Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Improve the mechanical properties of the weld" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

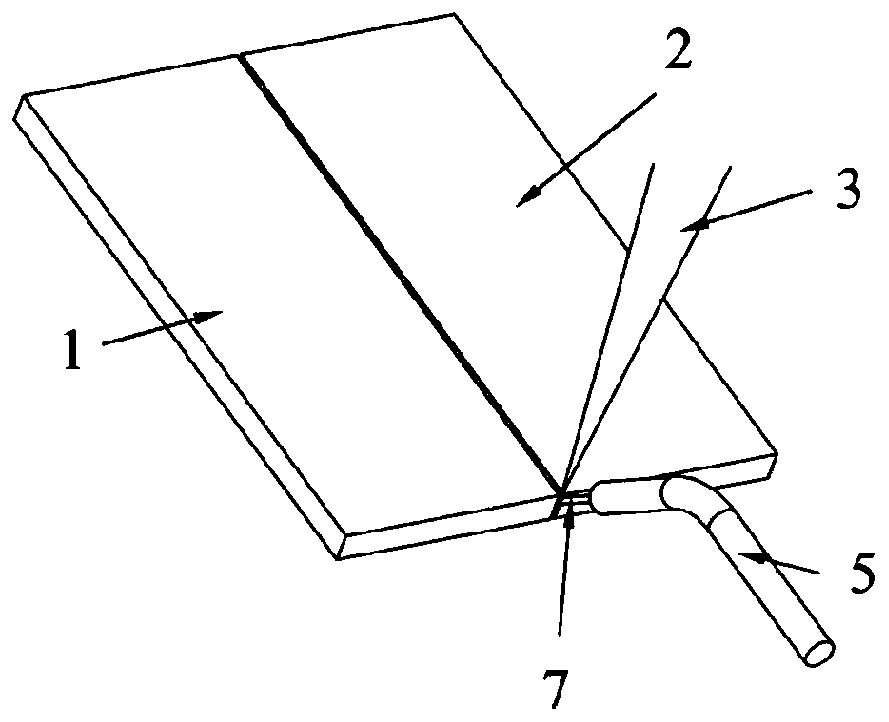

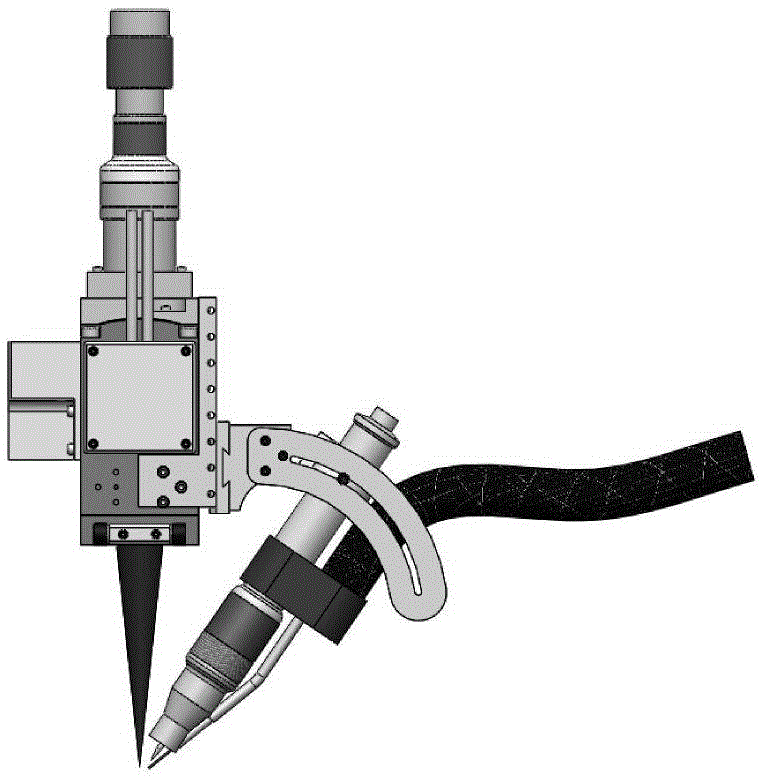

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

Welding medium entropy alloy material and welding method

ActiveCN109909643ADiffusion delays or even preventsAvoid formingWelding/cutting media/materialsSoldering mediaMetallic materialsAlloy

The invention discloses a welding medium entropy alloy material and a welding method, and relates to the technical field of welding materials. The medium entropy alloy material comprises CrCoNi and iscomposed of, by atomic percent, 20%-50% of Cr, 20%-50% of Co and 20%-50% of Ni, and the total percentage is 100%. The invention further discloses the welding method using the medium entropy alloy material for welding of metal materials, in particular to welding of dissimilar metal materials. The 'diffusion retardation' effect of the medium entropy alloy is utilized for delaying or even preventingdiffusion of dissimilar materials in the welding process, formation of various brittle intermediate phases is prevented, the mechanical properties of welds is greatly improved, involved elements arefew, preparation is simple, industrial production can be achieved easily, and meanwhile, the advantages of low cost and environmental friendliness are achieved.

Owner:SHANGHAI JIAO TONG UNIV

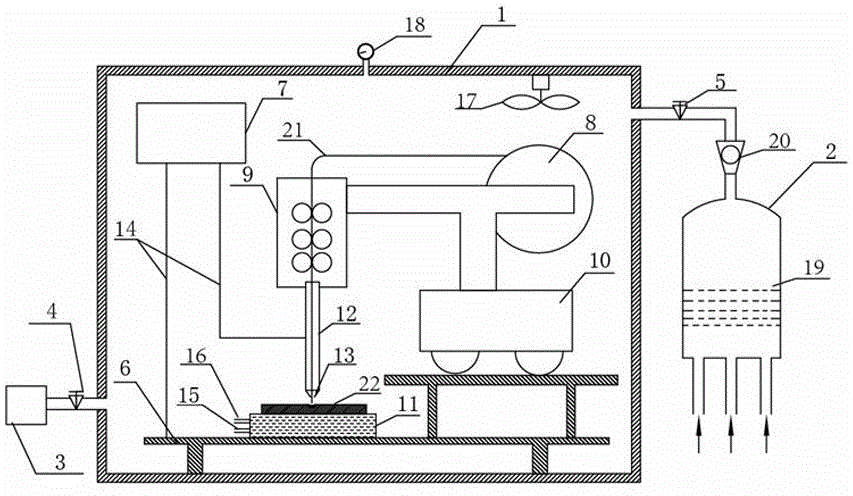

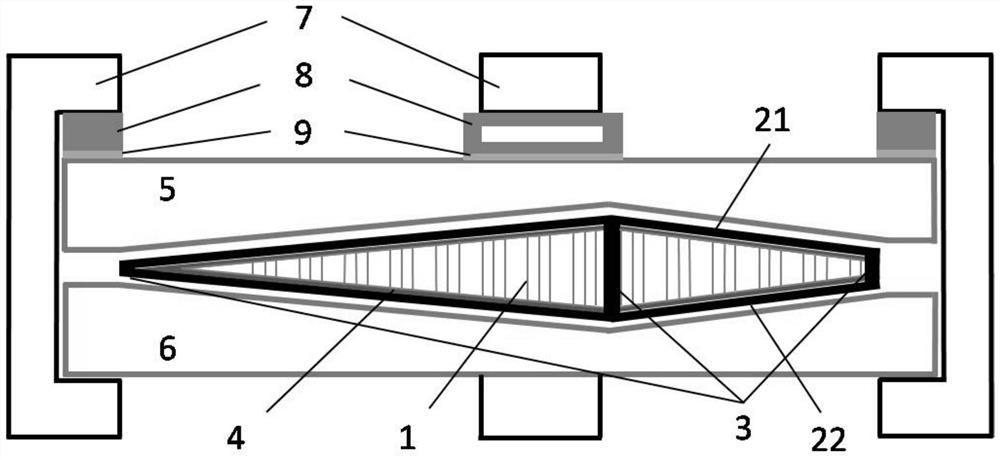

High-nitrogen steel pressure welding device and method for welding high-nitrogen steel by using same

InactiveCN106346171AImprove mechanical propertiesGood application effectWelding/cutting auxillary devicesAuxillary welding devicesWelding power supplyMixing chamber

The invention discloses a high-nitrogen steel pressurized welding device and a method for welding high-nitrogen steel by using the device, comprising an airtight welding chamber, a gas mixing chamber, and a vacuum pump; the airtight welding chamber communicates with the gas mixing chamber and the vacuum pump respectively through gas pipelines ;The airtight welding room is equipped with bracket, welding power supply, welding wire frame, wire feeding mechanism and welding torch; the cooling plate is arranged above the bracket; the welding wire sleeve is connected under the wire feeding mechanism; the welding power supply is connected with the welding wire sleeve and the bracket through electrode wires respectively The cold source is set in the cooling plate; the welding base metal is placed on the cooling plate; the raw material gas is mixed in the gas mixing chamber and then input into the airtight welding room; the position of the welding wire and the welding torch is adjusted, the welding power is turned on, and welding is carried out. By controlling the system shielding gas composition, system total pressure and cooling parameters, the nitrogen content in the high-nitrogen steel weld can be fixed, and the mechanical properties of the high-nitrogen steel weld can be improved. Using the system of the present invention for high-nitrogen steel welding, the nitrogen content of the weld can reach More than 95% of the base material.

Owner:SUZHOU UNIV

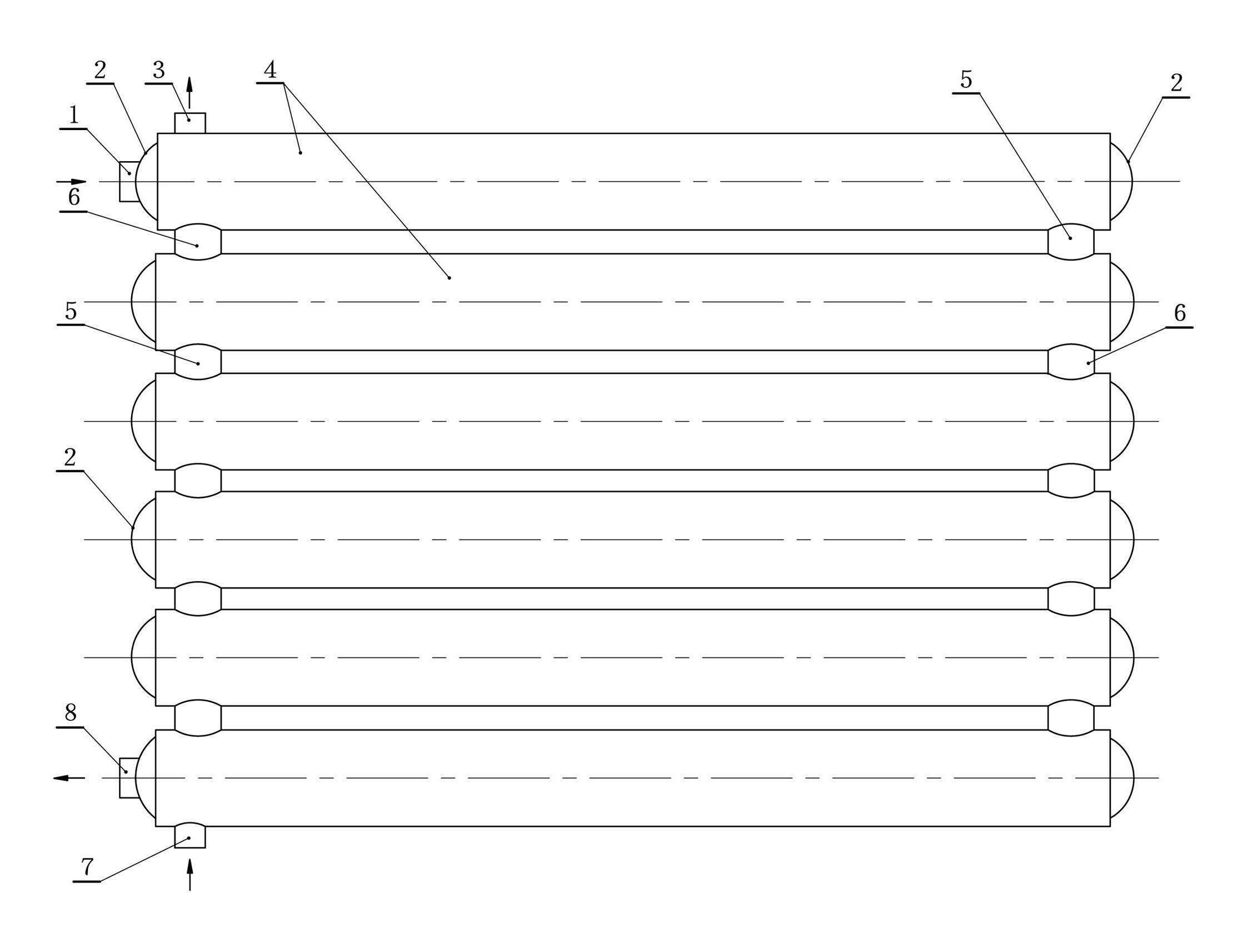

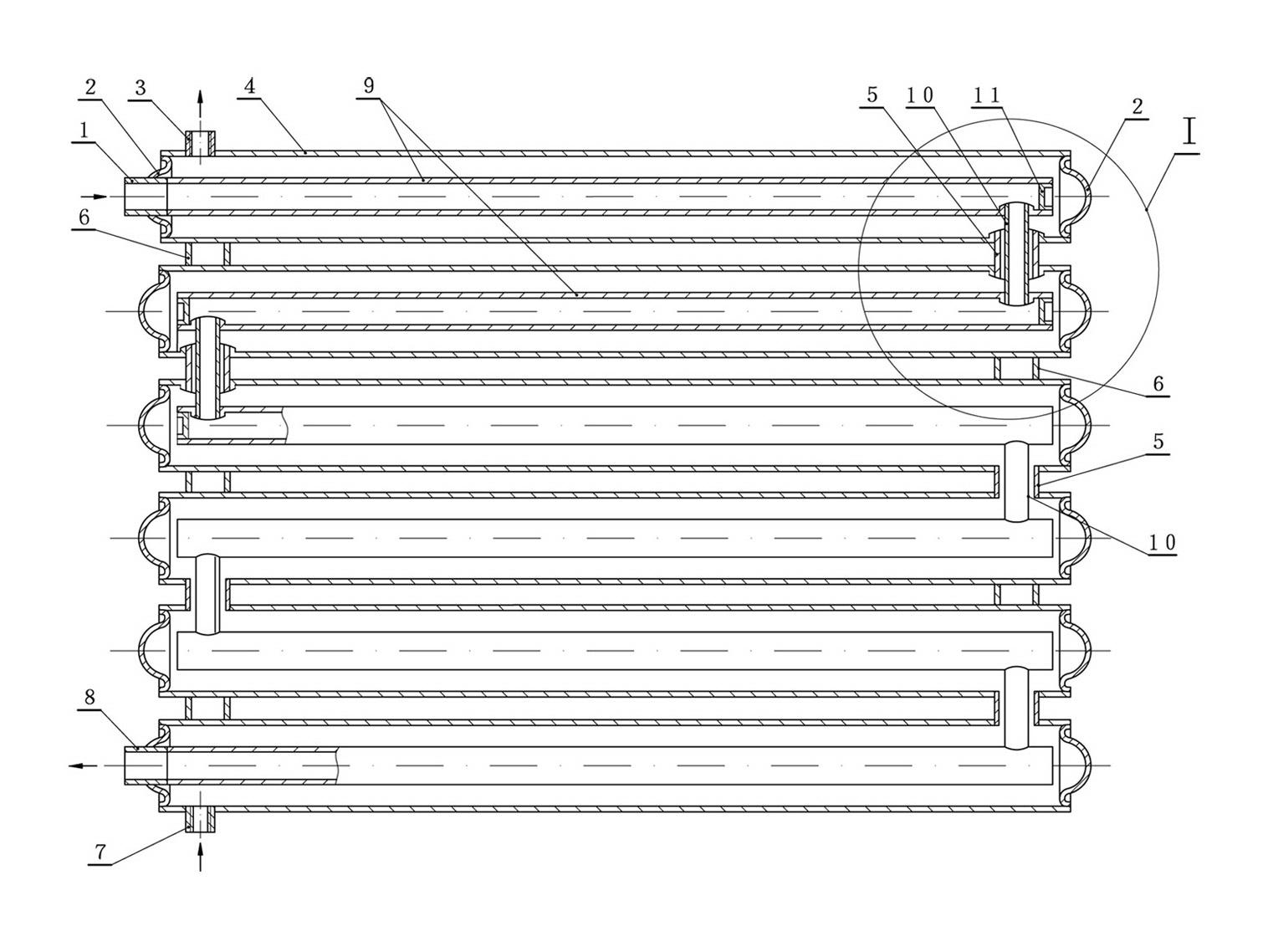

Pipe communication splice welding pressure-bearing type heat exchanger

InactiveCN102322754AIncrease heat transfer areaSolve the welding seam leakage rate is too highHeat exhanger sealing arrangementHeat exchanger casingsWater leakagePlate heat exchanger

The invention relates to a pipe communication splice welding pressure-bearing type heat exchanger, which comprises tap water heat absorption pipes. Heat supply pipes are arranged in the tap water heat absorption pipes. The tap water heat absorption pipes are communicated through tap water communication pipes. The heat supply pipes are communicated through heat supply pipe communication pipes. The seal heads of the tap water heat absorption pipes are outwardly flanged and embedded in the ports of the tap water heat absorption pipes. The flanges of the seal heads of the tap water heat absorption pipes and the port edges of the tap water heat absorption pipes are in splice bilateral alignment edge-kneading welding connection. The walls of the tap water heat absorption pipes are punched and inwardly flanged. The tap water communication pipes are inserted in the punches of the tap water heat absorption pipes. The port edges of the tap water communication pipes and the punched inward flanges of the tap water heat absorption pipes are in splice bilateral alignment edge-kneading welding connection. Heat supply pipe blocking plates are embedded in the ports of the heat supply pipes. The heat supply pipe blocking plates are outwardly flanged. The outward flanges of the heat supply pipe blocking plates and the port edges of the tap water heat absorption pipes are in splice alignment edge-kneading welding connection. According to the pipe communication splice welding pressure-bearing type heat exchanger disclosed by the invention, two technical defects of higher water leakage ratio of the welding line and incapability of continuously producing hot water of the original patent product can be solved; and the heat exchanger has the advantages of no leakage and continuous hot water production.

