Rechargeable magnesium battery taking oxygen-containing organic matter as cathode material, and preparation method thereof

A technology for positive electrode materials and magnesium batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex preparation and achieve the effects of simple preparation process, safe system and rich raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

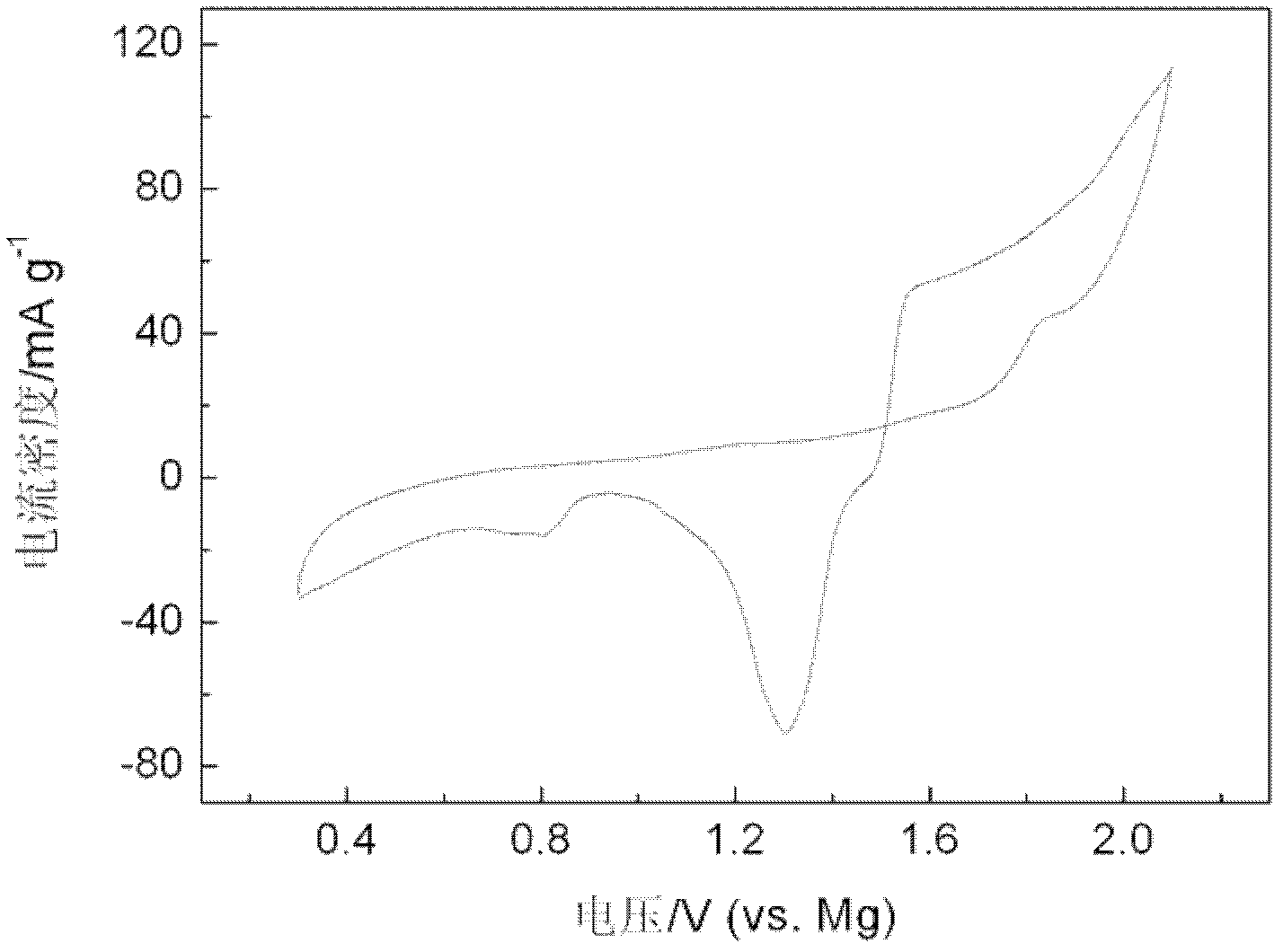

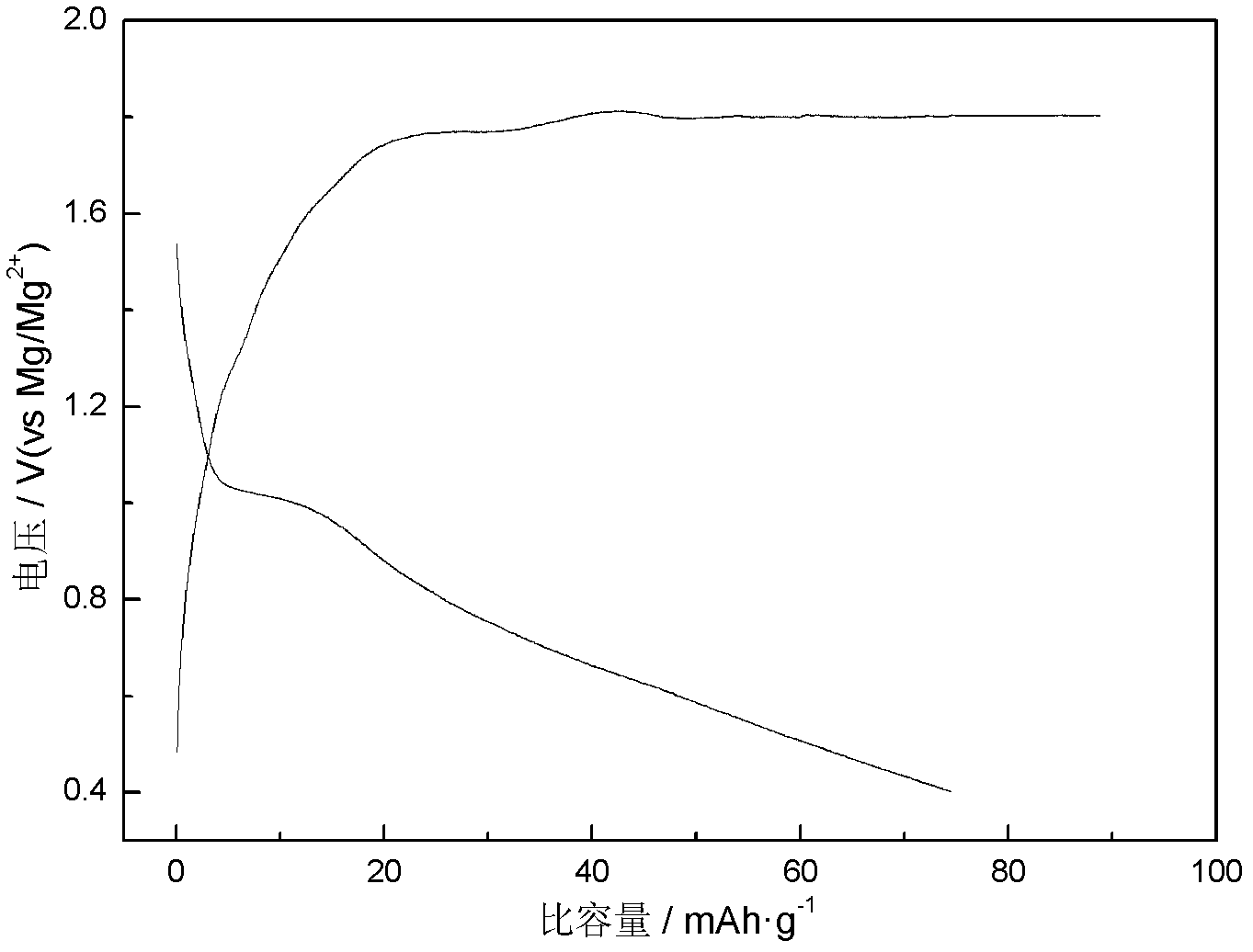

[0029] In 75mg of finely ground poly-4-methacrylic acid-2,2,6,6-tetramethylpiperidine-1-nitroxyl free radical ester, add 15mg of acetylene black as conductive agent, 10mg of polyvinylidene fluoride as adhesive Stir the binder evenly and coat it on the copper foil, put it in an oven with a temperature of 80°C and dry it, punch it into a pole piece with a punch with a diameter of 12mm, press it under a pressure of 1MPa, put it in a 100°C oven Dry in a vacuum oven for 4 hours to obtain a positive electrode sheet, which is then transferred to an argon glove box, with metal magnesium as the negative electrode, 0.25mol L -1 Mg(AlCl 2 BuEt) 2 / Tetrahydrofuran is used as the electrolyte to make a button-type rechargeable magnesium battery. Its cyclic voltammetry curve is as figure 1 As shown, the reduction potential of magnesium is around 1.3V and 0.8V. The charging and discharging test results are as follows: figure 2 As shown, the test charge and discharge current density is ...

