Manufacturing method of polytetrafluoroethylene orifice-plate corrugated packing

A PTFE, orifice corrugated technology, applied in metal processing and other directions, can solve the problems of the appearance and size of corrugated parisons, the complex process of PTFE tape, and the easy generation of cracks. The effect of strength, small deformation, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

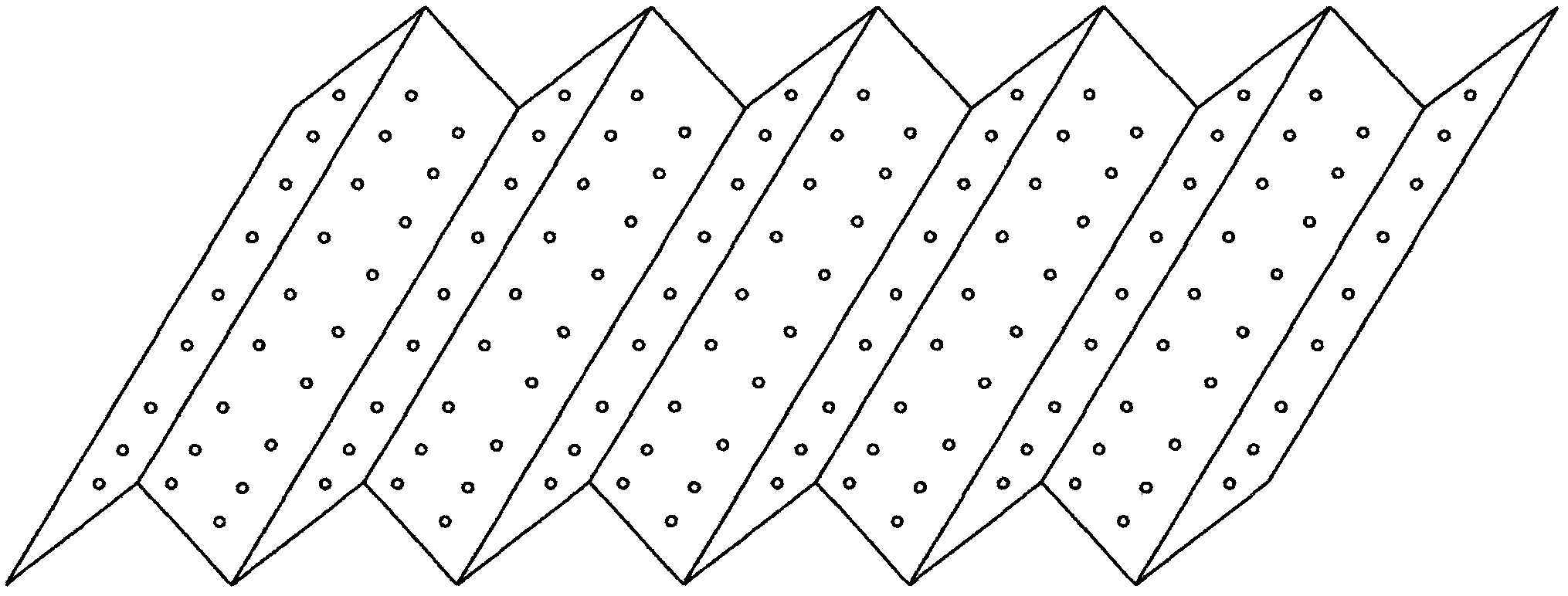

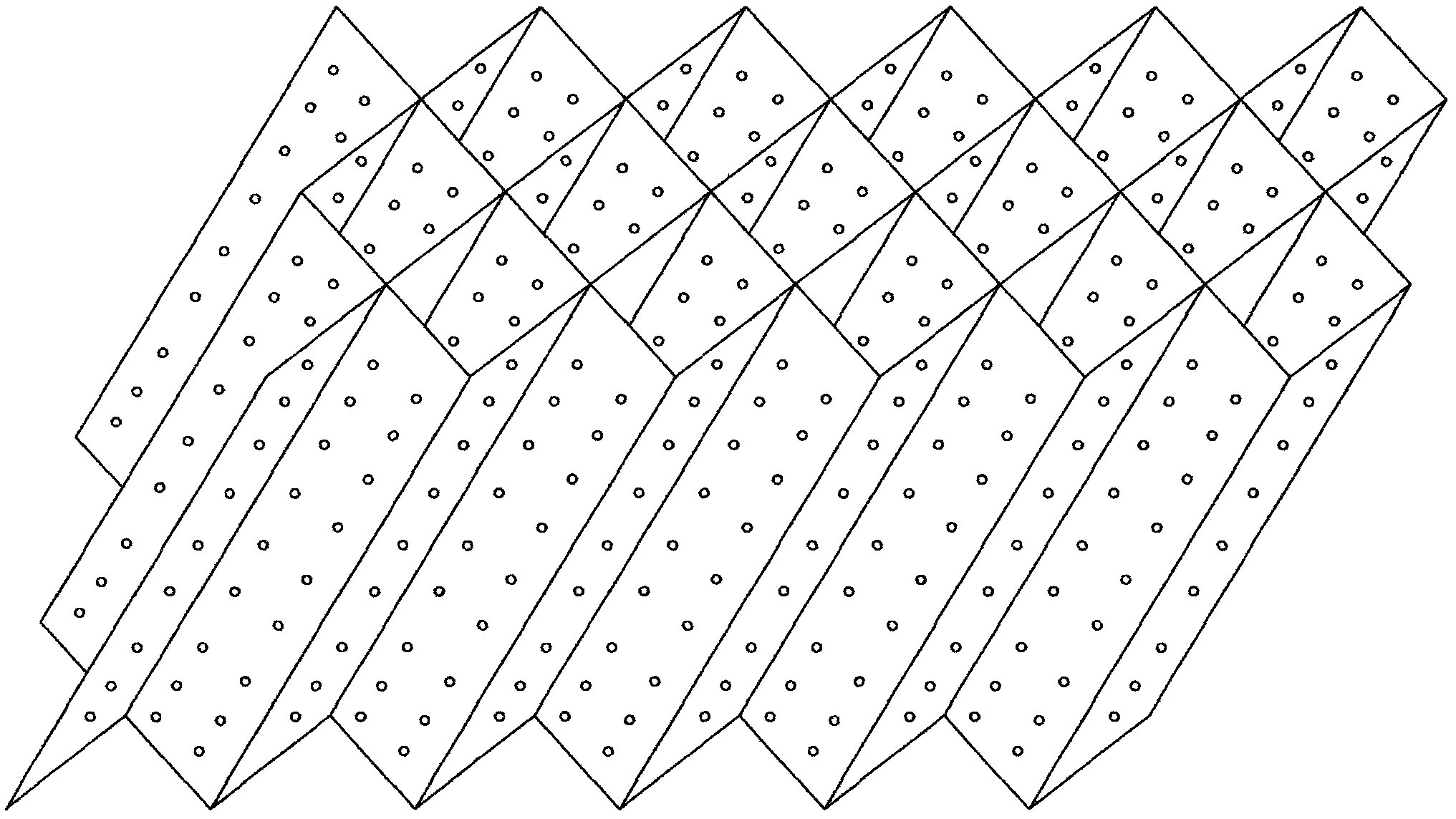

[0022] As the embodiment of the preparation method of polytetrafluoroethylene orifice corrugated packing of the present invention, as figure 1 and figure 2 shown, including the following steps:

[0023] (1) Press corrugated parison: inject powdery polytetrafluoroethylene raw material into the corrugated pressing mold, scrape it off with a knife when it is full, and then press it into a corrugated parison. The molding pressure is 20MPa. The pressure time is 5 minutes;

[0024] (2), parking: the corrugated parison that is pressed is taken out from the pressing mold, and placed in the natural environment for 15 hours;

[0025] (3), punching: putting the corrugated parison through step (2) into a punching die with the same corrugation, and punching;

[0026] (4) Sintering: put the punched corrugated parison into a sintering furnace for sintering, and divide it into a first heating stage and a second heating stage according to the heating rate of the sintering furnace, and the ...

Embodiment 2

[0032] As an embodiment of the manufacturing method of the polytetrafluoroethylene orifice corrugated filler of the present invention, the difference from Embodiment 1 is that the molding pressure is 30 MPa, and the holding time is 10 minutes; Take it out from the mold, and put it in the natural environment for 30 hours; the corrugation inclination of the corrugated parison is 45 degrees.

[0033] In this embodiment, the remaining steps and beneficial effects are consistent with those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0035] As an embodiment of the manufacturing method of the polytetrafluoroethylene orifice corrugated filler of the present invention, the difference from Embodiment 1 is that the molding pressure is 25 MPa, and the dwell time is 8 minutes; Take it out from the mold and put it in the natural environment for 24 hours; the corrugation inclination of the corrugated parison is 40 degrees.

[0036] In this embodiment, the remaining steps and beneficial effects are consistent with those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com