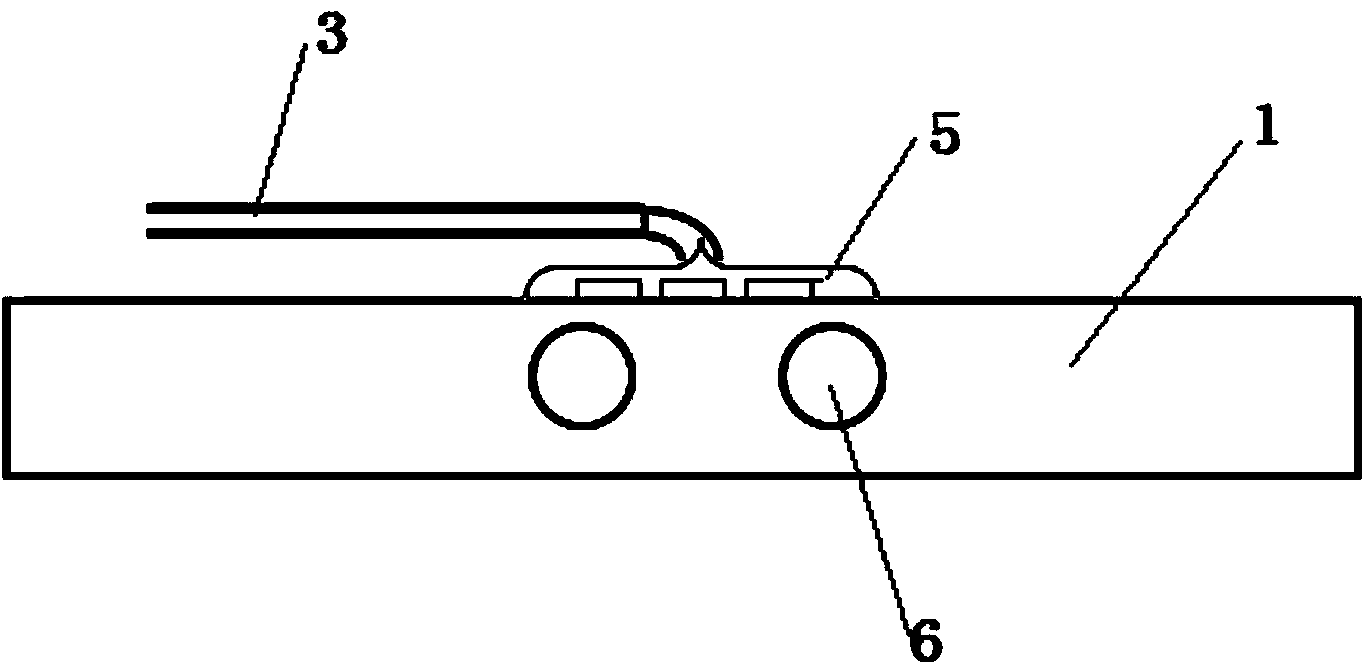

Connecting device for wound protection dressing, and wound protection dressing

InactiveUS20200179673A1Modification cost be lowSmoothly flow outIntravenous devicesSuction irrigation systemsComposite materialEngineering

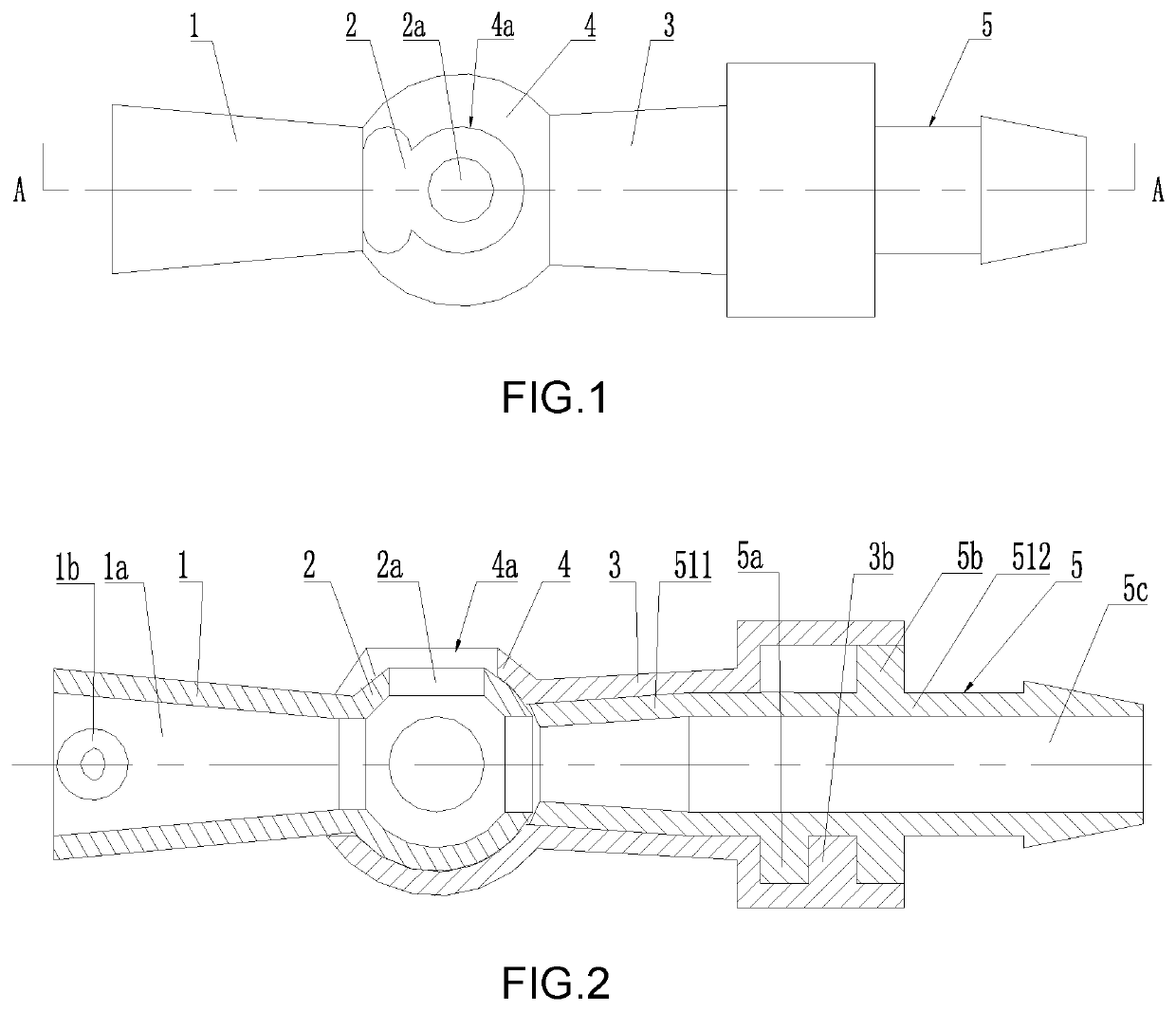

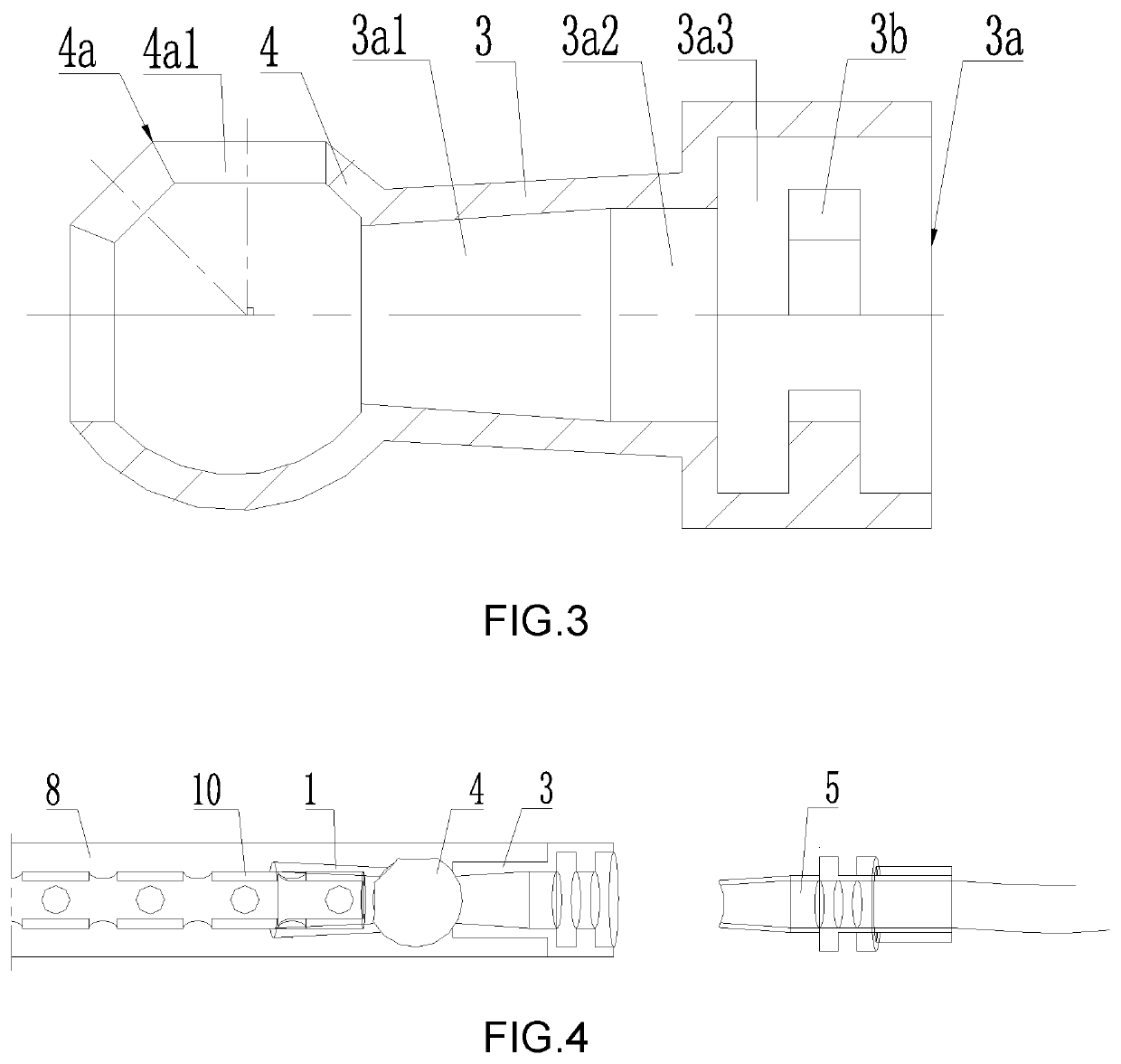

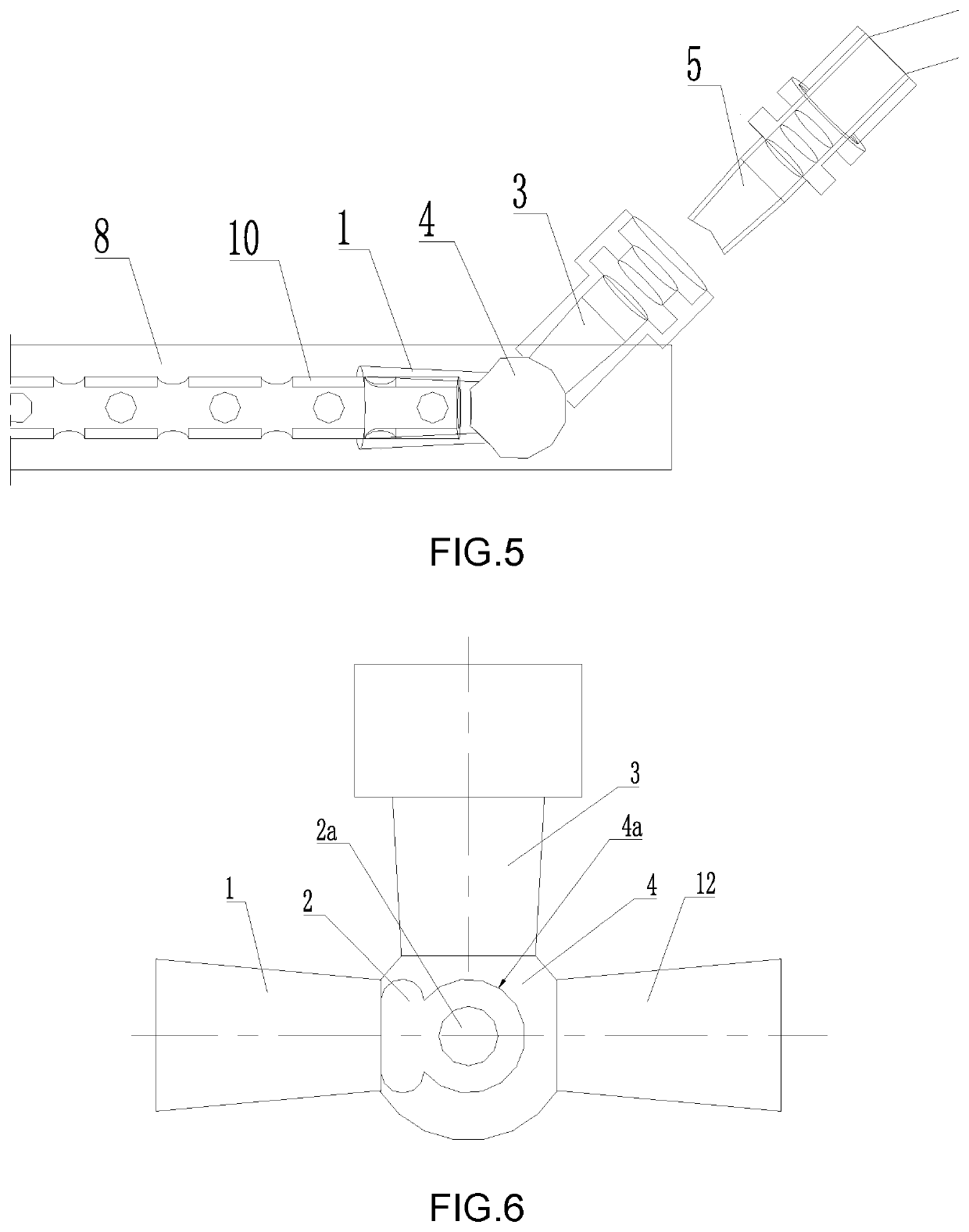

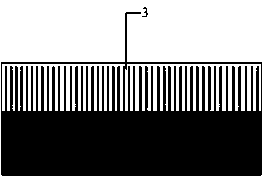

A connecting device for a wound protection dressing, and a wound protection dressing. The connecting device comprises a first tube connector (1) and a second tube connector (3); the first tube connector (1) and the second tube connector (3) are respectively provided with a first through hole (1a) and a second through hole (3a) that run through the respective ends of the first tube connector (1) and the second tube connector (3); a hollow ball head (2) is integrally formed on one end of the first tube connector (1); the inner cavity of the ball head (2) are in communication with the first through hole (1a); at least one via hole (2a) is provided on the ball head (2); a ball shell (4) adapted to the ball head (2) is integrally formed on one end of the second tube connector (3); the inner cavity of the ball shell (4) is in communication with the second through hole (3a); a snap-fit hole (4a) is provided on the ball shell (4); the snap-fit hole (4a) has at least one circular fastening hole (4a1); the ball head (2) is snap-fit in the ball shell (4); the end of the first tube connector (1) close to the ball head (2) is fastened in one of the fastening hole (4a1) of the snap-fit hole (4a). Thus, the connecting device for a wound protection dressing and the wound protection dressing which avoid pressing the skin and wound surface, allow the liquid to smoothly flow out, and facilitate flexible connection of the tube line are provided.

Owner:WAN MIANSHUI

Manufacturing method of ultramicropore broadband flexible micro-perforated plate

InactiveCN103387206AFast processingLow costDecorative surface effectsChemical vapor deposition coatingBroadbandPolyimide

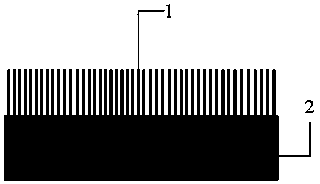

The invention relates to the manufacturing of sound absorbing material, and particularly to an ultramicropore broadband flexible micro-perforated plate. The manufacturing process comprises the following steps: first using micro mechanical processing method to produce a cylindrical array template formed by silicon, ceramic, metal and glass or plexiglass material, wherein the diameter of each cylinder is between 10 and 500 microns, the height of each cylinder is between 10 and 500 microns, and the distribution density of the cylinders is between 104 and 1010 cylinders per square meter; depositing liquid polymeric material on a substrate of the cylindrical array template with spin coating or casting techniques, and allowing the upper end surface of the cylinders to be exposed, wherein the polymeric material is polyurethane, polyimide, silica gel or the like; then carrying out solidification processing on the polymeric material deposited on the surface of the cylindrical array template; and finally removing the cylindrical array template to obtain a finished flexible micro-perforated plate. The method is high in processing speed, low in cost, compact in structure, and small in size, with consistent apertures, wide sound absorbing bands, and good flexibility, and thus can satisfy noise reduction needs of devices in different shapes.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

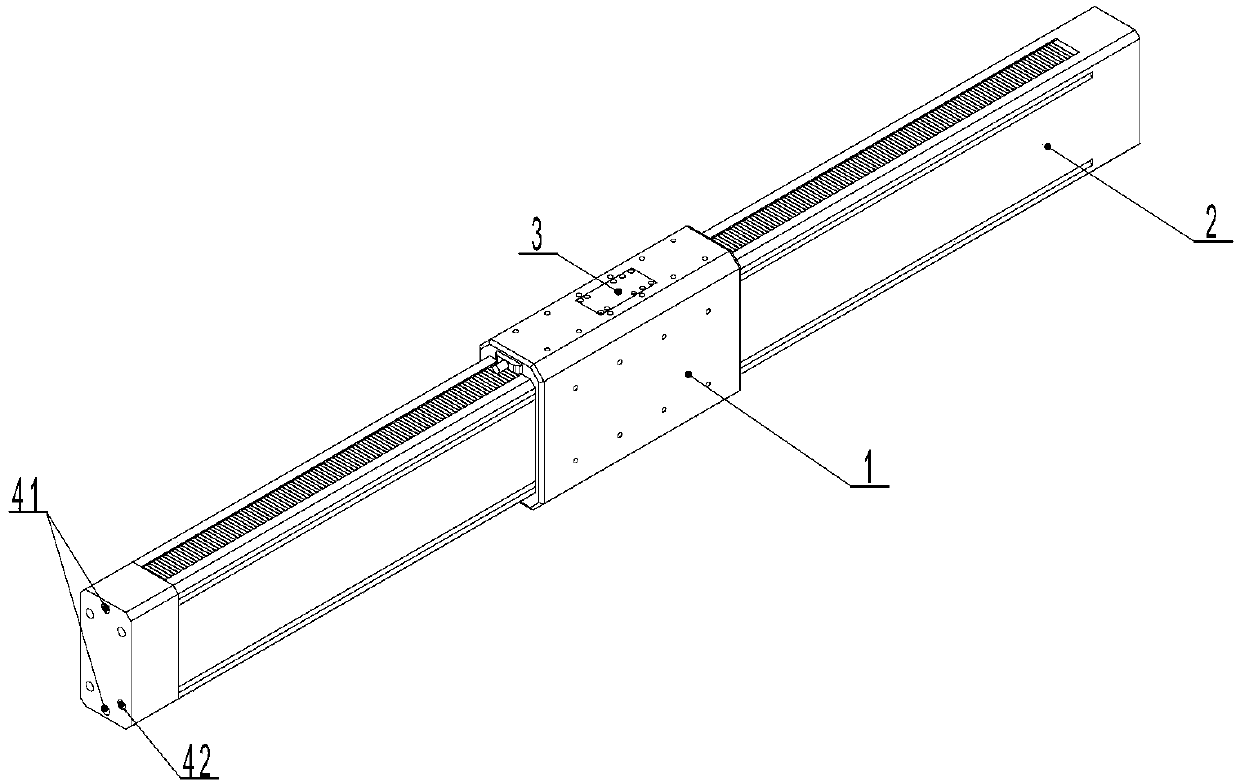

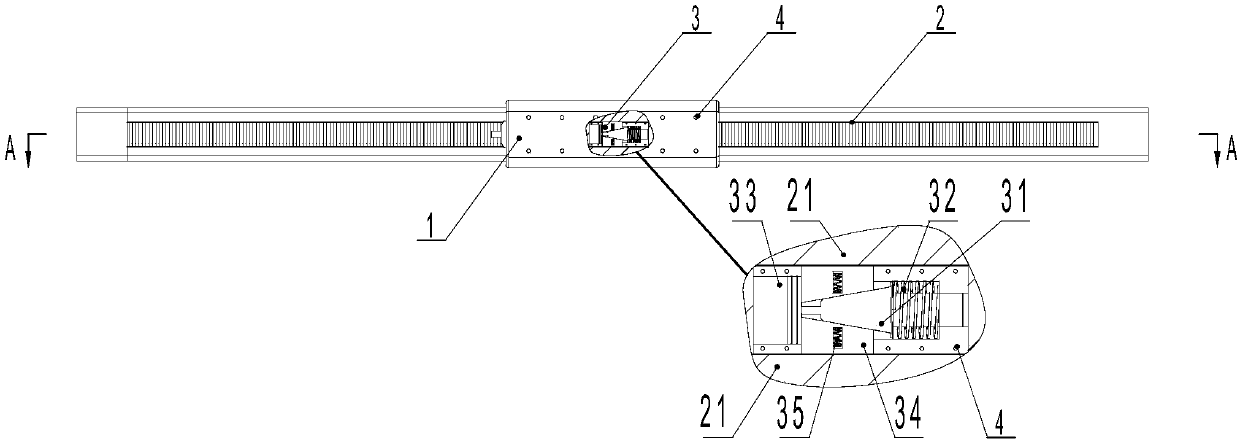

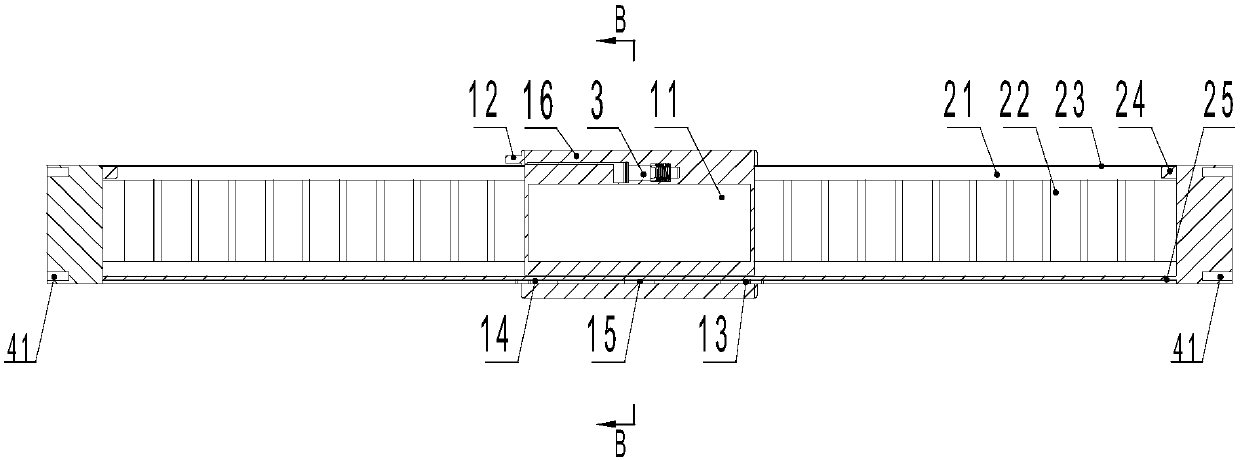

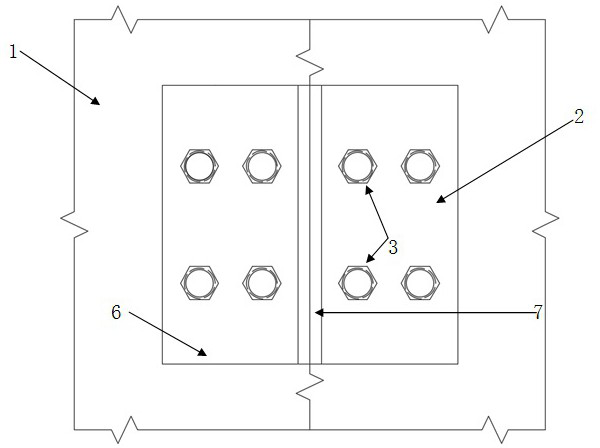

Linear motor module for robot splicing

PendingCN107733204ACompact structureReduce power lossProgramme-controlled manipulatorMechanical energy handlingElectric machineControl engineering

The invention relates to a linear motor module for robot splicing. The linear motor module comprises a rotor assembly, a stator assembly, a brake and a controller, wherein the brake is connected to the rotor assembly, the rotor assembly sleeves the stator assembly, connection holes are formed in both of the rotor assembly and the stator assembly, the rotor assembly comprises a shell, a coil, a connector, a grating reading head, a first limit switch and a second limit switch, the stator assembly comprises a stator body, a permanent magnet and a grating, the brake comprises a wedge-shaped block,a braking spring, a piston, a braking block and an extrusion spring, and the grating reading head, the first limit switch, the second limit switch and the piston all are electrically connected with the controller.

