Welding medium entropy alloy material and welding method

A welding method, entropy alloy technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of low strength and toughness, achieve low cost, simple preparation, and prevent the formation of brittle mesophase Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

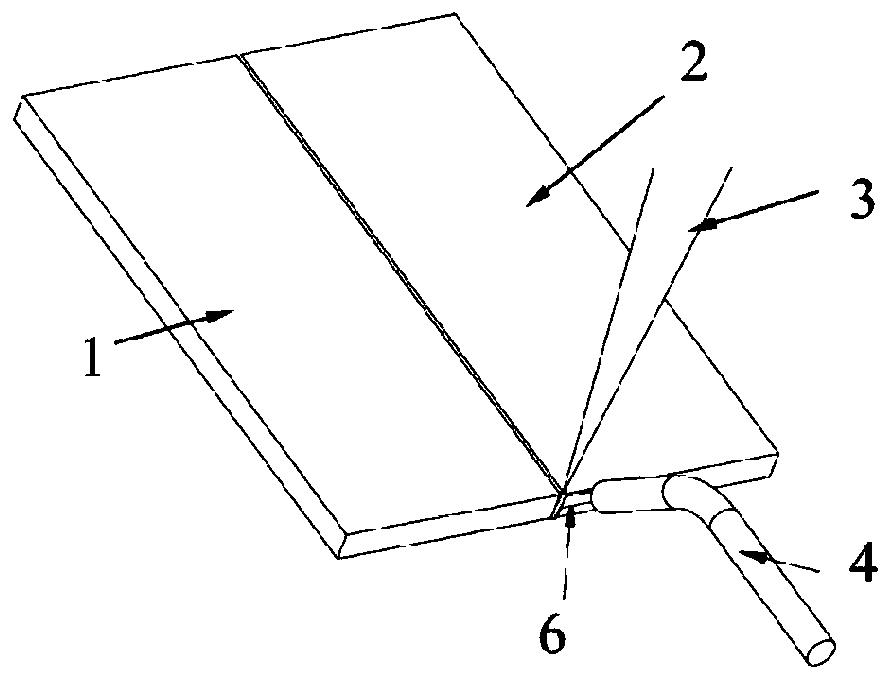

[0045] This embodiment uses a medium-entropy alloy material with a particle size of 10-200μm in the form of a powder, with a composition formula of Cr50%, Co30%, and Ni20%, for welding between stainless steel and titanium. The structural diagram of the welding system is as follows figure 1 As shown, the steps are as follows:

[0046] (1) The base material of the metal material to be welded in this embodiment is treated with a V-shaped groove between the base material material A1 and the base material material B2, and the apex angle is 60°;

[0047] (2) Clean the groove to a clean state without oil, rust, impurities, and dust, and polish the groove to smooth;

[0048] (3) Under the protection of argon gas, an industrial robot is equipped with a laser 3 and a powder feeding system 4 is connected in parallel, and the entropy alloy material 6 in the powder form after drying in this embodiment is filled into the powder feeding system 4;

[0049] (4) According to the scanning speed of 800mm / ...

Embodiment 2

[0052] In this embodiment, a medium-entropy alloy material in the form of powder with a particle size of 10 to 200 μm is used, and the composition formula is Cr33%, Co33%, and Ni34% for welding between stainless steel and aluminum. The schematic diagram of the welding method is as follows figure 1 As shown, the steps are as follows:

[0053] (1) The base material of the metal material to be welded in this embodiment is treated with a V-shaped groove between the base material material A1 and the base material material B2, and the apex angle is 60°;

[0054] (2) Clean the groove to a clean state without oil, rust, impurities, and dust, and polish the groove to smooth;

[0055] (3) Under the protection of argon gas, an industrial robot is equipped with a laser 3 and a powder feeding system 4 is connected in parallel, and the entropy alloy material 6 in the powder form after drying in this embodiment is filled into the powder feeding system 4;

[0056] (4) According to the scanning speed o...

Embodiment 3

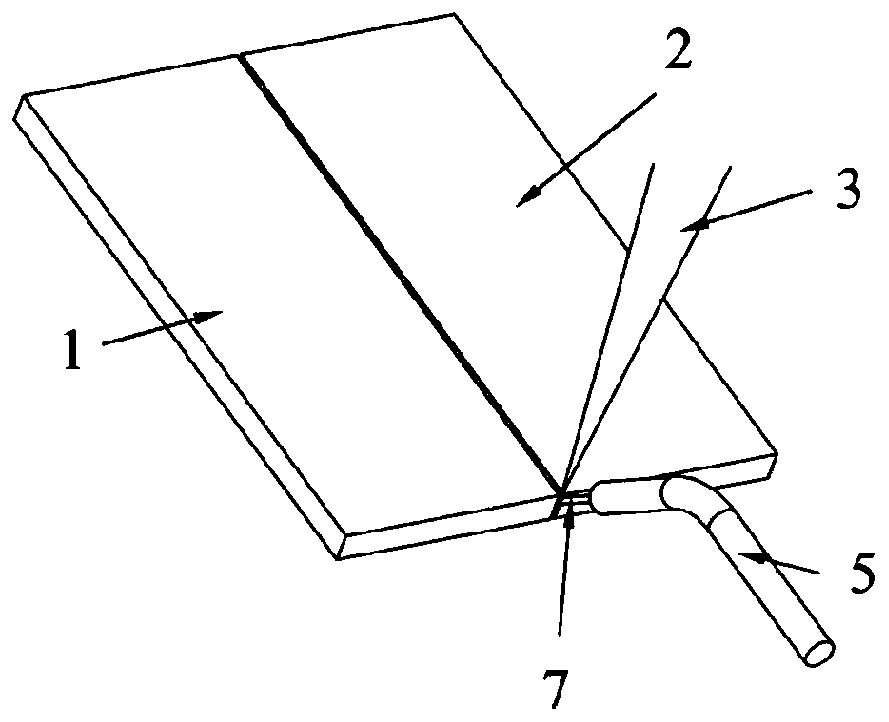

[0060] In this embodiment, a medium-entropy alloy material in the form of a welding wire with a diameter of 1.5 mm is used, and the composition formula is Cr30%, Co20%, and Ni50%. The welding between stainless steel and titanium is carried out. The schematic diagram of the welding method is as follows image 3 As shown, the steps are as follows:

[0061] (1) The base material of the metal material to be welded in this embodiment is treated with a V-shaped groove between the base material material A1 and the base material material B2, and the apex angle is 60°;

[0062] (2) Clean the groove to a clean state without oil, rust, impurities, and dust, and polish the groove to smooth;

[0063] (3) Under the protection of argon gas, an industrial robot is equipped with a laser 3 and a wire feeding system 5 is connected in parallel, and the entropy alloy material 7 in the form of welding wire in this embodiment is filled into the wire feeding system 5;

[0064] (4) According to the scanning sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com