High-performance Prussian blue @ graphite lithium battery composite cathode material and preparation method thereof

A composite positive electrode material, Prussian blue technology, applied in the direction of battery electrodes, graphite, secondary batteries, etc., can solve the problems of high cost, poor cycle stability, low Coulombic efficiency, etc., and achieve good conductivity, good conductivity, high power The effect of chemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

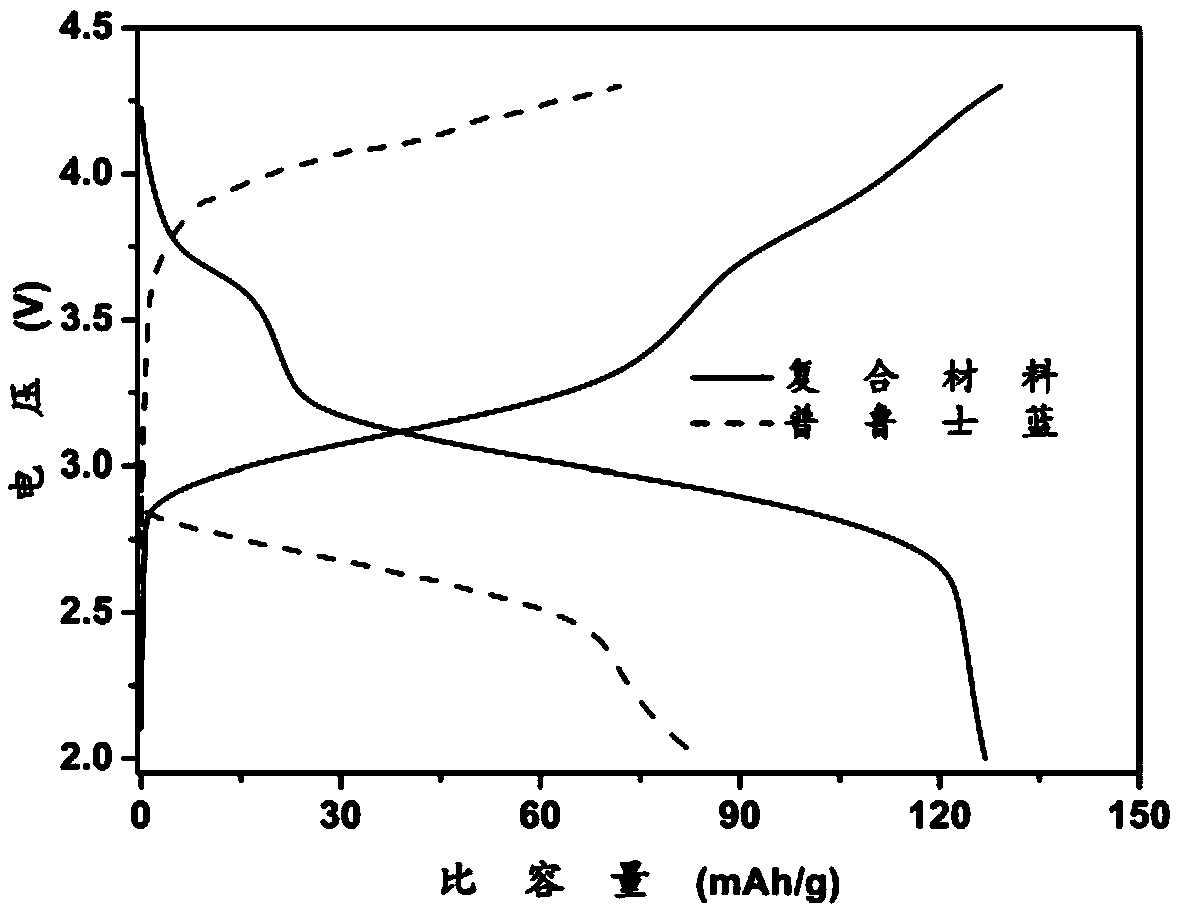

Image

Examples

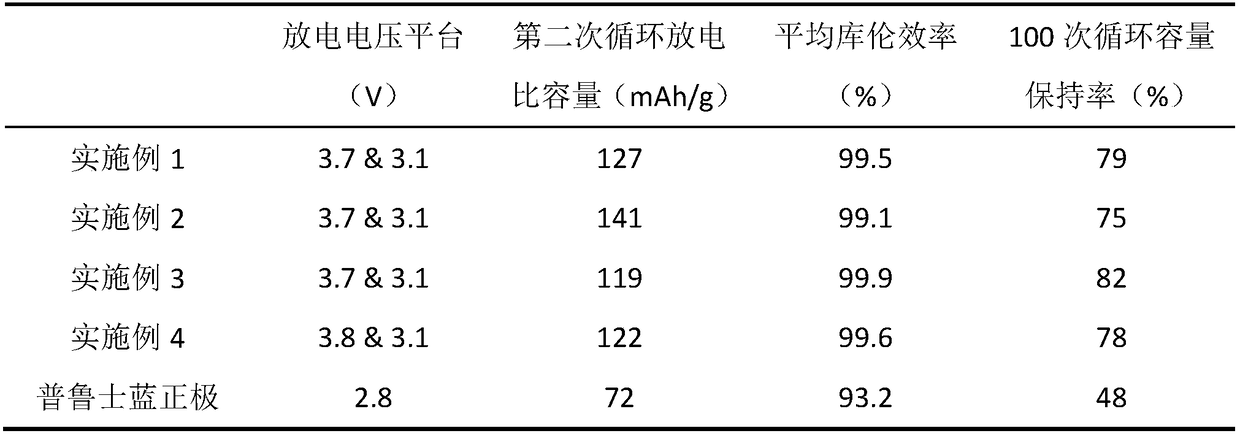

Embodiment 1

[0032] A method for preparing a high-performance Prussian blue@graphite lithium battery composite positive electrode material, comprising the following steps:

[0033] (1) In terms of parts by mass, 7 parts of natural graphite are added to 100 parts of deionized water, and ultrasonically dispersed for 1 hour to form a uniform natural graphite dispersion;

[0034] (2) In terms of parts by mass, dissolve 8.5 parts of potassium ferrocyanide and 4.3 parts of ferric chloride in the natural graphite dispersion obtained in step (1), stir vigorously at 65°C for 6h, and the stirring rate is 1000r / min , the resulting suspension was centrifuged, washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 90°C for 12 hours to obtain a composite material of Prussian blue and graphite;

[0035] (3) Mix the composite material obtained in step (2) with the binder polyvinylidene fluoride in a mass ratio of 90:10 to obtain a mixture, add solvent N-methylpyrrolido...

Embodiment 2

[0042] A method for preparing a high-performance Prussian blue@graphite lithium battery composite positive electrode material, comprising the following steps:

