Fabricated prefabricated externally-hung wallboard splicing part fixed by cross-shaped steel plates in bell and spigot joint mode

An external wall panel, cross-shaped technology, which is applied in the direction of construction and building structure, can solve the problems of increased construction cost, unfavorable application and promotion of prefabricated buildings, and increased transportation difficulty, and achieves simple structure, accelerated promotion and application, and connection. and good stress performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in combination with specific embodiments.

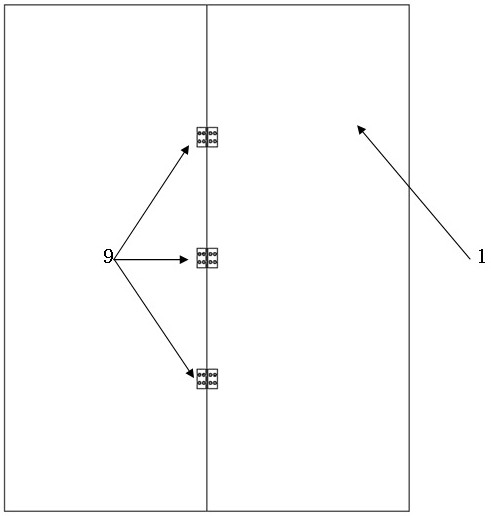

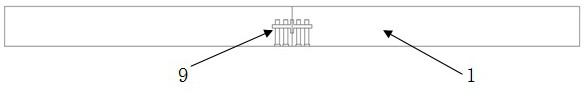

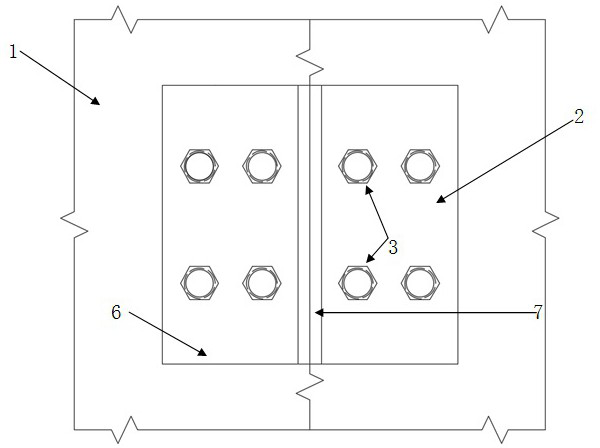

[0028] The invention relates to an assembled prefabricated external wallboard splicing piece which is socketed and fixed by cross-shaped steel plates. The spliced piece comprises a cross-shaped steel plate 2, and the two ends of the cross-shaped steel plate 2 are inserted into the end faces of two adjacent concrete inner leaf plates 1 to realize assembly.

[0029] The cross-shaped steel plate 2 includes two flange plates 6 on the same plane, and the two flange plates 6 are connected by a web 7, and the web 7 is sandwiched between two flange plates 6 that are aligned with each other. 7 and the flange plate 6 are perpendicular to each other, and the cross section forms a cross shape. The flange plate 6 of the cross-shaped steel plate 2 is arranged vertically, and the two transverse ends are inserted into the end faces of the concrete inner leaf plate 1 . The flange plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com