Owner:GSK CNC EQUIP

A mouthpiece for heating a non-combustible smoky product

The invention discloses a mouthpiece for heating a non-combustible smoky product, comprising a mouthpiece, wherein the mouthpiece is sequentially composed of, from a distal lip end to a proximal lip end, a hollow section a cooling section and a filter section by wrapping molding paper externally, and the position of the hollow section is a proximal smoky section. The cooling section is connected with the diversion section, and the filter section is connected with the cooling section. The hollow section material can be a circular or polygonal piece made of corrugated paper, polylactic acid fiber and polyethylene material for supporting airflow passage, and the hollow section material can be circular or polygonal made of corrugated paper, polylactic acid fiber and polyethylene material for supporting airflow passage. A mouthpiece composite machine is directly adopted in the invention, and the guide section, the cooling section and the filter section are integrated into a single off-linemolding according to the conventional composite filter rod specifications, so that the preparation is simple and convenient for flexible cigarette connection with the smoke-emitting section. While ensuring a certain amount of smoke to be transported in the suction process, a high-efficiency cooling section is adopted to effectively reduce the temperature of the flue gas.

Owner:YUNNANHENGGANGSCIENCE&TECH LTD

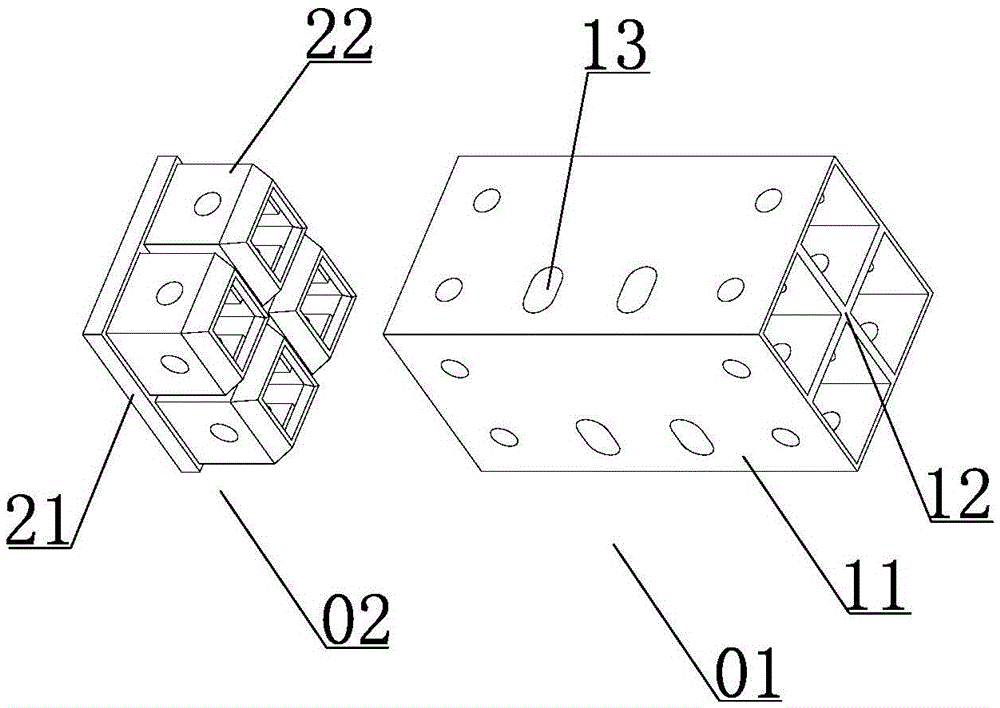

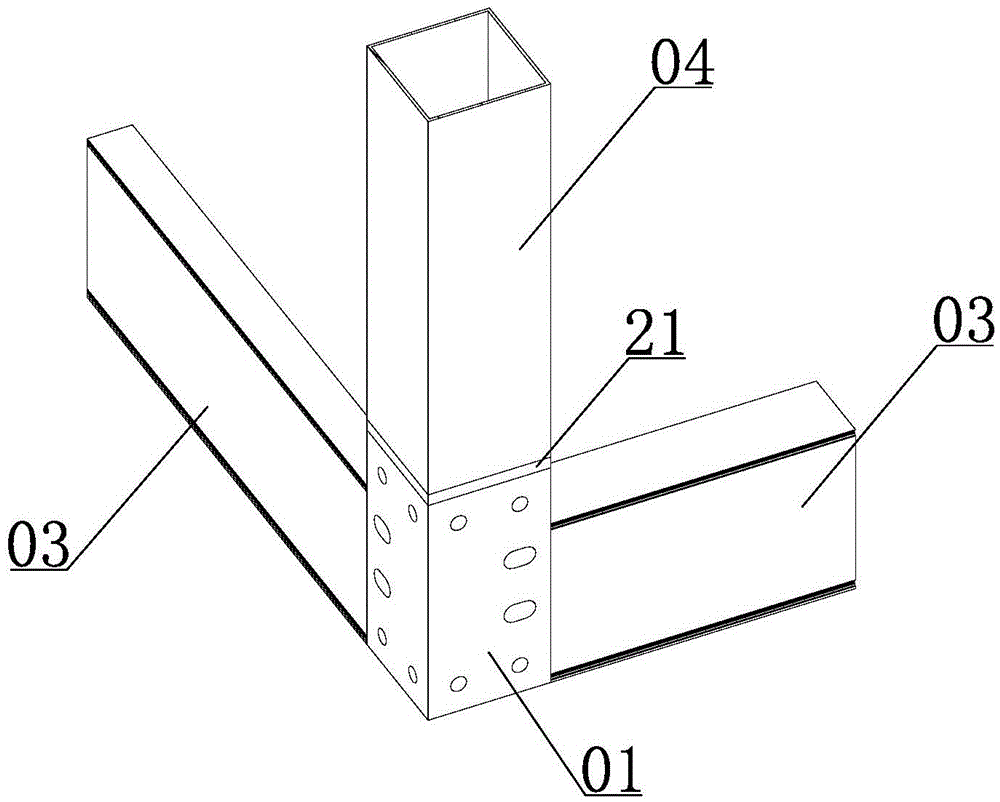

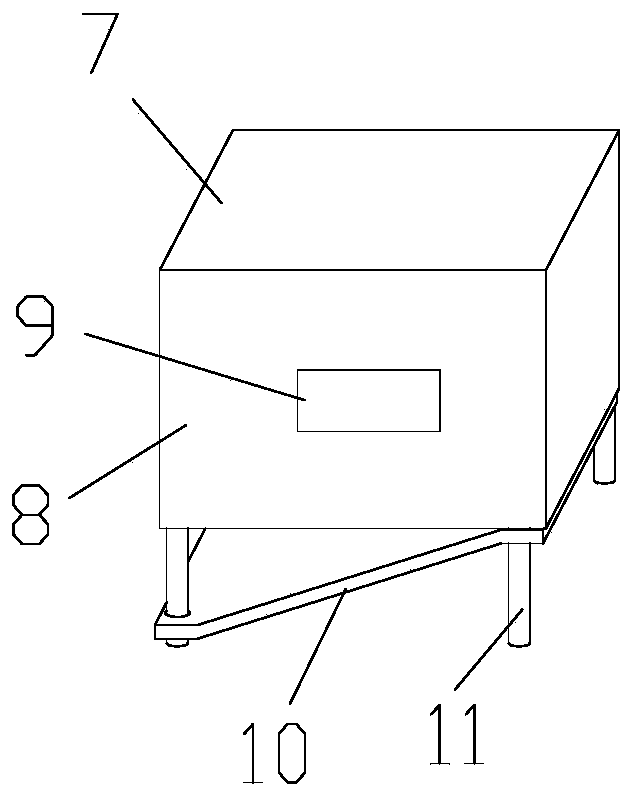

Building joint of modular house combining and splicing structure

InactiveCN105544741AStrong structural versatilityFlexible splicingBuilding constructionsVertical tubeChinese characters

Owner:朱方勇

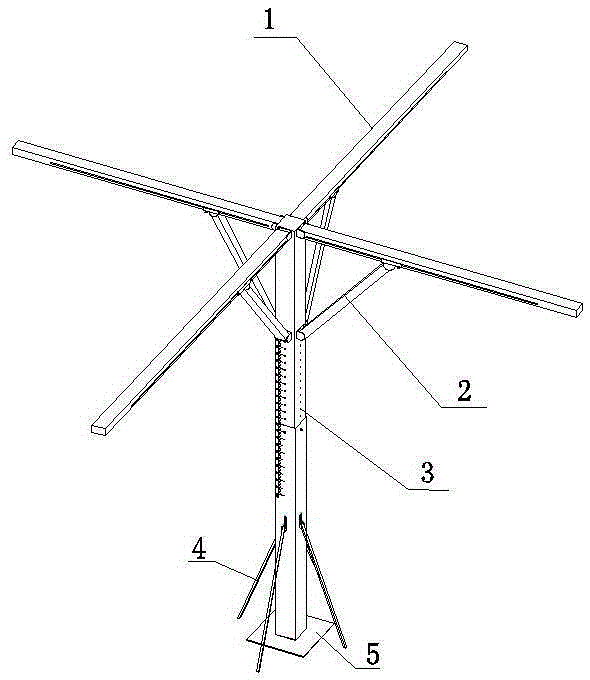

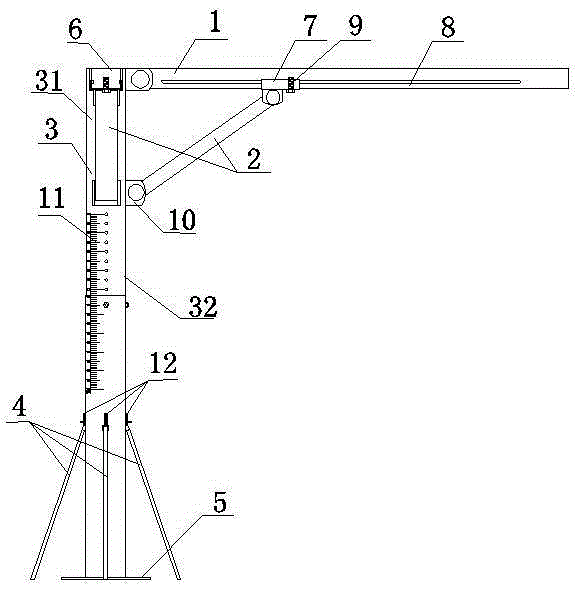

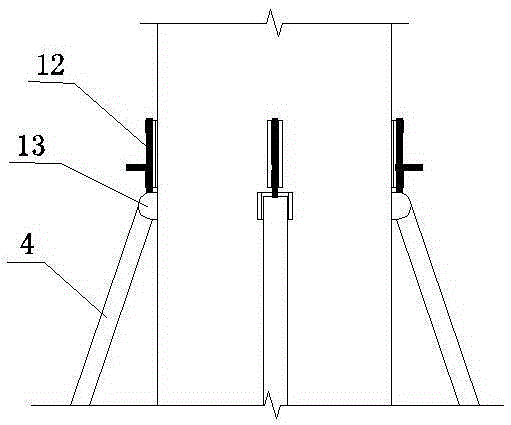

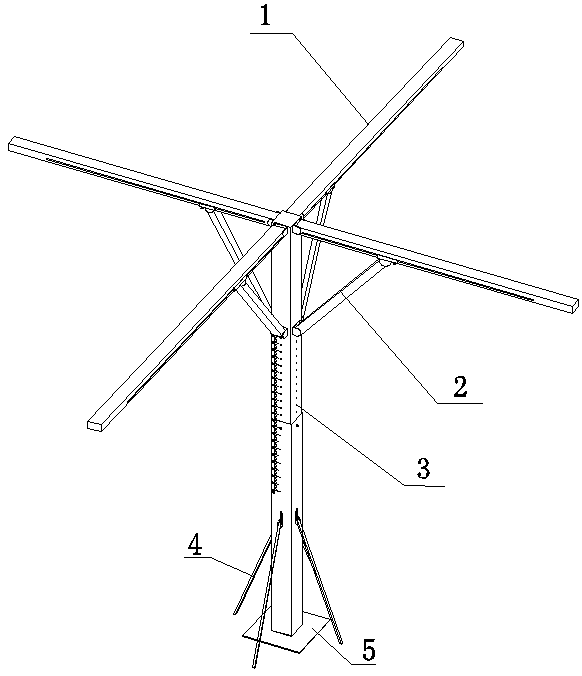

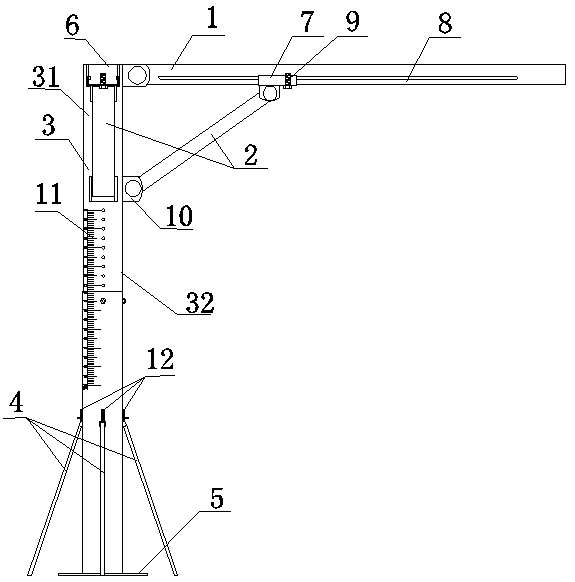

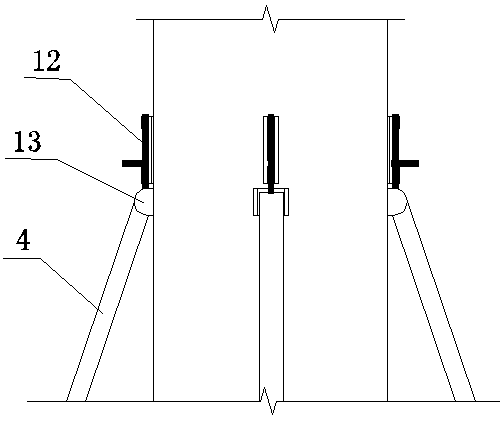

Umbrella-type template supporting system

ActiveCN105401721AHeight adjustableEasy to assemble and disassembleAuxillary members of forms/shuttering/falseworksSupporting systemCable stayed

The invention discloses an umbrella-type template supporting system. A vertical rod is formed by an inner pipe and an outer pipe which are sleeved together in a telescopic manner. The upper end of the inner pipe is uniformly hinged with four horizontal steel rods whose lower end faces are provided with sliding chutes. A sliding base is slidably connected with the sliding chute of the horizontal steel rod. The lower end of an inclined strut steel rod is hinged with the inner pipe of the vertical rod, and the upper end is hinged with the sliding base. The upper end face of a bottom inclined strut is hinged with the lower end portion of the outer pipe of the vertical rod, and the upper end face is provided with a spliced eye, and a bolt corresponding to the spliced eye is fixed on the outer pipe of the vertical rod on the upper end of the bottom inclined strut. When the bolts are inserted in the spliced eye, the bottom inclined struts support each side of the bottom of the vertical rod outer pipe in a cable-stayed manner. When the bolts are pulled out, the bottom inclined struts free hang on the lower end of the vertical rod outer pipe. Each component of the system are connected with each other, assembling and dismounting are simple and convenient, splicing is flexible, and time is saved, and construction efficiency is improved. Components would not be lost in dismounting and storage, and service life is prolonged. The system is wide in application range, and can support templates in various dimensions and heights.

Owner:HEBEI CONSTR GRP CO LTD

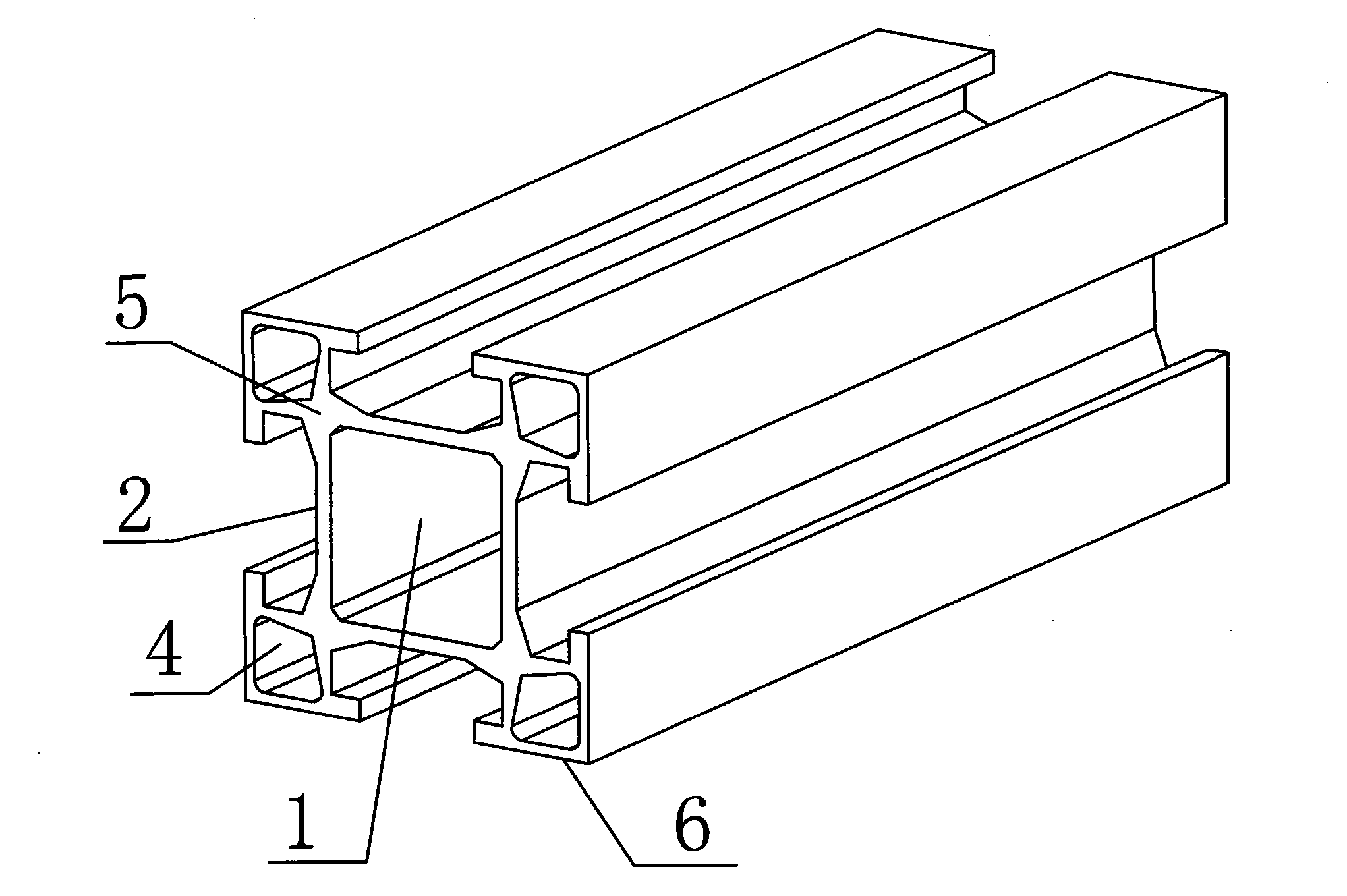

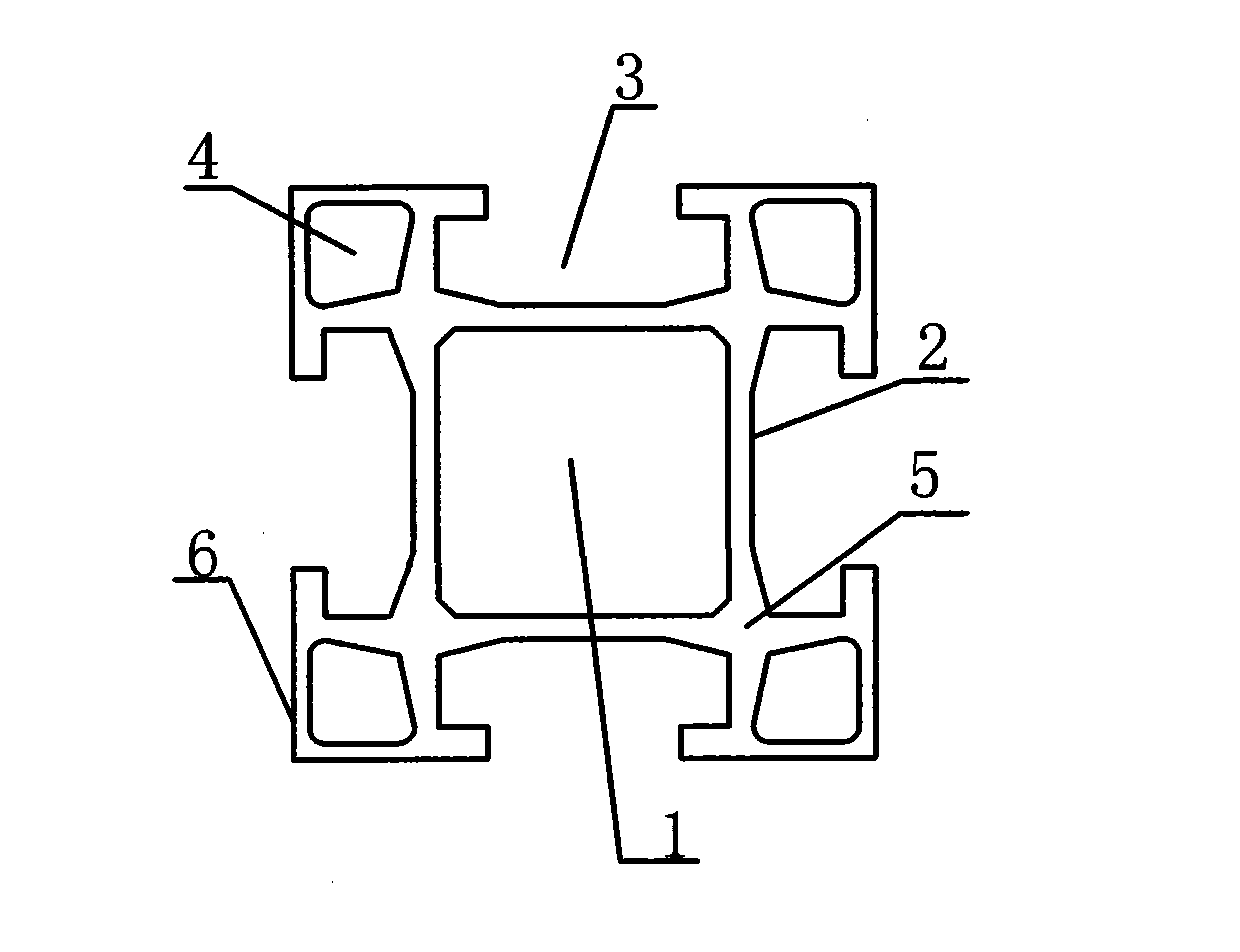

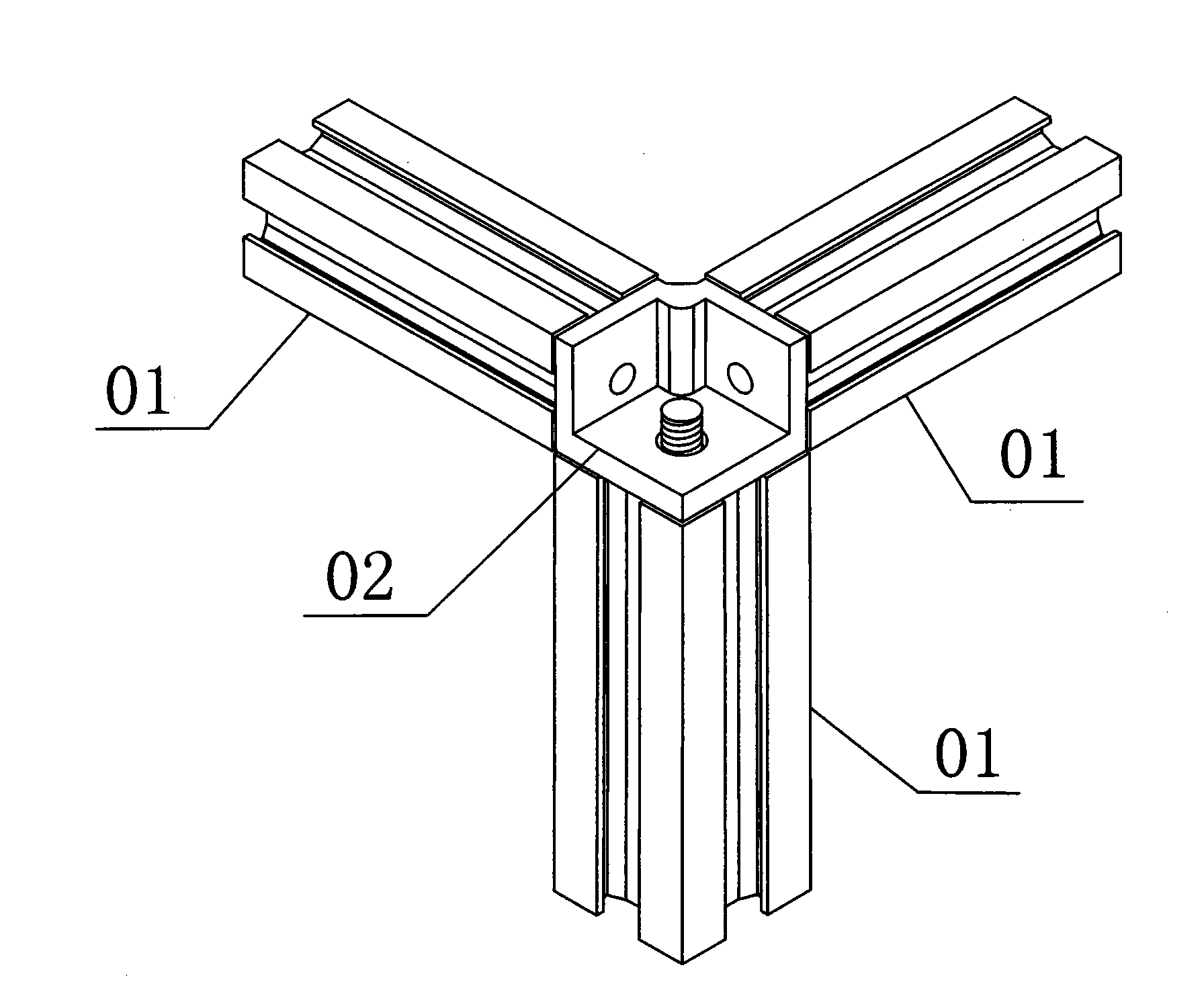

Aluminum alloy frame and its splicing method

InactiveCN102269318ATake advantage of multiple functionsUnique structureElongated constructional elementsMetallurgyPlastic materials

The invention discloses an aluminum alloy frame and a splicing method thereof. The aluminum alloy frame is a planar frame and a three-dimensional frame composed of a plurality of aluminum alloy profiles and splicing pieces. The aluminum alloy profiles are composed of a main hollow tube and an auxiliary hollow tube. , "well"-shaped ribs and embedded inner grooves distributed on four sides; the splicing pieces include alloy steel splicing pieces, plastic splicing pieces and angle aluminum splicing pieces, and plastic decoration matched with the alloy steel splicing pieces Cover, so there are a variety of splicing methods. The alloy steel splicing piece is composed of a three-dimensional splicing plane and a two-dimensional right-angle flange located on the side of the three-dimensional splicing plane; the plastic splicing piece is made of plastic material and consists of a two-dimensional splicing plane and a two-dimensional right-angle flange; The angled aluminum splicing pieces are composed of reinforced aluminum with unequal sides and angles, and are used for T-shaped splicing or inner corner splicing of frames. The invention has unique structure, multiple application functions, flexible splicing mode, wider application range and strong practicability.