Owner:张伟

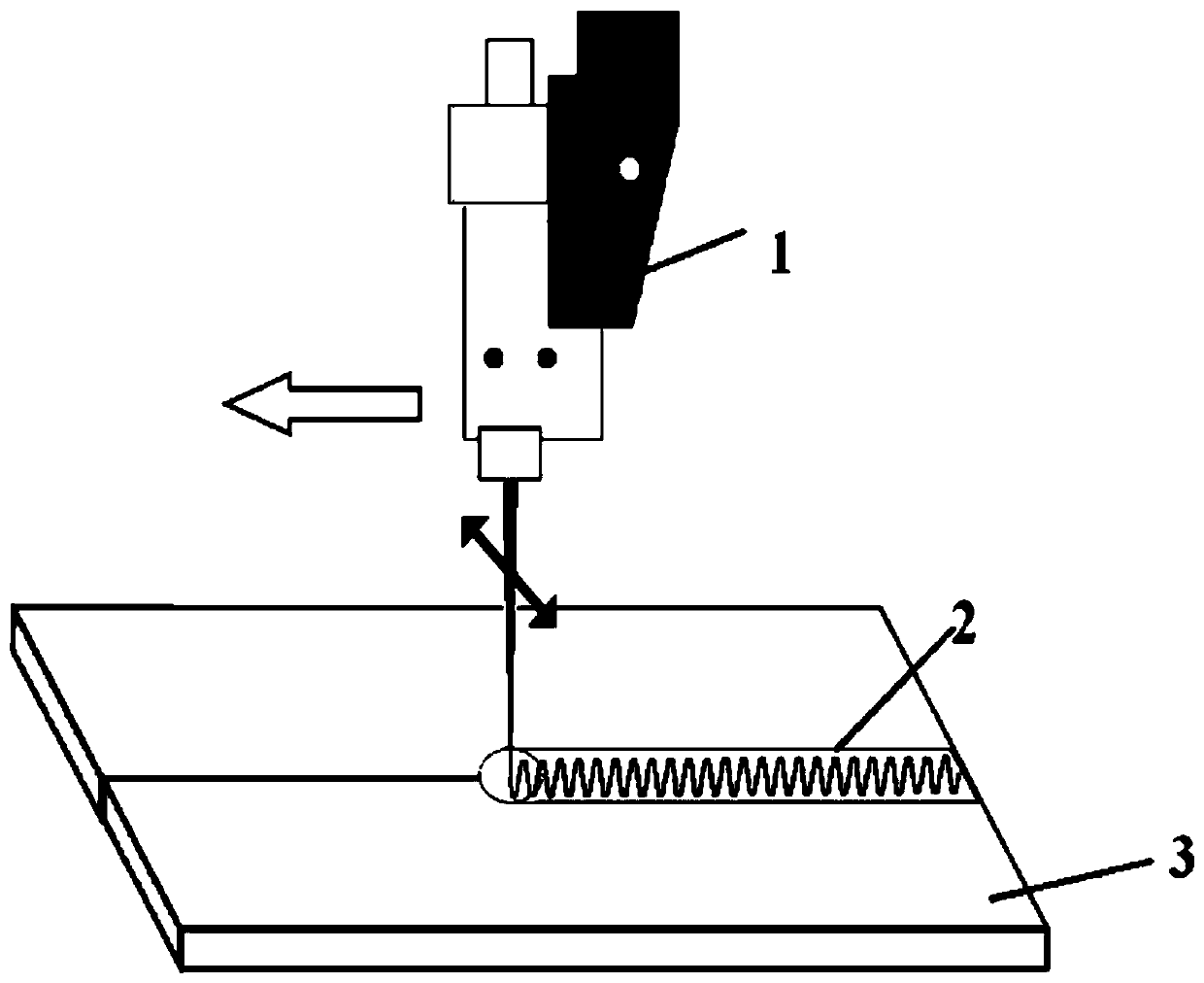

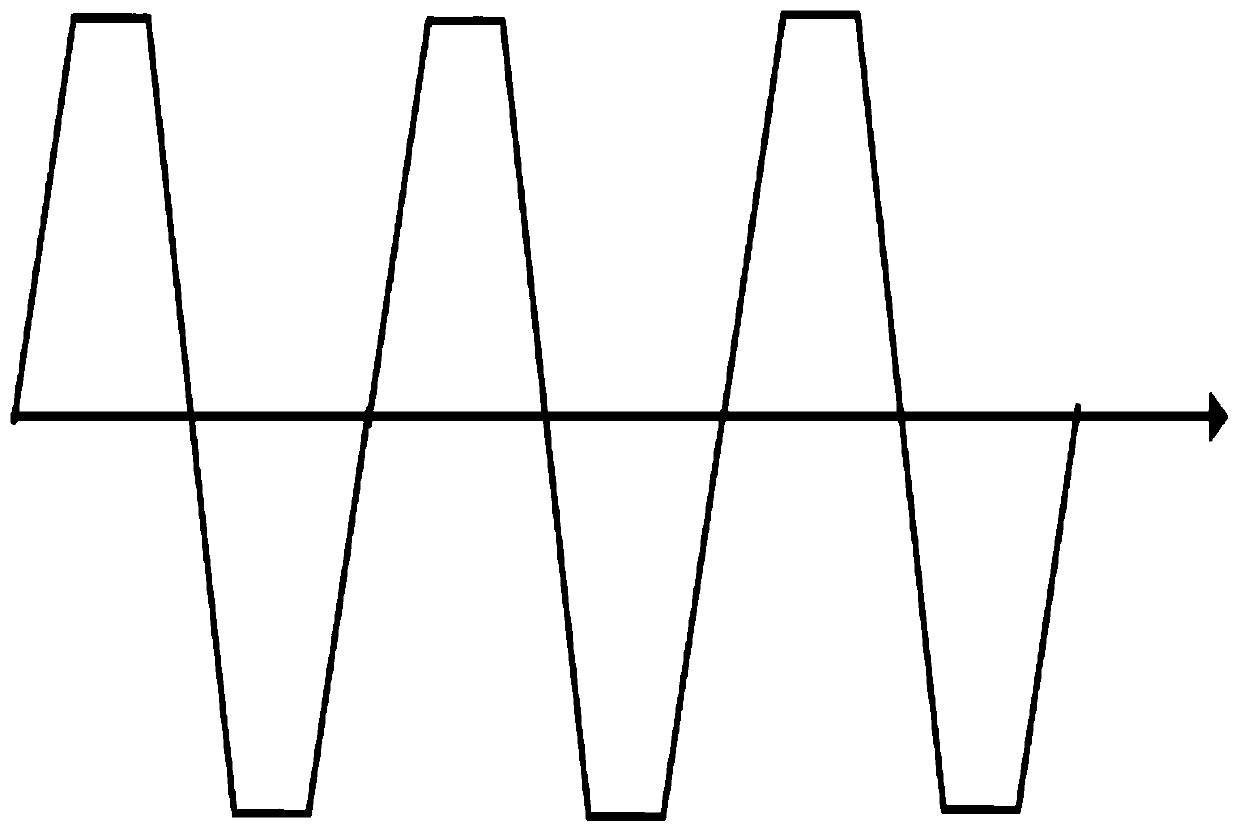

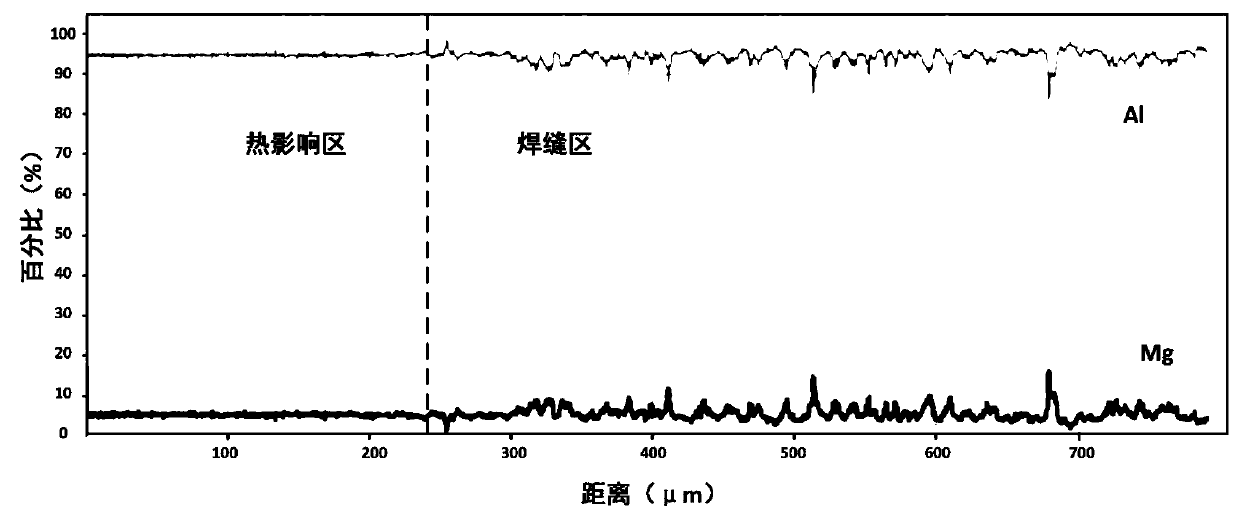

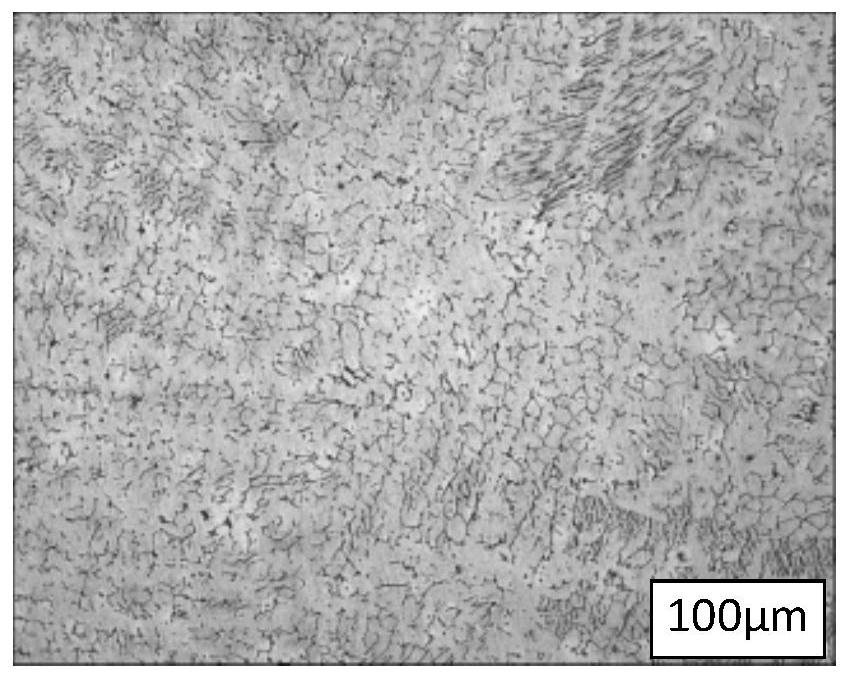

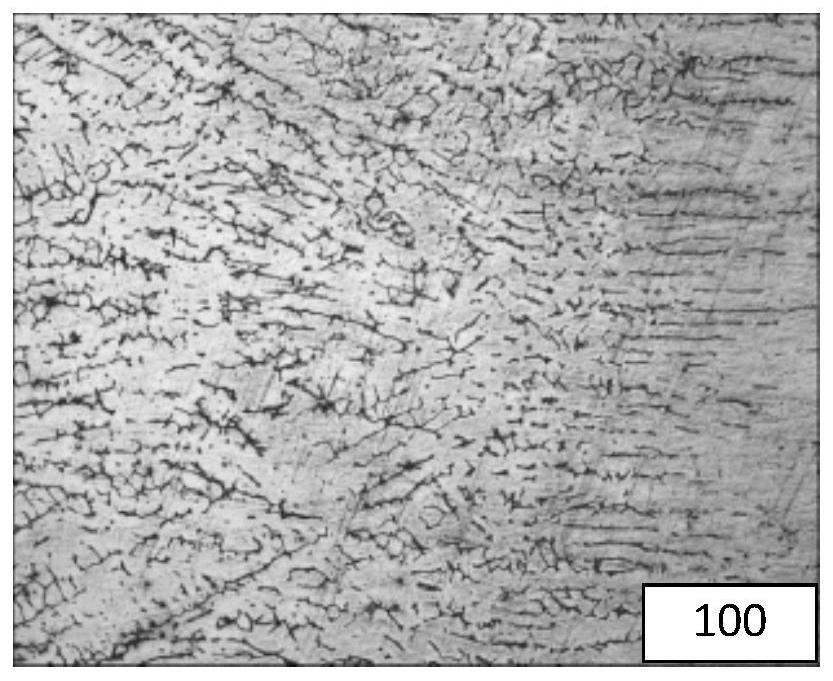

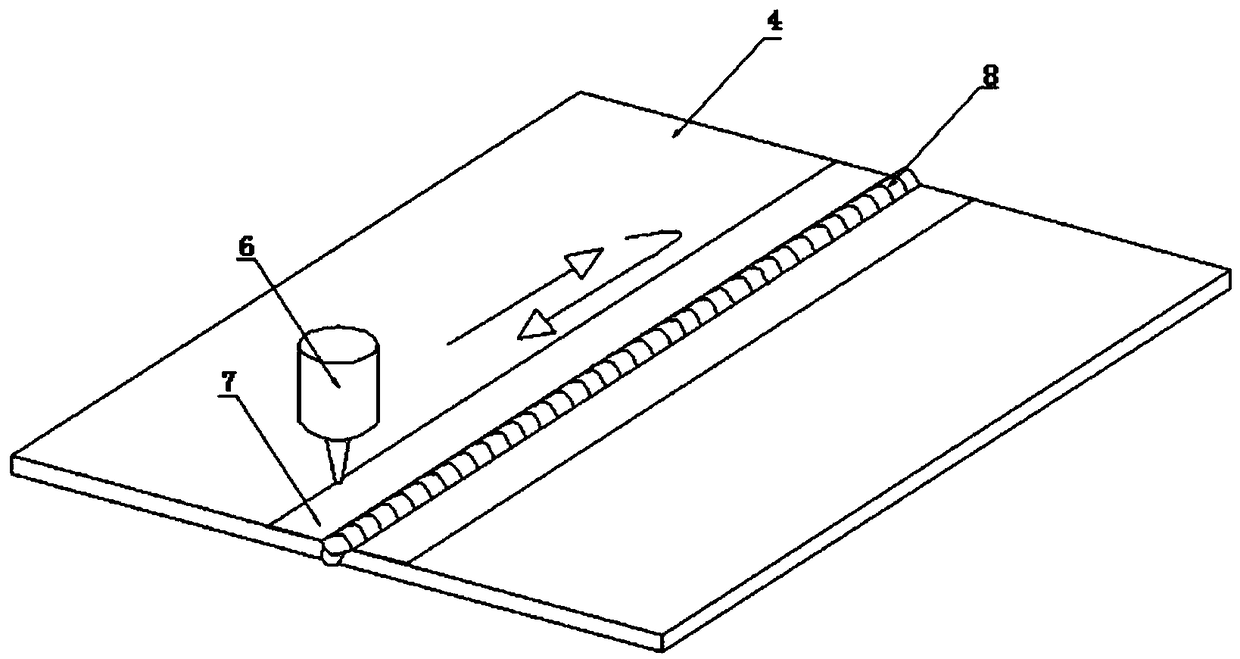

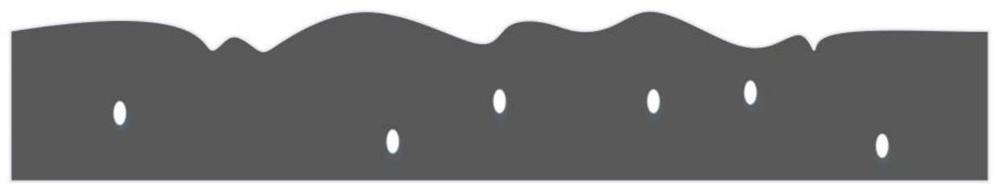

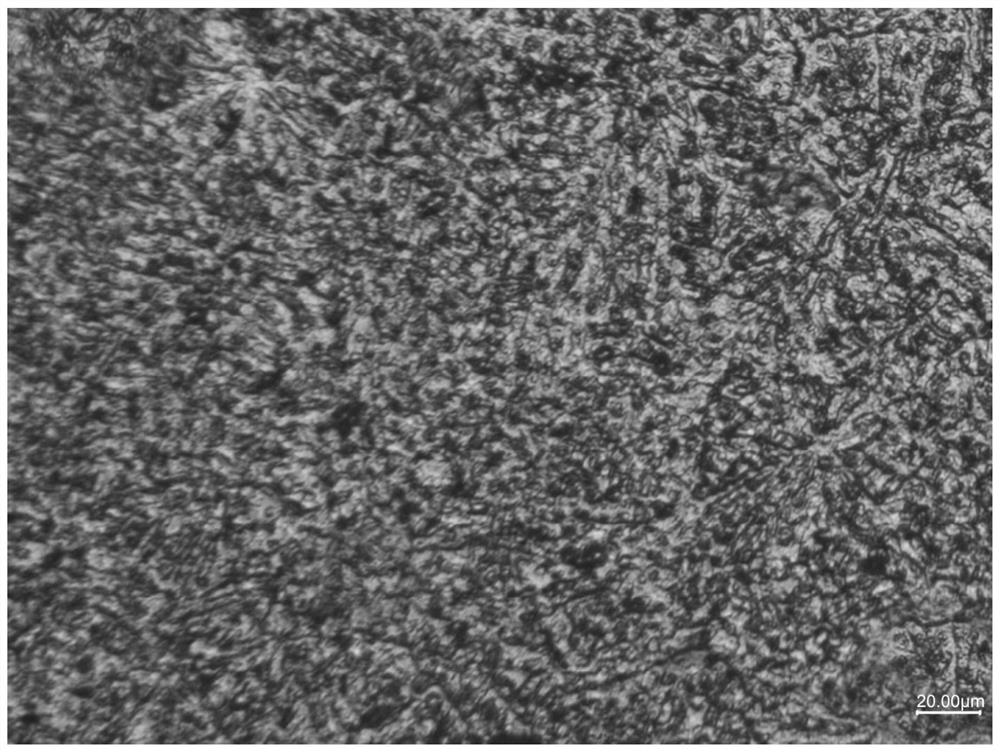

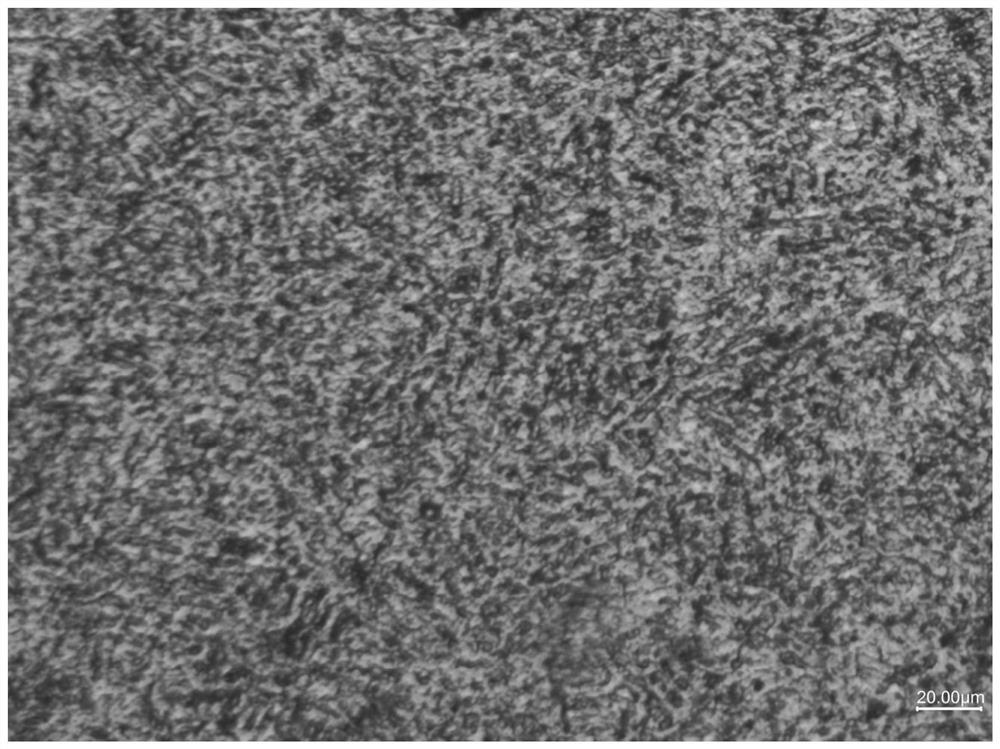

Homogenized Al-Mg series aluminum alloy weld microstructure laser welding method

InactiveCN110153557AAchieve homogenizationImprove efficiencyLaser beam welding apparatusBeta phaseShielding gas

The invention provides a homogenized Al-Mg series aluminum alloy weld microstructure laser welding method. The homogenized Al-Mg series aluminum alloy weld microstructure laser welding method comprises the following steps that (1), pre-welding polishing is carried out, wherein a weld center area is firstly mechanically ground, oxide skin on the weld surface is taken out, and acetone is used for wiping oil stains or other impurities; (2), pre-welding parameter adjustment is carried out, wherein a laser head of a laser device is aligned to the place, needing to be welded, of a workpiece, and theheight is adjusted; and (3), waveform welding is carried out, wherein the position needing to be welded is welded, protective gas is used for protection, laser beams advance in the weld direction inparallel, in the advancing process, a galvanometer is used for making the oscillating laser beams symmetrically move back and forth on the two sides in the welding direction, and the light spot motiontrajectory is a square wave path. In the welding process, oscillating of the laser beams can agitate a molten pool and delay solidification in the molten pool, Mg elements in the weld are uniformly distributed, the beta phase (Mg2Al3) is uniformly precipitated, the weld microstructure homogenization is achieved, and the weld mechanical properties are improved.

