Manufacturing method of ultramicropore broadband flexible micro-perforated plate

A technology of micro-perforated plate and manufacturing method, which is applied in the field of vibration reduction and noise reduction, can solve the problems of not suitable, lack of flexibility of micro-perforated plate, small deformation, etc., and achieve the effect of high processing precision, compact structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Using MEMS technology to process a single crystal silicon template with a cylinder array diameter of 50um

[0017] (1) Use a square glass with a side length of 10cm to make a photolithographic plate, and the distribution density of the opaque circular patterns on the photolithographic plate is 5×10 7 piece / square meter;

[0018] (2) Choose a single-sided polished silicon wafer with a diameter of 4 inches and a crystal orientation of (100), with a thickness of 500 microns, then chemically clean the single-crystal polished silicon wafer, and then dry it;

[0019] (3) A 600nm thick silicon dioxide film and a 300nm thick metal aluminum film are sequentially grown and deposited on the polished surface of the single crystal silicon wafer;

[0020] (4) Spin-coat a layer of photoresist with a thickness of 2 microns on the metal aluminum film;

[0021] (5) After exposure, development, fixing, film hardening and other steps, the cylindrical array pattern on the ...

Embodiment 2

[0026] Example 2 Using the above-mentioned cylindrical array template to fabricate a flexible micro-perforated plate with an ultra-micro pore diameter of 50um

[0027] (1) Carry out chemical treatment to reduce the surface energy of the above-mentioned processed monocrystalline silicon cylinder array template, and dry after cleaning;

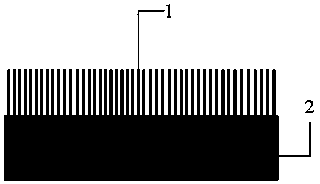

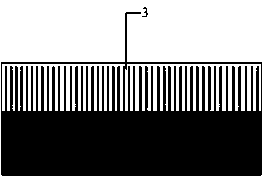

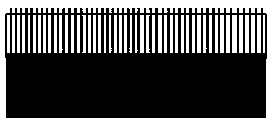

[0028] (2) The two-component polyether polyurethane, a flexible material configured in a liquid state and with a certain viscosity, is deposited on the surface of the cylindrical array template by spin coating or casting; see figure 2 , the gaps between the cylinder arrays are filled with flexible material two-component polyether polyurethane, and the flexible material 3 completely contains the cylinder array 2;

[0029] (3) Place the above template with the flexible material 3 in an oven with a set temperature of 80 degrees Celsius for about 30 minutes, so that the two-component polyether polyurethane flexible material deposited on the surfa...

Embodiment 3

[0032] Example 3 Using LIGA technology to process a template with a cylindrical array diameter of 100um

[0033] (1) Make an X-ray photolithography plate with Au as the absorber, so that the distribution density of the opaque circular patterns on the photolithography plate is 6×10 6 piece / square meter.

[0034] (2) Chemically clean single crystal polished silicon wafers and then dry them; single crystal silicon wafers can be single-sided polished or double-sided polished silicon wafers with any crystal orientation and any resistivity, and the diameter can be 2 inches to 4 inches. etc.; in this example, a single-sided polished silicon wafer with a diameter of 4 inches and a crystal orientation of (100) is selected, and the thickness is 500 microns;

[0035] (3) On the polished surface of the single crystal silicon wafer, a layer of conductive material nickel metal film is grown and deposited by radio frequency sputtering process, and its thickness is 300 nanometers;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com