Umbrella formwork support system

A technology of formwork support and diagonal bracing, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, construction, etc., which can solve the problems of disassembly, preservation of easily lost parts, cumbersome assembly, and long installation and disassembly time and other problems to achieve the effect of saving assembly time, saving process and saving disassembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

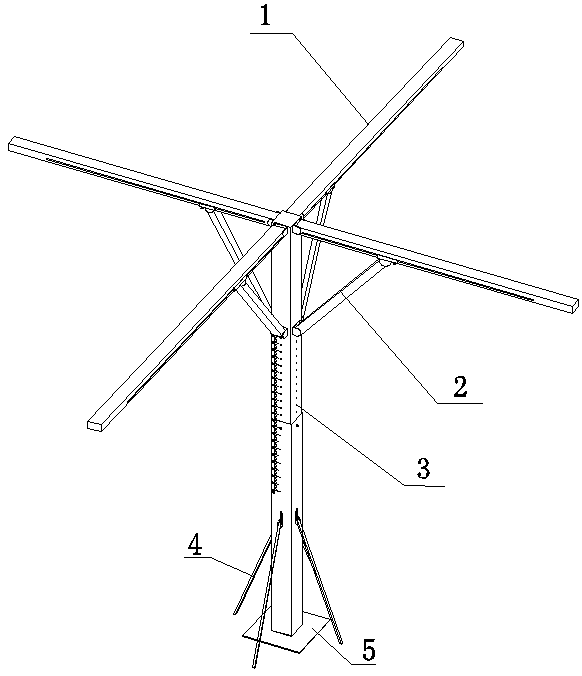

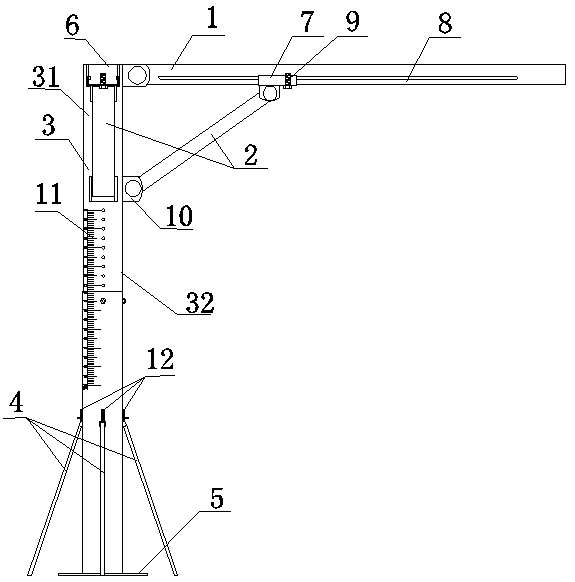

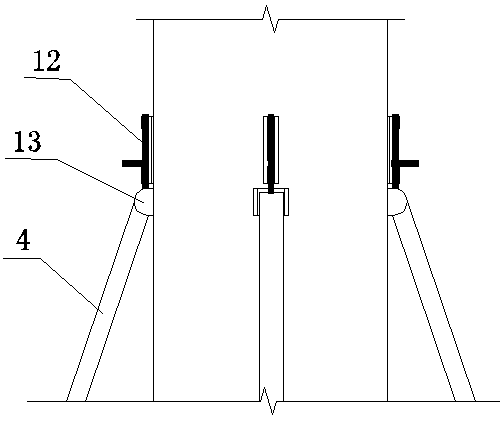

[0014] Such as figure 1 , figure 2 and image 3 As shown, this embodiment includes a vertical pole 3 , a diagonal brace steel pole 2 , a horizontal steel pole 1 and a bottom diagonal brace 4 . The cross-sections of the diagonally braced steel rod 2 and the horizontal steel rod 1 are both rectangular. The vertical rod 3 is composed of two inner tubes 31 and outer tubes 32 that are nested together. The inner tube 31 is telescopically fixed in the outer tube 32: the outer tube 32 of the vertical rod is provided with a plurality of vertically arranged pin holes, and the inner tube There are a plurality of vertical pin holes in the corresponding position of 31, the inner tube 31 is sleeved in the outer tube 32, after the inner tube 31 is stretched to a suitable height in the outer tube 32, the inner tube 31 and the outer tube 32 are fixed togeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com