Owner:HUST WUXI RES INST

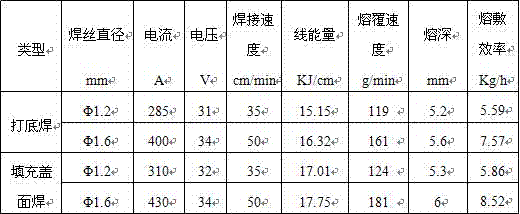

Method for automatically welding hydraulic support structural component through welding wires with diameter being 1.6 mm

ActiveCN106914686AMeet the requirements of the weldSolve serious burn damageArc welding apparatusFillet weldButt welding

The invention discloses a method for automatically welding a hydraulic support structural component through welding wires with the diameter being 1.6 mm. The method includes the steps that firstly, the part tolerance and the splicing precision of the hydraulic support structural component are checked before welding, and the depth tolerance of a welding groove and the angle tolerance of the welding groove are controlled; secondly, the two sides of a weld bead are ground before welding till metallic luster appears; thirdly, all to-be-welded weld joints of the hydraulic support structural component are located at flat welding or flat fillet welding positions; fourthly, off-line programming or on-site programming teaching is conducted on a welding robot; and fifthly, multi-layer and multi-channel welding is conducted on the to-be-welded weld joints through the welding robot by means of the welding wires with the diameter being 1.6 mm in a gas shielded welding manner. According to the method, robot welding is conducted through the welding wires with the diameter being 1.6 mm, and compared with traditional welding conducted through welding wires with the diameter being 1.2 mm, under the condition that the ton cost of the welding wires is not changed and all mechanical properties of the weld joints can meet requirements, the weld penetration of the weld joints is increased, efficiency is improved by 40% or above, and the comprehensive cost of welding conducted through each ton of welding wires is saved by RMB 1500 yuan or above.

Owner:ZHENGZHOU COAL MINING MACHINERY GRP

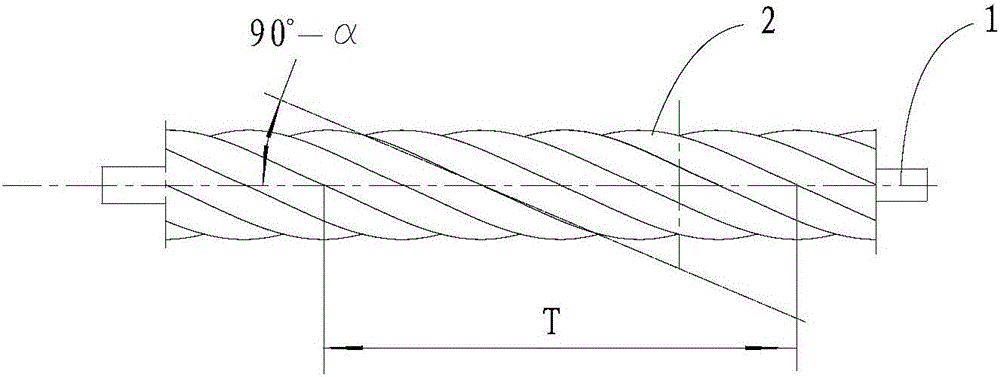

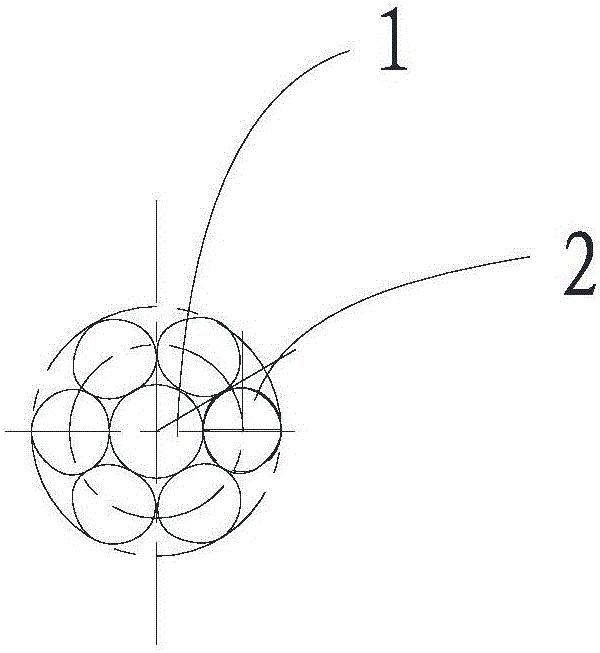

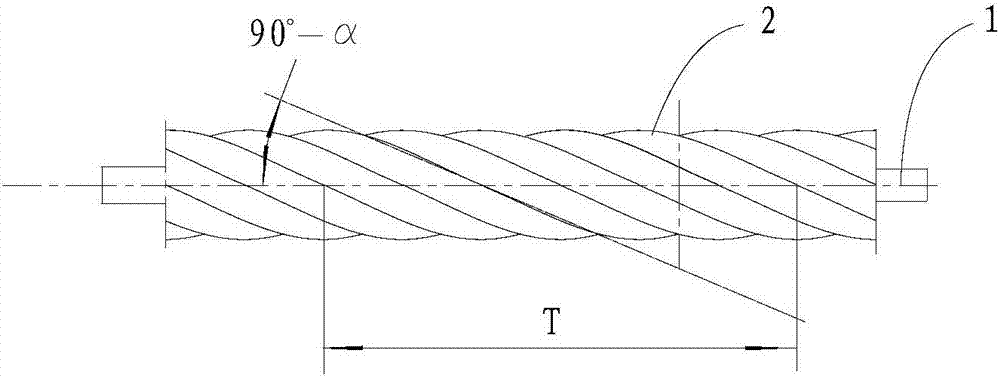

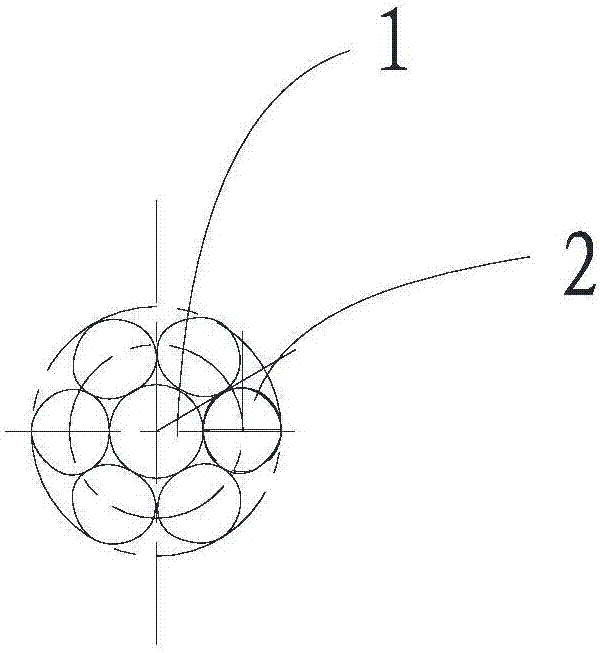

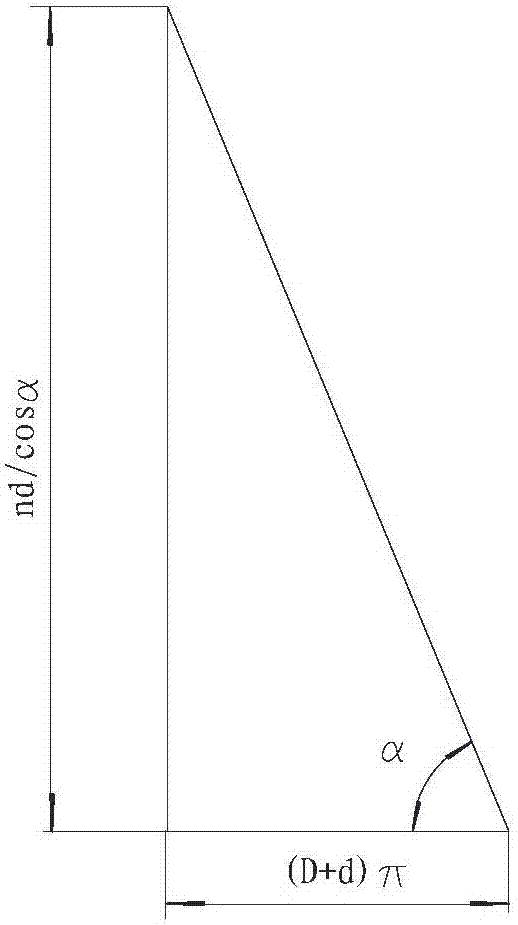

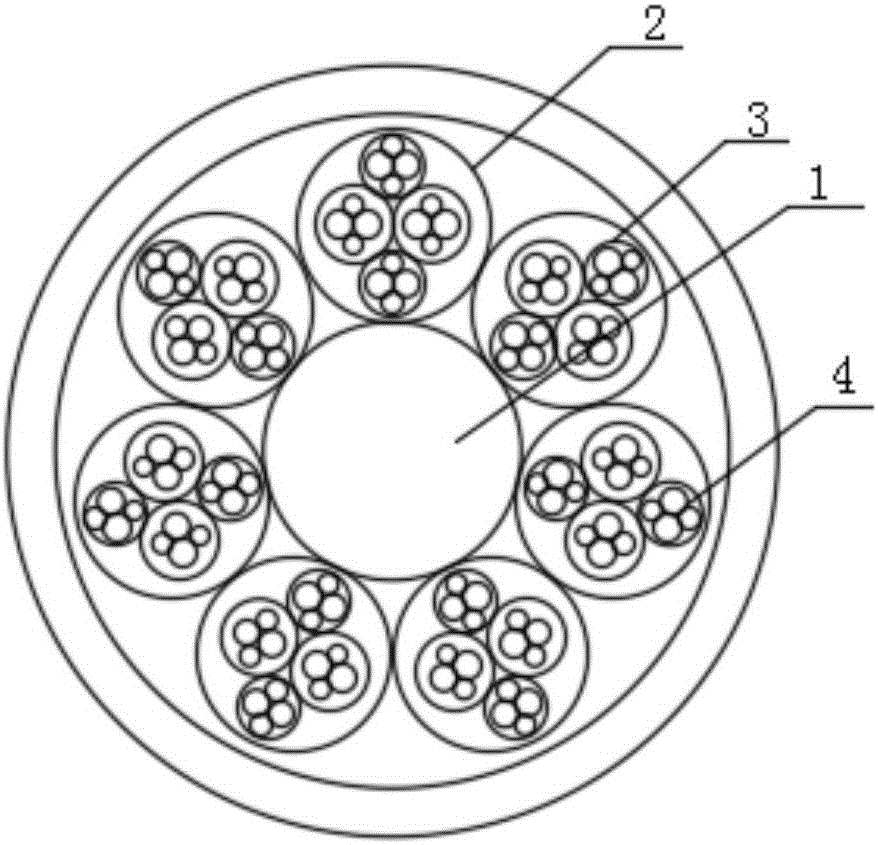

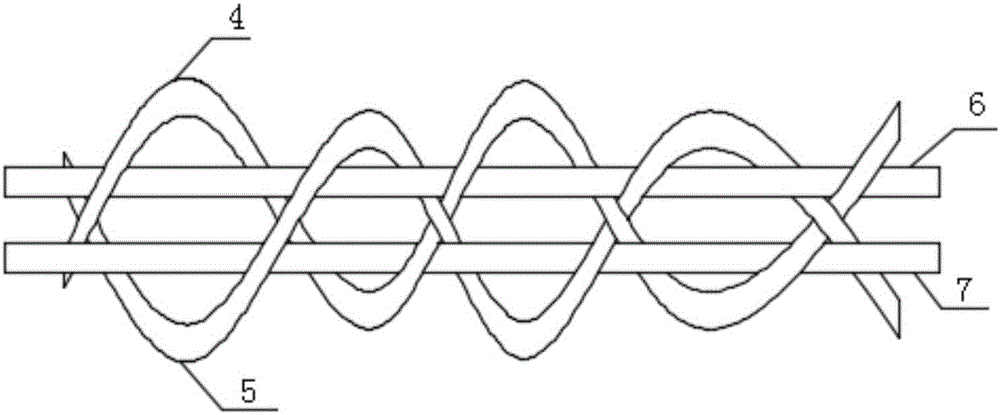

Cable type welding wire

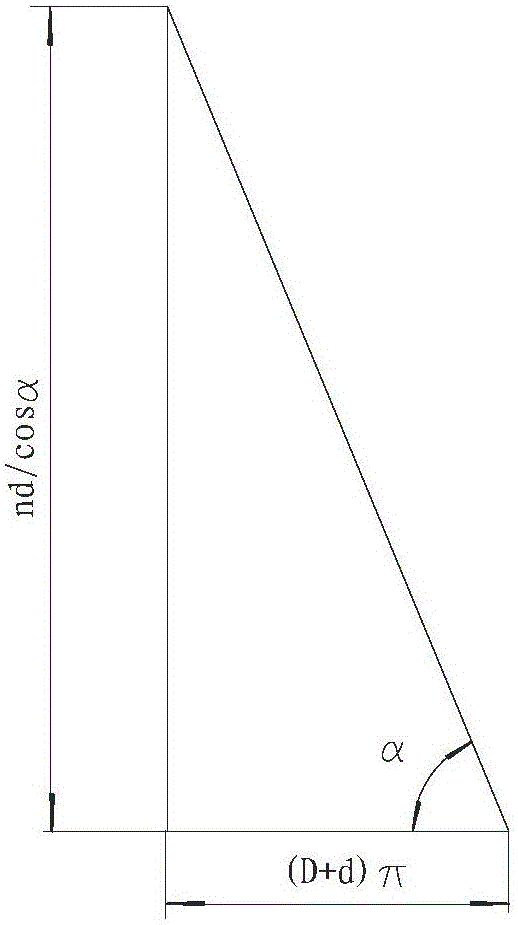

ActiveCN105665955AStable weldabilityImprove the pass rate of twistingWelding/cutting media/materialsSoldering mediaStructure factorWire breakage

The invention provides a cable type welding wire. The cable type welding wire comprises a center welding wire and n peripheral welding wires arranged around the center welding wire in a spiral rotating manner, wherein the diameter of each of the peripheral welding wires is d, and the neighboring peripheral welding wires are separately arranged in an intersecting manner. The cable type welding wire is characterized in that the lay length T of each of the peripheral welding wires is equal to K*m*d, wherein K is the structure factor of the peripheral welding wires, m is the lay length multiple, and d is the diameter of each of the peripheral welding wires; K is larger than or equal to 1, and less than or equal to 1.5; m is larger than or equal to 20, and less than or equal to 25. According to the cable type welding wire provided by the invention, wire breakage is not liable to generate in the manufacturing process; during welding, the peripheral welding wires are arranged compactly, so that the wire feeding process is more stable, and the welding performance of the cable type welding wire is improved.

Owner:SUZHOU YINLI WELDING IND TECH CO LTD

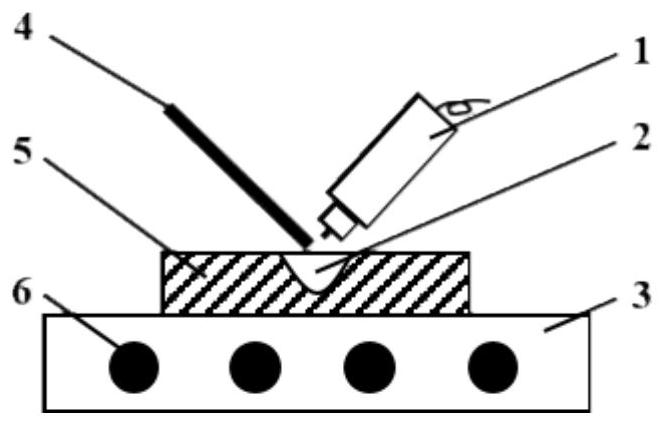

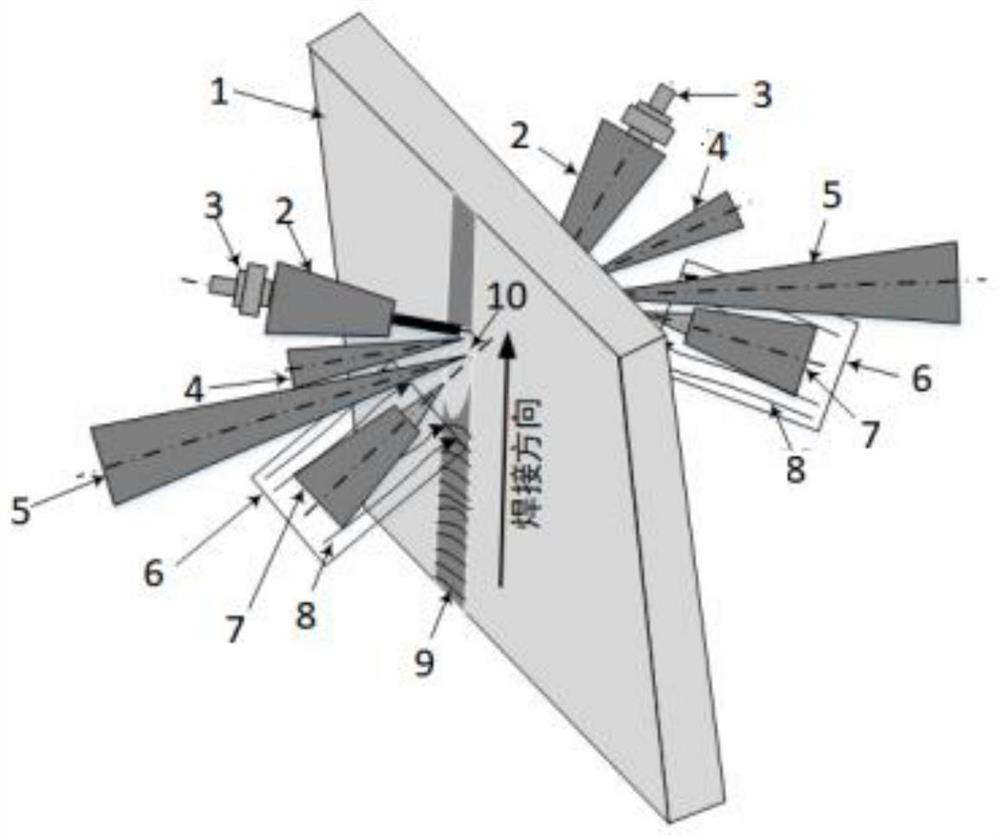

Laser-TOPTIG hybrid welding method

ActiveCN104014933AReduce wire feeding accuracySimplify operating proceduresLaser beam welding apparatusShielding gasCarbon Dioxide / Helium

The invention relates to a laser-TOPTIG hybrid welding method. The laser-TOPTIG hybrid welding method includes the following steps: firstly, polishing or cleaning the surface of a workpiece to be welded, and installing a clamp; secondly, setting geometrical parameters; thirdly, setting welding parameters of laser-TOPTIG hybrid welding; fourthly, turning on a control switch, leading in shielding gas, then igniting an electric arc, emitting lasers after 1.0 s to 2.0 s, feeding a welding wire to the area at the highest temperature under mutual effects of laser beams and the electric arc, and then moving a laser device and a welding gun together to carry out laser-TIG electric arc welding. By means of the welding method, an operational program is simplified, efficiency is improved, the welding accuracy and the welding stability are guaranteed, and the welded joint quality is improved.