Owner:上海奢腾智能科技有限公司

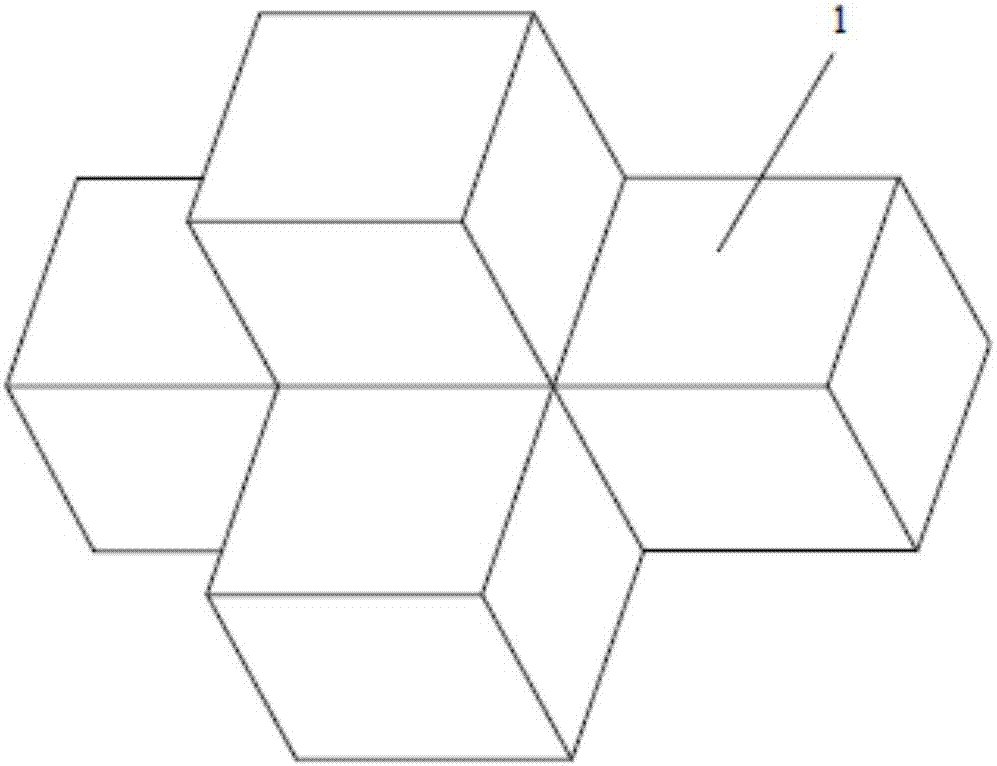

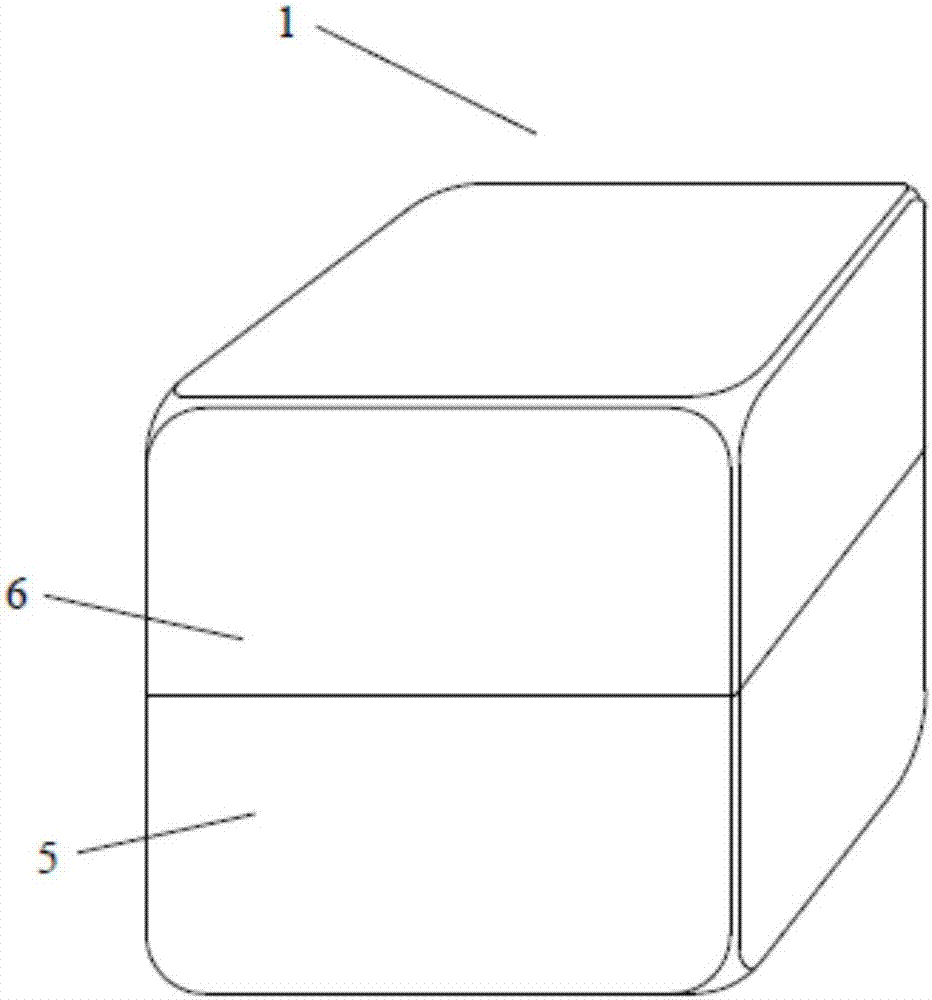

Magnetic building block structure

The invention provides a magnetic building block structure which comprises multiple building blocks. Irony magnetic balls capable of freely rotating are arranged in the inner cavities of the building blocks. By arranging the irony magnetic balls capable of freely rotating and provided with outer surface magnetic poles N and S poles in the inner cavities of the building blocks, any splicing and erection of different building blocks can be achieved through any two building blocks and the irony magnetic balls, a splicing mode is more flexible, the magnetic building block structure looks more harmonious and beautiful, and meanwhile the thinking and cognitive ability of a game player is exercised.

Owner:BEIJING AIQI TECH CO LTD

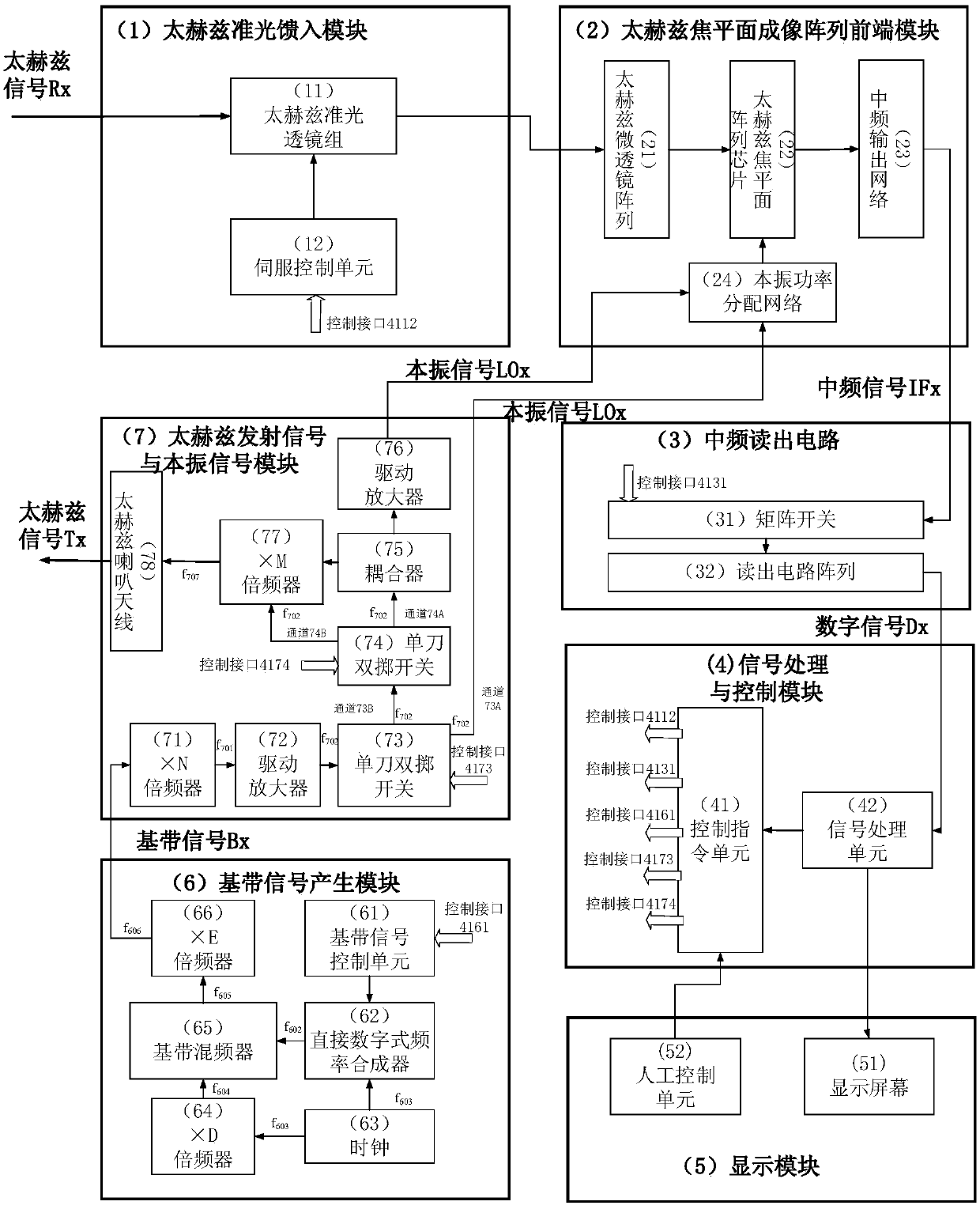

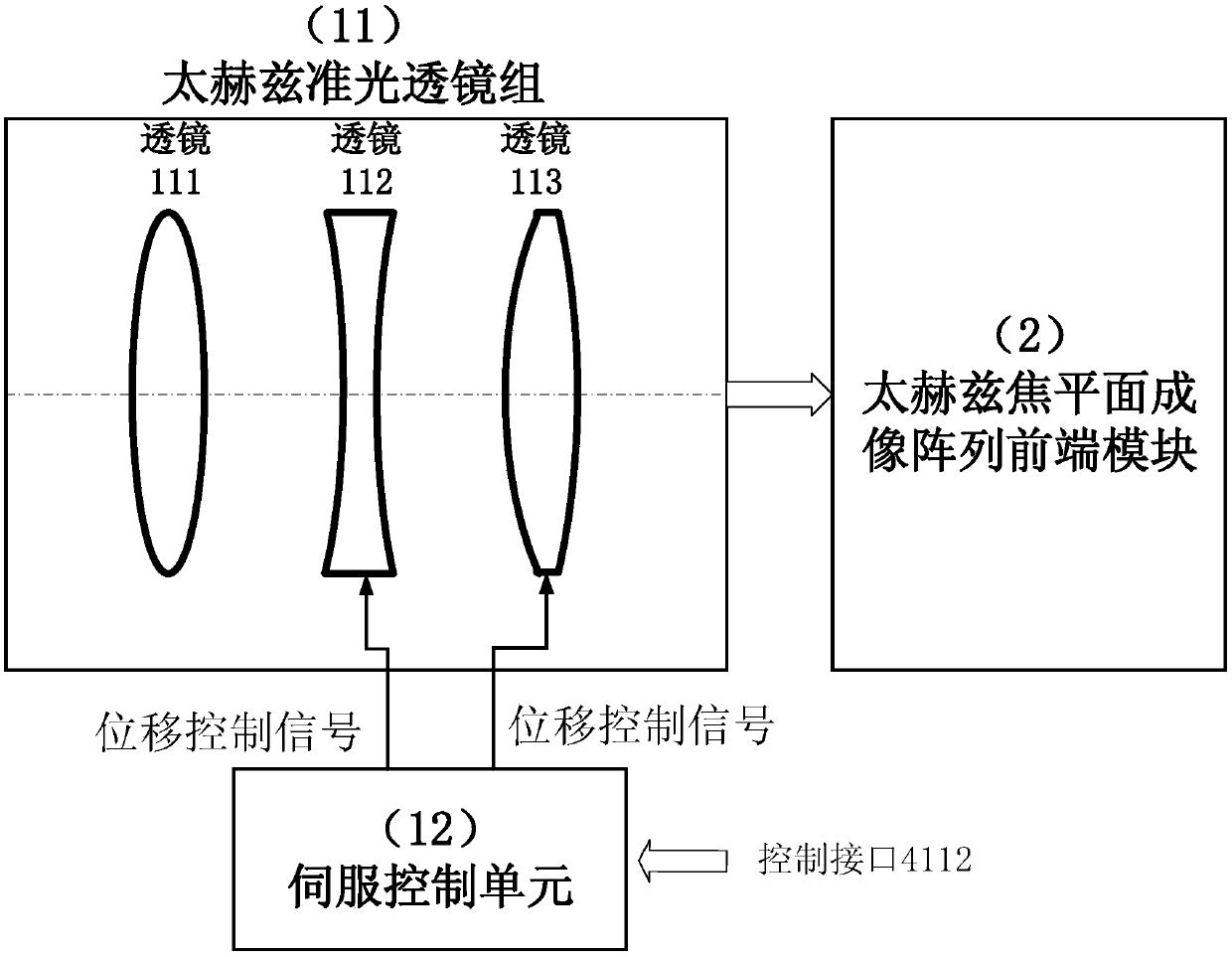

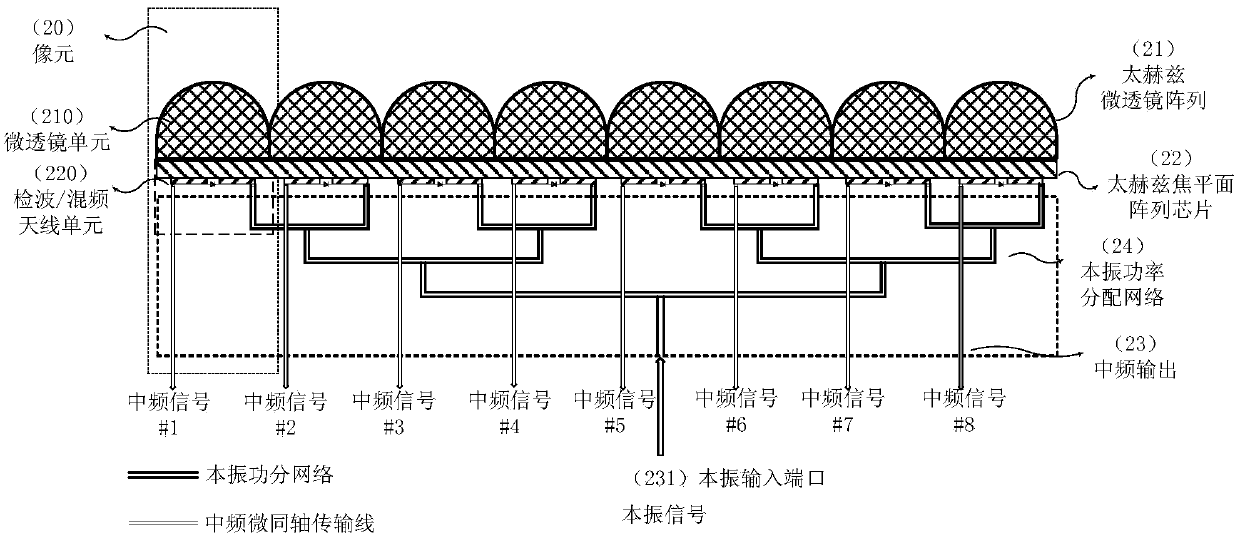

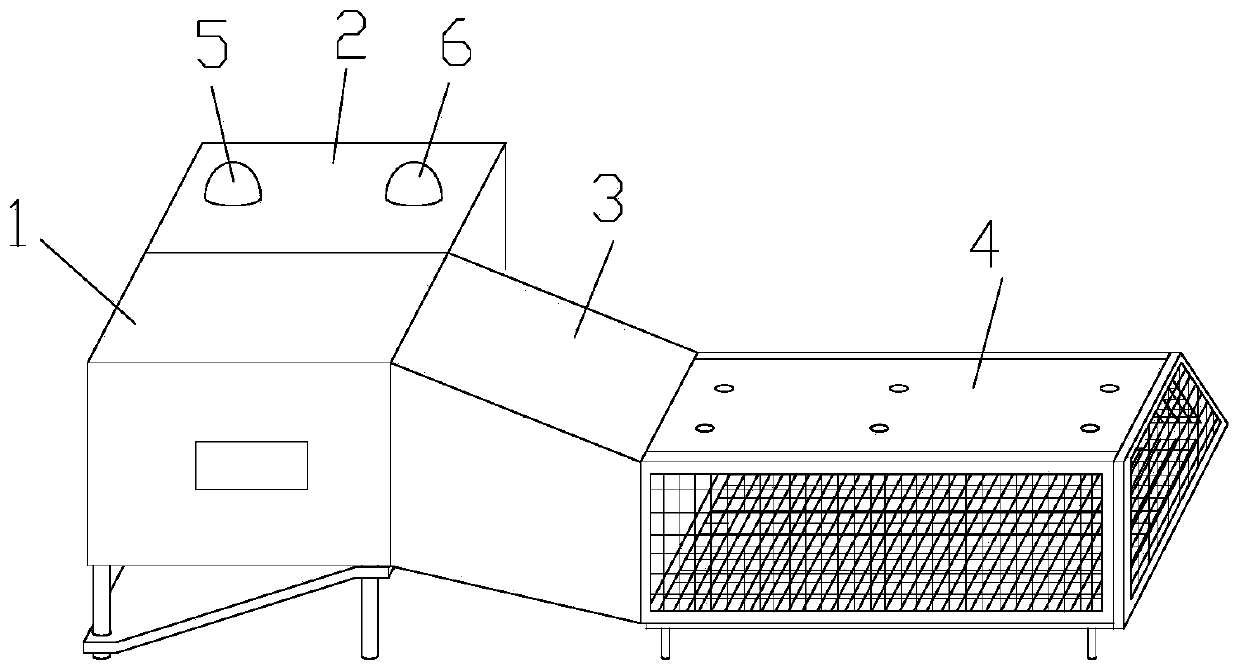

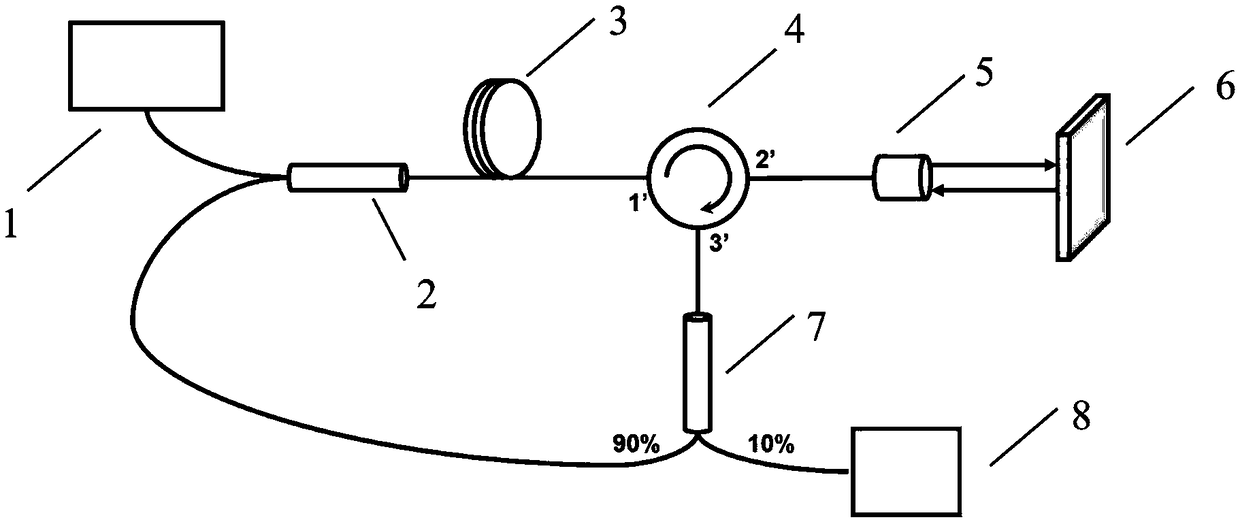

Terahertz multi-mode real-time imaging system

ActiveCN109655841AFlexible switchingFix staring imagingMaterial analysis by optical meansElectromagnetic wave reradiationLocal oscillator signalIntermediate frequency

The invention discloses a terahertz multi-mode real-time imaging system which comprises a terahertz quasi-optical feed-in module, a terahertz planar imaging array frontend module, an intermediate-frequency readout circuit, a signal processing and control module, a display module, a baseband signal generating module, a terahertz transmitting signal and a local oscillator signal module. The system can operate in four working modes of passive non-coherent, passive coherent, active non-coherent and active coherent, and can satisfy application requirements such as all-weather mute supervision, suspected key target imaging and tracking. Furthermore the system can improve image contrast on the condition of imaging quality reduction caused by environment factors. The system is suitable for aerospace situation perception and aerospace target imaging tracking.

Owner:BEIJING RES INST OF TELEMETRY +1

Nursing bed

InactiveCN110292493AMeet daily needsAchieve conversionWheelchairs/patient conveyanceNursing bedsWheelchairEngineering

The invention relates to the technical field of nursing equipment, in particular to a nursing bed. The nursing bed comprises a bed frame part and a wheelchair part, wherein the bed frame part is provided with a gap, the wheelchair part and the bed frame part are detachably connected through the gap, and the top of the gap of the bed frame part is provided with a notch; a first bracket is mounted at the bottom of the notch, the bed frame part is provided with a movable plate which can rotate around the bed frame part, the movable plate is provided with a second bracket, and the first bracket and the second bracket are positioned on the same plane. The bed frame part and the wheelchair part realize quick lapping through a lifting system, the lapping mode is more convenient and flexible thana common splicing mode, and the operation requirement is not high. Through the free movement of the nursing bed and the lifting function of the wheelchair, the daily life demands of a user are met, the high intelligence and automation provide great convenience for the user, and the operability is high.