[0043] (1) In terms of parts by mass, 6 parts of natural graphite are added to 100 parts of deionized water, and ultrasonically dispersed for 1.5 h to form a uniform natural graphite dispersion;

[0044] (2) In terms of parts by mass, 8.5 parts of potassium ferrocyanide and 4.6 parts of ferric chloride were dissolved in the dispersion obtained in step (1), and vigorously stirred at 65°C for 6 hours at a stirring rate of 1000r / min. The resulting suspension was centrifuged, washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 90°C for 12 hours to obtain a composite material of Prussian blue and graphite;

[0045] (3) The composite material obtained in step (2) is mixed with the binder polytetrafluoroethylene in a mass ratio of 85:10 to obtain a mixture, and the solvent N, N-dimethyl...

Embodiment 3

[0048] A method for preparing a high-performance Prussian blue@graphite lithium battery composite positive electrode material, comprising the following steps:

[0049] (1) In terms of parts by mass, 8 parts of natural graphite are added to 100 parts of deionized water, and ultrasonically dispersed for 2 hours to form a uniform natural graphite dispersion;

[0050] (2) In terms of parts by mass, 8.5 parts of potassium ferrocyanide and 4.9 parts of ferric chloride were dissolved in the dispersion obtained in step (1), and vigorously stirred at 65°C for 6 hours at a stirring rate of 800r / min. The resulting suspension was centrifuged, washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 90°C for 12 hours to obtain a composite material of Prussian blue and graphite;

[0051] (3) Mix the composite material obtained in step (2) with the binder sodium carboxymethyl cellulose in a mass ratio of 85:10 to obtain a mixture, add solvent deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com