Owner:HARBIN INST OF TECH

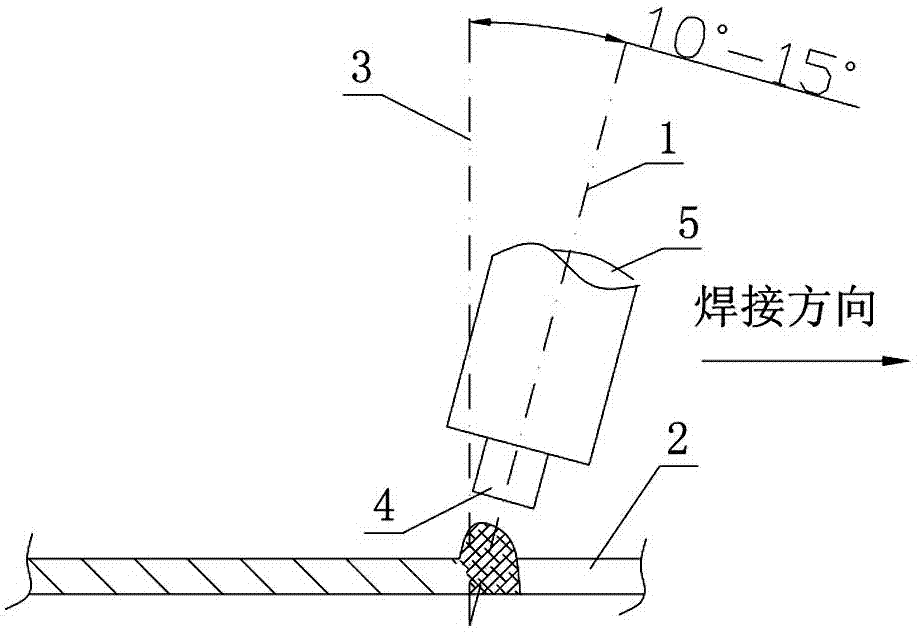

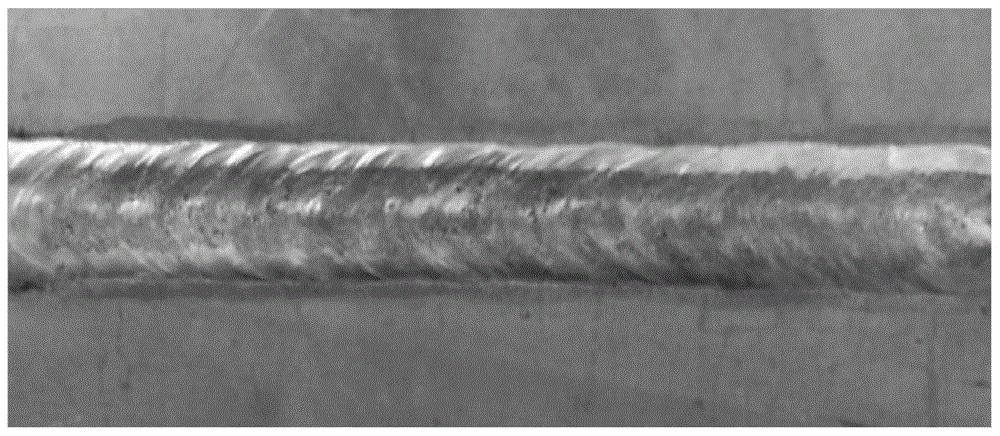

Method for welding single-arc double-wire pipelines

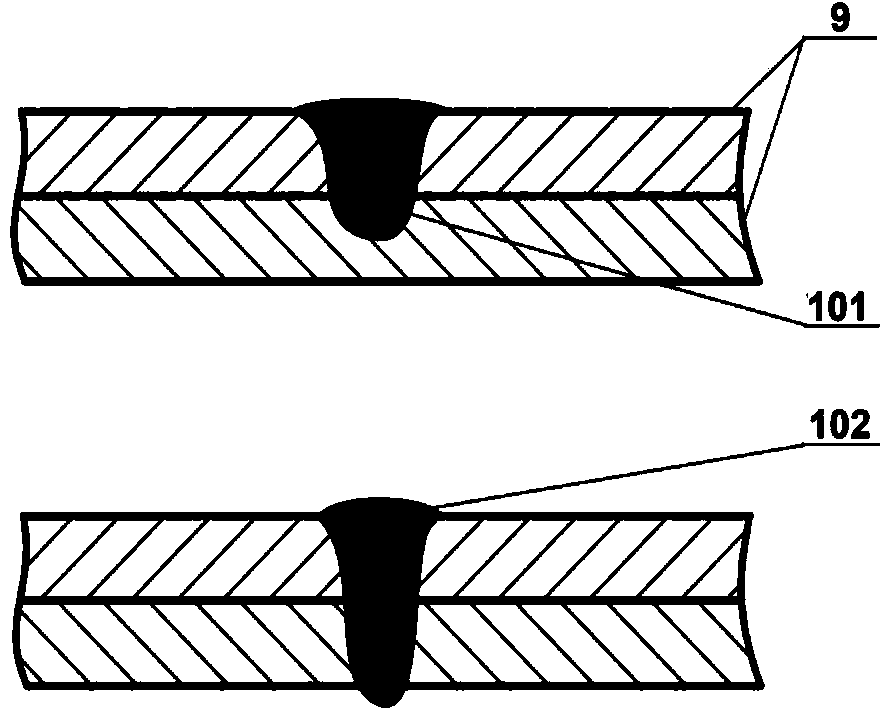

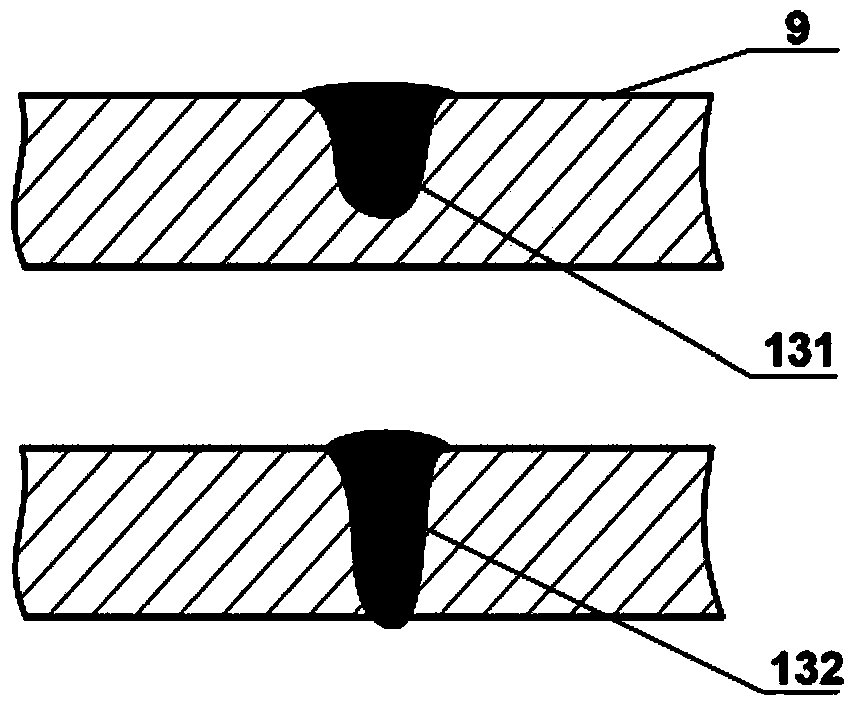

ActiveCN102615395AImprove welding efficiencyImprove the mechanical properties of the weldArc welding apparatusWorkpiece edge portionsHeat-affected zoneEngineering

The invention discloses a method for welding single-arc double-wire pipelines, and belongs to the technical field of welding of oil and gas pipelines. The method comprises the following steps of: processing grooves at pipe ends of two pipelines to be welded respectively, and butting the grooves of the two pipelines through a butting function of an internal welding machine; setting welding working parameters of the internal welding machine and an all-position automatic welding machine for the single-arc double-wire pipelines; preheating pipe orifices to be welded to over 50 DEG C, performing root welding on the pipe orifices to be welded by using the internal welding machine; performing hot welding, filling welding and cosmetic welding from inside to outside on the pipe orifices subjected to the root welding by using the all-position automatic welding machine for the single-arc double-wire pipelines until the circumferential surface of a welding seam is not lower than the surfaces of the outer walls of the pipelines; and performing filling welding on a plurality of layers, wherein the filling welding height of each layer is not less than 4 mm. By the method for welding the single-arc double-wire pipelines, the welding efficiency of large-caliber thick-wall pipelines can be effectively increased, and the method has the advantages of high welding deposition efficiency, high welding speed, small heat input, stable heat affected zone and high welding seam mechanical properties.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

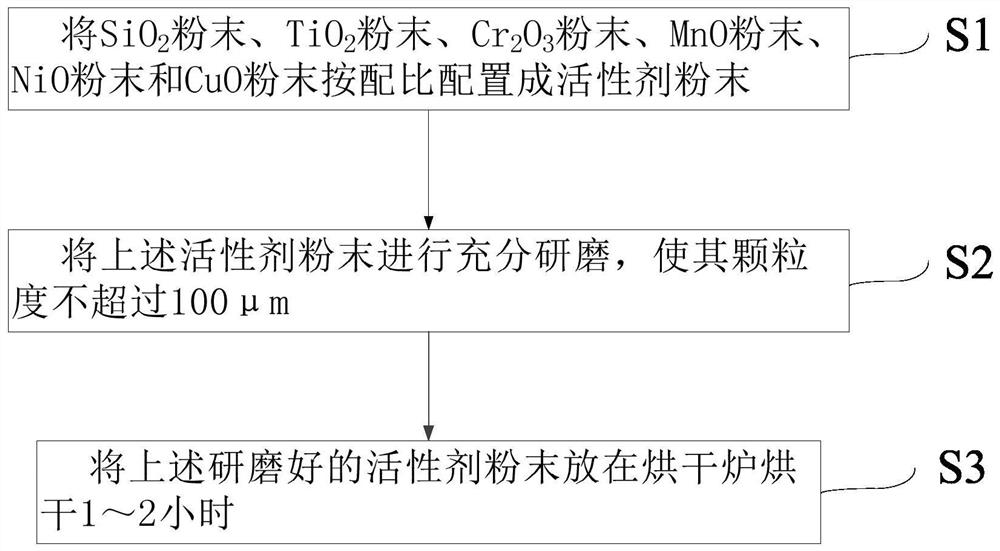

Stainless steel argon tungsten-arc welding active agent and preparation method and application thereof

InactiveCN111604618AQuality improvementLow costArc welding apparatusWelding/cutting media/materialsActive agentSS - Stainless steel

The invention belongs to the field of active agents for welding, and particularly relates to a stainless steel argon tungsten-arc welding active agent and a preparation method and application thereof.The stainless steel argon tungsten-arc welding active agent is prepared from the following components in percentage by weight: 35-45% of SiO2 powder, 20-25% TiO2 powder, 8-12% of Cr2O3 powder, 5-10%of MnO powder, 5-10% of NiO powder and 10-15% of CuO powder. The stainless steel argon tungsten-arc welding active agent does not contain precious metal, is low in cost, is non-poisonous and environmentally friendly, compared with methods such as general argon tungsten-arc welding, and the efficient active agent performs A-TIG welding on stainless steel and has the advantages of deep weld penetration, high production efficiency and reliable quality. The active agent is coated on the surface to be welded, the weld penetration is increased, the welding joint mechanical performance is obviously improved at the same parameter, 13mm welding by one side and molding by two sides can be realized, expensive welding equipment is not required, and good economic benefits and wide application prospectsare achieved.

Owner:JIUJIANG HAITIAN EQUIP MFG CO LTD

Repair method for welding defects of large-size friction stir welding

InactiveCN108788504AEliminate stomataEliminate defects such as cracksWelding apparatusWeld seamEngineering

The invention discloses a repair method for welding defects of large-size friction stir welding. The repair method comprises the following steps of: (1) forming an open groove in a welding defect position of the friction stir welding; (2) filling and welding the open groove by adopting a fusion welding method which can add a filling material; (3) welding a fusion welding process repair welding region by adopting pullback type friction stir welding, wherein a welding tool moves in the welding direction of the last friction stir welding step; the welding tool moves forwards again after the repair welding region is welded; and meanwhile a stirring needle is gradually pulled back; and (4) after the stirring needle is pulled back, stopping the welding tool for 1-5 seconds and starting to lift up the welding tool to obtain a repair welded joint which is good in surface formation, excellent in mechanical properties and free of keyholes in surface so as to finish the repair welding. The repairmethod for the welding defects of large-size friction stir welding disclosed by the invention is high in process stability, economic efficiency and operability, and remarkably improves the mechanicalproperties of a repair welding seam; and the repair welded joint is good in surface formation and free of keyholes.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Thick steel plate vertical welding method

InactiveCN104999167AThe overall shape is smooth and beautifulFusion transition without defectsWelding/cutting auxillary devicesAuxillary welding devicesFurnace temperatureHeat-affected zone

The invention discloses a thick steel plate vertical welding method which comprises the following steps of welding preparation, welding, and postweld heat treatment, wherein in the step of postweld heat treatment, a workpiece enters a furnace wholly and subjected to postwelding stress relieving annealing treatment, and a method of the postweld heat treatment comprises the steps that the workpiece is arranged in the furnace with the furnace temperature not great than 300 DEG, heated to 625 DEG plus-minus 20 DEG at a rate of 65 DEG / h and kept for 6h, then cooled to below 300 DEG at a rate of 65 DEG / h, discharged out of the furnace and cooled in still air. Macrocosmically, no arc breaking occurs in a welding process; the surface of a welding seam is shaped smoothly and attractively; except lack of fusion at an arc end, no defect is found in fusion and transition between welding deposits of subsequent welding seams and wood. A cutting sampling analysis on the welding seams of a test piece for welding indicates that the mechanical properties of the welding seams are higher than those of parent metal; the rigidity of the parent metal in a heat-affected zone is lower than the rigidity of the welding seams, and is lightly higher than the rigidity of the parent metal outside the heat-affected zone; and the forming widths of the welding seams at the front and back are consistent.

Owner:SUZHOU HUARI JINLING MACHINERY

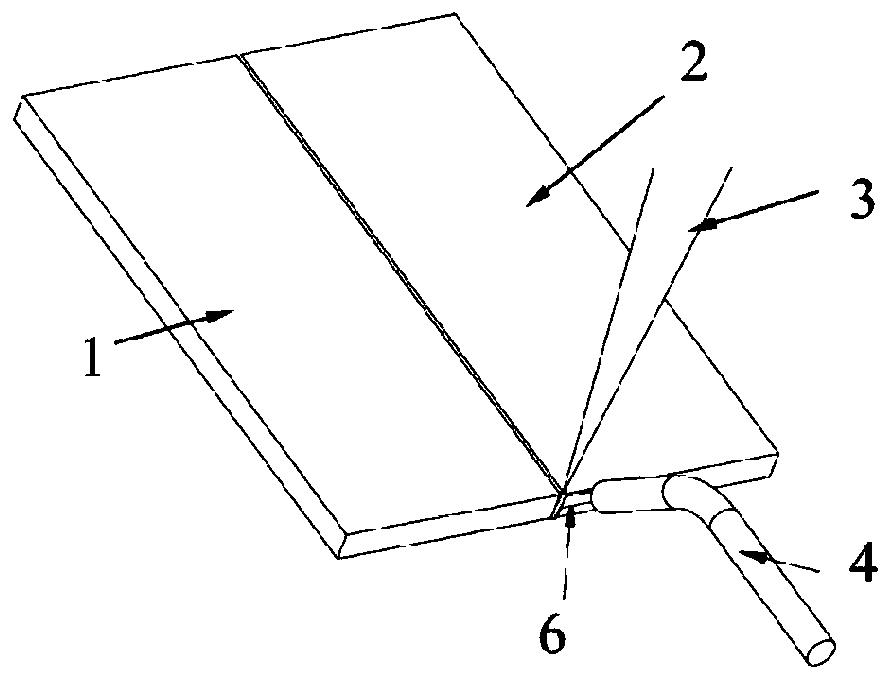

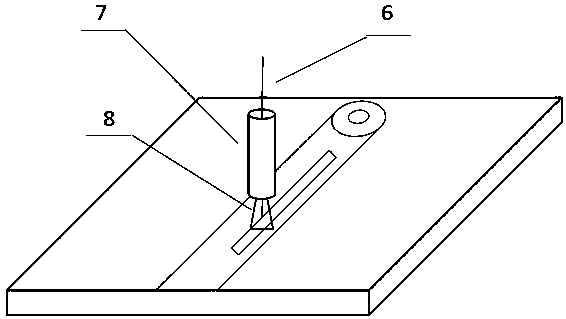

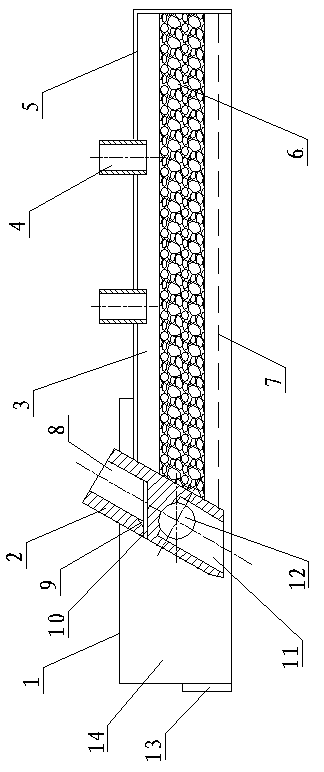

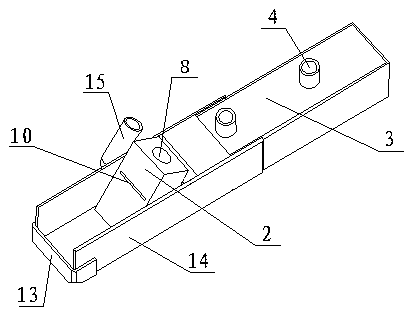

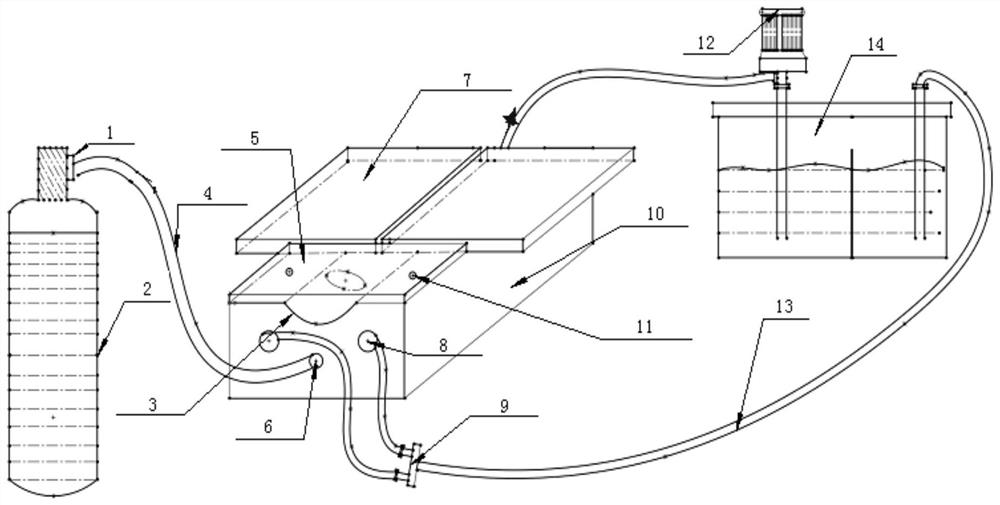

Laser welding multifunctional negative pressure gas protection device and method

PendingCN108581193APremium Laser WeldingLower the altitudeLaser beam welding apparatusSolid structureEngineering

The invention discloses a laser welding multifunctional negative pressure gas protection device and method. During small-batch multi-variety laser welding, the problems that production efficiency is seriously affected since tools are repeatedly replaced, air holes are likely to be produced, forming is not uniform, and fusion depth loss is serious in the welding process are prominent. The device comprises a negative pressure fence (1), an isolation separation bin (2) is installed in the negative pressure fence, the rear side of the isolation separation bin is provided with a tail drag cover (3), two air inlet pipes (4) are installed above the tail drag cover, one side of the negative pressure fence is provided with a direct protection channel air inlet pipe (15), the isolation separation bin is of a square cylindrical solid structure in the appearance and forms an angle of 20-50 degrees with the vertical direction, a compressed air injection air chamber (8), a gradual transition structure (9) and a straight air outlet (10) are sequentially arranged above the interior of the isolation separation bin, and a direct conveying type gas protection channel (11) is arranged below the interior of the isolation separation bin and communicates with a separation bin air inlet hole (12). The device is used for laser welding multifunctional negative pressure gas protection.