Owner:CHANGCHUN UNIV OF SCI & TECH

Poultry cultivation cage between crop rows

PendingCN110741966AFlexible splicingFree stitchingAnimal housingCereal cultivationSmall animalPoultry farming

The invention discloses a poultry cultivation cage between crop rows. The poultry cultivation cage comprises a feeding cage, a power supply box and a free-ranging cage and is characterized in that thefeeding cage and the free-ranging cage are integrally connected through a connecting channel, the feeding cage is a centralized poultry feeding place, and the free-ranging cage is a place where poultry moves around and eats weeds and insects and is placed between the crop rows; an automatic poultry driving device used for driving the poultry from the free-ranging cage to the feeding cage is arranged in the free-ranging cage; the power supply box is connected with the automatic poultry driving device, controls the action of the automatic poultry driving device and supplies power for the automatic poultry driving device. The poultry cultivation cage has the advantages that green and novel facility-aided cultivation of the poultry or other small animals in a field where crops grow can be achieved, the crops can be various dry-land grain crops suitable for sowing in drill and commercial crops such as most of vegetables and medicinal plants, and the poultry cultivation cage is suitable fora sloping field, a flat field, a terraced field and irregular terrain and high in actual popularization and application value.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

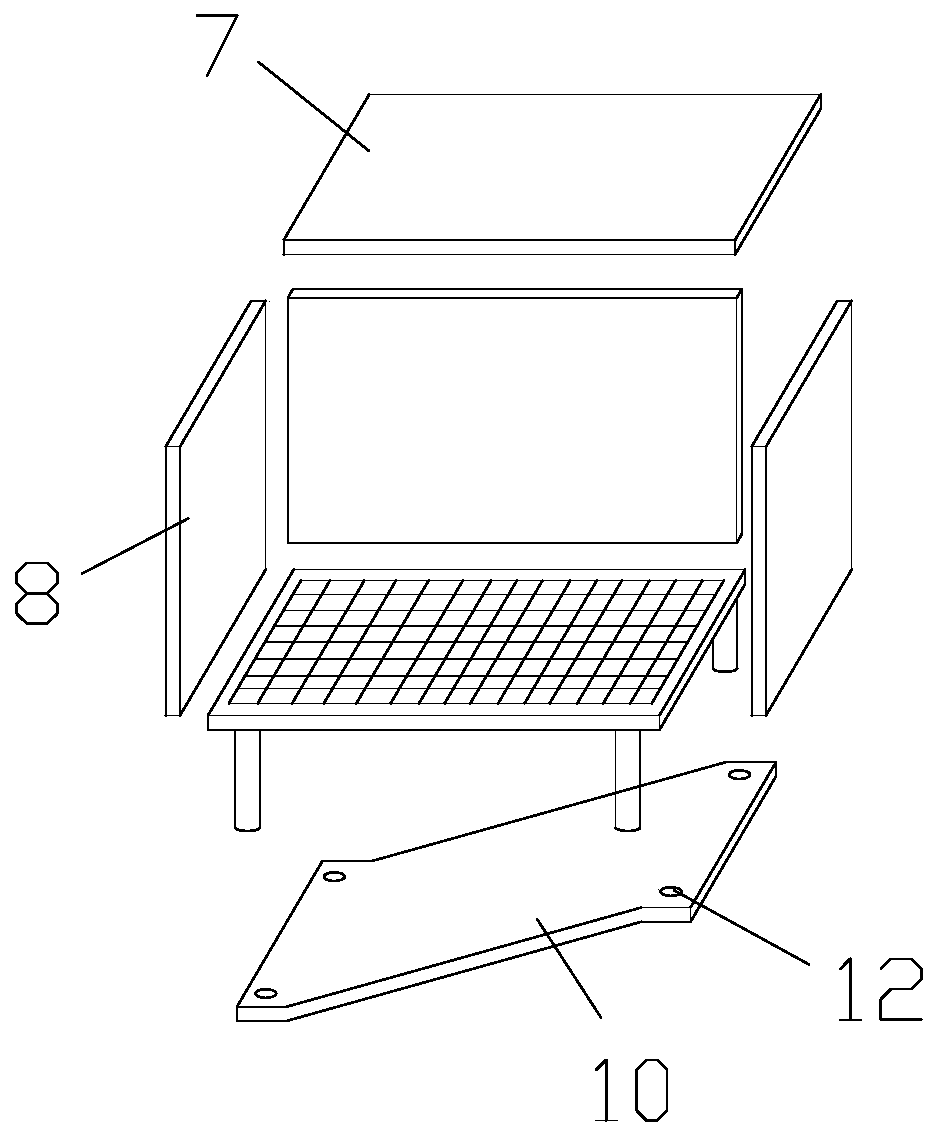

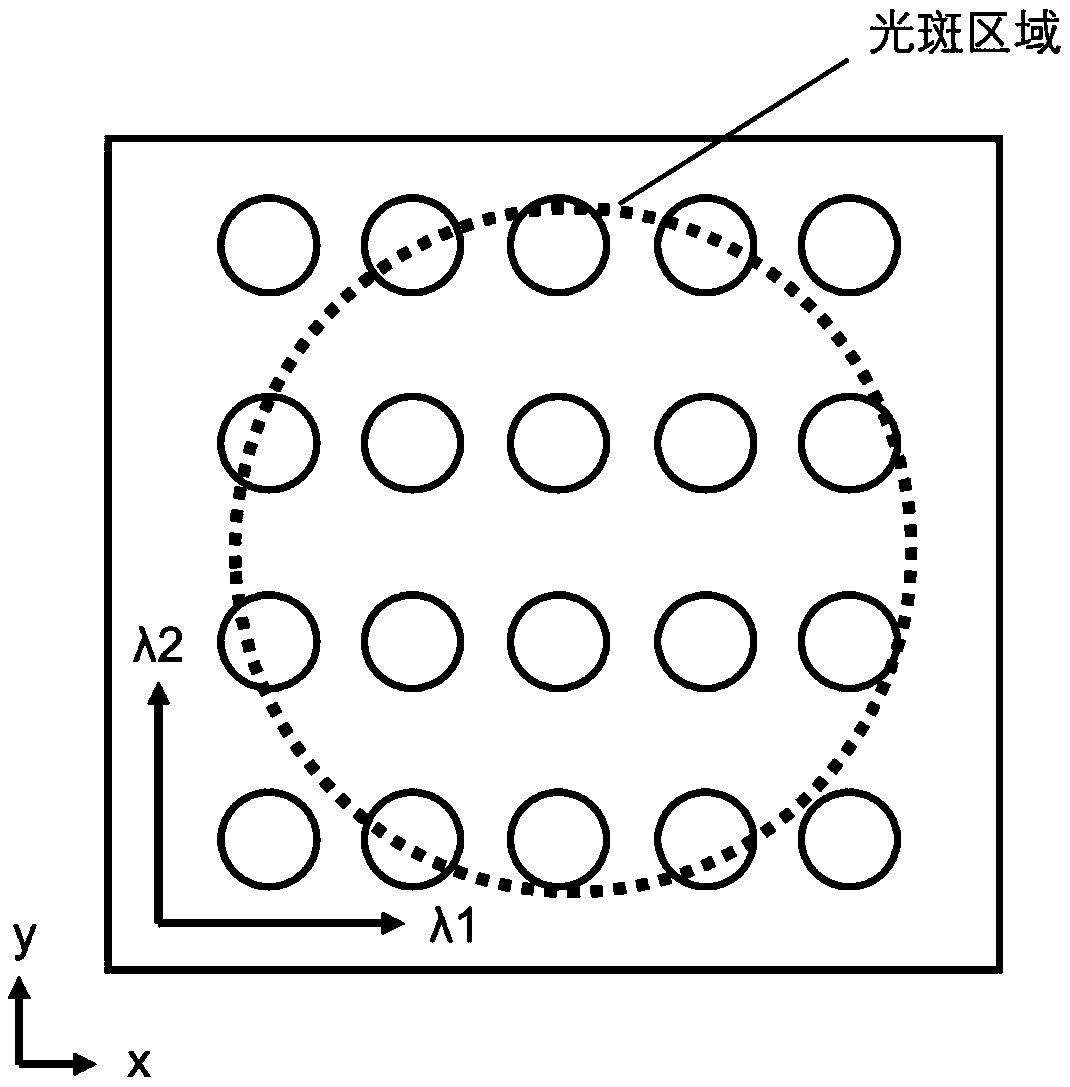

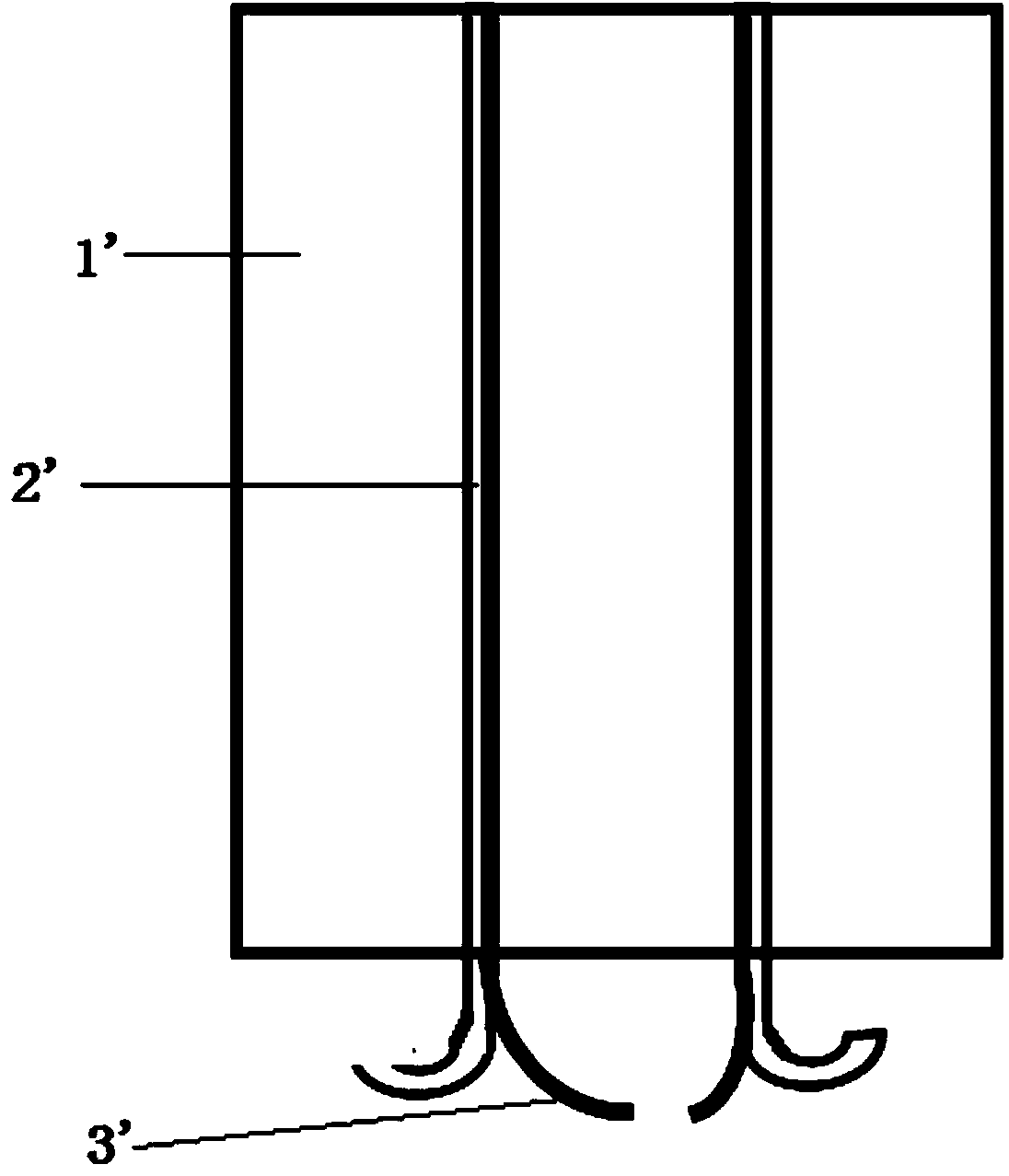

A controllable multi-wavelength fiber external cavity laser based on super-surface external cavity mirror

ActiveCN108988106AChanging the reflection wavelengthImplement reflectionOptical resonator shape and constructionActive medium shape and constructionFiberExternal cavity laser

The invention discloses a controllable multi-wavelength optical fiber external cavity laser based on a super-surface external cavity mirror and belongs to the field of lasers. The laser comprises an optical fiber amplifier, an optical fiber ring, an optical fiber collimator, an optical fiber coupler, and a super-surface external cavity mirror, wherein, signal light is amplified in that optical fiber amplifier, transmitted to the port 2 ' through the optical fiber ring port 1', collimated by the optical fiber collimator, and vertically incident on the super-surface external cavity mirror; The super-surface external cavity mirror is used for receiving incident collimated light, wavelength selecting the collimated light, and reflecting the selected single / multiple wavelengths to the optical fiber collimator; The reflected light is collected by the optical fiber collimator and transmitted to the port 3 'through the optical fiber annulator port 2', then enters the optical fiber coupler forpartial output and partially returns to the optical fiber amplifier to form a loop. The invention realizes the controllable output of the single / multi-wavelength laser through the super-surface external cavity mirror, and has the advantages of simple structure, low cost and good reliability.

Owner:HUAZHONG UNIV OF SCI & TECH

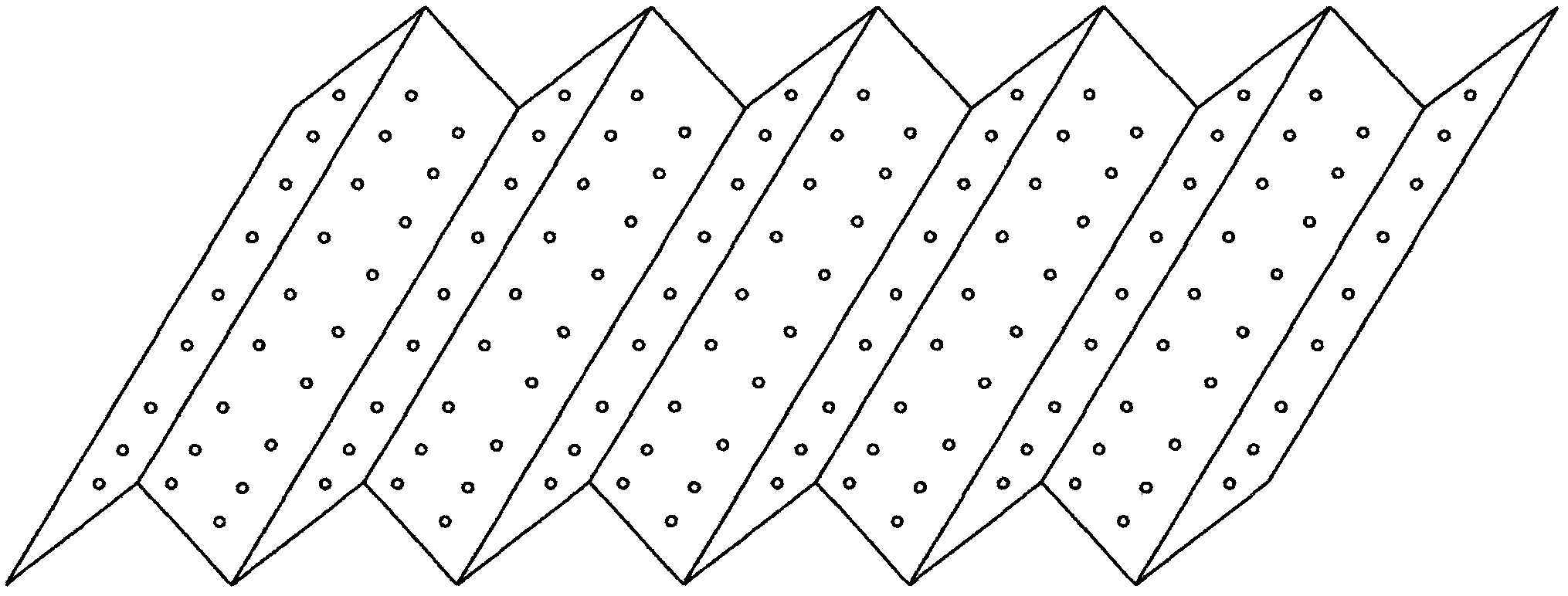

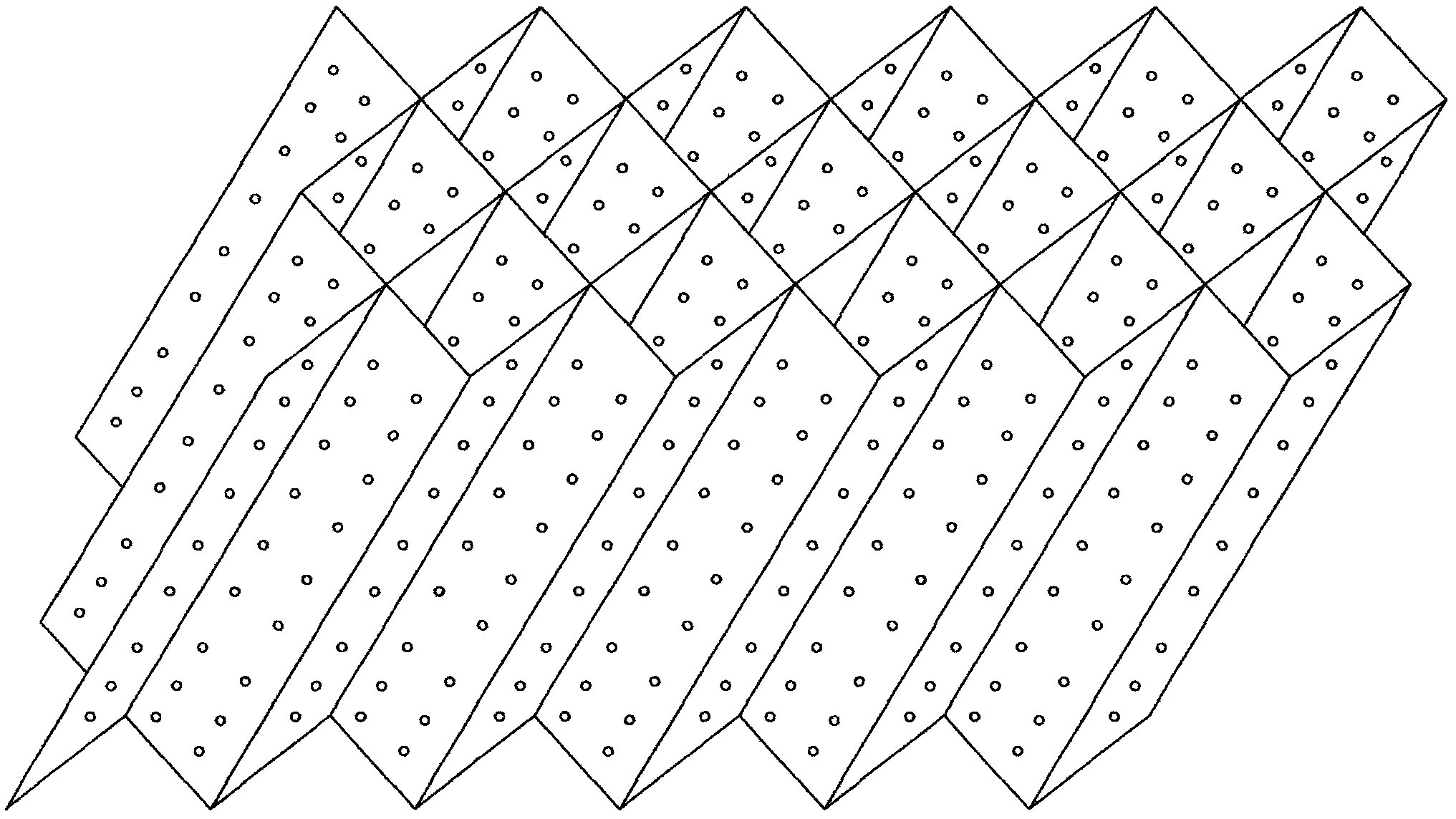

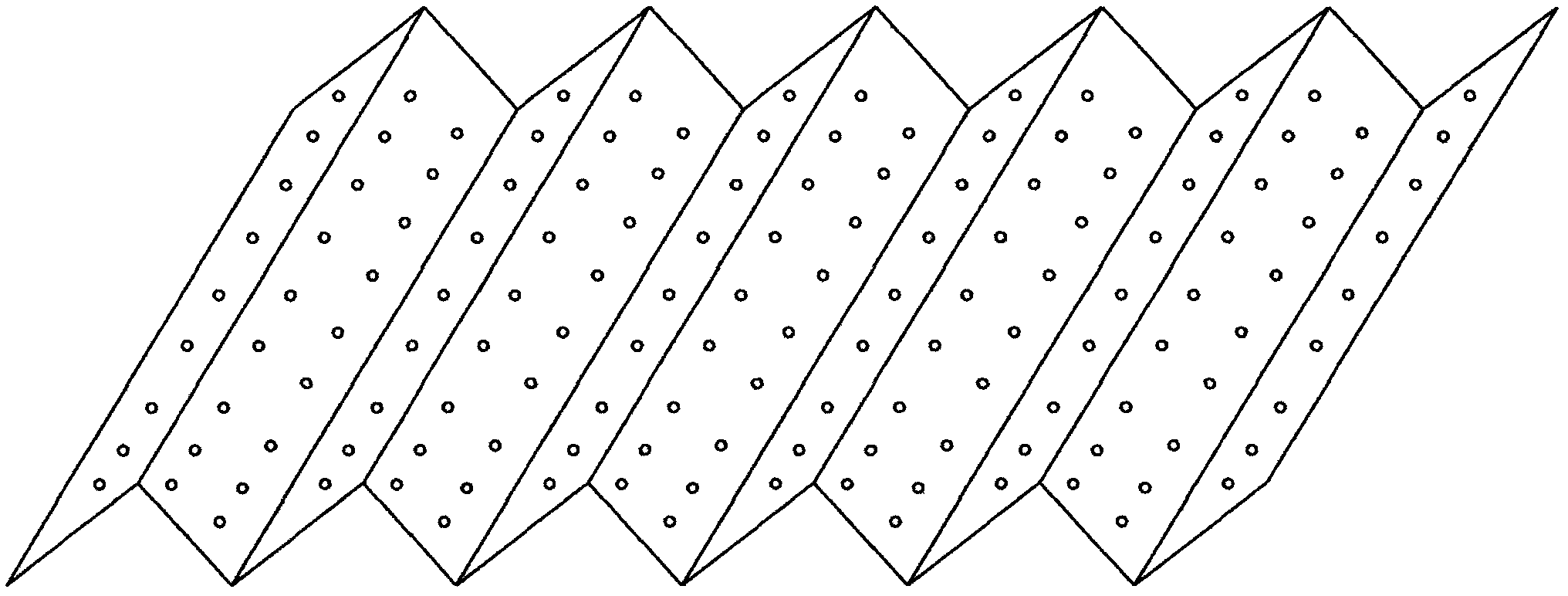

Manufacturing method of polytetrafluoroethylene orifice-plate corrugated packing

InactiveCN102700041ASmall sizeSmall amount of deformationMetal working apparatusVena contracta diameterPunching

The invention relates to a manufacturing method of polytetrafluoroethylene orifice-plate corrugated packing. The manufacturing method of the polytetrafluoroethylene orifice-plate corrugated packing comprises the following steps of pressing a corrugated blank, placing, punching, sintering and assembling. The invention provides the manufacturing method of the polytetrafluoroethylene orifice-plate corrugated packing, which has the advantages of simple process and high strength in the obtained packing.

