Sintered flux for efficient submerged arc welding and its production process

A technology of sintering flux and production process, which is applied in welding medium, manufacturing tools, welding equipment, etc., can solve the problems that the mechanical properties can only meet the requirements of 2Y level, the height requirement of the factory building is high, and the time wasted by turning over the plate, etc., to achieve slag removal Good, uniform weld width and height, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

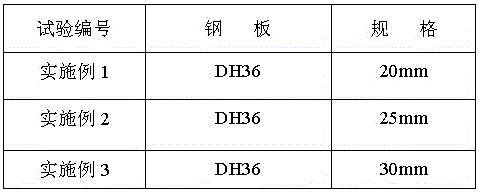

Embodiment 1

[0041] The front side flux consists of the following components by weight percentage:

[0042] al 2 o 3 : 5 kg, CaO: 8 kg, CaF 2 : 5 kg, MgO: 25 kg, SiO 2 : 15.2 kg, TiO 2 : 8 kg, B 2 o 3 : 0.8 kg, Fe powder: 30 kg, silicon-calcium alloy: 3 kg;

[0043] The reverse side flux consists of the following components by weight percentage:

[0044] al 2 o 3 :50kg, CaF 2 : 5 kg, MgO: 10 kg, MnO: 8.2 kg, SiO 2 : 10 kg, TiO 2 : 7 kg, Fe 2 o 3 : 4.8 kg, silicon-calcium alloy: 5 kg;

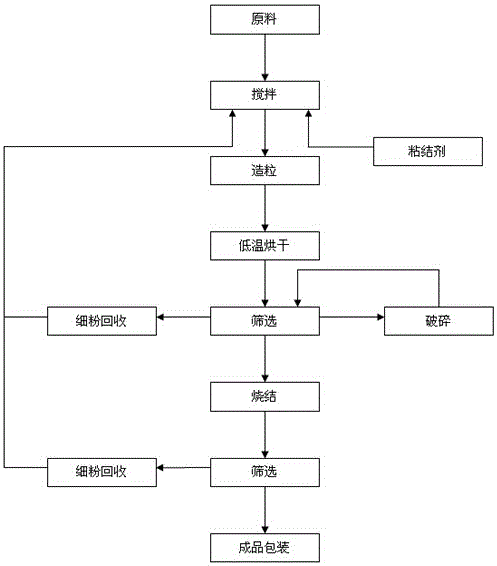

[0045] Flux production is carried out using the following processes:

[0046] Bauxite, wollastonite, fluorite, dead burnt magnesia, quartz, rutile titanium dioxide, borax, silicon-calcium alloy and iron powder are used as raw materials, and ingredients are prepared according to the composition of the positive flux, put into a mixer and stirred evenly to obtain a mixed material, adding a binder accounting for 18% of the total mass of the mixture, the binder is potassium silicate and sodium si...

Embodiment 2

[0049] The front side flux consists of the following components by weight percentage:

[0050] al 2 o 3 : 6.8 kg, CaO: 5 kg, CaF 2 : 7 kg, MgO: 21.2 kg, SiO 2 : 18.5 kg, TiO 2 : 3 kg, B 2 o 3 : 1.5 kg, Fe powder: 32 kg, silicon-calcium alloy: 5 kg;

[0051] The reverse side flux consists of the following components by weight percentage:

[0052] al 2 o 3 : 42 kg, CaF 2 : 10 kg, MgO: 6 kg, MnO: 5 kg, SiO 2 : 18 kg, TiO 2 : 9 kg, Fe 2 o 3 : 3 kg, silicon-calcium alloy: 7 kg;

[0053] Flux production is carried out using the following processes:

[0054] Bauxite, wollastonite, fluorite, dead burnt magnesia, quartz, rutile titanium dioxide, borax, silicon-calcium alloy and iron powder are used as raw materials, and ingredients are prepared according to the composition of the positive flux, put into a mixer and stirred evenly to obtain a mixed material, adding a binder accounting for 20% of the total mass of the mixture, the binder is potassium silicate and sodium ...

Embodiment 3

[0057] The front side flux consists of the following components by weight percentage:

[0058] al 2 o 3 : 3 kg, CaO: 10 kg, CaF 2 : 3 kg, MgO: 18 kg, SiO 2 : 20 kg, TiO 2 : 5 kg, B 2 o 3 : 2 kg, Fe powder: 38 kg, silicon-calcium alloy: 1 kg;

[0059] The reverse side flux consists of the following components by weight percentage:

[0060] al 2 o 3 :40kg, CaF 2 : 8 kg, MgO: 5 kg, MnO: 12 kg, SiO 2 : 12 kg, TiO 2 : 12 kg, Fe 2 o 3 : 1 kg, silicon-calcium alloy: 10 kg;

[0061] Flux production is carried out using the following processes:

[0062] Bauxite, wollastonite, fluorite, dead burnt magnesia, quartz, rutile titanium dioxide, borax, silicon-calcium alloy and iron powder are used as raw materials, and ingredients are prepared according to the composition of the positive flux, put into a mixer and stirred evenly to obtain a mixed material, adding a binder accounting for 19% of the total mass of the mixture, the binder is potassium silicate and sodium silicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com