Owner:HARBIN WELDING INST LTD

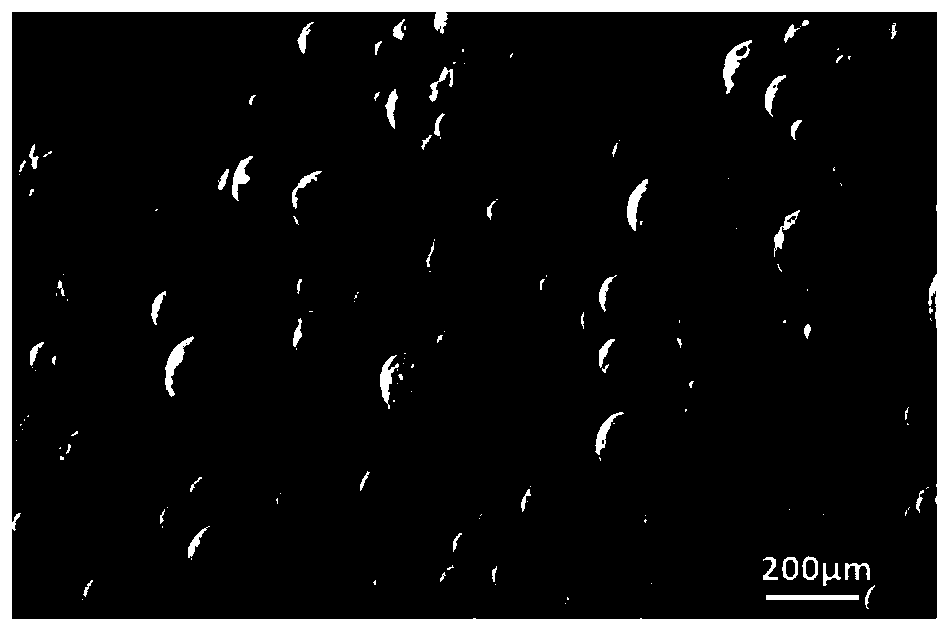

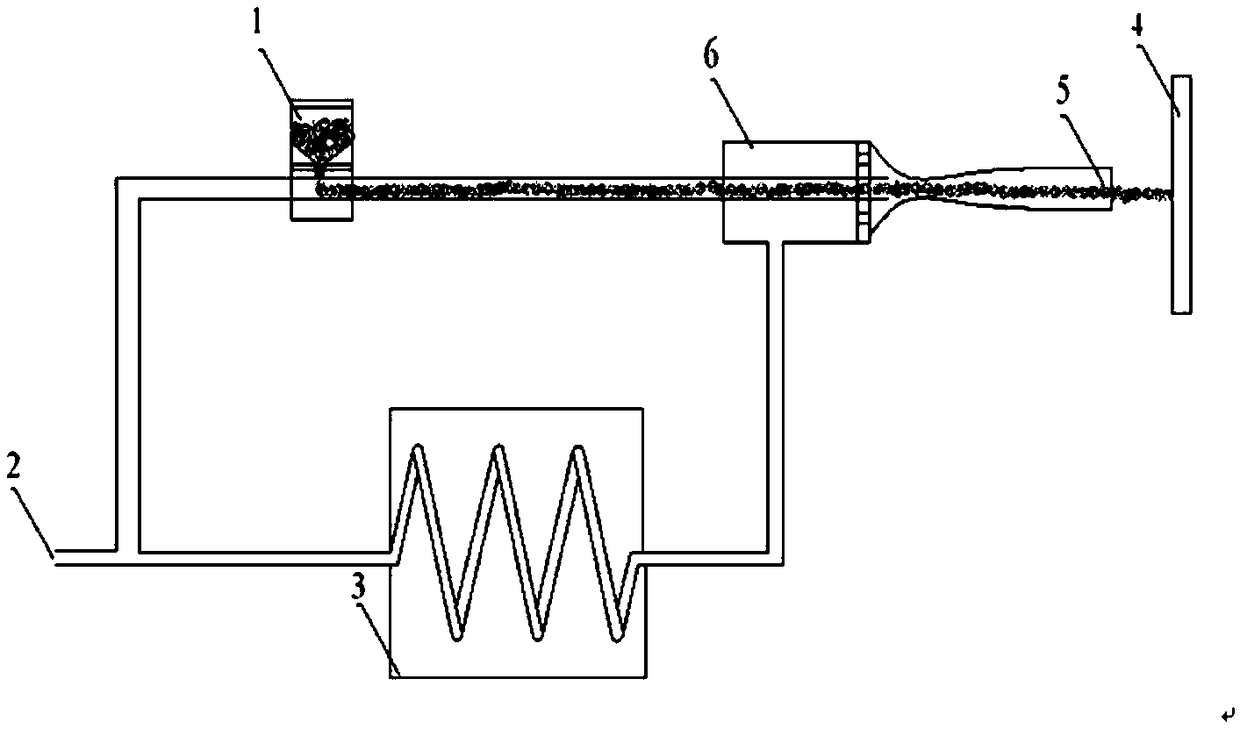

Method for reducing residual stress of metal structure material fusion welding joint

InactiveCN108838904AReduce or eliminate residual tensile stressStrong load bearing capacityEdge grinding machinesBlast gunsHigh pressureNitrogen gas

The invention provides a method for reducing residual stress of a metal structure material fusion welding joint. According to the method, heated gas and high-speed particle flows are utilized to simultaneously impact a weld joint area and the part near the weld joint area, the pressure stress is generated on the surface of the joint, so that the stress distribution is improved, the fatigue strength of the joint is improved, and the service life of the joint is prolonged; the size of the impact particles mostly ranges between 10 microns and 100 microns, the acceleration of the particles can berealized through high-pressure compressed gas (helium, nitrogen or compressed air), the gas pressure generally ranges from 1.5 MPa to 3.5 MPa, and the particle speed can reach the speed ranging from 400 m / s to 1000 m / s; in addition, the gas can be preheated according to requirements, and the preheating temperature generally ranges from 200 DEG C to 600 DEG C; in the method, the high-speed particleimpact effect and the hot gas impact effect are combined so that the residual tension of a component can be effectively reduced or eliminated, the mechanical property of the joint can be improved, and the service life of the component can be prolonged; and the method can be used for regulating and controlling the residual stress of the metal structure material fusion welding joint, and can also be used for improving the residual stress distribution of various welding joints of other materials, so that the safety and reliability of the joint are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Repair welding method for reducing welding cracks of magnesium rare earth alloy casting

ActiveCN111843109AAvoid it happening againImprove pass rateArc welding apparatusSolution treatmentAC - Alternating current

The invention discloses a repair welding method for reducing welding cracks of a magnesium rare earth alloy casting. The repair welding method comprises the following steps of carrying out solution treatment on the magnesium rare earth alloy casting of which a defect part material is removed before repair welding; then carrying out filler wire repair welding on the casting on a heating platform byusing argon tungsten-arc welding of an ultrahigh-frequency pulse alternating current arc; and after welding is finished, rapidly putting the casting in a heat treatment furnace for postweld heat treatment, and finally obtaining a magnesium rare earth alloy repaired casting without welding cracks. According to the repair welding method, not only can liquefied cracks and crystal cracks of a magnesium rare earth alloy in a repair welding process be remarkably reduced, but also a weld structure can be strengthened, and the repair welding quality of the magnesium rare earth alloy casting is effectively improved.

Owner:SHANGHAI JIAO TONG UNIV

Large-area metal wall surface field patching surfacing welding method and surfacing welding device

InactiveCN104827168ASoft textureGood high temperature resistanceArc welding apparatusInstabilityEngineering

The invention provides a large-area metal wall surface field patching surfacing welding method. A synchronous moving mechanism is installed on a welding gun of a surfacing welding device, in a surfacing welding process, a graphite sliding block on the synchronous moving mechanism is always located at the back of a welding pool and tightly pressed onto a surface welding layer by an elastic pressing mechanism on the synchronous moving mechanism, the graphite sliding block moves together with the welding gun, and welding current enters into a workpiece through electric arcs from a welding wire of the welding gun and returns to the welding machine power source negative pole from the graphite sliding block. The surfacing welding device comprises the welding gun, a welding machine power source and the synchronous moving mechanism. The synchronous moving mechanism comprises an elastic pressing mechanism and an insulation connecting plate. The elastic pressing mechanism comprises a shell, a pushing plate, a spring, an end cap, the graphite sliding block and a concave disk, and in surfacing welding, the spring generates a pressing force on the graphite sliding block. According to the large-area metal wall surface field patching surfacing welding method, the graphite sliding block is used for achieving the moving type connection between welding machine ground wires and the workpiece, the backward current distribution in the welding pool is strengthened, and combined with an externally added transverse magnetic field or a longitudinal magnetic field, the problems of the welding pool instability and organizational regulation and control caused by the gravity of metal wall surface field patching surfacing welding are solved.

Owner:NANHUA UNIV

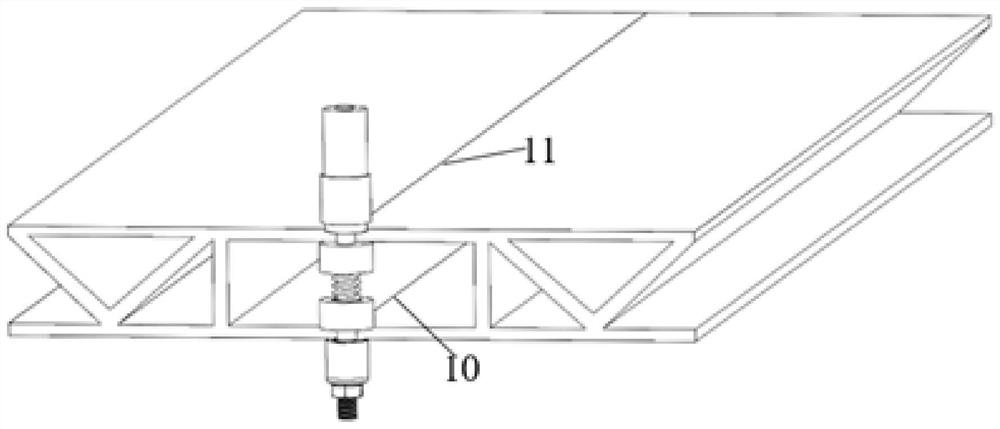

Honeycomb structure diffusion brazing connection method

ActiveCN111872508AImprove mechanical propertiesReduce corrosionSoldering auxillary devicesHoneycomb structureMechanical properties of carbon nanotubes

The invention relates to a honeycomb structure diffusion brazing connection method, and belongs to the technical field of welding. The method comprises the steps that 1, a framework is arranged on thehorizontal circumferential side wall of a honeycomb core; 2, after a middle layer is preset on the upper surface of lower skin, the lower skin is attached to the bottom of the honeycomb core, after amiddle layer is preset on the lower surface of upper skin, the upper skin is attached to the top of the honeycomb core, and the honeycomb core is placed on a lower graphite mold, and an upper graphite mold is placed at the top; 3, a pressing block is preset at the top of the upper graphite mold, and a workpiece is formed; 4, n graphite clamping blocks are evenly arranged on the side wall of the workpiece to achieve clamping of the circumferential edge of the workpiece; and 5, a clamping tool is heated and cooled, and a honeycomb structure obtained after diffusion brazing is obtained. According to the method, the welding quality is higher, and the method is particularly suitable for high-temperature alloy honeycomb structure products with complex molded surfaces and high requirements for mechanical properties and forming precision.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

cable welding wire

ActiveCN105665955BStable weldabilityImprove the pass rate of twistingWelding/cutting media/materialsSoldering mediaEngineeringStructure factor

The invention provides a cable type welding wire. The cable type welding wire comprises a center welding wire and n peripheral welding wires arranged around the center welding wire in a spiral rotating manner, wherein the diameter of each of the peripheral welding wires is d, and the neighboring peripheral welding wires are separately arranged in an intersecting manner. The cable type welding wire is characterized in that the lay length T of each of the peripheral welding wires is equal to K*m*d, wherein K is the structure factor of the peripheral welding wires, m is the lay length multiple, and d is the diameter of each of the peripheral welding wires; K is larger than or equal to 1, and less than or equal to 1.5; m is larger than or equal to 20, and less than or equal to 25. According to the cable type welding wire provided by the invention, wire breakage is not liable to generate in the manufacturing process; during welding, the peripheral welding wires are arranged compactly, so that the wire feeding process is more stable, and the welding performance of the cable type welding wire is improved.

