cable welding wire

A cable-type welding wire and welding wire technology, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of poor production quality and welding performance of cable-type welding wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

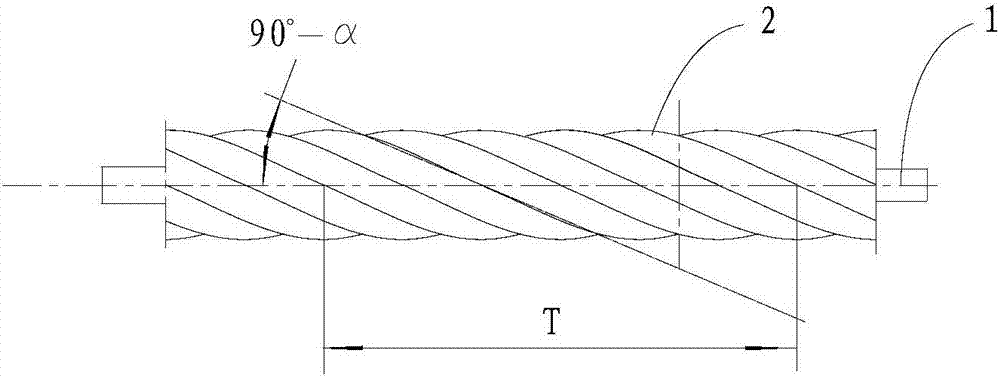

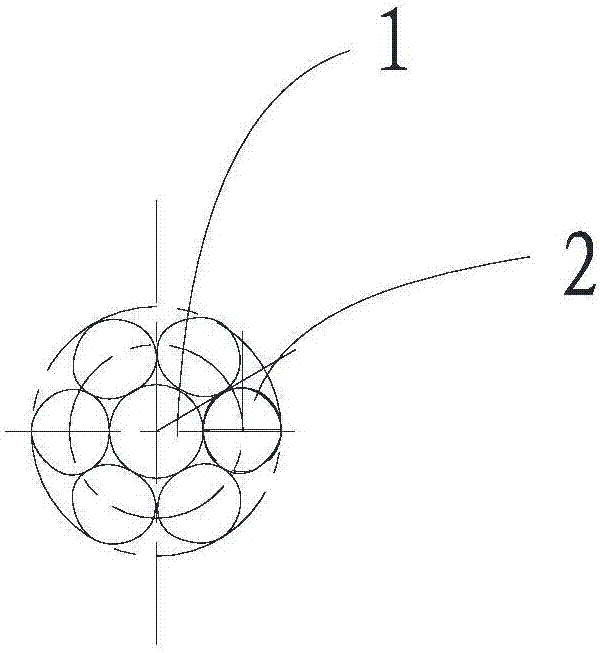

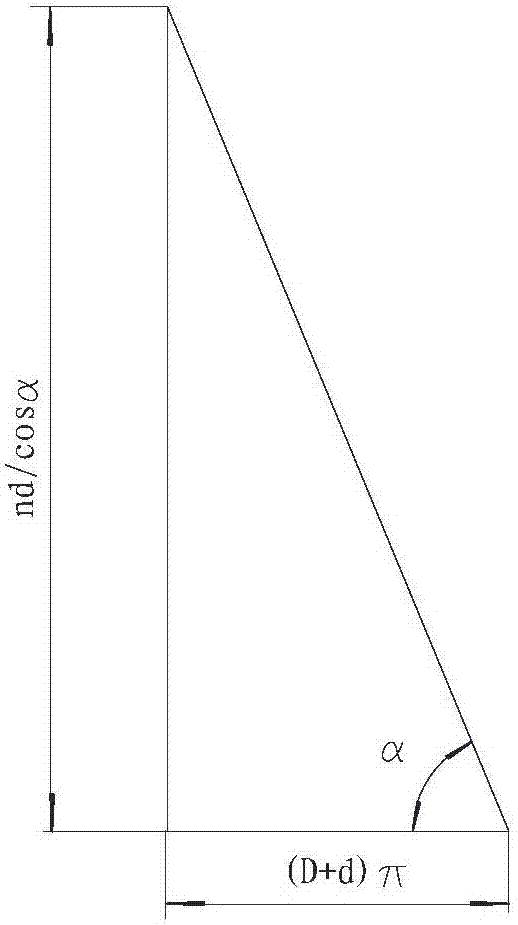

[0042] The structure of the cable type welding wire provided in this embodiment is 1+6, such as figure 1 and figure 2 As shown, that is, the number of peripheral welding wires is 6, and the peripheral welding wires are solid welding wires, K=1, then T=md (m=20-25, helix angle α=72.5°~76.1°). At the same time, the diameter d of the peripheral welding wire is equal to 1.6mm, and the diameter of the cable-type welding wire is about 5mm, so the optional range of lay length T is 32-40mm, and the optimum lay length (ie when m=24) = 38mm.

Embodiment 2

[0052] The structure of the cable type welding wire provided in this embodiment is 1+7, such as Figure 4 As shown, that is, the number of peripheral welding wires is 7, and the peripheral welding wires are solid welding wires, K=1, then T=md, (m=20-25, helix angle α=69.5°~73.7°). At the same time, the diameter of the peripheral welding wire is 1.85mm, the diameter of the central welding wire is 2.3mm, and the diameter of the cable welding wire is about 6mm, so the optional range of twist length is 37-46.25mm, and the best twist length (ie when m=24) = 44.4 mm. And when the welding wire feeding speed is 44.4mm / sec, the rotation frequency of the arc is 1 Hz.

Embodiment 3

[0054] The structure of the cable type welding wire provided in this embodiment is 1+8, such as Figure 5 As shown, the number of peripheral welding wires is 8, and the peripheral welding wires are solid welding wires, K=1, T=md (m=20-25, helix angle α=α=66.4°~71.3°). At the same time, when the diameter of the peripheral welding wire is 1.73mm, the diameter of the central welding wire is 2.54mm, and the diameter of the cable-type welding wire is about 6mm, then the optional range of lay length: 34.6-43.25mm, the best lay length (ie when m=24) = 41.5mm. And when the welding wire feeding speed is 41.5 mm / s, the rotation frequency of the arc is 1 Hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com