Embodiment 2

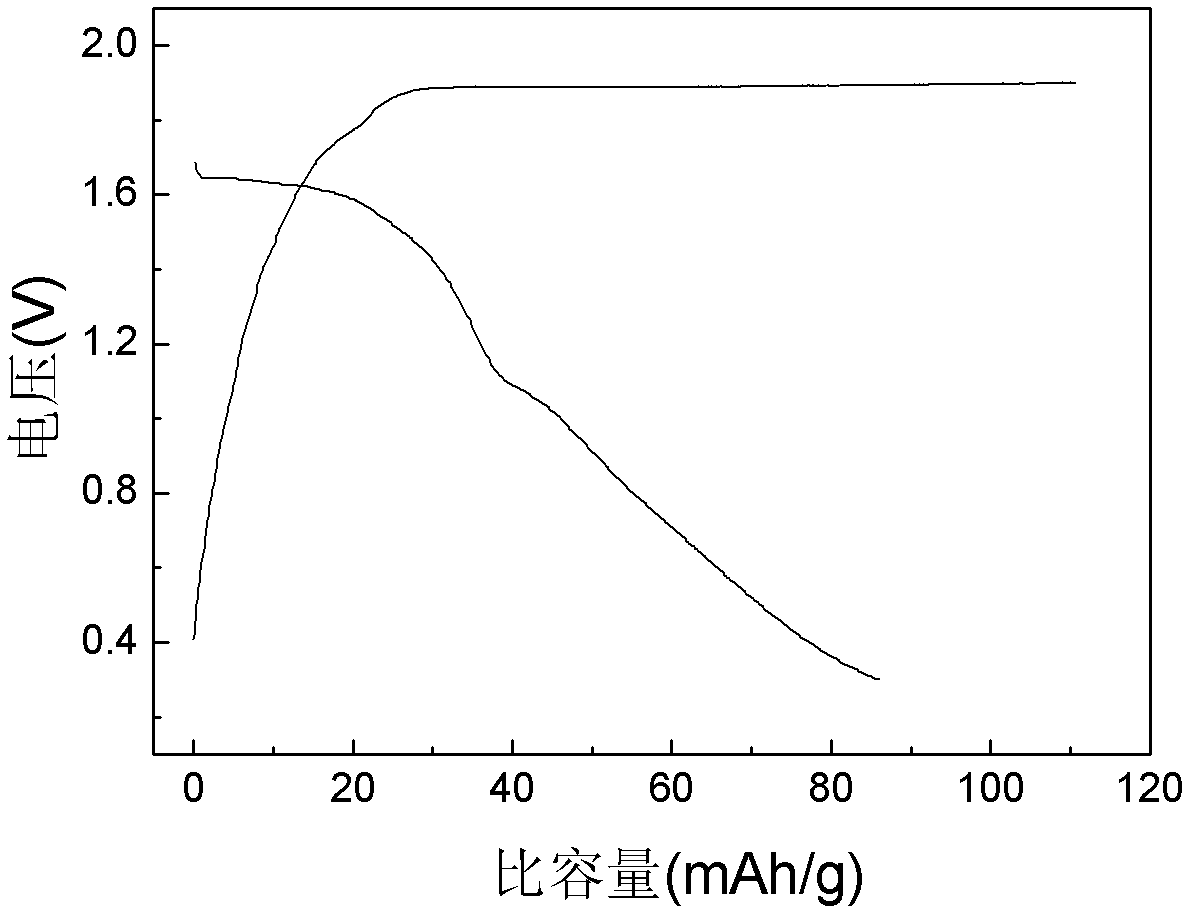

[0031] Add 15mg of acetylene black as a conductive agent and 10mg of polyvinylidene fluoride as a binder to 75mg of finely ground 3,4,9,10-perylenetetracarboxylic dianhydride, stir well and coat on copper foil , put it in an oven with a temperature of 80°C for drying, punch a pole piece with a punch with a diameter of 12mm, press it under a pressure of 1MPa, and dry it in a vacuum oven at 100°C for 4 hours to obtain a positive pole piece. Transfer to an argon glove box, use metal magnesium as the negative electrode, 0.25mol L -1 Mg(AlCl 2 BuEt) 2 / Tetrahydrofuran is used as the electrolyte to make a button-type rechargeable magnesium battery. Discharge capacity can reach 130mAh·g -1 .

Embodiment 3

[0033] Add 15 mg of acetylene black as a conductive agent and 10 mg of polyvinylidene fluoride as a binder to 75 mg of finely ground poly-3,4,9,10-perylenetetracarboxylic dianhydride ethylenediamine, stir evenly and coat On the copper foil, put it in an oven with a temperature of 80°C and dry it, punch it into a pole piece with a punch with a diameter of 12mm, press it under a pressure of 1MPa, and dry it in a vacuum oven at 100°C for 4 hours to obtain The positive electrode sheet was then transferred to an argon glove box, with metal magnesium as the negative electrode, 0.25mol L -1 Mg(AlCl 2 BuEt) 2 / Tetrahydrofuran is used as the electrolyte to make a button-type rechargeable magnesium battery. Discharge capacity can reach 160mAh·g -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com