Owner:SUZHOU YINLI WELDING IND TECH CO LTD

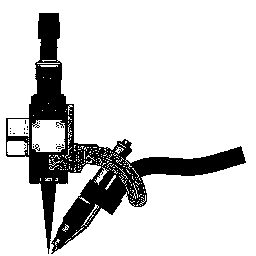

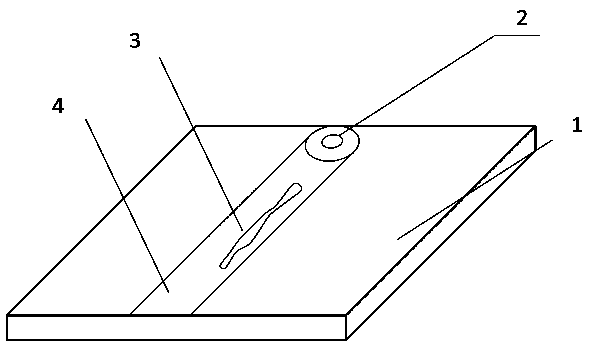

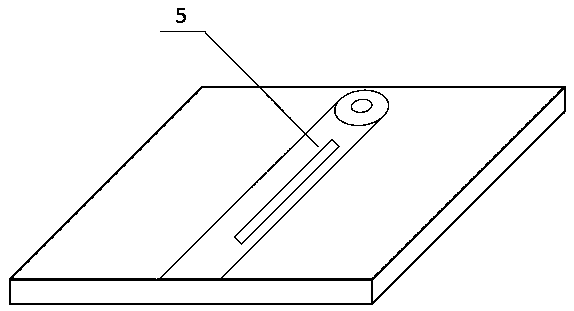

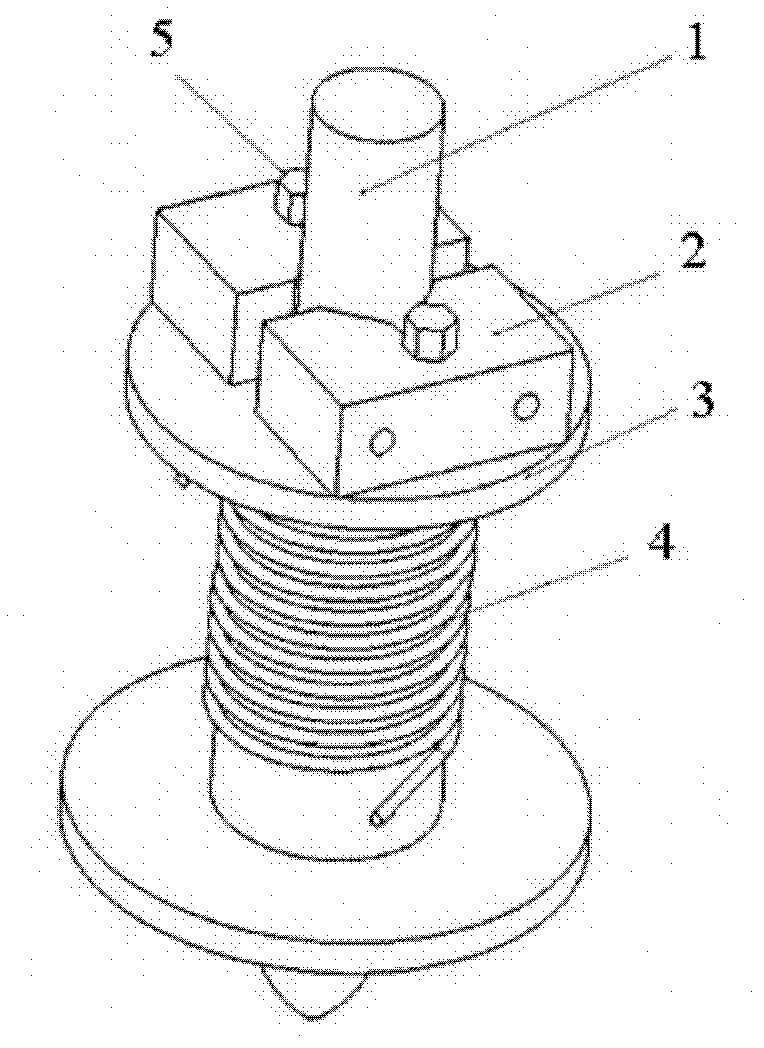

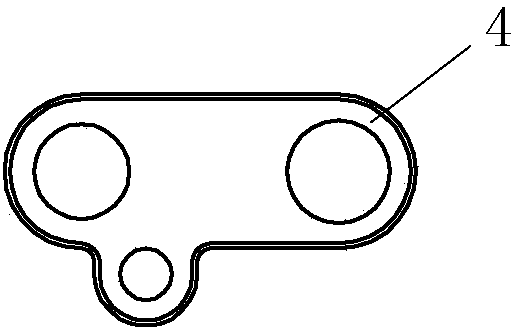

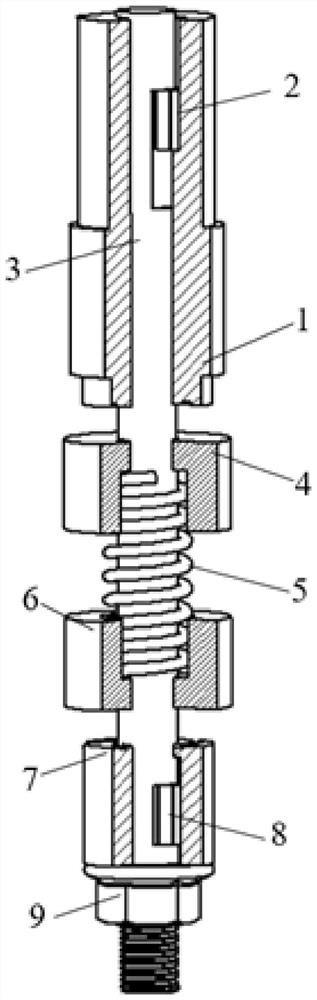

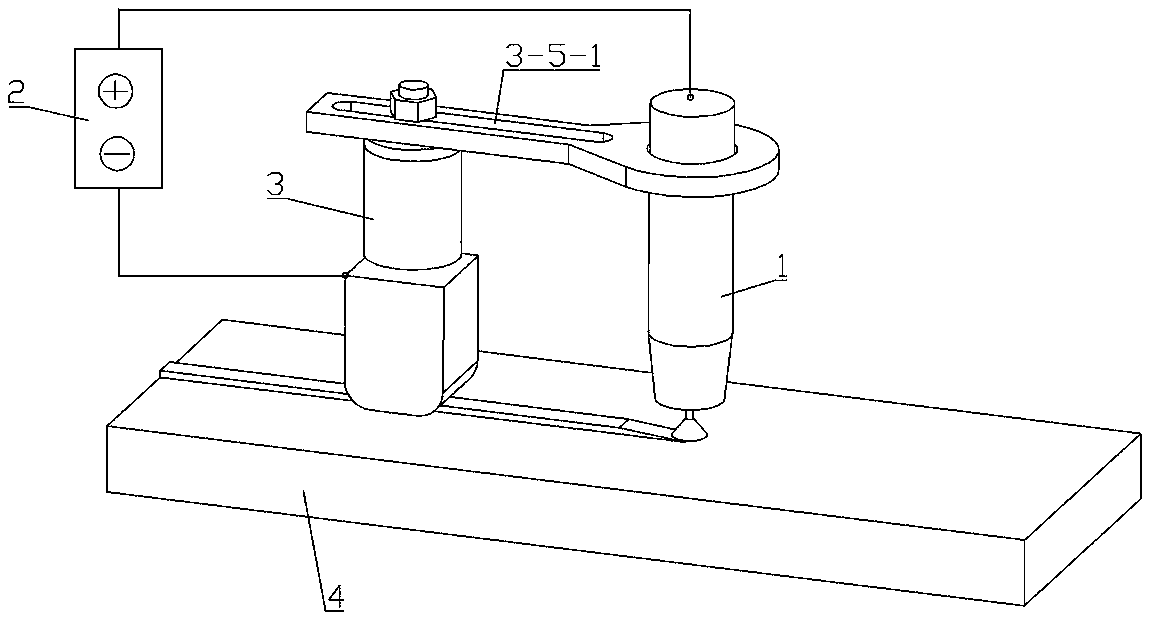

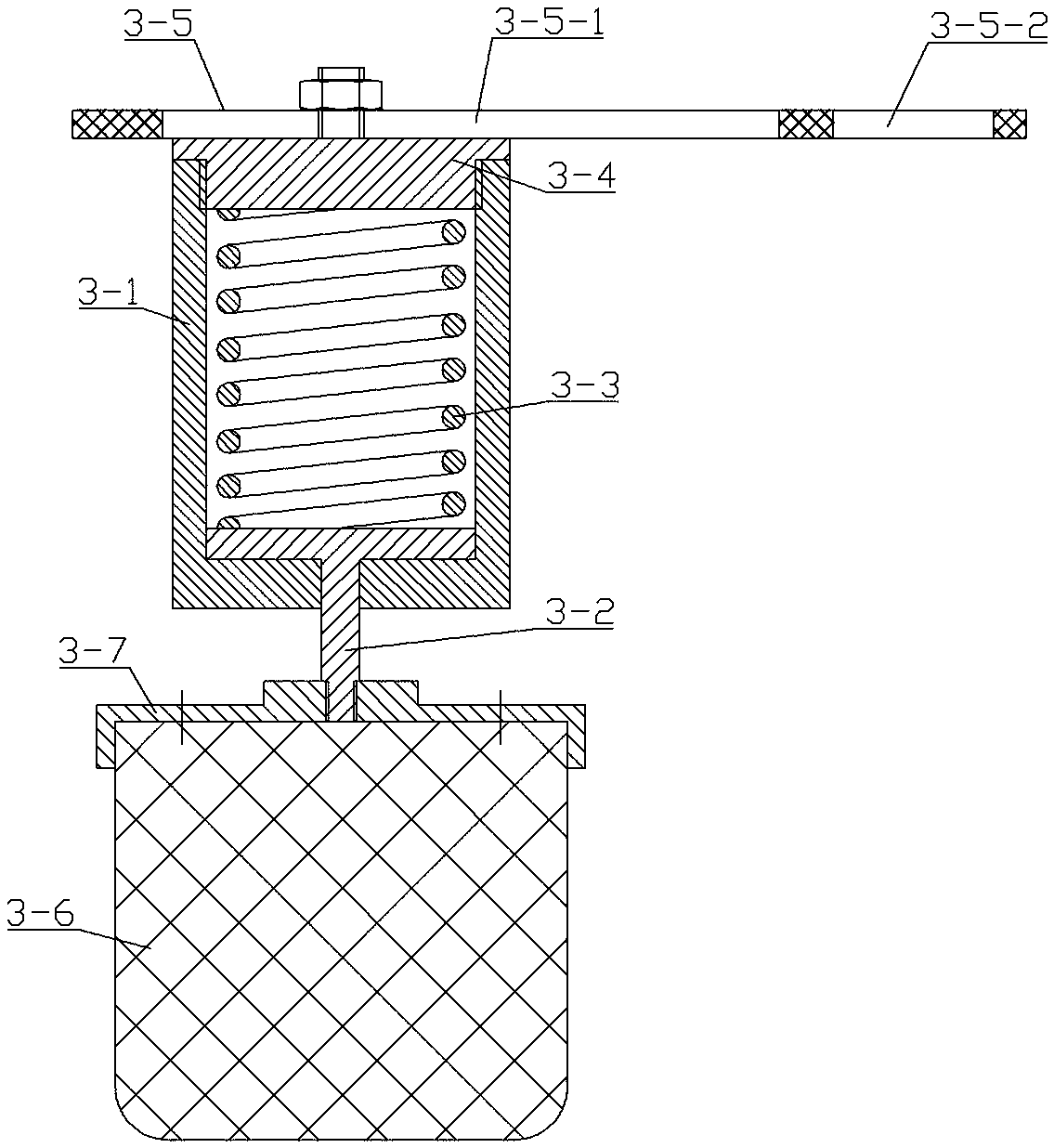

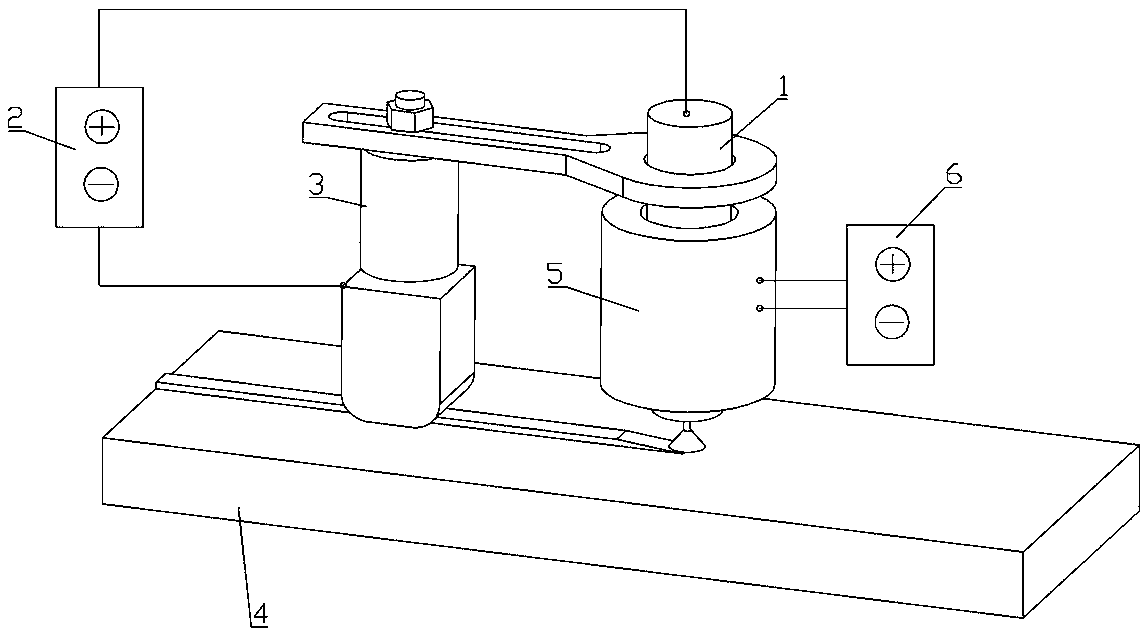

TIG (Tungsten Inert Gas) welding gun using external magnetic field

InactiveCN103302381AChange the direction of crystallizationCompact structureArc welding apparatusAlternating currentElectric current

The invention provides a welding gun which is arranged on a TIG (Tungsten Inert Gas) welder. A welding gun 1 is locked with threads of a reel 3 through a bolt 5 and a clamping device 2; a coil 4 is wound outside the reel 3 and is connected to a power supply; current produces a magnetic field through the coil 4; the current which passes through the coil 4 is intermittent alternating current; the produced magnetic field is an intermittent alternating magnetic field; the intermittent alternating magnetic field has an effect on electric arc so as to improve the welding quality.

Owner:SHENYANG AIRCRAFT CORP

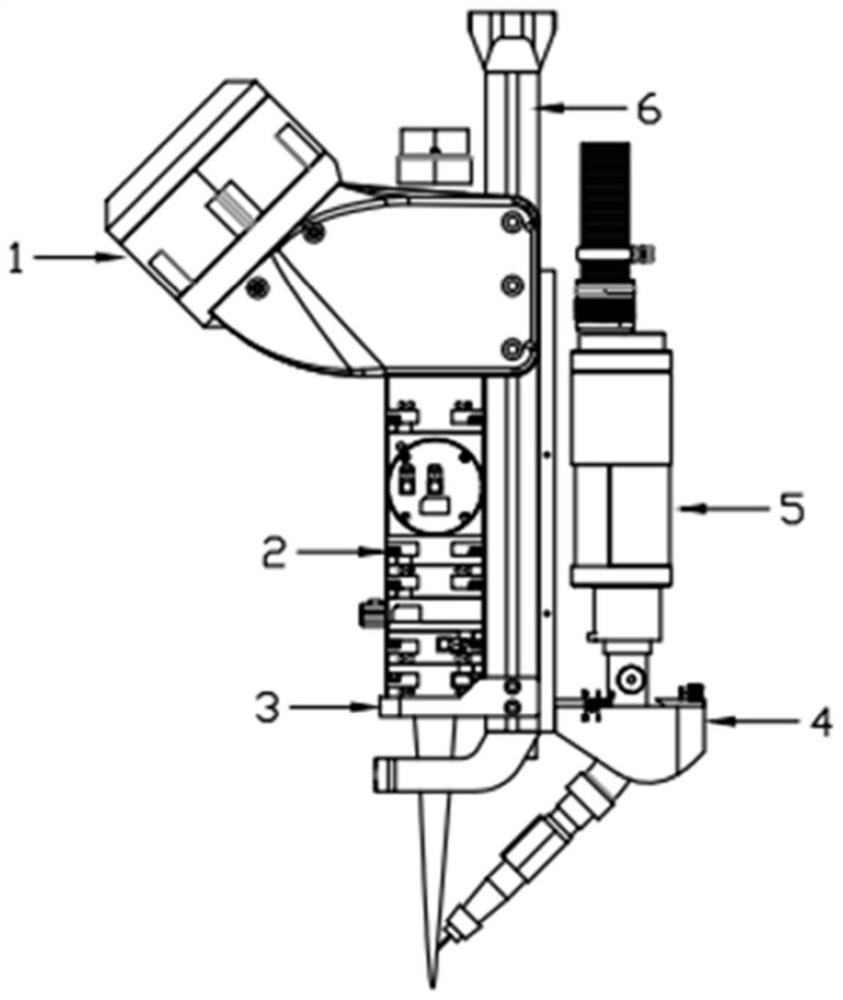

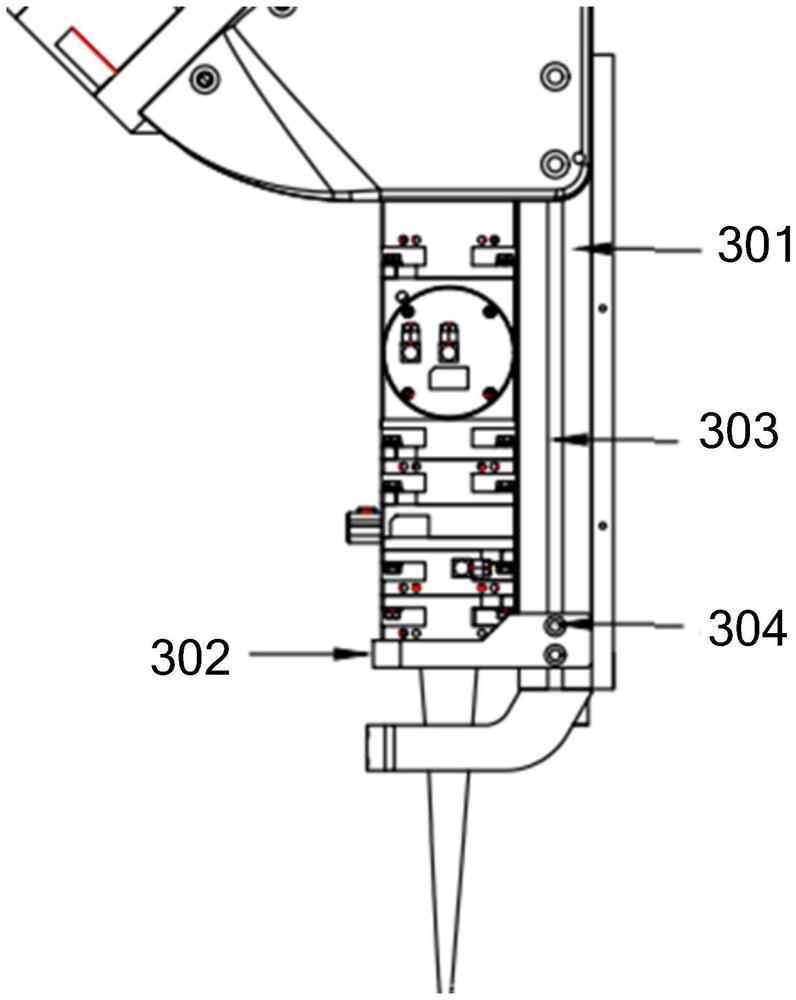

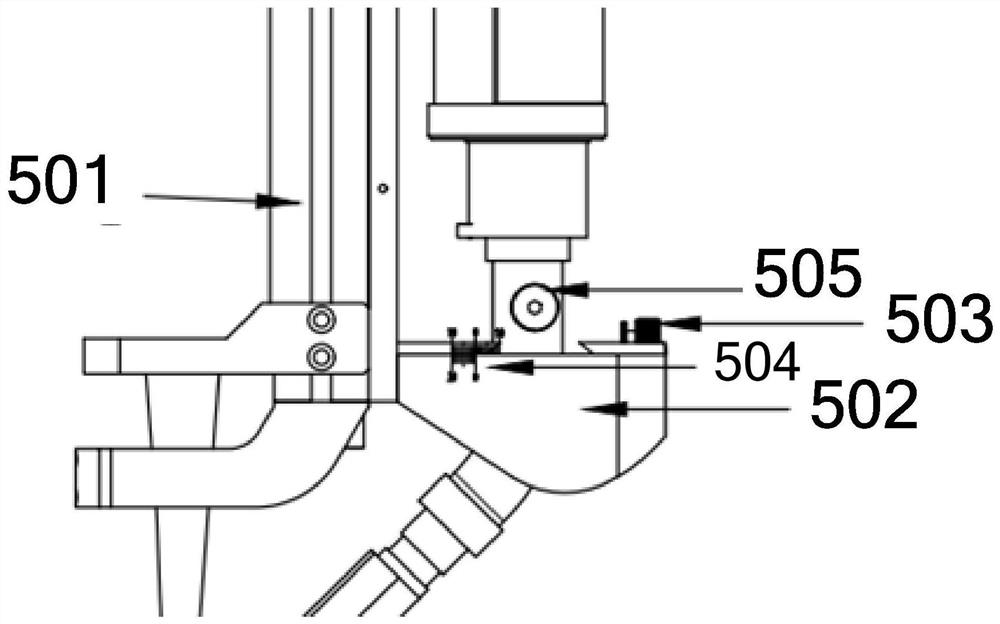

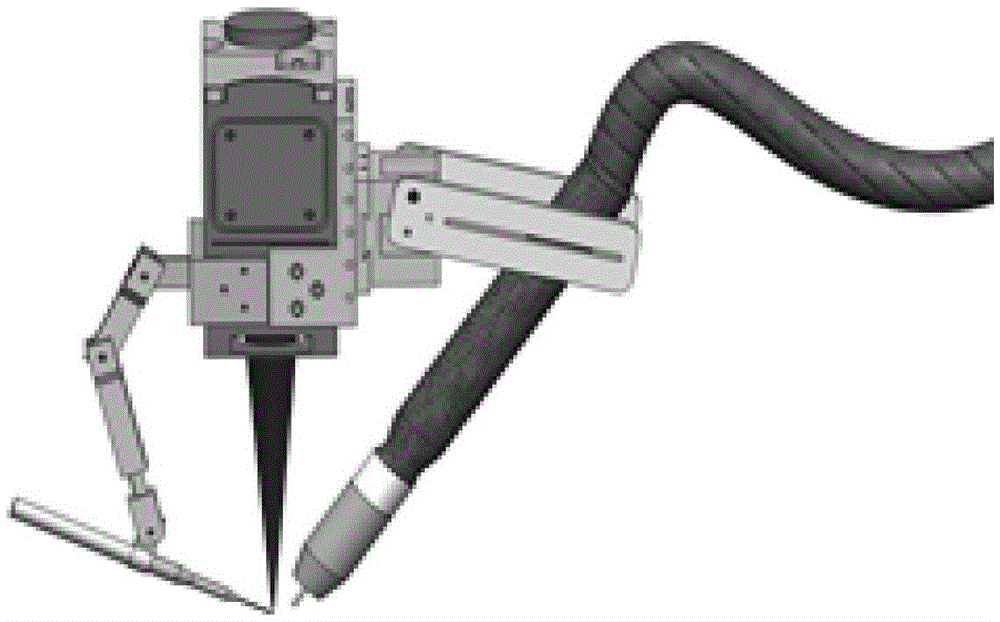

Laser-arc hybrid welding system

PendingCN114029621AConvenient process welding adjustmentReduce weld crackingLaser beam welding apparatusControl systemLaser light

The invention provides a laser-arc hybrid welding system. A welding device comprises a main body framework, wherein the main body framework is provided with a laser focusing device, a first adjusting mechanism, a welding gun, a second adjusting mechanism and a movement mechanism connecting assembly; the laser focusing device is connected to the first adjusting mechanism, and the first adjusting mechanism is connected to the main body framework; the movement mechanism connecting assembly is connected to the main body framework; the welding gun is connected to the second adjusting mechanism, and the second adjusting mechanism is connected to the main body framework; a laser light-emitting system is connected with the laser focusing device through an optical fiber; and the control system is connected with the laser light-emitting system, the laser focusing device, the first adjusting mechanism, the welding gun and the second adjusting mechanism. The system is favorable for reducing welding cracks and improving the mechanical property of welding seams, and is suitable for various welding processes with high requirements.

