Spliced type vacuum sealing drainage device and vacuum sealing drainage method

A splicing, negative pressure technology, applied in the direction of wound drainage, suction equipment, etc., can solve the problems of incomplete irrigation and drainage, poor drainage, negative pressure failure, etc., to achieve better flushing effect, convenient operation, The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. These exemplary embodiments are provided to enable those of ordinary skill in the art to clearly understand the present invention and, based on the description herein, to implement the present invention. The drawings and specific examples are not intended to limit the invention, the scope of which is defined by the appended claims.

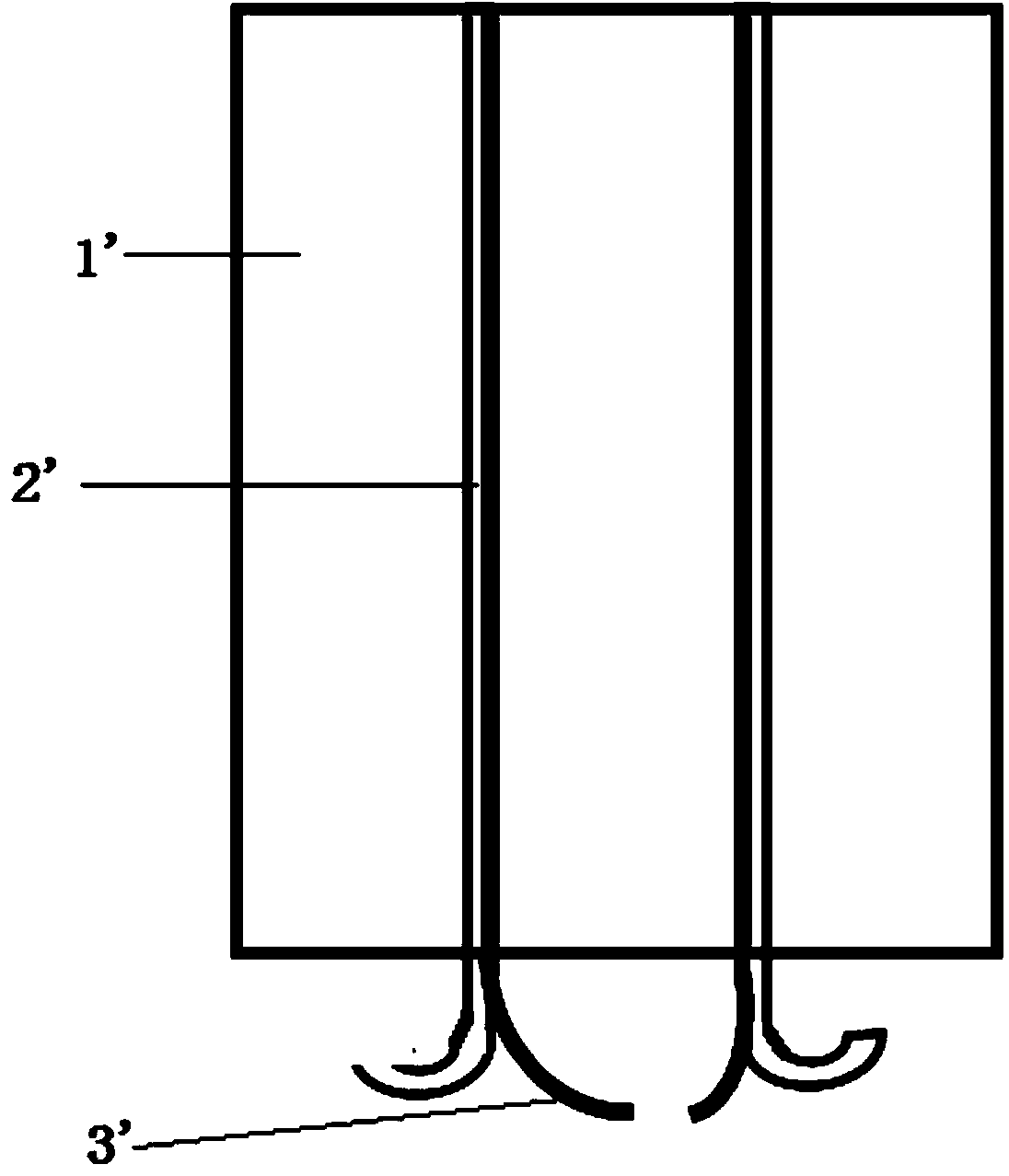

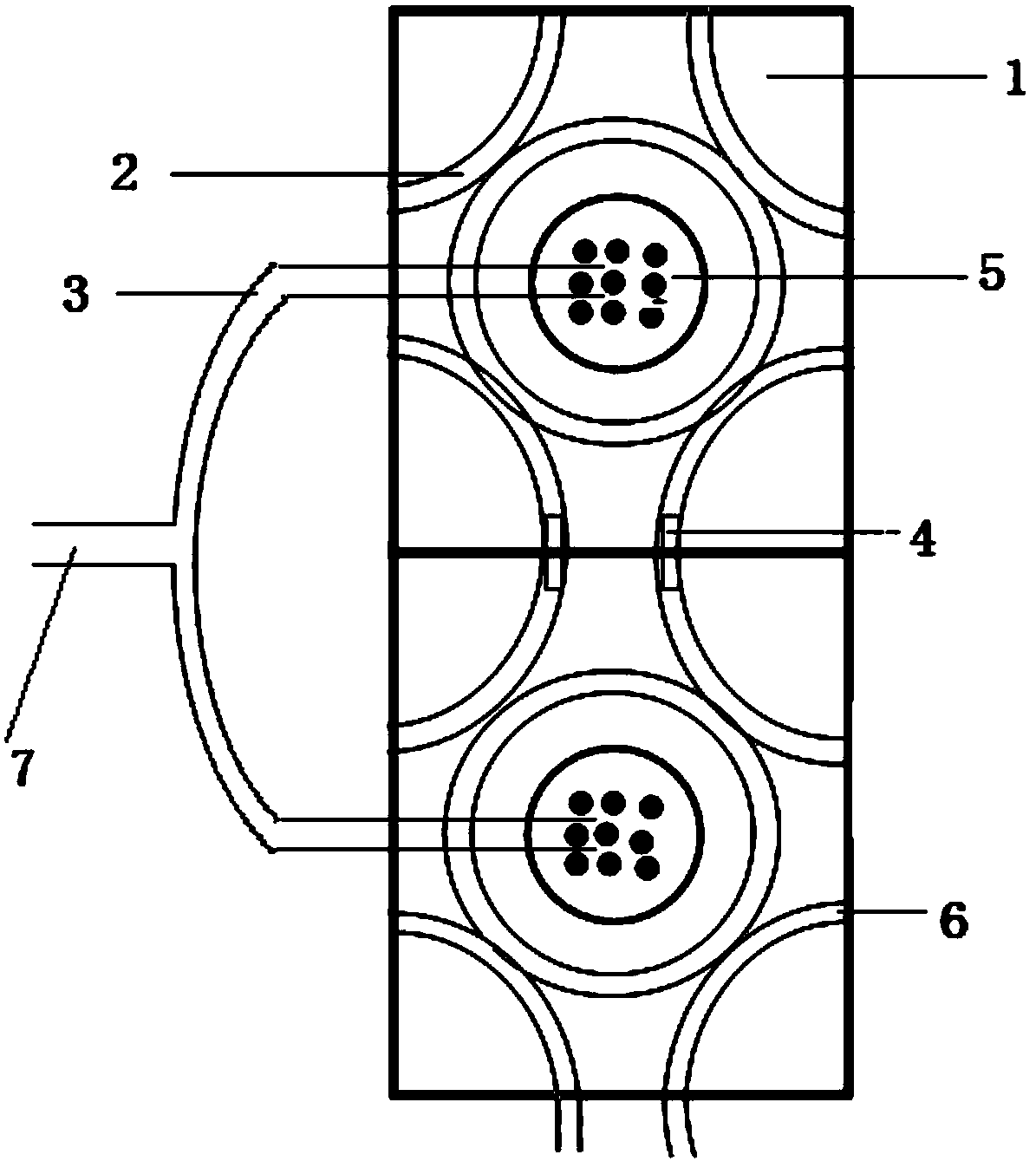

[0036] According to one aspect of the present invention, a VSD drainage device is provided. figure 2 A schematic top view of the