Owner:朱树烽

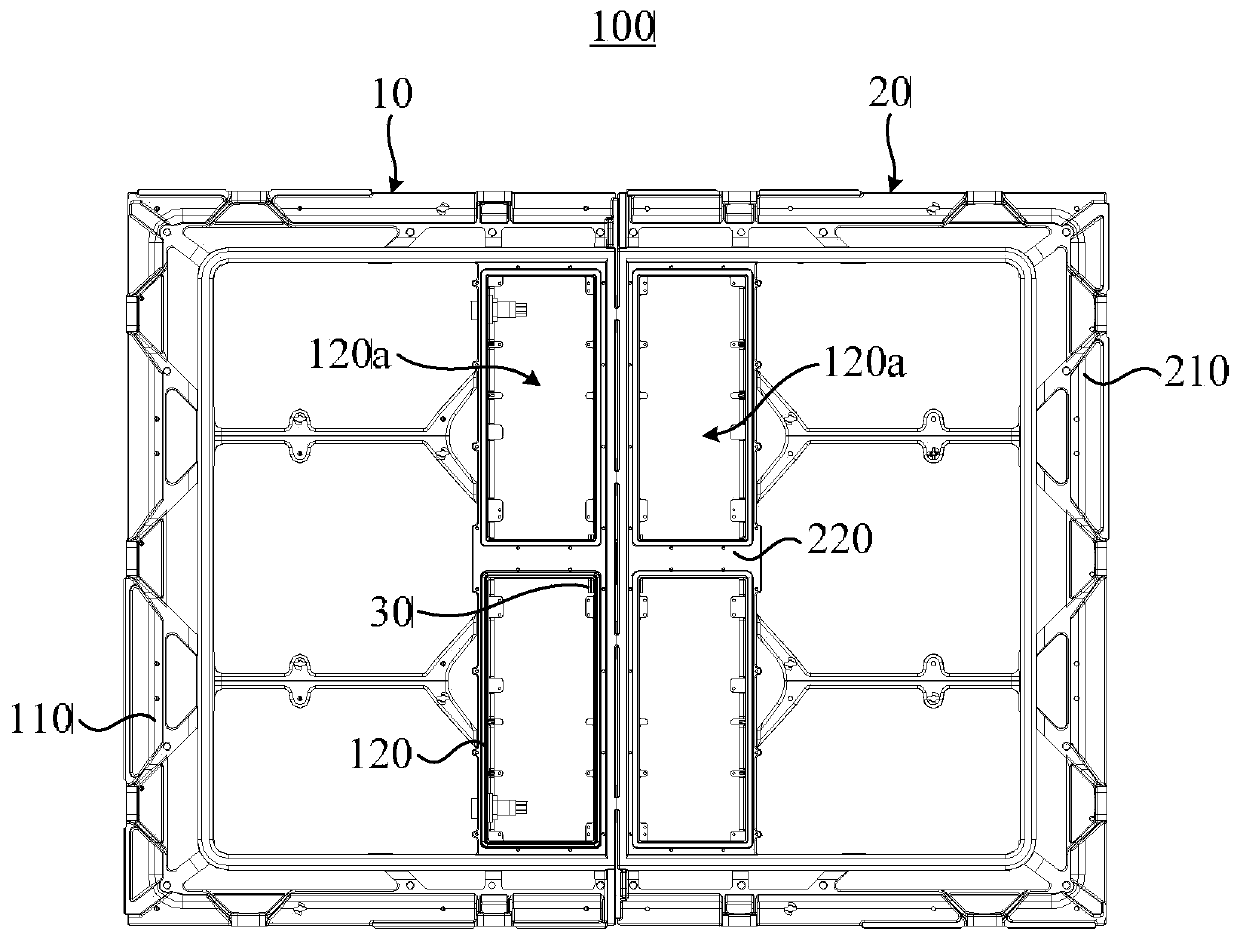

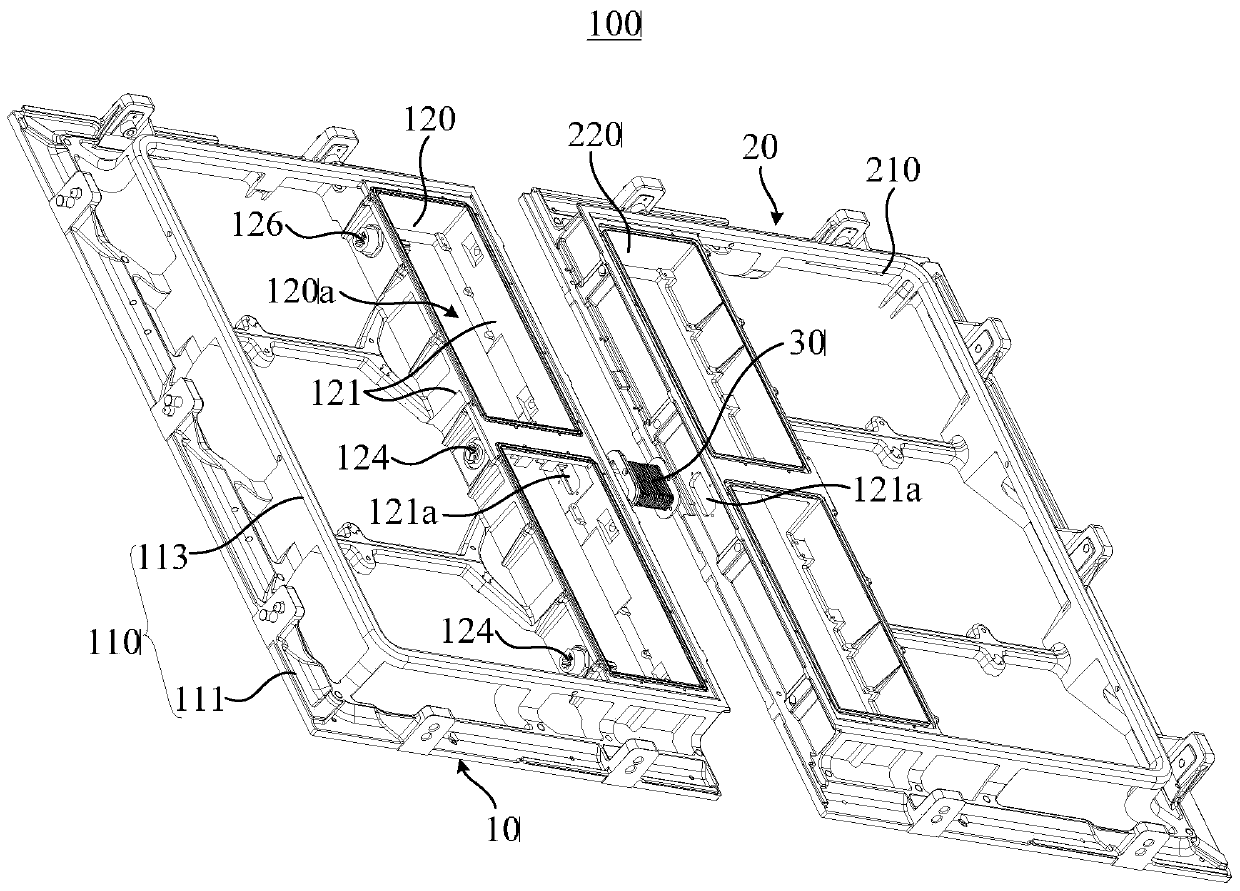

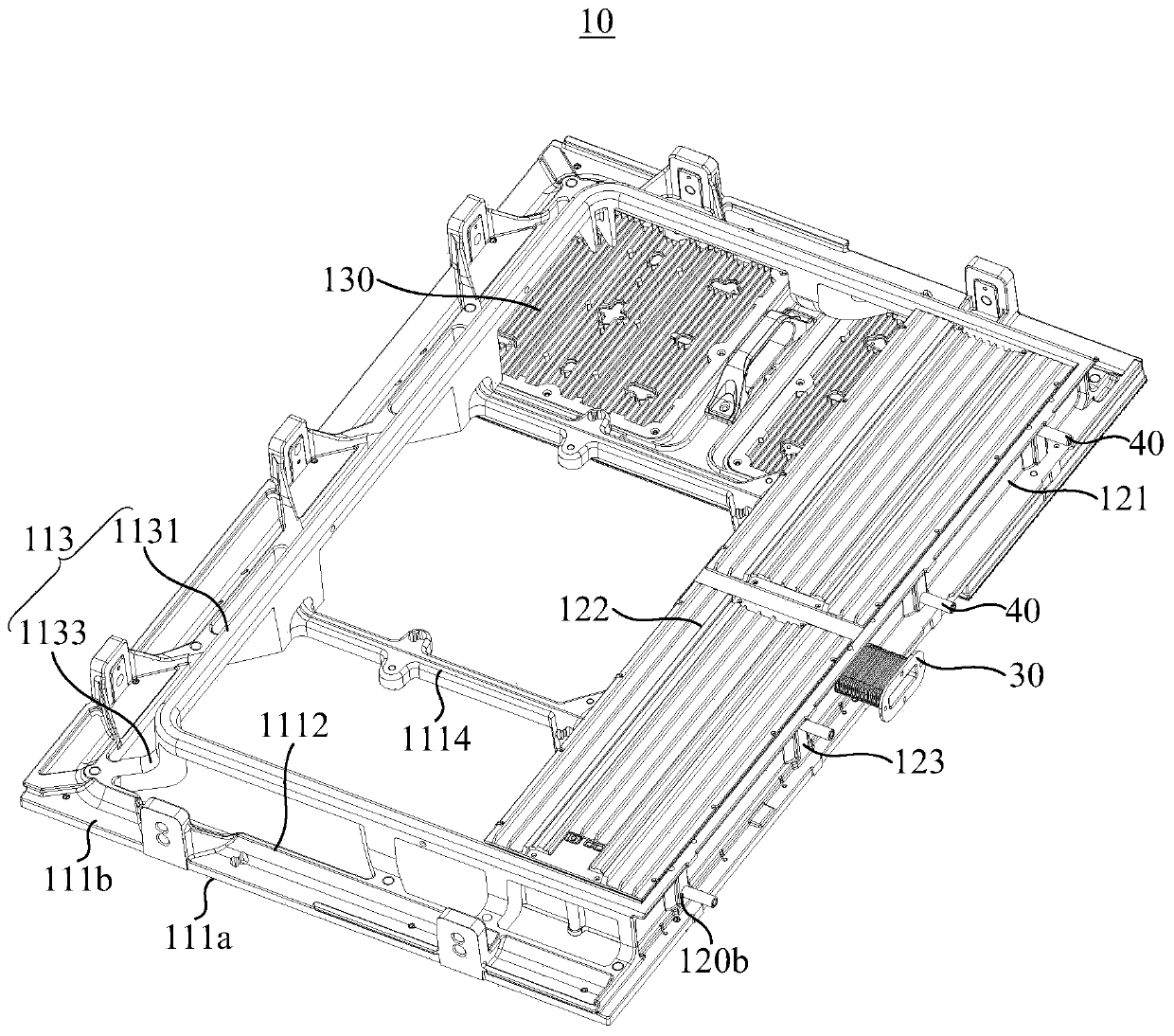

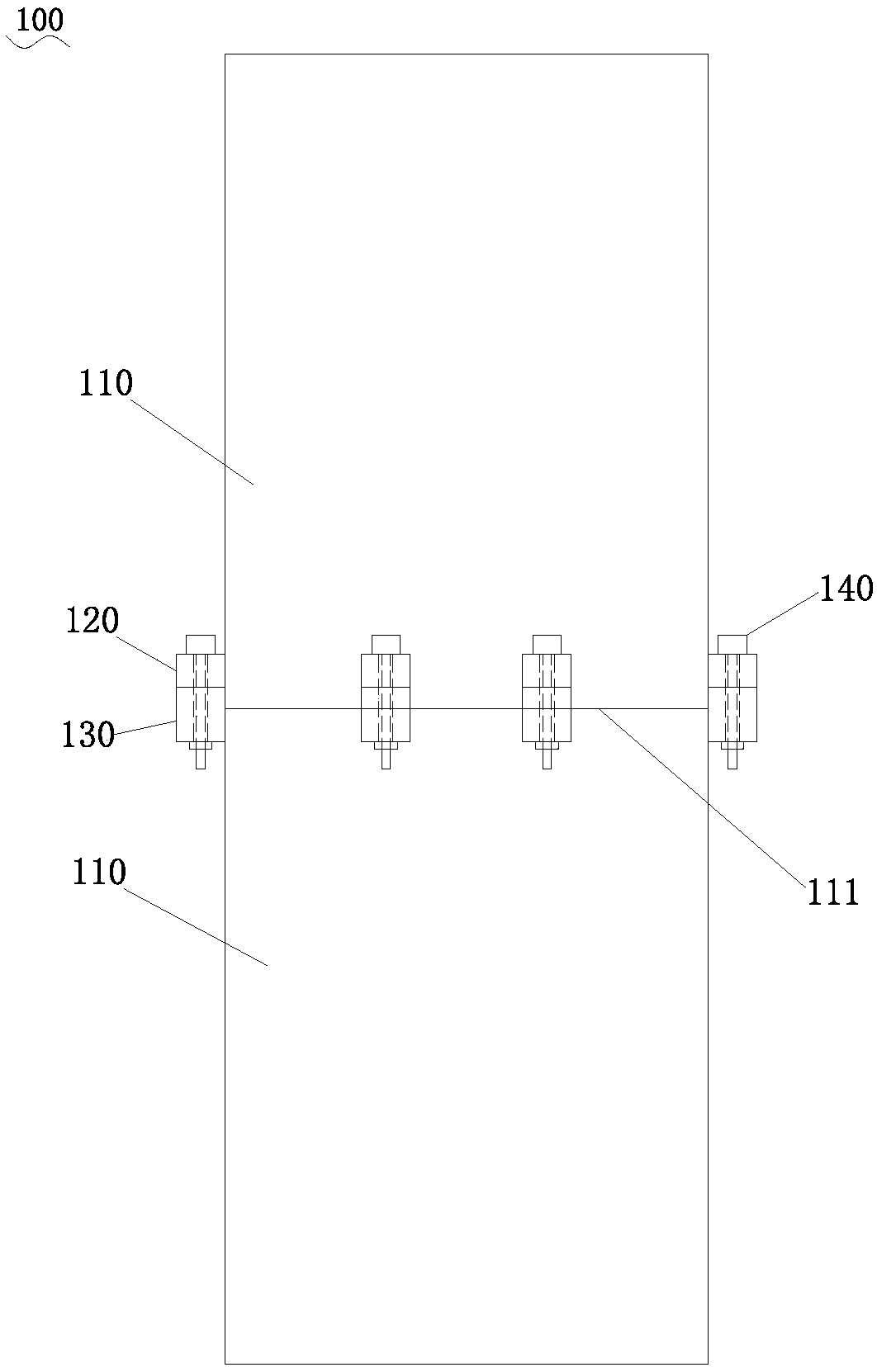

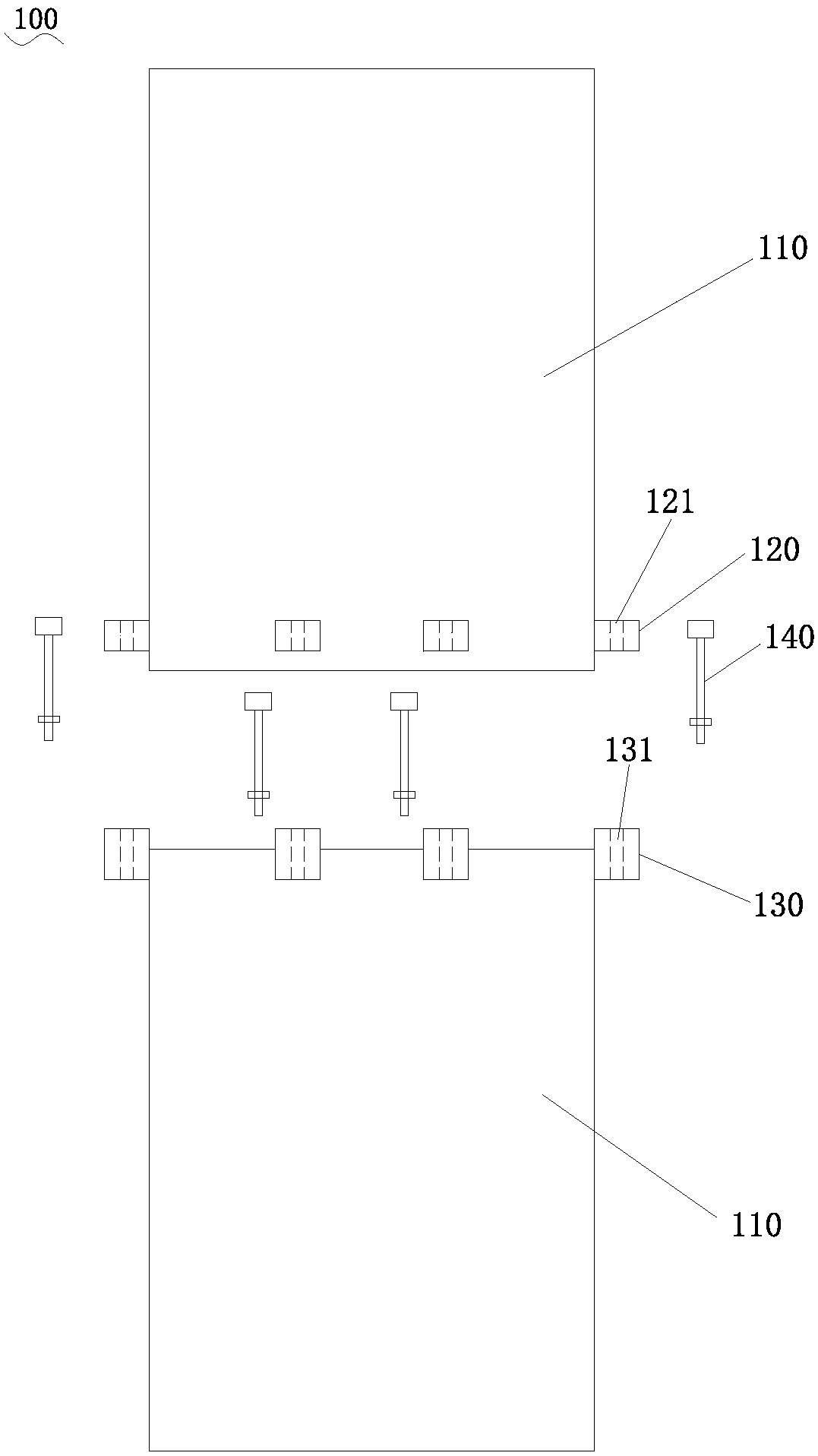

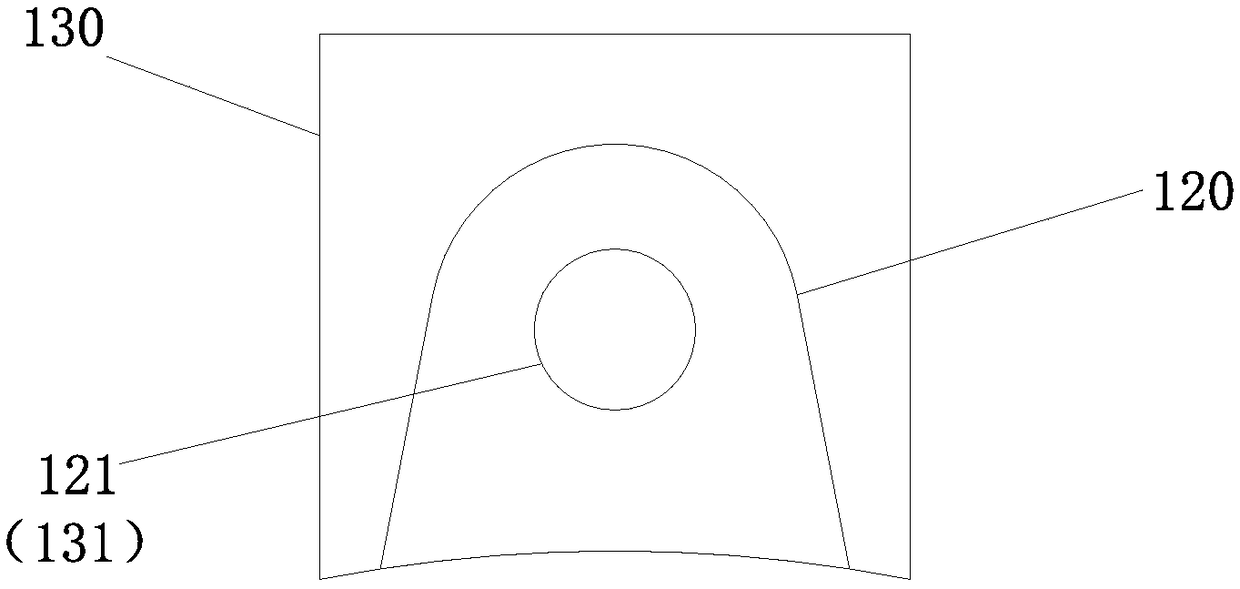

LED display screen box body group and LED display screen

The invention relates to an LED display screen box body group and an LED display screen. The LED display screen box body group comprises at least two box bodies; two adjacent box bodies are fixedly connected; each box body is correspondingly provided with a power supply box; the power supply box is provided with a box body; an inner cavity is formed in the box body; a through hole is formed in thebox body; the inner cavities of the plurality of power supply boxes are mutually communicated through the through holes; a power supply is arranged in at least one power supply box; the power supplyboxes of the plurality of box bodies are connected with an external power supply cable by sharing the same interface; an HUB plate is arranged in the power supply box; the cable passes through the through hole to communicate the HUB plates in the two power supply boxes; a control card is arranged in at least one power supply box; the plurality of box bodies are connected with a data input cable bysharing the same interface and are connected with a data output cable by sharing the same interface. The LED display screen is formed by splicing the LED display screen box body group. The box body group is formed by splicing the plurality of box bodies; splicing can be conducted by the box body group, or splicing can be conducted after splitting, so that flexible splicing can be realized.