Owner:上海杭和智能科技有限公司

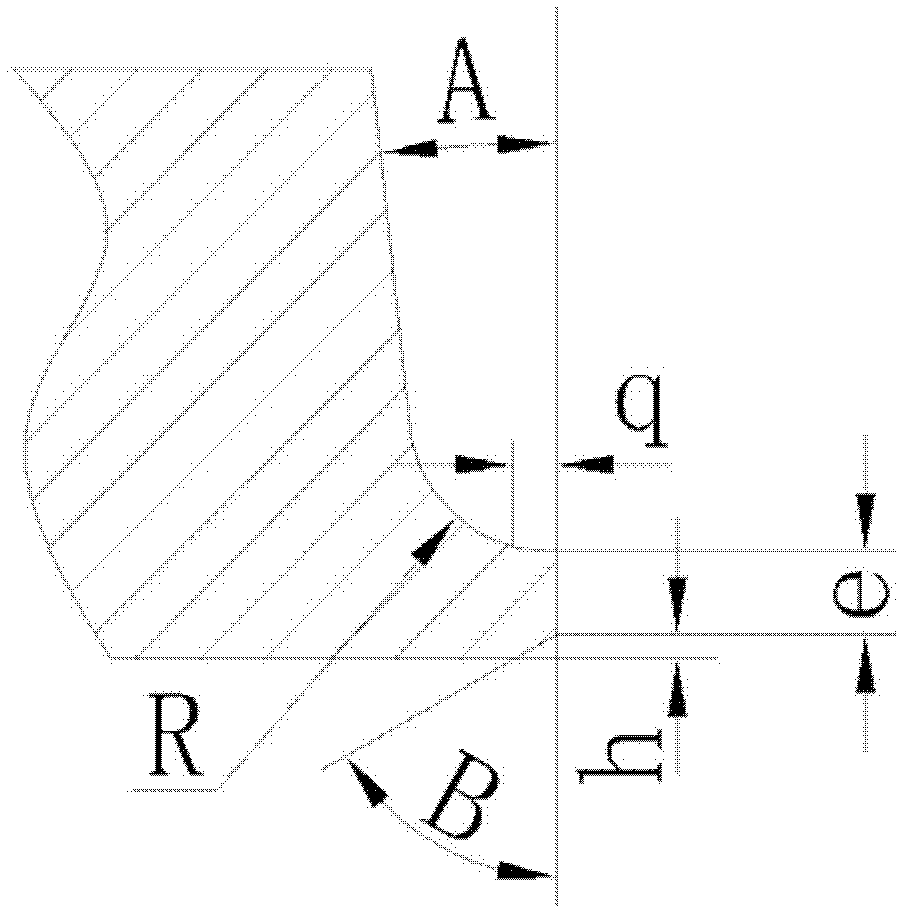

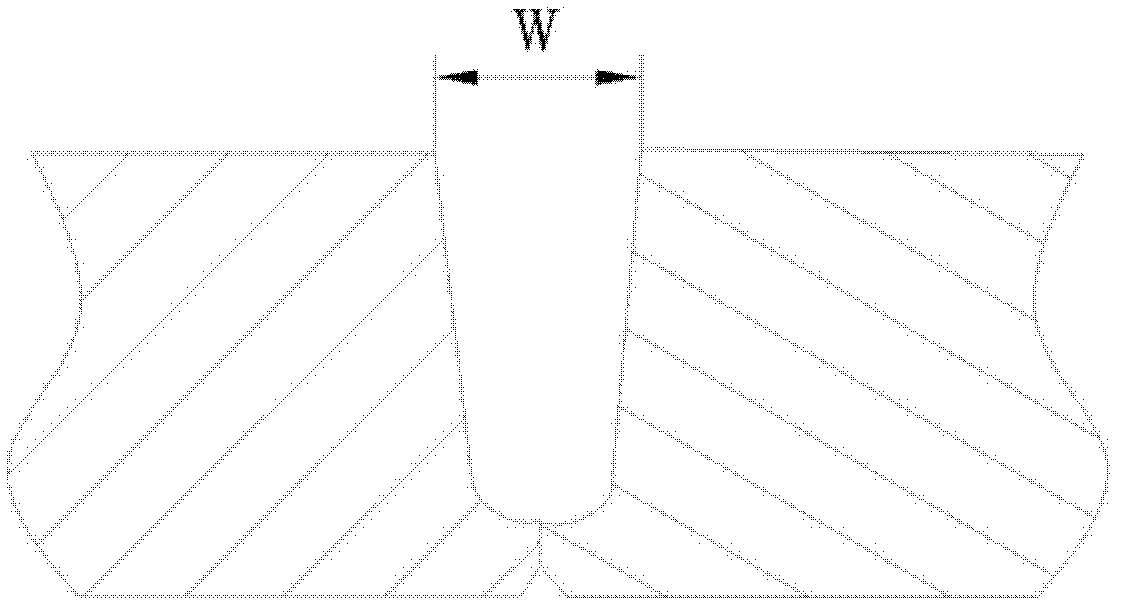

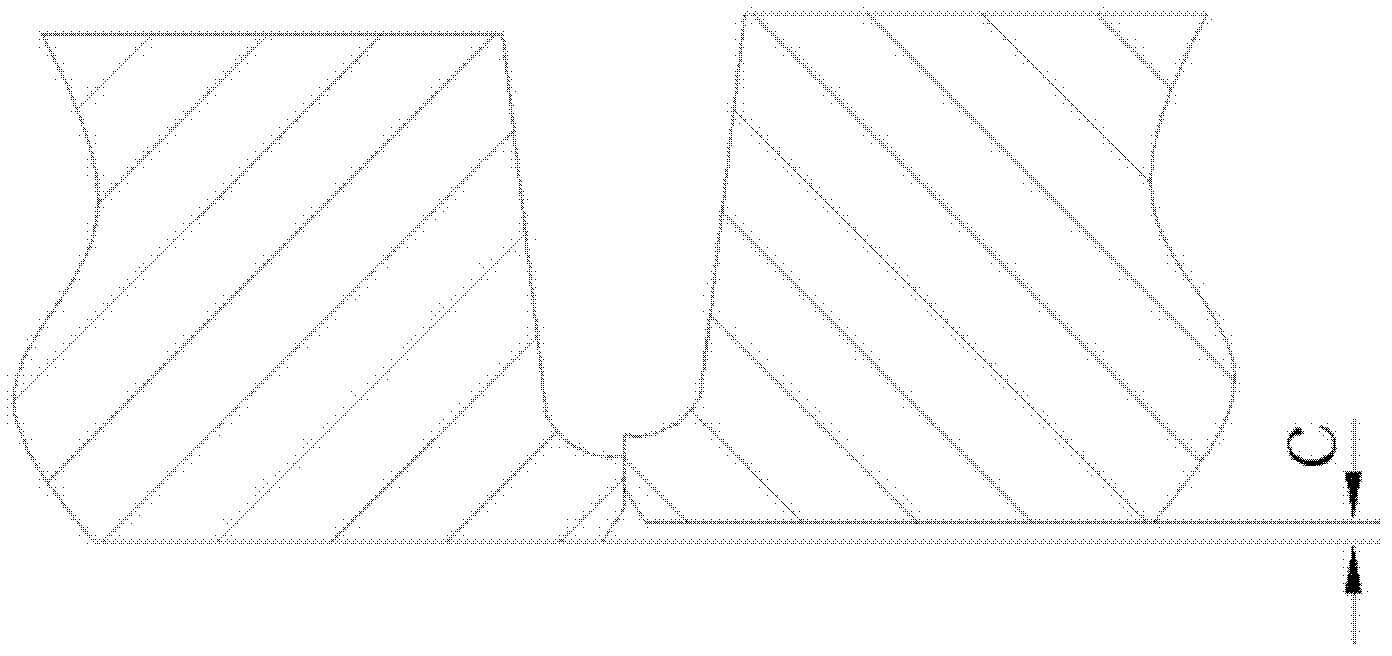

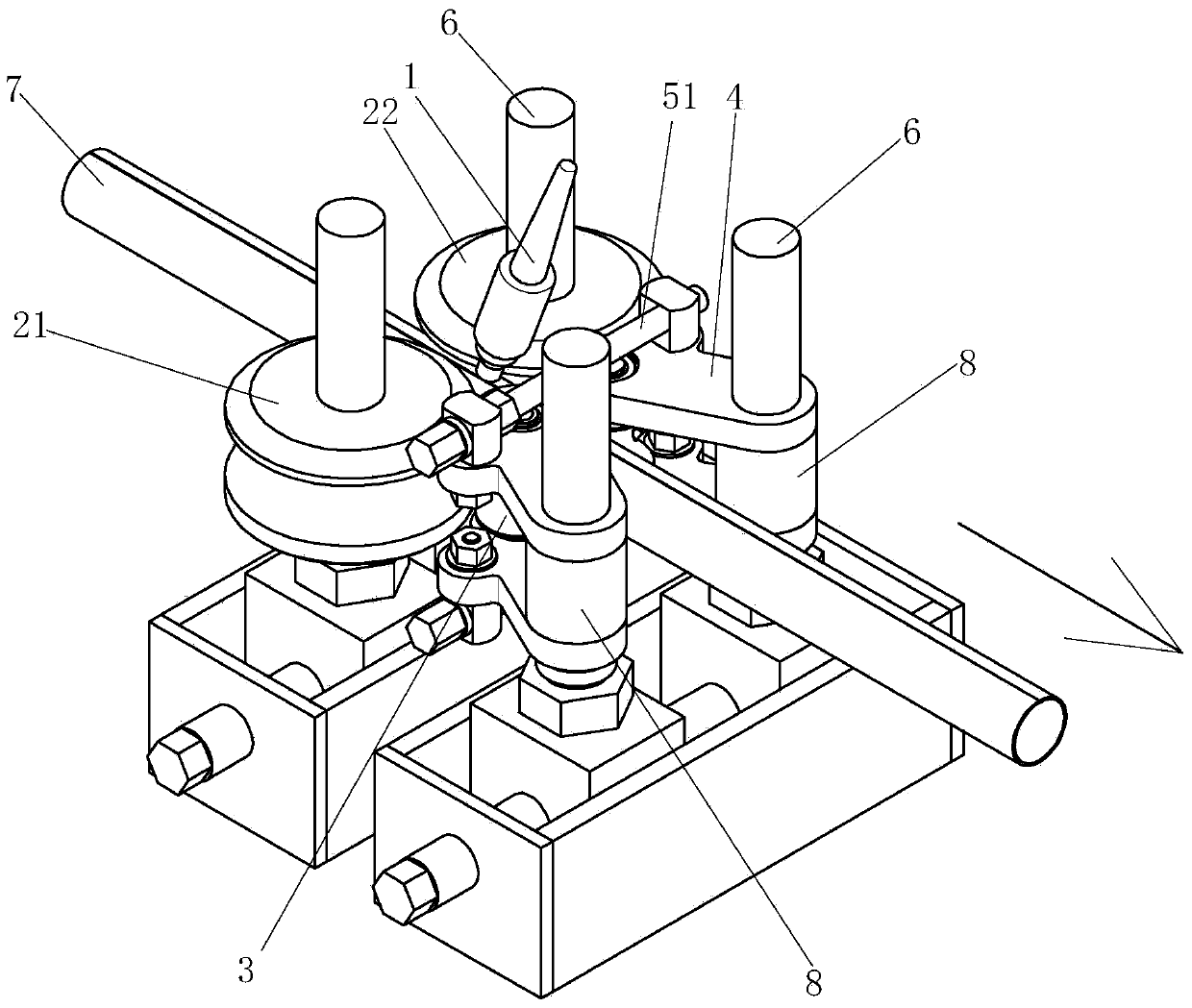

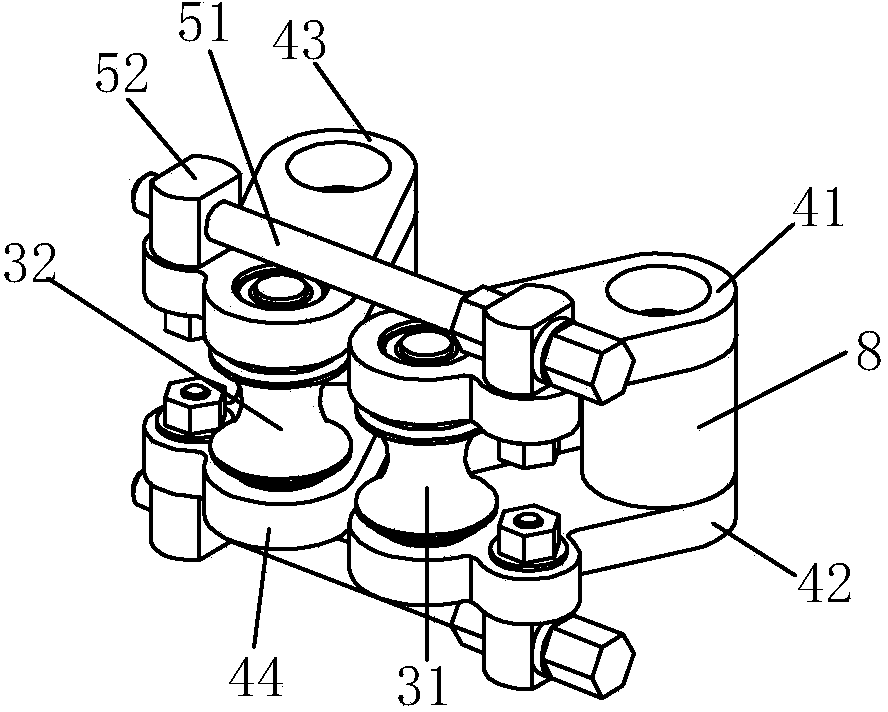

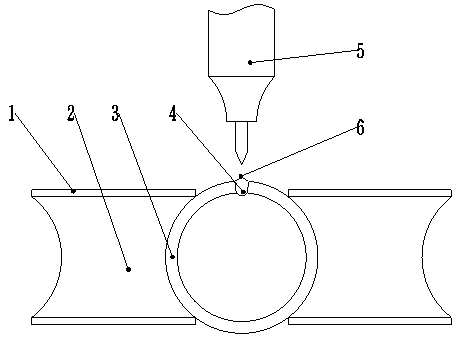

Welding pipe adjustable vertical roll tool

ActiveCN104625367AImprove the mechanical properties of the weldReduce weld crackingWelding accessoriesPipe weldingManufacturing engineering

The invention relates to a welding pipe adjustable vertical roll tool comprising a welding torch, large vertical rolls, small vertical rolls, cantilevers and pull rods. The small vertical rolls include the first small vertical roll and the second small vertical roll, the cantilevers include the first cantilever, the second cantilever, the third cantilever and the fourth cantilever, the pull rods include the first pull rod and the second pull rod, two ends of the first small vertical roll are respectively mounted on the first cantilever and the second cantilever, two ends of the second small vertical rod are respectively mounted on the third cantilever and the fourth cantilever, two ends of the first pull rod are respectively mounted on the first cantilever and the third cantilever through screw pairs, two ends of the second pull rod are respectively mounted on the second cantilever and the fourth cantilever through screw pairs, a first roll shaft is arranged on the first cantilever and the second cantilever, a second roll shaft is arranged on the third cantilever and the fourth cantilever, and the first roll shaft and the second roll shaft are mounted on a pipe welding machine through the screw pairs respectively. By the arrangement, mechanical property of welding lines is improved, weld failure caused by subsequent bend machining or flaring machining is reduced, and rejection rate of products is decreased.

Owner:LIUZHOU HENGZHUO AUTO PARTS

Cable solder wire for CMT welding system and CMT welding system

ActiveCN106363314AImprove welding effectReduce the number of weld layersArc welding apparatusWelding/cutting media/materialsTight bindingEngineering

The invention discloses a cable solder wire for a CMT welding system. The solder wire comprises a central solder wire. The outer side of the central solder wire is provided with a spiral solder wire which is twined tightly around the central solder wire in a spiral manner. The outer side of the spiral solder wire is provided with a protection ring. The inside of the spiral solder wire is provided evenly with 4 subordinate solder wire groups. The subordinate solder wire groups are tangentially arranged. The inside of each subordinate solder wire group is provided with a first solder wire, a second solder wire, a third solder wire and a fourth solder wire. The fusion depth in the welding operation is deep. This structure can reduce the quantity of overlapping welding seams layers and can fundamentally increase the welding efficiency, reduce the production costs with negligible splashes. The high mechanical property of the welding seam and the tight binding structure of the solder wire stabilize the solder wire feeding process, enhances the welding property of the cable solder wire and makes the CMT welding system to render a better soldering effects.

Owner:QINGDAO BRANCH CO., LTD. OF MECHANICAL SCIENCE RESEARCH INSTITUTE

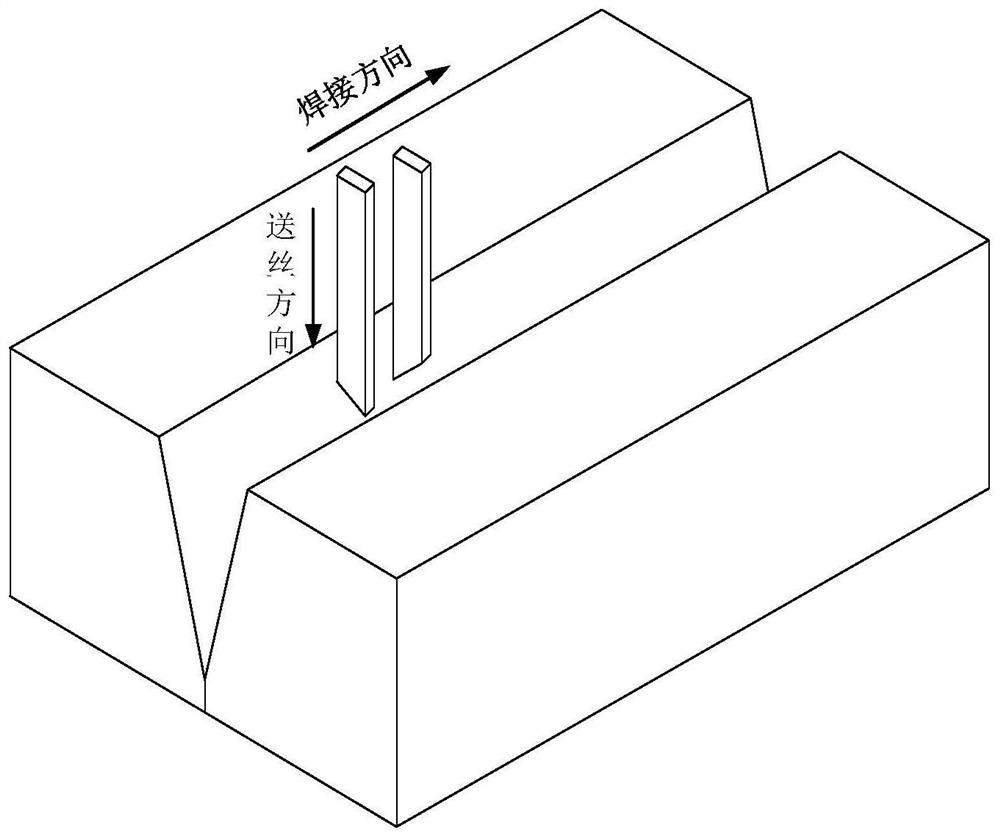

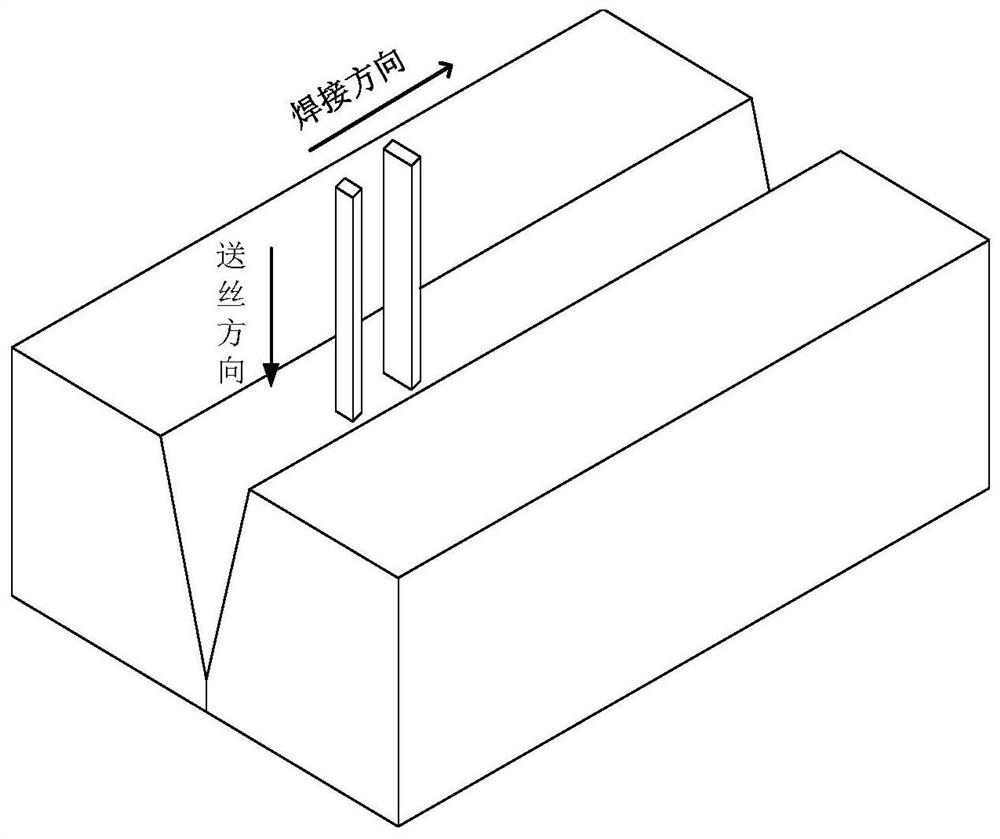

Large thick plate welding method and system based on double strip-shaped welding wires

ActiveCN112809138AEfficient and high-quality weldingStrong weld adaptabilityElectrode supporting devicesElectrode accessoriesThick plateWelding process

The invention provides a large thick plate welding method and system based on double strip-shaped welding wires. The method works on the basis of the double-welding-wire arc welding principle. In the welding process of a large thick plate, a welding bead layer is divided into backing welding, filling welding and cosmetic welding; and according to the characteristics of different welding bead layers, size selection and arrangement are carried out on the strip-shaped welding wires. The system comprises a double strip-shaped welding wire welding gun A, a double strip-shaped welding wire welding gun B and a welding control center. The double strip-shaped welding wire welding gun A is provided with two strip-shaped welding wires with the same width; the double strip-shaped welding wire welding gun B is provided with two strip-shaped welding wires with different widths; and the welding control center is used for presetting a welding program and controlling the double strip-shaped welding wire welding gun A and the double strip-shaped welding wire welding gun B to work according to the preset welding program. The preset welding program comprises selection of welding modes including a backing welding mode, a filling welding mode, a cosmetic welding mode I and a cosmetic welding mode II. By adopting the method and the system, high-efficiency and high-quality welding of large thick plates can be realized.