structure of the VSD drainage device according to the embodiment of the present invention is shown.

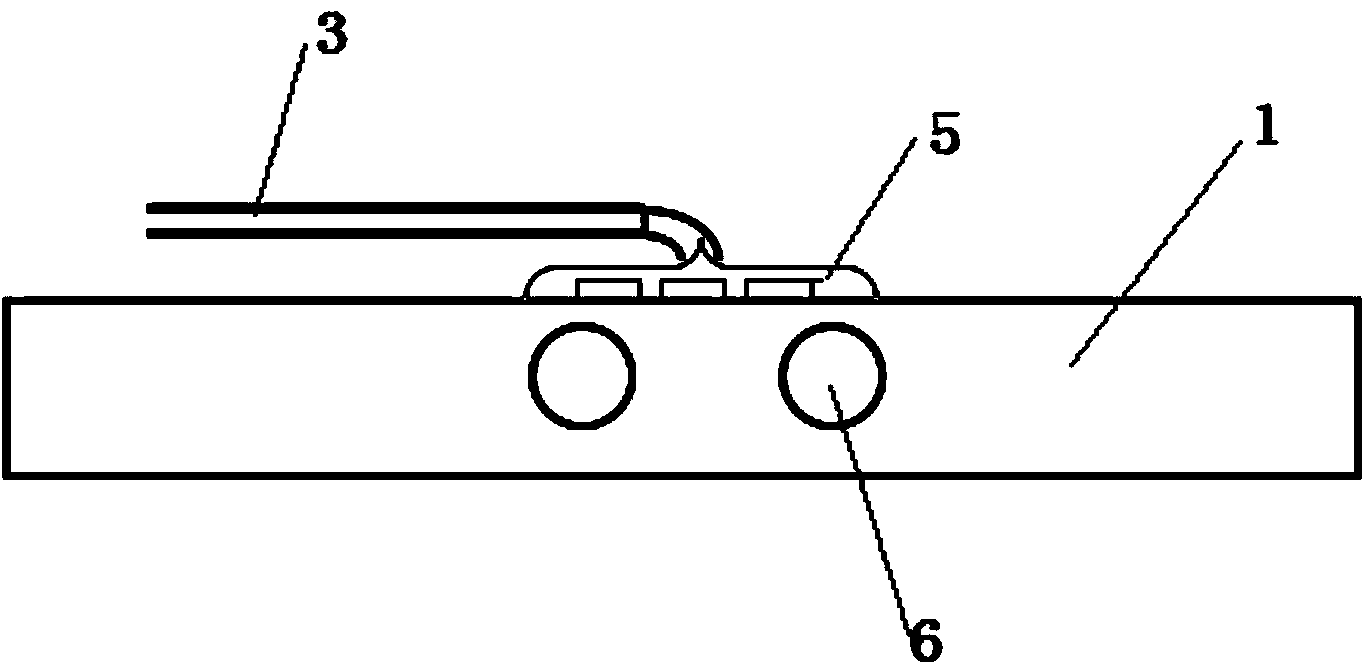

[0037] Such as figure 2 As shown, the splicing negative pressure sealing drainage device according to the present invention includes a medical sponge (usually a VSD medical sponge) 1, a drainage tube 2, a flushing tube, and a connecting inner tube 4, wherein the tube wall of the drainag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com