Owner:SHENZHEN AOTO ELECTRONICS

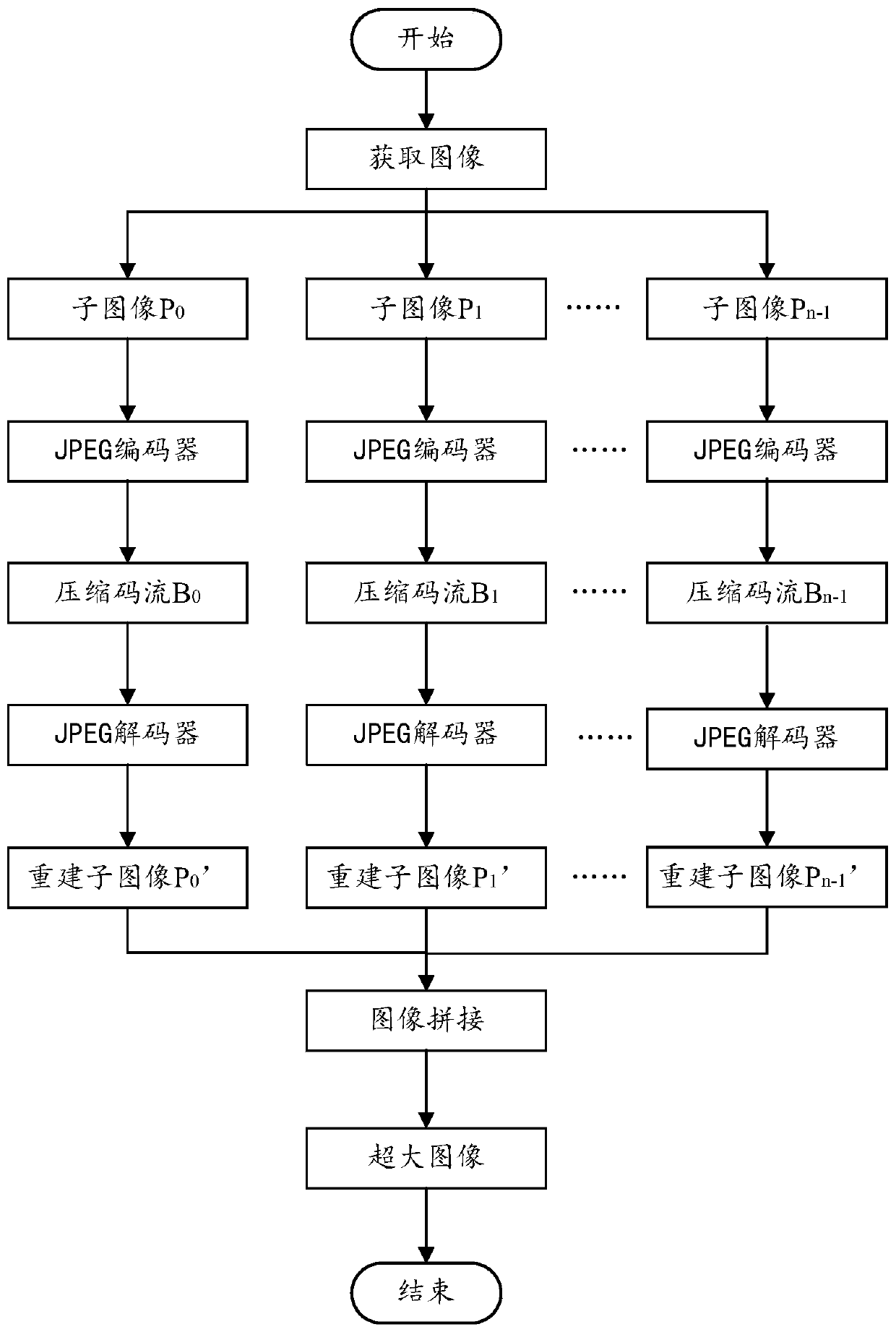

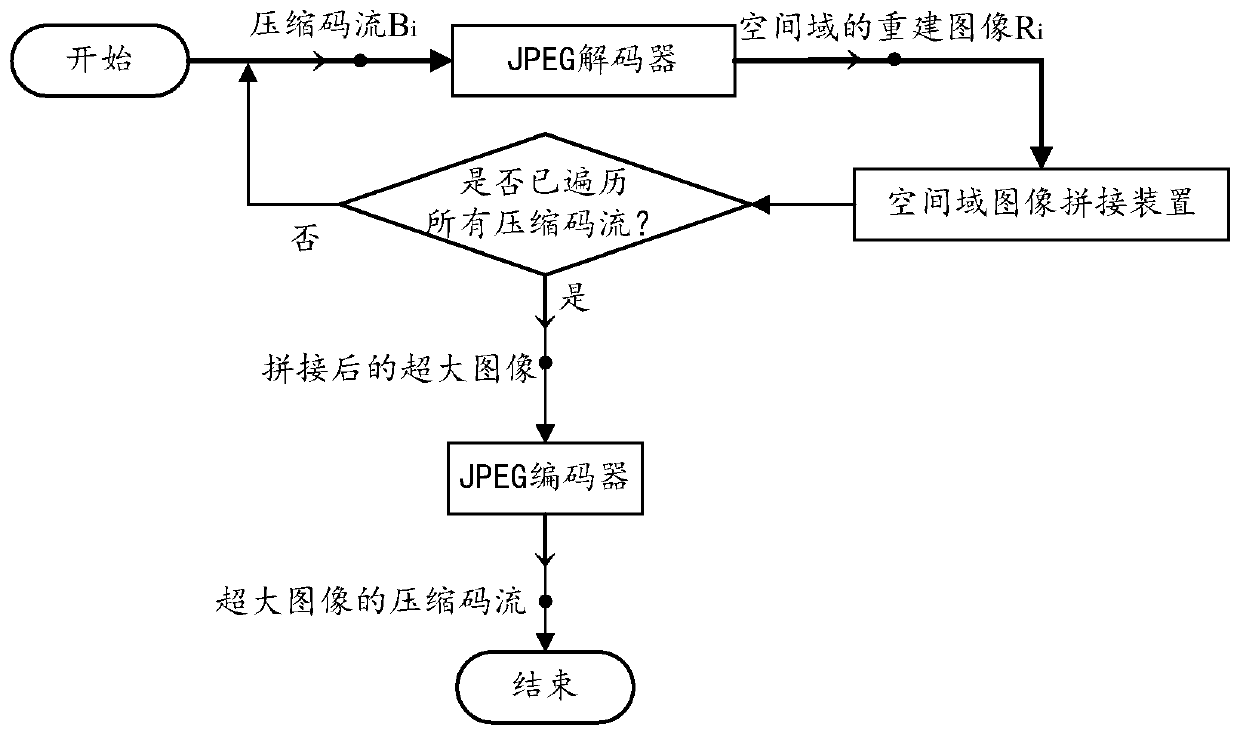

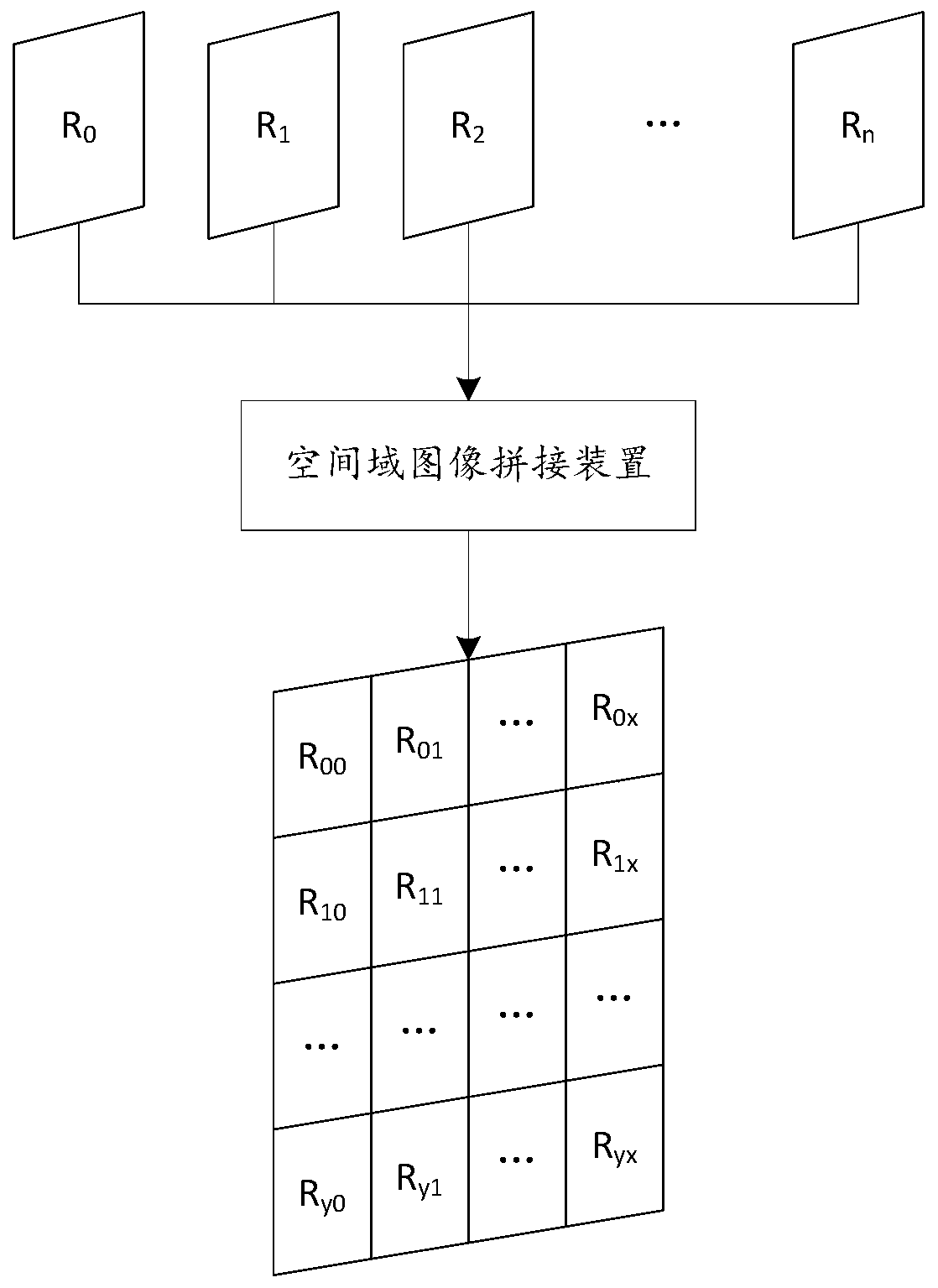

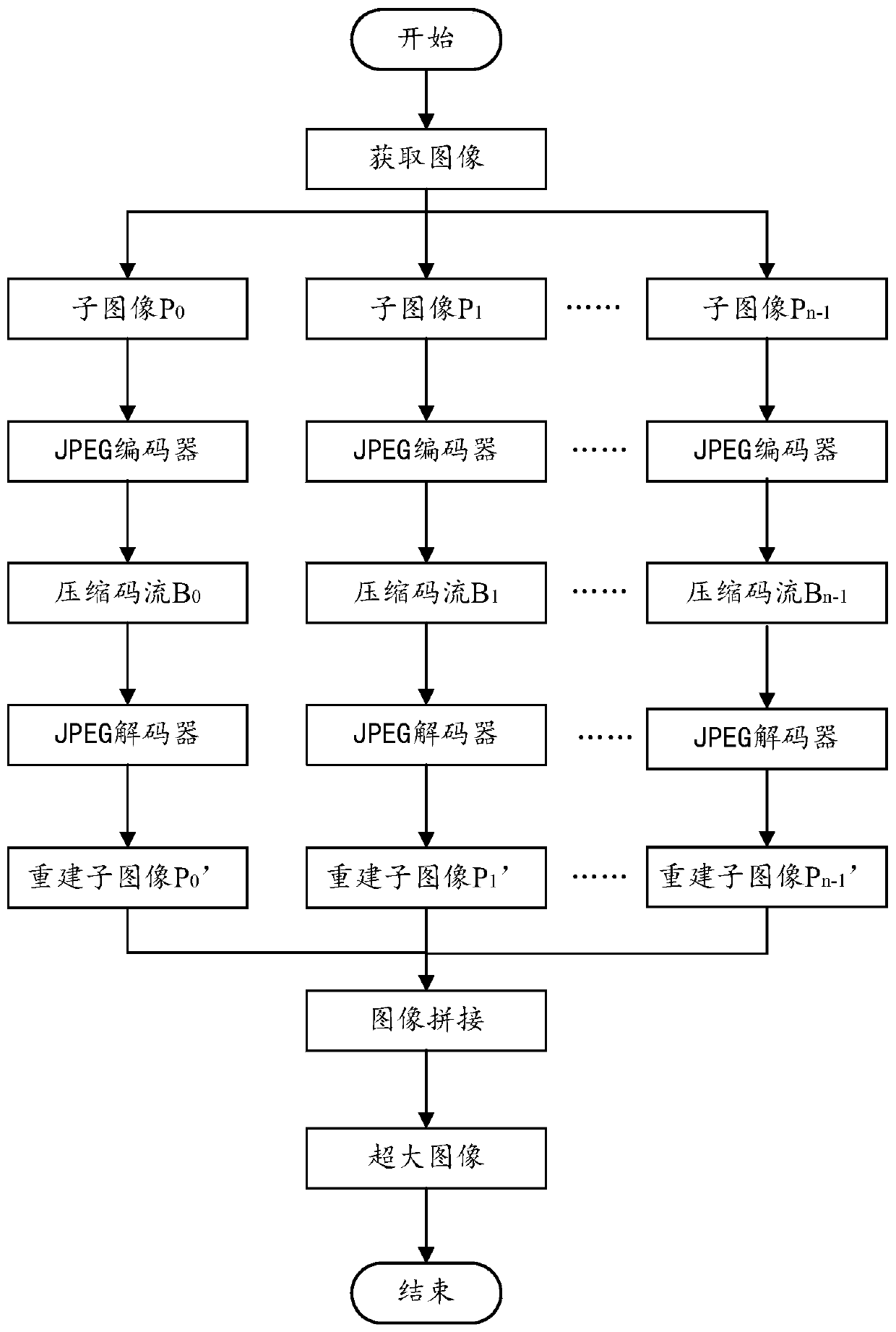

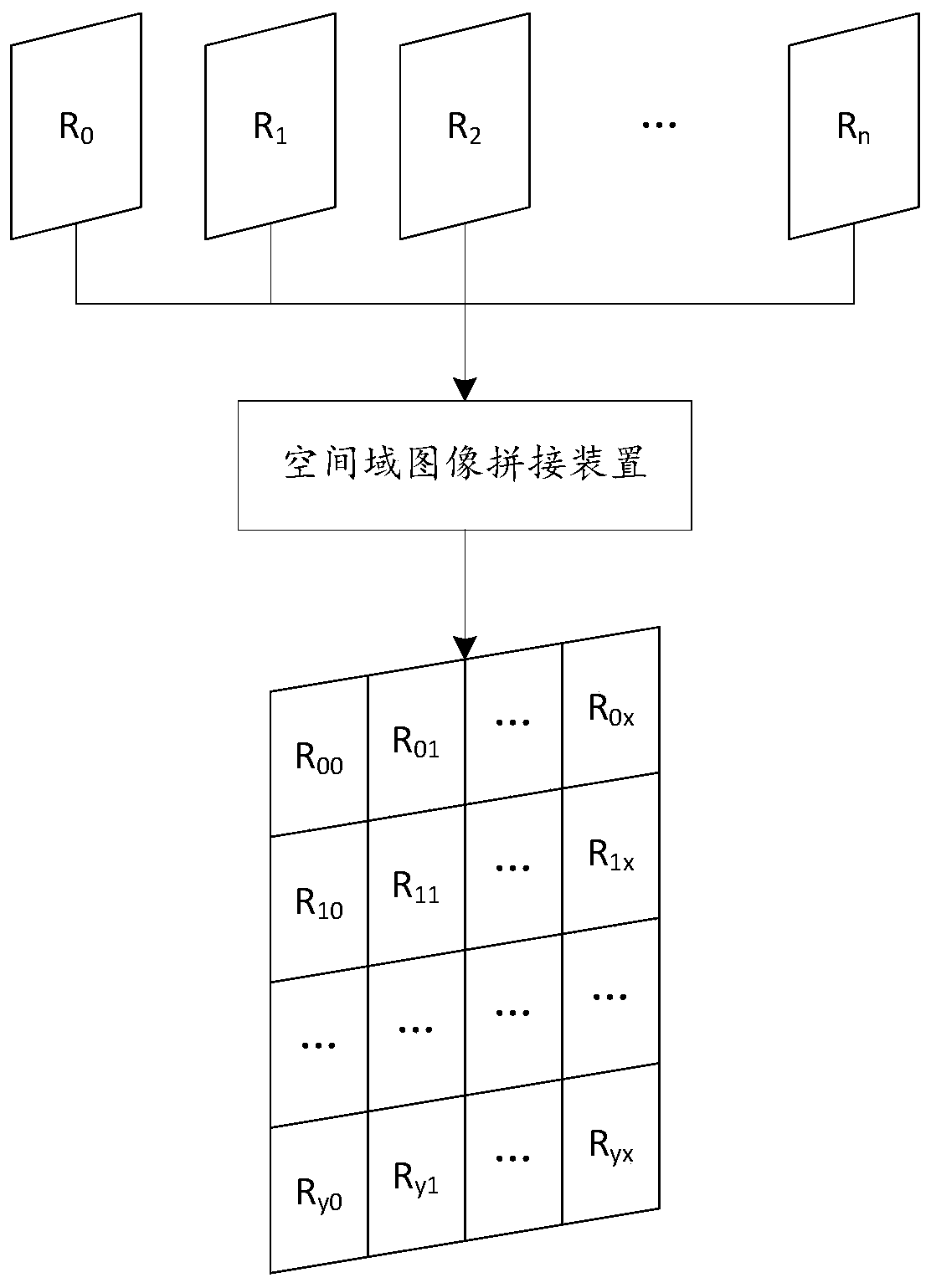

Image splicing method and device

ActiveCN111510717ARealize horizontal splicingRealize horizontal stitching, also can realize vertical stitching of multiple imagesTelevision system detailsColor television detailsPattern recognitionEngineering

The invention provides an image splicing method and device. The method comprises the steps of determining a target restart interval of N sub-images needing to be spliced, wherein the target restart interval is used for encoding the N sub-images before image splicing, and N is a positive integer greater than or equal to 2; separately encoding the N sub-images into corresponding compressed code streams according to the target restart interval; splicing all compressed code streams corresponding to the N sub-images according to predetermined splicing positions of the N sub-images in a spliced image to obtain a target code stream corresponding to the spliced image of the N sub-images; and splicing the N sub-images at least along the width direction of the image. Therefore, the steps of decodingthe sub-image compressed code streams of the plurality of sub-images, splicing all the decoded spatial domain reconstructed images, encoding the spliced ultra-large image and the like are eliminated,the memory and operation resources of hardware equipment are saved, and the operation efficiency of the hardware equipment is improved.

Owner:HANGZHOU HIKVISION DIGITAL TECH

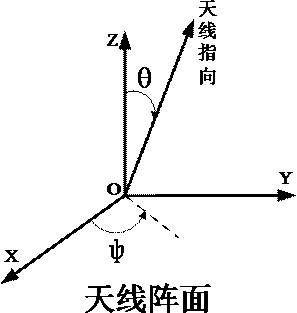

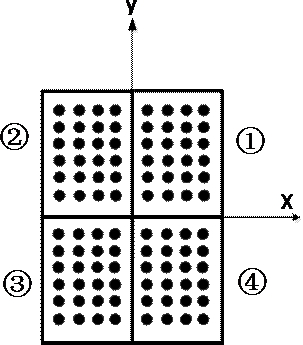

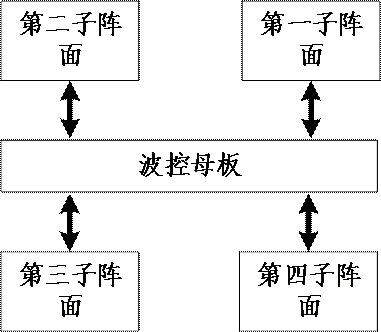

Array element work control method and device, electronic equipment and storage medium

ActiveCN112327728AFlexible splicingProgramme controlComputer controlArray elementMechanical engineering

The invention provides an array element work control method and device, electronic equipment and a storage medium, and relates to the technical field of phased-array antennas. The method comprises thesteps that firstly, initialization parameters and a control instruction sent by a wave control mother board are received, wherein the initialization parameters comprise a rotation angle and a translation coordinate which are determined based on the condition that at least two identical sub-array planes are located in the same coordinate system, and the control instruction comprises control parameters; the physical coordinate of each array element in a target sub-array plane is determined according to the rotation angle, the translation coordinate, a preset reference coordinate and a preset physical coordinate conversion formula; the phase values of the array elements are determined according to the physical coordinates, the control parameters and a preset phase formula; and finally the array elements are controlled to work according to the phase values. The array element work control method and device, the electronic equipment and the storage medium provided by the invention have theadvantage of flexible splicing.

Owner:CHENGDU T-RAY TECH CO LTD

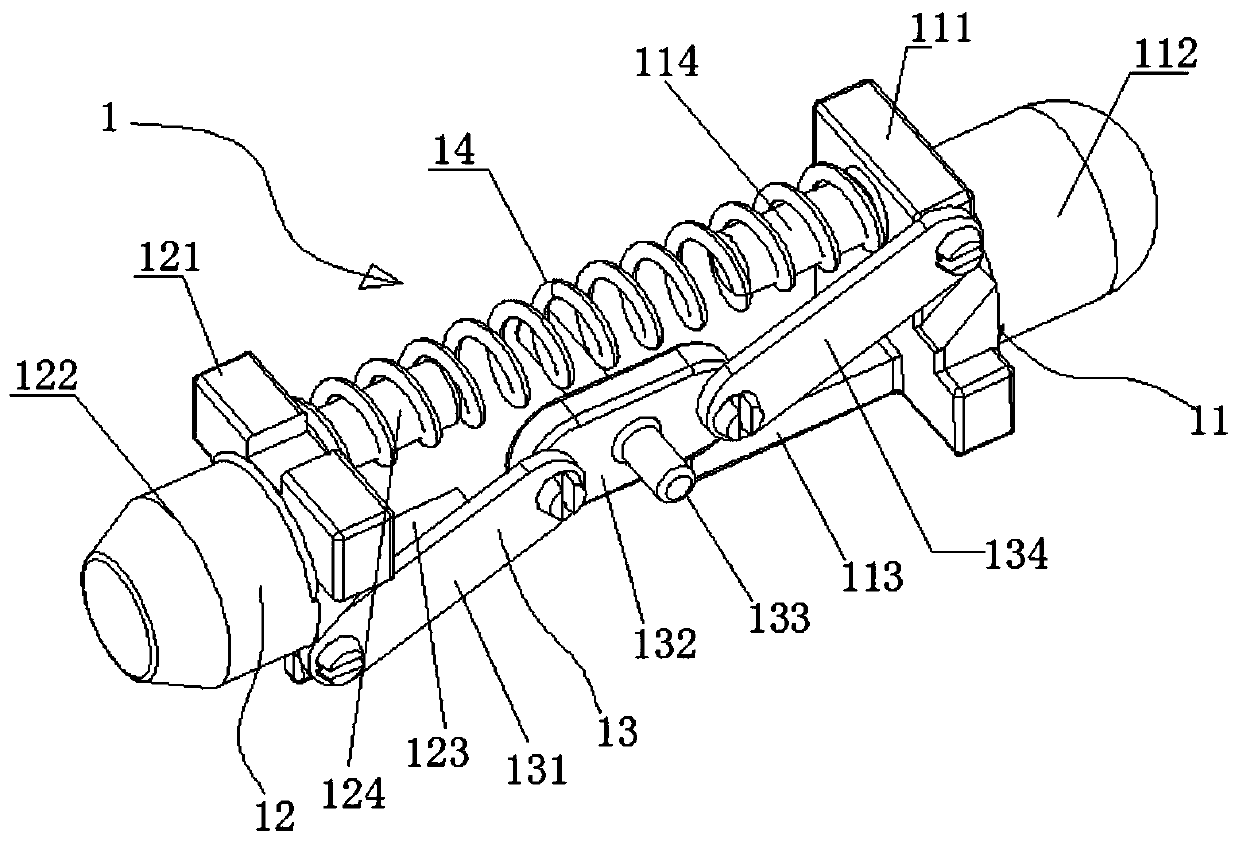

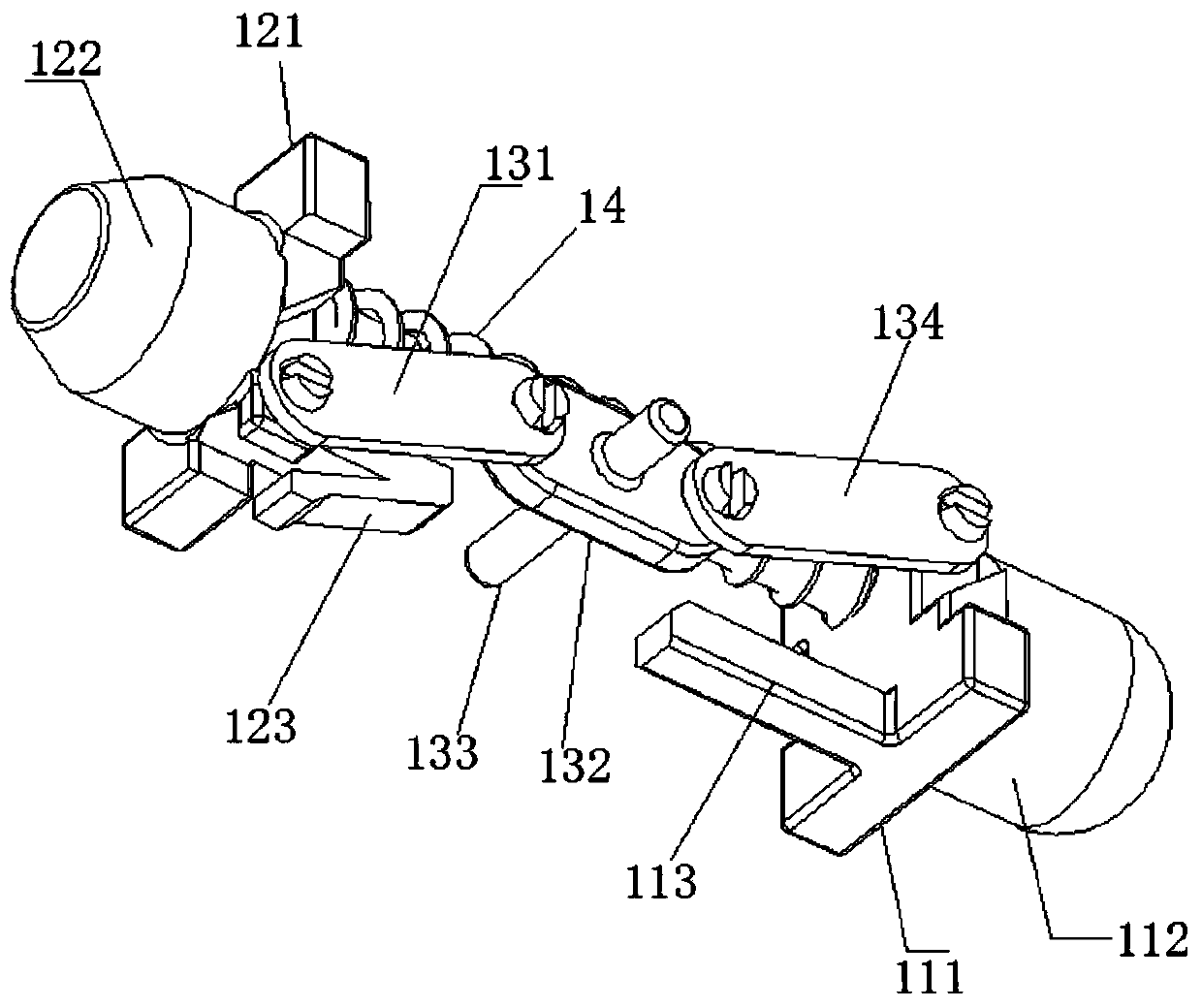

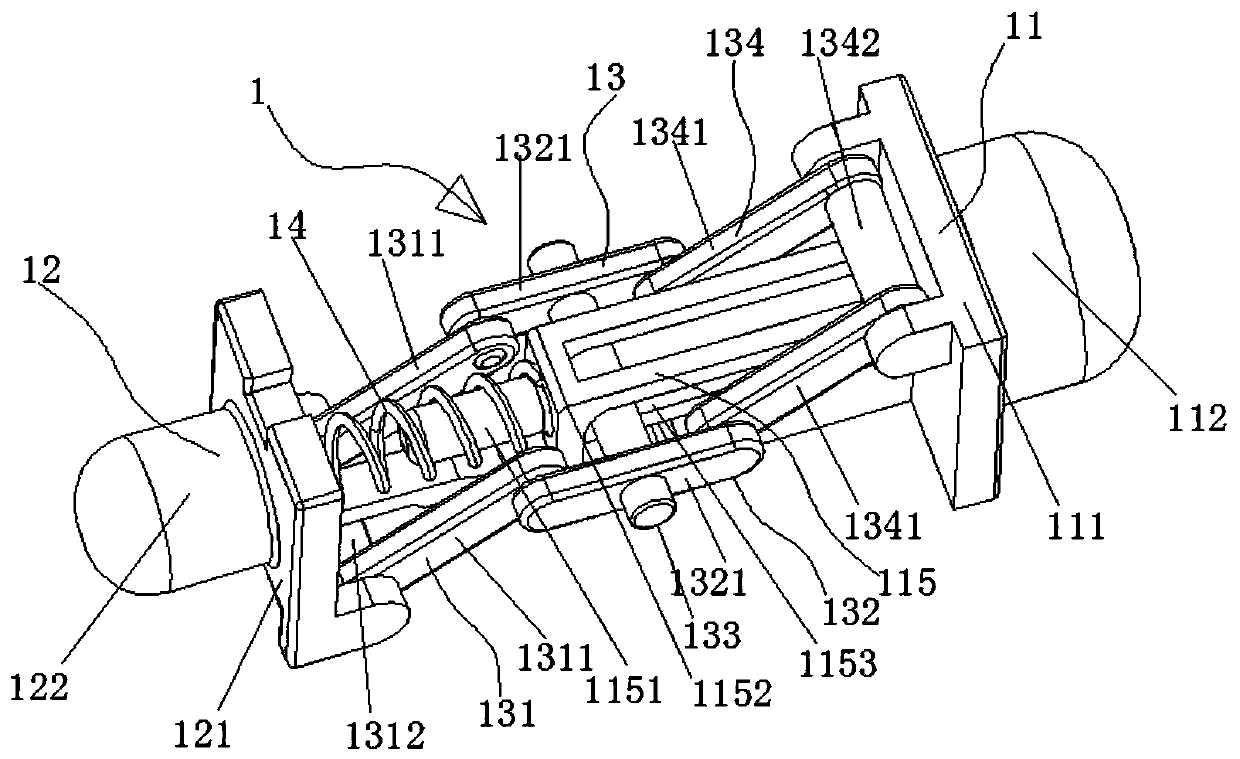

Both-way locking mechanism, splicing unit and spliced body

PendingCN109882483AGuaranteed stabilitySimple structureSnap-action fastenersRod connectionsLocking mechanismEngineering

The invention discloses a both-way locking mechanism, a splicing unit and a spliced body. The both-way locking mechanism comprises an elastic pin, a button, a connecting rod assembly and a compressionspring. The connecting rod assembly is innovatively designed between the button and the elastic pin, the compression spring is positioned and installed, the both-way locking mechanism capable of both-way driving of unlocking and locking is formed, the both-way locking mechanism is free of edge-by-edge locking, and the locking mechanism is in a work state. The splicing unit is composed of a frameA and a square middle plate A, the frame A is composed of a barrier strip A, a connecting protruding block A, a connecting protruding block B and an inserting groove A, wherein the connecting protruding block A and the connecting protruding block B are formed on the top face of the barrier strip A in a spaced manner, and the inserting groove A is formed in the bottom face of the barrier strip A and extends in the axial direction. The splicing unit is formed by assembling the frame and the middle plate, more forms can be achieved through splicing, and splicing is more flexible. The spliced bodyapplying the splicing unit can be locked in the process of direct splicing of the splicing unit, assembling is simple, and operation is convenient.