Owner:SOUTHWEST JIAOTONG UNIV

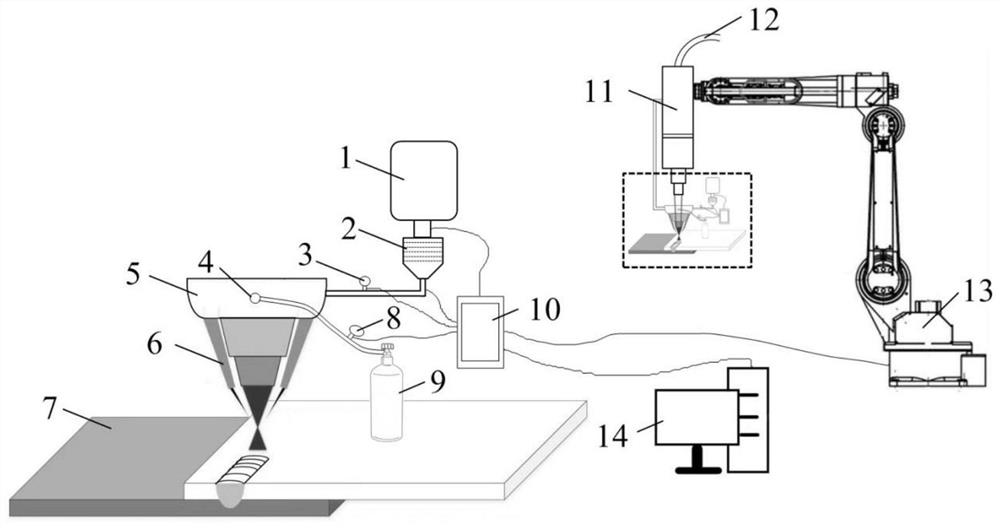

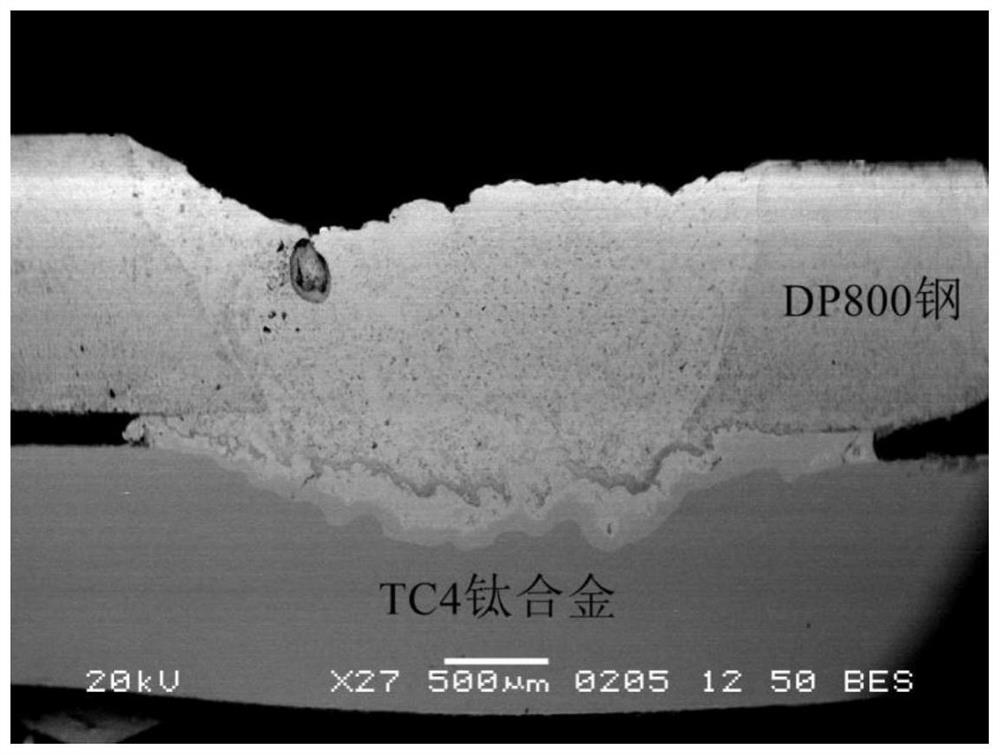

Dissimilar metal laser cladding welding device and method

PendingCN114178699AStrengthen the connection structureRapid responseWelding/soldering/cutting articlesLaser beam welding apparatusControl systemAlloy

The invention discloses a dissimilar metal laser cladding welding device and a dissimilar metal laser cladding welding method. A powder feeding device; the gas source is used for providing protective atmosphere into the powder feeding device; the cladding device is used for providing heat for the surface of the workpiece to enable the alloy powder to react with the surface of the workpiece; a conveying channel of the powder feeding device is fixed relative to the cladding device; a control system; and the powder screening device, the powder feeding device and the cladding device are respectively connected. According to the method, a heat source is adopted for melting metal powder, the molten metal powder enters the lap welding upper metal test plate, and the mechanical property of a welding seam is improved by controlling the adding amount of the metal powder in an upper metal molten pool and adjusting welding heat input; the variety, thickness and number of phases at the joint of the dissimilar metal interfaces are regulated and controlled, and the dissimilar metal connecting structure is further expanded; the welding method is simple, and batch production is facilitated.

Owner:JIANGSU UNIV OF SCI & TECH

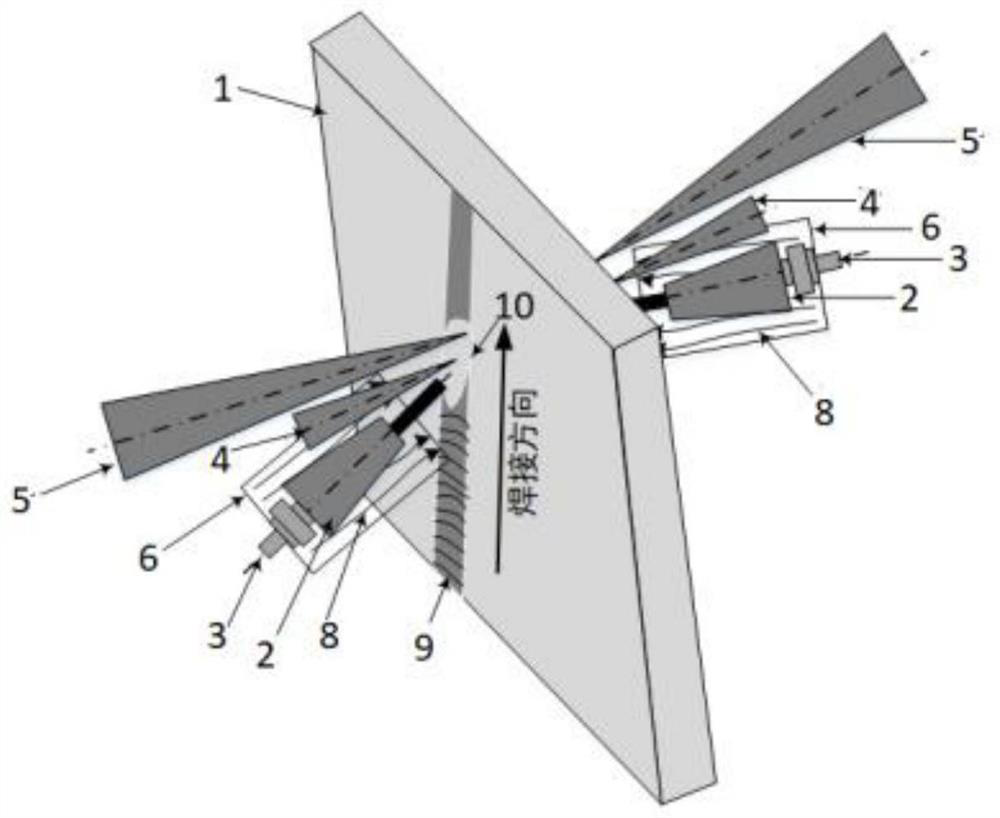

Laser arc double-sided synchronous vertical position welding method and device for medium plate

PendingCN114850664AReduce direct impactResolving Incomplete Weld DefectsLaser beam welding apparatusEngineeringLaser beams

The invention discloses a laser arc double-sided synchronous vertical position welding method and device for a medium plate. The method comprises the steps of groove design, backing welding and multi-layer filling welding. The liquid molten drops generated by the GMAW welding gun have a certain distance from the second laser beam for forming the key hole, namely, the liquid molten drops are far away from the key hole, so that the direct impact of the liquid molten drops on the key hole can be reduced, and the problem that the key hole is even blocked by the molten drops after a welding wire is molten due to the fact that the laser forming a molten pool melts the welding wire is solved. Key holes on the two sides are difficult to be communicated, and the stability of the key holes is reduced. The vertical upward welding of the heat sources symmetrically arranged on the two sides can improve the heated symmetry of the two sides of the base metal, so that the heat sources on the two sides are fully compounded, the welding precision is guaranteed, deformation caused by welding stress can be greatly reduced, meanwhile, the filling pass of vertical upward welding of the medium-thickness plate is reduced, and the welding efficiency is improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

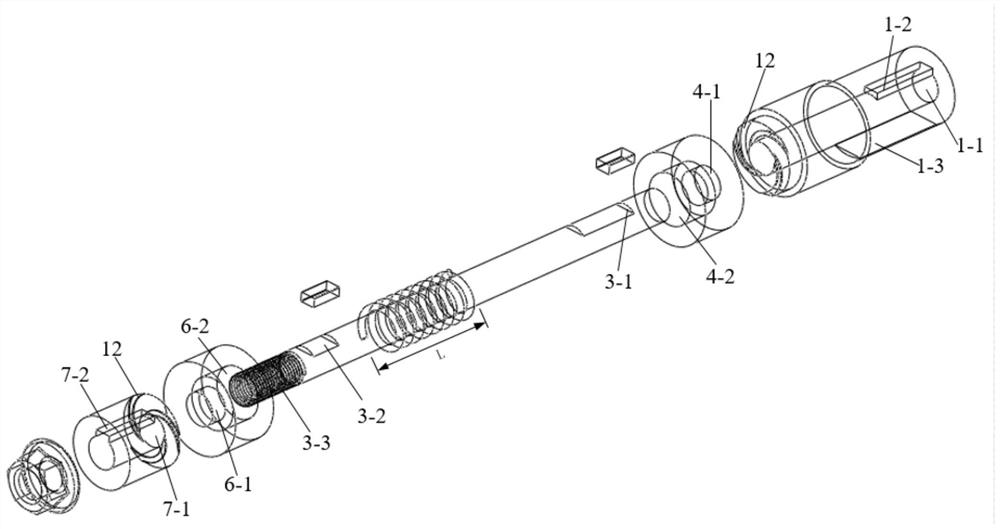

Self-supporting friction stir welding device and welding method thereof

PendingCN112108757ARealize one clampingSimplify the welding processNon-electric welding apparatusClassical mechanicsStructural engineering

The invention relates to a self-supporting friction stir welding device and a welding method thereof. The device solves the problem that a box-shaped structure to be welded formed by assembling hollowprofiles needs double-sided friction stir welding. The device is provided with a stirring needle, wherein the stirring needle sequentially penetrates an upper shaft shoulder, a first middle shaft shoulder, a spring, a second middle shaft shoulder and a lower shaft shoulder, a first counter bore is formed in the lower end of the first middle shaft shoulder, a second counter bore is formed in the upper end of the second middle shaft shoulder, one end of the spring stretches into the first counter bore and makes contact with the upper end face of the first counter bore, the other end of the spring stretches into the second counter bore and makes contact with the lower end face of the second counter bore, the upper shaft shoulder is provided with an upper position key groove, the lower shaftshoulder is provided with a lower position key groove, upper position keys are arranged in an upper end key groove and the upper position key groove, and lower keys are arranged in a lower end key groove and the lower position key groove. According to the device, a distance between the first middle shaft shoulder and the second middle shaft shoulder can be automatically adjusted according to fluctuation of heights of inner cavities of the hollow profiles, and good manufacturability and universality are achieved.

Owner:HARBIN INST OF TECH AT WEIHAI +1

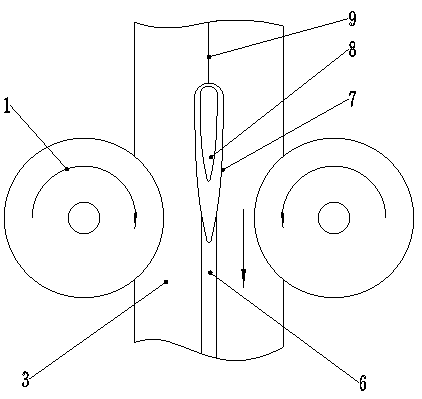

Welding method for S32750 super duplex stainless steel welded pipe

InactiveCN108890087AImprove mechanical propertiesSimple and efficient operationArc welding apparatusSteel tubeWeld seam

The invention relates to a welding method for an S32750 super duplex stainless steel welded pipe. The method comprises the following steps that 1, a pair of forming wheels are additionally mounted onan argon tungsten-arc welding production line, wherein the forming wheels are provided with arc-shaped forming grooves, the forming grooves of the two forming wheels are clamped to both sides of the steel pipe, and the steel pipe drives the forming wheels to rotate; 2, a welding gun is used for welding a to-be-welded groove above the steel pipe, after a welding molten pool is formed, a thermal imager is used for finding an area, at the temperature of 800-1200 DEG C, of the rear end of the molten pool of argon tungsten-arc welding, and a connection line of the two forming wheels is moved to thearea through adjustment; 3, the distance between the two forming wheels is adjusted, and the area, at 800-1200 DEG C, of the rear end of the molten pool is extruded to make the thickness of protrusions on the upper surfaces of welding seams after extrusion be 5-20% of the wall thickness of the steel pipe. The strength of the longitudinal welding seams of the welded S32750 duplex stainless steel welded pipe is higher than that of S32750 duplex stainless steel welded pipe base metal.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

A laser-toptig hybrid welding method

ActiveCN104014933BGuarantee welding qualityGuaranteed stabilityLaser beam welding apparatusLaser-hybrid weldingShielding gas

Owner:HARBIN INST OF TECH

On-site repair and surfacing method for large-area metal walls

InactiveCN104827168BConstitute a mobile connectionSoft textureArc welding apparatusPower flowCurrent distribution

The invention provides a large-area metal wall surface field patching surfacing welding method. A synchronous moving mechanism is installed on a welding gun of a surfacing welding device, in a surfacing welding process, a graphite sliding block on the synchronous moving mechanism is always located at the back of a welding pool and tightly pressed onto a surface welding layer by an elastic pressing mechanism on the synchronous moving mechanism, the graphite sliding block moves together with the welding gun, and welding current enters into a workpiece through electric arcs from a welding wire of the welding gun and returns to the welding machine power source negative pole from the graphite sliding block. The surfacing welding device comprises the welding gun, a welding machine power source and the synchronous moving mechanism. The synchronous moving mechanism comprises an elastic pressing mechanism and an insulation connecting plate. The elastic pressing mechanism comprises a shell, a pushing plate, a spring, an end cap, the graphite sliding block and a concave disk, and in surfacing welding, the spring generates a pressing force on the graphite sliding block. According to the large-area metal wall surface field patching surfacing welding method, the graphite sliding block is used for achieving the moving type connection between welding machine ground wires and the workpiece, the backward current distribution in the welding pool is strengthened, and combined with an externally added transverse magnetic field or a longitudinal magnetic field, the problems of the welding pool instability and organizational regulation and control caused by the gravity of metal wall surface field patching surfacing welding are solved.

Owner:NANHUA UNIV

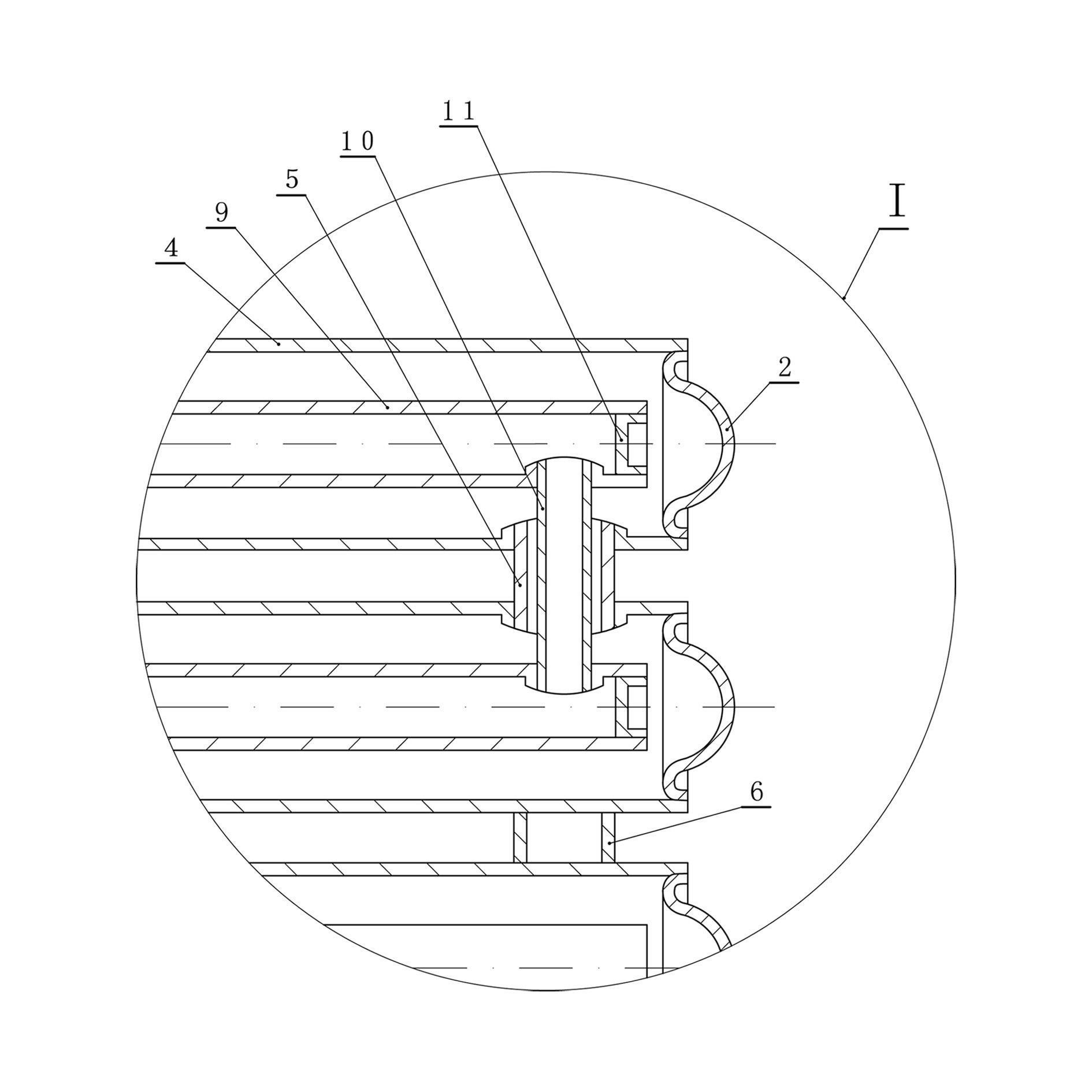

A single-sided soldering copper pad device with water cooling and backside protection and a corresponding soldering method

ActiveCN109865966BCompact structureReduce weightWelding/cutting auxillary devicesAuxillary welding devicesShielding gasWeld seam

The invention belongs to the technical field of welding, and particularly relates to a single-sided welding copper liner device with water cooling and back protection and a corresponding welding method. By circulating cooling water and shielding gas inside a copper liner, the good welding forming effect of workpieces to be welded is ensured, many beneficial effects of reducing welding deformation,prolonging the service life of the liner, preventing oxidation inclusion on the back of a weld seam, refining weld seam grains, improving the tensile strength of the weld seam and the like are realized, and the single-sided welding copper liner device is suitable for various electric-arc welding methods.

Owner:WUHAN UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com