A mouthpiece for heating a non-combustible smoky product

A technology for heat-not-burn and smoke-generating products, which is applied in applications, tobacco, smoke oil filter elements, etc. It can solve problems such as lowering the temperature of the smoke, excessively high smoke temperature, and insufficient aroma, and achieves lower smoke temperature and simple preparation , the effect of easy rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

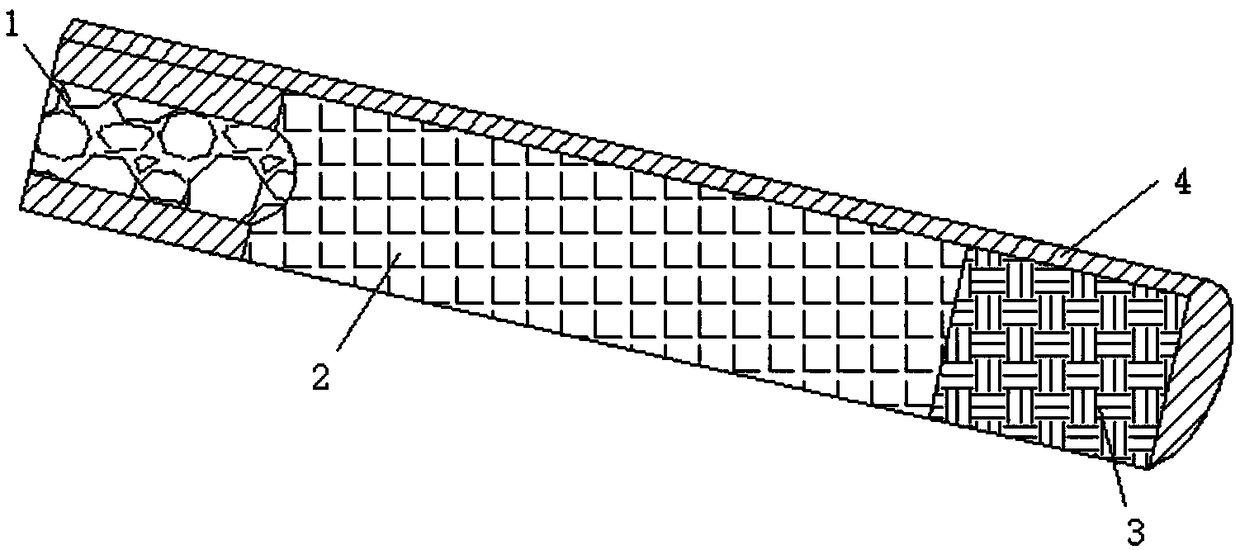

[0017] Such as figure 1 shown

[0018] A mouthpiece for heat-not-burn smoking products proposed by the present invention comprises the following steps:

[0019] A mouth stick for heat-not-burn smoking products, which is composed of a hollow section 1, a cooling section 2 and a filter section 3 from the far lip end to the near lip end, and is wrapped with molding paper 4 outside, and the hollow section is near the hair The smoke section, the cooling section is connected with the diversion section, and the filter section is connected with the cooling section. The length of the nozzle stick of the heat-not-burn smoking product is 30mm, wherein the length of the hollow section is 5mm, the length of the cooling section is 20mm, and the length of the filter section is 5mm. The material of the hollow section is a circular shape made of corrugated paper to support the passage of airflow; the material of the cooling section is a cylinder made of polylactic acid polymer with a honeycom...

Embodiment 2

[0021] A mouthpiece for heat-not-burn smoking products proposed by the present invention comprises the following steps:

[0022] A mouth stick for heat-not-burn smoking products, which is composed of a hollow section 1, a cooling section 2 and a filter section 3 from the far lip end to the near lip end, and is wrapped with molding paper 4 outside, and the hollow section is near the hair The smoke section, the cooling section is connected with the diversion section, and the filtering section is connected with the cooling section. The length of the mouthpiece of the heat-not-burn smoking product is 25mm, in which the length of the hollow section is 5mm, the length of the cooling section is 15mm, and the length of the filter section is 5mm. The material of the hollow section is a circle made of polylactic acid fiber to support the passage of airflow ; The material of the cooling section is a polylactic acid polymer prepared by mold molding, and the internal structure is a spiral ...

Embodiment 3

[0024] A mouthpiece for heat-not-burn smoking products proposed by the present invention comprises the following steps:

[0025] A mouth stick for heat-not-burn smoking products, which is composed of a hollow section 1, a cooling section 2 and a filter section 3 from the far lip end to the near lip end, and is wrapped with molding paper 4 outside, and the hollow section is near the hair The smoke section, the cooling section is connected with the diversion section, and the filter section is connected with the cooling section. The length of the nozzle stick of the heat-not-burn smoking product is 30mm, wherein the length of the hollow section is 5mm, the length of the cooling section is 20mm, and the length of the filter section is 5mm. The material of the hollow section is a circular shape made of polyethylene to support the passage of airflow; the material of the cooling section is a polylactic acid polymer prepared by mold molding, and the inner structure is a mesh-like wavy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com