Owner:崔晓翔

Seamless connection type plate

The invention discloses a seamless connection type plate, which comprises at least two plate blocks and at least one connecting piece; at least one edge of the plate blocks is provided with a concave connecting groove; the connecting piece is at least provided with two connecting parts; the end parts of the connecting parts are provided with flanges; and the connecting parts of the connecting piece are inserted in the concave connecting grooves of two plate blocks respectively. The plate blocks are connected by the connecting piece and the concave connecting grooves, so that the plate blocks are not easily shifted due to small splicing seams among them. Therefore, the technical difficulty in installation construction is completely solved and the problem that some plates are difficultly slotted for seam connection due to low strength is solved as well.

Owner:NANJING FORTUNE RECYCLING TECH

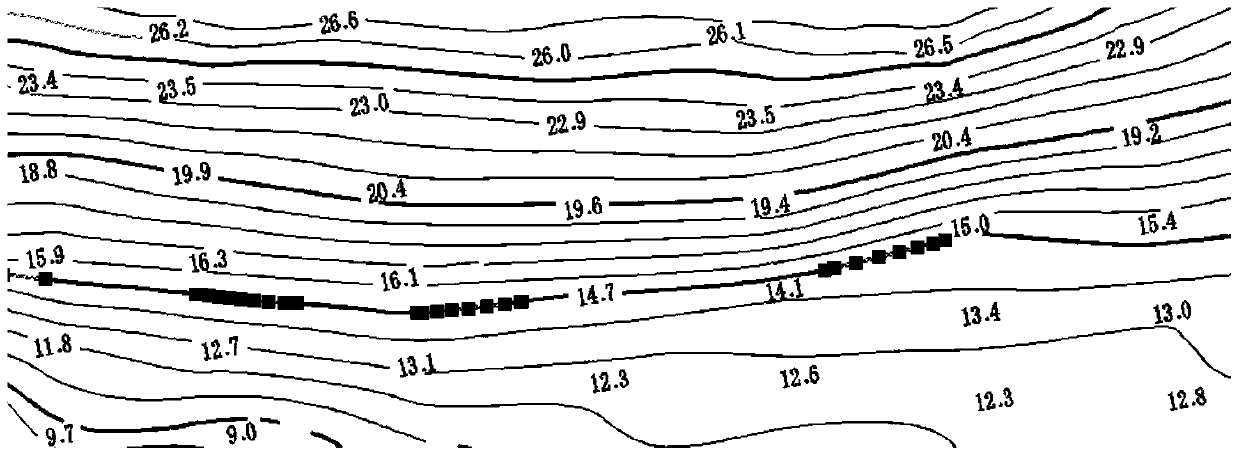

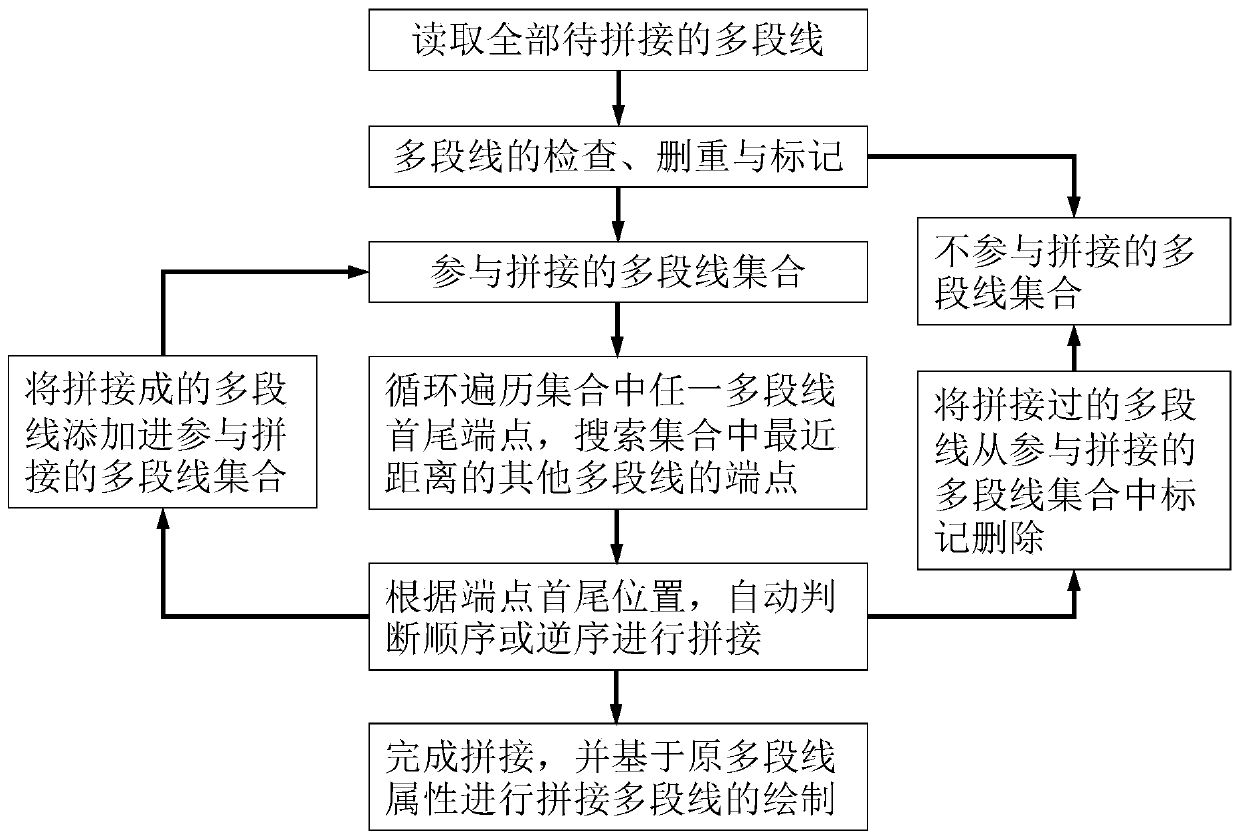

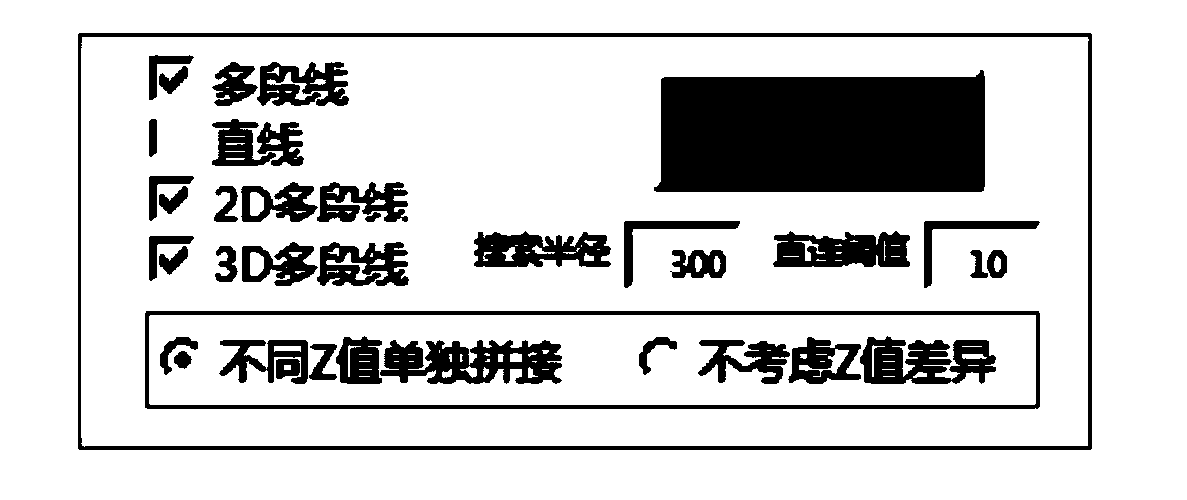

CAD (Computer-Aided Design) arbitrary multi-segment line batch rapid splicing method

ActiveCN110503727AWith automationRealize splicingImage data processingManufacturing computing systemsComputer Aided DesignMulti segment

The invention provides a CAD (Computer-Aided Design) arbitrary multi-segment line batch rapid splicing method. The method comprises the following steps: step 1, reading multi-segment lines to be spliced, selecting and reading XY coordinates and Z elevations of vertexes on straight lines, the multi-segment lines, two-dimensional multi-segment lines and three-dimensional multi-segment lines in batch; step 2, checking, deleting duplication and marking the read multi-segment lines; 3, cyclically traversing the head end point and the tail end point of any multi-segment line to be spliced, sequentially searching the head end point and the tail end point of the nearest spliced multi-segment line with the same attribute from the end point Z, and marking the head end point and the tail end point; 4, according to the spliced multi-segment line, the nearest multi-segment line to be spliced and the head and tail end points of the nearest multi-segment line to be spliced, automatically judging whether a sequential or reverse splicing mode is adopted or not, and splicing and marking; and step 5, repeating the steps 3 and 4 in sequence to complete splicing, and drawing the spliced multi-segment lines based on the attributes of the original multi-segment lines. The method is simple in technical principle and easy to operate, has great superiority compared with methods in the prior art, and isworthy of popularization and application in a large number of CAD engineering drawings in the future.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Fabricated prefabricated externally-hung wallboard splicing part fixed by cross-shaped steel plates in bell and spigot joint mode

InactiveCN112482588AFlexible splicingGuaranteed Shipping CostsBuilding constructionsMechanical engineeringJoint (building)

The invention relates to a fabricated prefabricated externally-hung wallboard splicing part fixed by cross-shaped steel plates in a bell and spigot joint mode. The splicing part comprises a cross-shaped steel plate; the two ends of the cross-shaped steel plate are inserted into the end faces of every two adjacent concrete inner leaf plates to achieve splicing; reserved bolt holes are formed in thepositions, corresponding to cross-shaped steel plate bolt holes, of the concrete inner leaf plates; and bolts are inserted into the reserved bolt holes and the steel plate bolt holes to fix the cross-shaped steel plate and the concrete inner leaf plates, so that the splicing of every two adjacent concrete inner leaf plates is achieved. According to the fabricated prefabricated externally-hung wallboard splicing part fixed by the cross-shaped steel plates in the bell and spigot joint mode, a plurality of prefabricated externally-hung wallboards can be reliably connected into a whole, so that the requirements for bearing capacity and normal use are basically met; and meanwhile a plurality of small fabricated prefabricated externally-hung wallboards can be flexibly spliced into a whole, so that the transportation cost and the transportation difficulty of large-scale fabricated prefabricated parts and accessories are reduced, and the popularization and the application of prefabricated buildings are accelerated.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

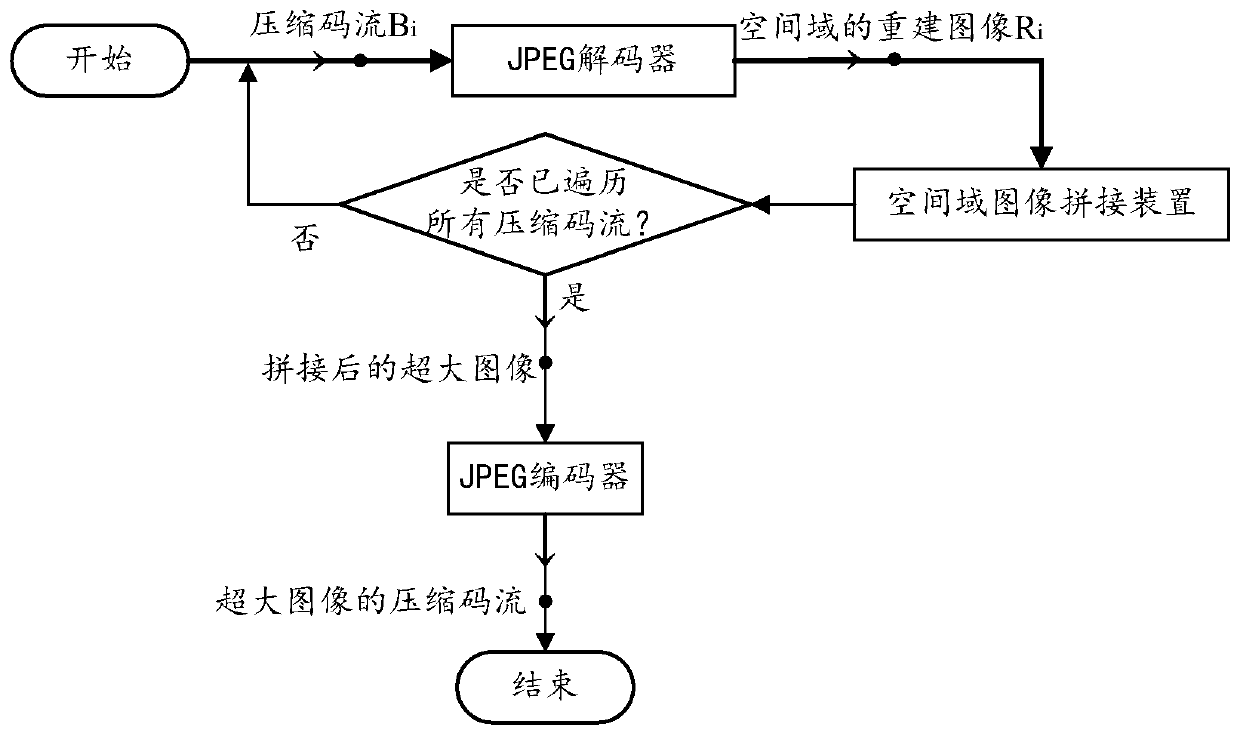

Traffic image splicing system and method

ActiveCN111510731AFlexible splicingRealize horizontal splicingClosed circuit television systemsDigital video signal modificationPattern recognitionEngineering

The invention provides a traffic image splicing system and method, wherein the system comprises an image obtaining device which is used for obtaining a plurality of traffic images, and transmitting the plurality of traffic images to a splicing device; and the splicing device which is used for splicing the compressed code streams of the plurality of traffic images to obtain a target code stream ofa spliced image obtained by splicing at least along the width direction of the images. Therefore, the steps of decoding the compressed code streams of a plurality of traffic images, splicing all decoded spatial domain reconstructed images, encoding spliced images obtained through splicing and the like are eliminated, the memory and operation resources of hardware equipment are saved, and the operation efficiency of the hardware equipment is improved.

Owner:HANGZHOU HIKVISION DIGITAL TECH

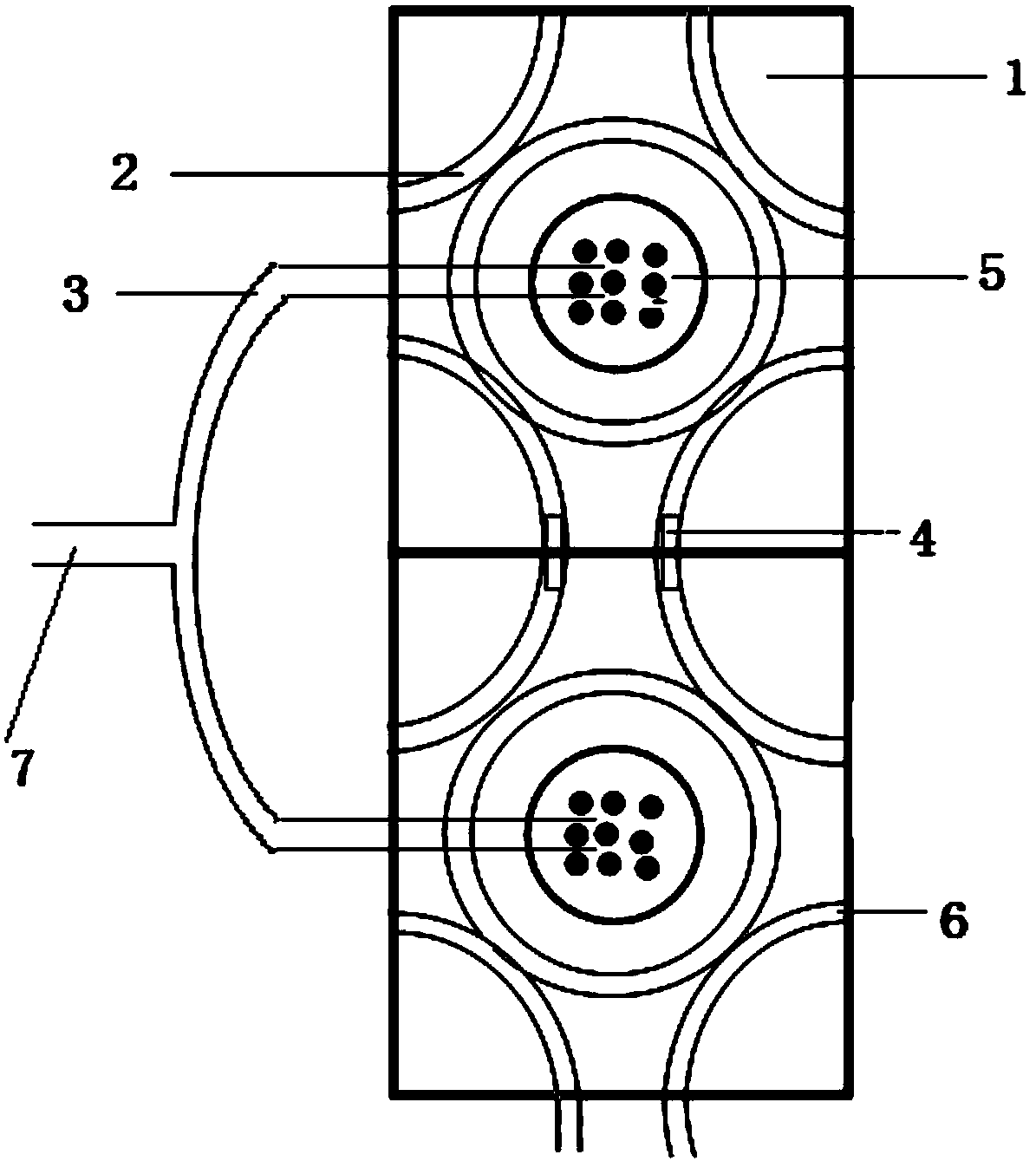

Spliced type vacuum sealing drainage device and vacuum sealing drainage method

ActiveCN103961791AFlexible splicingReduce wasteWound drainsSuction devicesEngineeringPulp and paper industry

The invention provides a spliced type vacuum sealing drainage device and a vacuum sealing drainage method. The spliced type vacuum sealing drainage device comprises a medical sponge, drainage tubes, washing tubes and inner connecting tubes, and a plurality of drainage holes are formed in the tube walls of the drainage tubes. The washing tubes comprise washing tube bodies and shower nozzles in a hindu lotus seedpod type, the shower nozzles are arranged at one ends of the washing tube bodies and are located in the medical sponge, and the washing tube bodies are located outside the medical sponge to be connected to a washing source. The drainage tubes extend in the medical sponge and are branched, and at least one drainage tube joint is formed on each side portion of the medical sponge. The inner connecting tubes are through tubes, the outer diameter of the inner connecting tubes is matched with the inner diameter of the drainage tube joints, and the inner connecting tubes can be inserted into the drainage tube joints in a fluid sealed mode. According to the prior art, the spliced type vacuum sealing drainage device has the advantages that the size of a needed single block is small, the device can be spliced, the exposed tubes are few, and the device can be provided with the independent washing tube.

Owner:黄鹭强

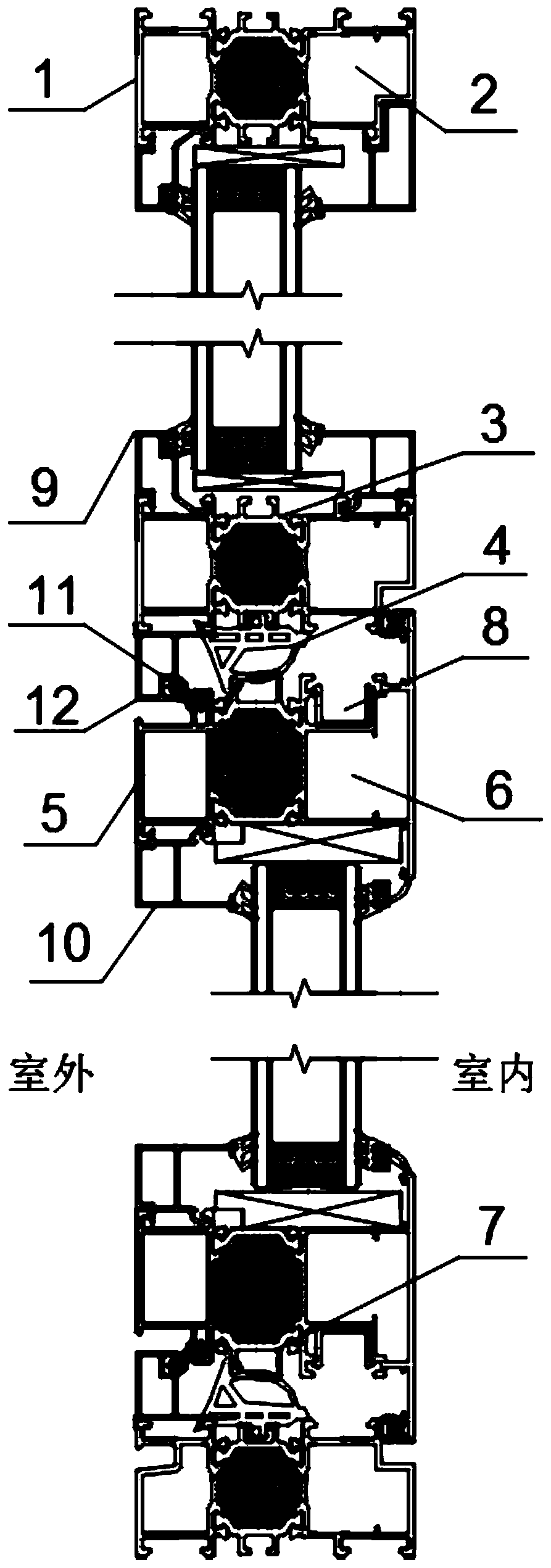

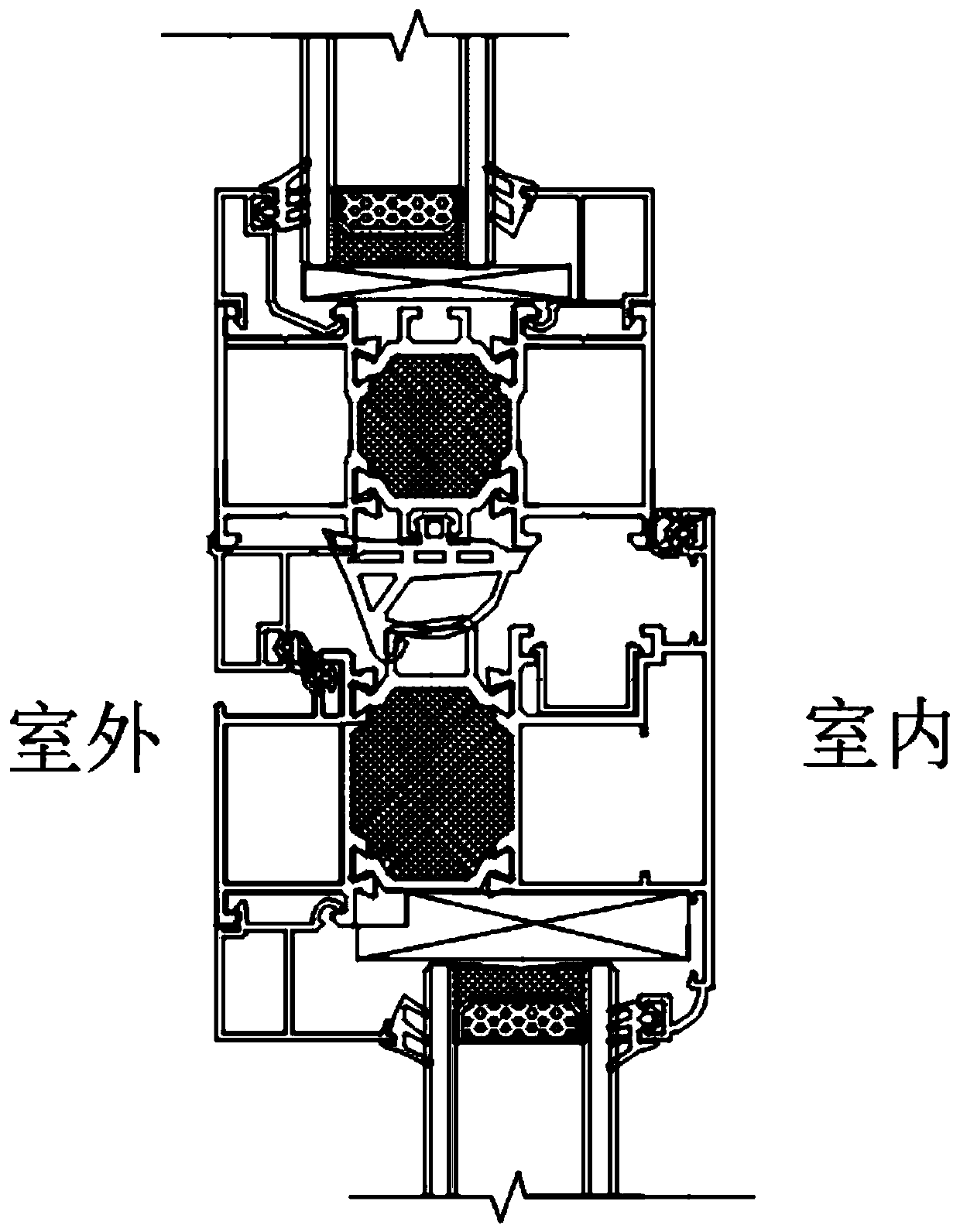

Internal/external double-plane heat-insulating bridge-cut-off casement window

PendingCN111119670AImprove waterproof performanceImprove insulation effectSealing arrangementsWing arrangementsVertical planeMechanical engineering

The invention discloses an internal / external double-plane heat-insulating bridge-cut-off casement window. The internal / external double-plane heat-insulating bridge-cut-off casement window comprises awindow frame and a window sash or glass, wherein the window frame is defined by an upper frame, a lower frame, a left frame and a right frame; the window sash or the glass is installed inside the window frame; when the window frame and the window sash of the internal / external double-plane heat-insulating bridge-cut-off casement window disclosed by the invention are closed, vertical planes at the indoor side and the outdoor side each form one plane, thus the aesthetic sense of the overall window is improved; the window frame and the window sash form a relatively small clearance in the same plane, so the overall waterproofness and heat insulation property of the window are improved; when a right profile of the frame is as wide as an outer profile of a sash frame, the indoor part and the outdoor part of the window can both reach the same plane; when the right profile of the frame is not as wide as the outer profile of the sash frame and when the window sash is opened outwards, the part, at the indoor side, of the window frame and the window sash are positioned at the same vertical plane; when the window sash is opened inwards, the part, at the outdoor side, of the window frame and thewindow sash are positioned at the same vertical plane; and thus the window can meet the using needs of different users.

Owner:连云港双源窗业有限公司

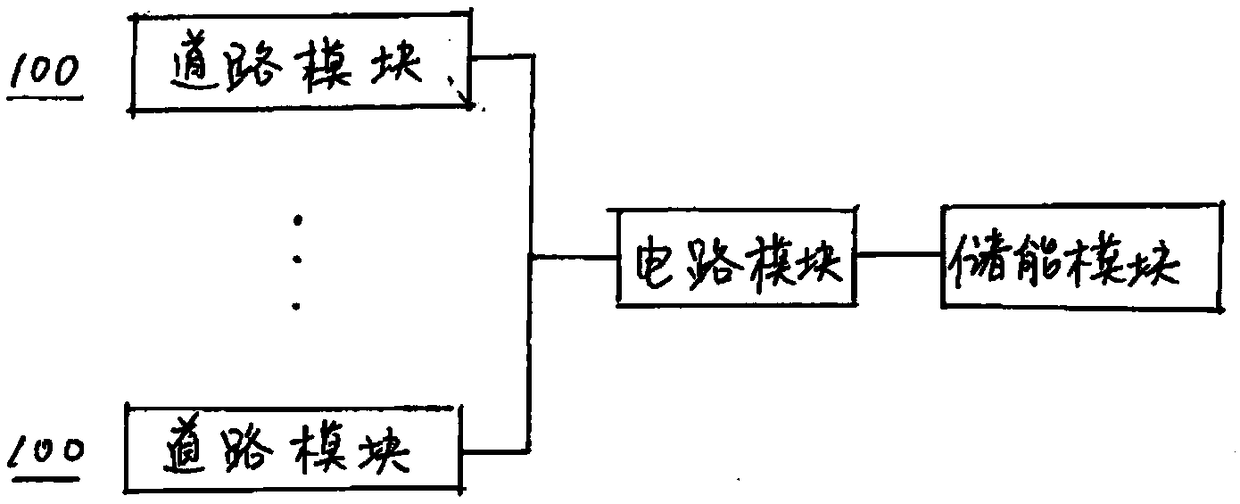

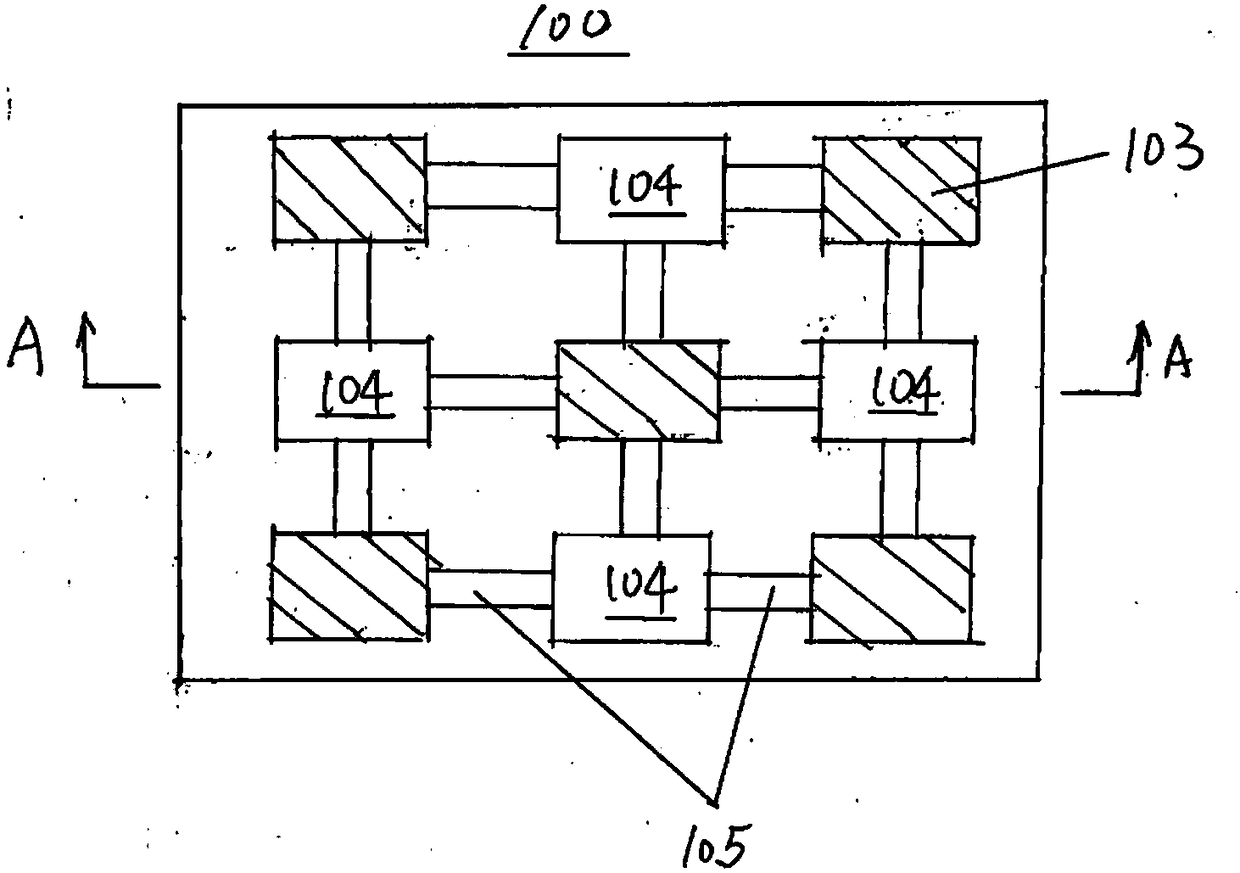

Bidirectional vibration energy collecting system based on piezoelectric element

PendingCN108832844AFlexible assemblyFlexible splicingPiezoelectric/electrostriction/magnetostriction machinesVertical vibrationElectricity

The invention discloses a bidirectional vibration energy collecting system based on a piezoelectric element. The system comprises a plurality of road modules, a circuit module and an energy storage module; wherein the plurality of road modules are electrically connected with the circuit module; the circuit module and the energy storage module are electrically connected; the road module includes aforce layer, an elastic layer, a support unit, a vertical vibration energy collection unit, and a horizontal vibration energy collection unit. The energy collecting system of the present invention caneffectively collect the energy in the vertical direction and the horizontal direction generated in a road by the vertical vibration energy collection unit and the horizontal vibration energy collection unit, thereby improving the efficiency of energy collection.

Owner:北京中微融通科技有限公司

Combined steel casing for rotary drilling of cast-in-place pile in backfilled soil and construction method thereof

The invention relates to a combined steel casing for rotary drilling of a cast-in-place pile in backfilled soil and a construction method thereof, and belongs to the technical field of rotary drillingbored pile construction. The combined steel casing is formed by splicing a plurality of steel casting units in sequence, the steel casting units on the upper side and the lower side of each spliced seam are provided with a plurality of upper connection lug plates and a plurality of lower connection lug plates in pairs, and the upper connection lug plates and the lower connection lug plates are provided with first connection holes and second connection holes in a correspondence mode and connected through bolts. Each steel casting unit of the combined steel casing is low in weight and convenient to machine, transport and construct on site, can be flexibly spliced according to the required length, has wider applicability and is reliable in connection, convenient to splice and low in manufacturing cost. The construction method has the advantages that procedures are simple, operation is convenient, and the construction efficiency is high.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

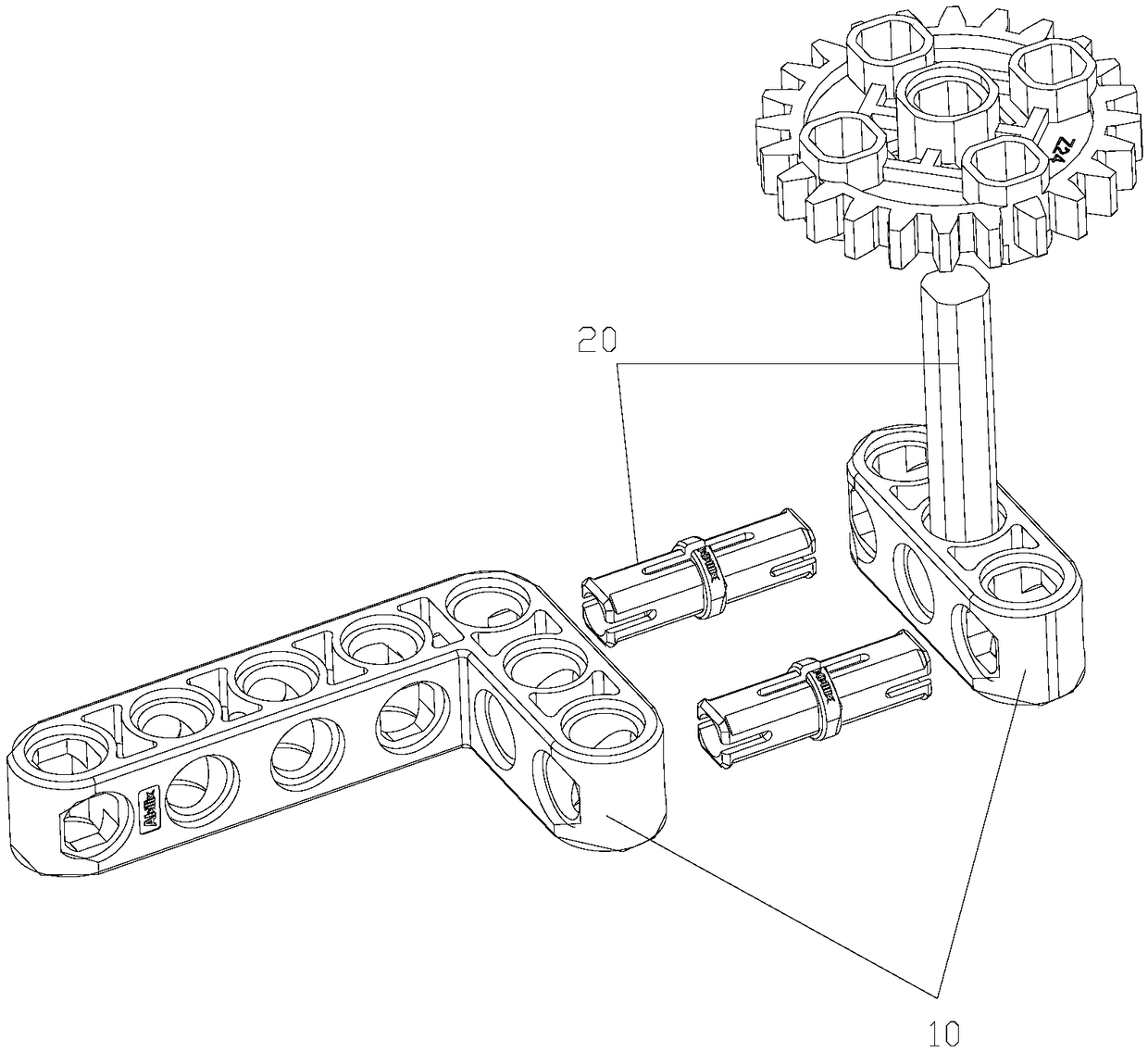

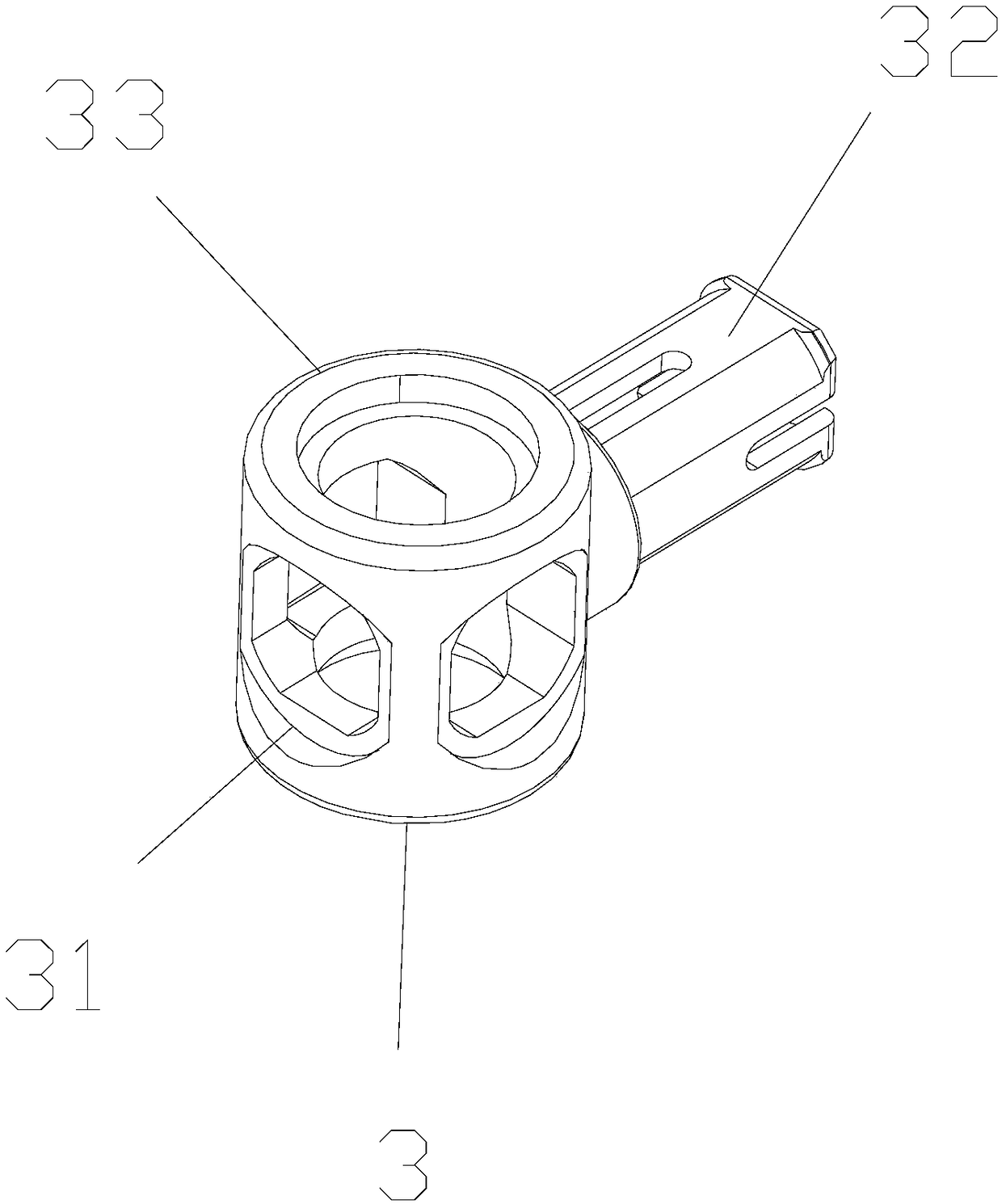

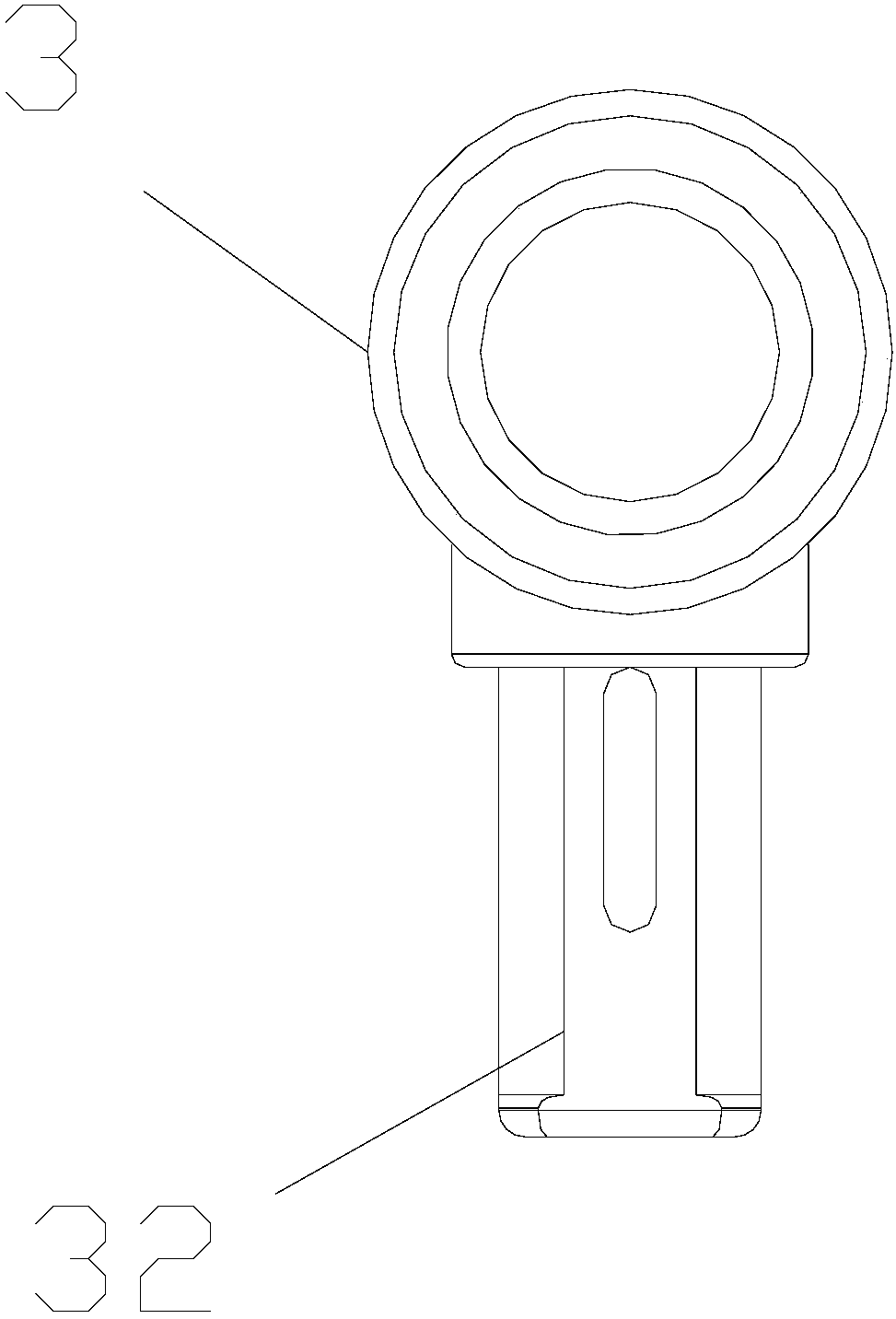

Multifunctional connector used for building block connection

InactiveCN109420351ATo achieve multi-functional connectionIncrease diversityToysBlocked ConnectionEngineering

Owner:SHANGHAI XPARTNER ROBOTICS +1

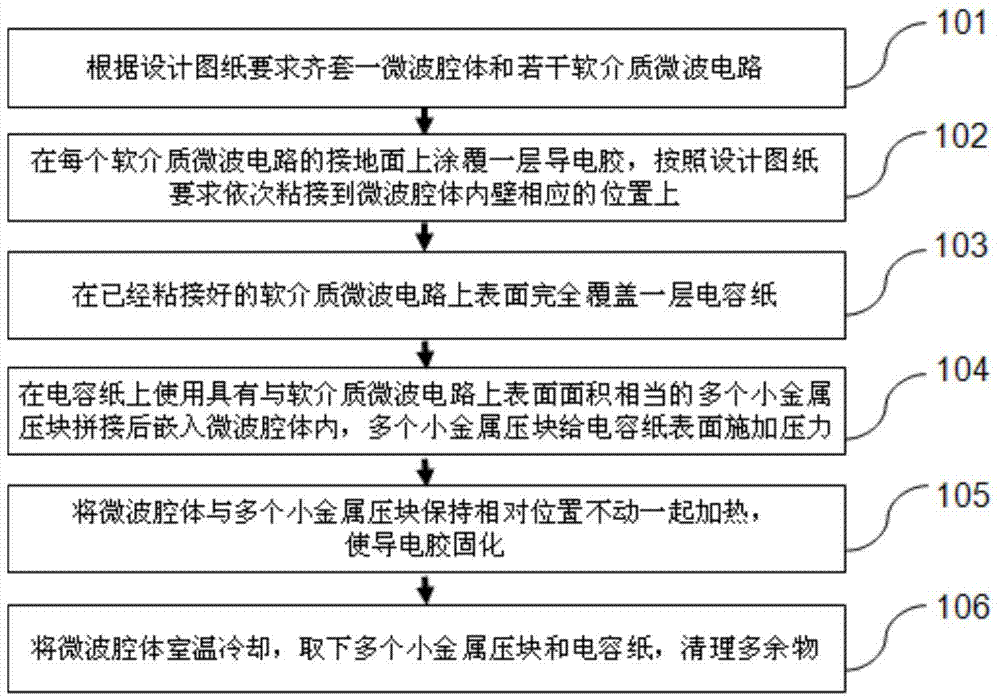

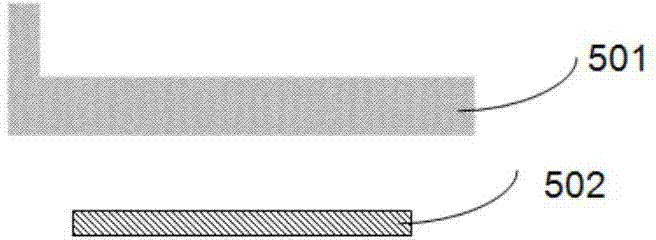

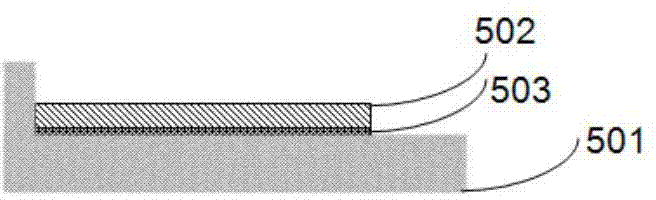

Method for pasting soft medium microwave circuits by metal pressure block splicing technology

ActiveCN104332692ASolve the gap problemImprove reliabilityWaveguide type devicesCapacitanceMicrowave cavity

The invention discloses a method for pasting soft medium microwave circuits by a metal pressure block splicing technology. The method comprises the following steps: a microwave cavity and a plurality of soft medium microwave circuits are kitted according to the drawing requirements; the grounding surface of each soft medium microwave circuit is coated with a layer of conductive adhesive, and the soft medium microwave circuits are sequentially pasted to corresponding positions of the inner wall of the microwave cavity according to the drawing requirements; the upper surfaces of the pasted soft medium microwave circuits are completely covered with capacitor paper; a plurality of small metal pressure blocks of which the area is equal to that of the upper surfaces of the soft medium microwave circuits are spliced on the capacitor paper and embedded into the microwave cavity, and the small metal pressure blocks apply pressure to the capacitor paper; the microwave cavity and the small metal pressure blocks are kept unchanged in relative position and heated to cure the conductive adhesive; and cooling is carried out, and the small metal pressure blocks and the capacitor paper are removed. The problem that gaps and holes are generated between the existing soft medium microwave circuit and the adhesive layer of the inner wall of the cavity in the adhering and curing process is solved, the number of design types and design difficulty of the metal pressure blocks are reduced, and the product production cycle is shortened.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Umbrella formwork support system

ActiveCN105401721BHeight adjustableEasy to assemble and disassembleAuxillary members of forms/shuttering/falseworksSupporting systemCable stayed

The invention discloses an umbrella-type template supporting system. A vertical rod is formed by an inner pipe and an outer pipe which are sleeved together in a telescopic manner. The upper end of the inner pipe is uniformly hinged with four horizontal steel rods whose lower end faces are provided with sliding chutes. A sliding base is slidably connected with the sliding chute of the horizontal steel rod. The lower end of an inclined strut steel rod is hinged with the inner pipe of the vertical rod, and the upper end is hinged with the sliding base. The upper end face of a bottom inclined strut is hinged with the lower end portion of the outer pipe of the vertical rod, and the upper end face is provided with a spliced eye, and a bolt corresponding to the spliced eye is fixed on the outer pipe of the vertical rod on the upper end of the bottom inclined strut. When the bolts are inserted in the spliced eye, the bottom inclined struts support each side of the bottom of the vertical rod outer pipe in a cable-stayed manner. When the bolts are pulled out, the bottom inclined struts free hang on the lower end of the vertical rod outer pipe. Each component of the system are connected with each other, assembling and dismounting are simple and convenient, splicing is flexible, and time is saved, and construction efficiency is improved. Components would not be lost in dismounting and storage, and service life is prolonged. The system is wide in application range, and can support templates in various dimensions and heights.

Owner:HEBEI CONSTR GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com