Cable solder wire for CMT welding system and CMT welding system

A welding system and cable-type welding wire technology, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems of limited welding wire diameter and low efficiency, and achieve good welding effect, reduce cost, and improve the qualification rate of twisting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

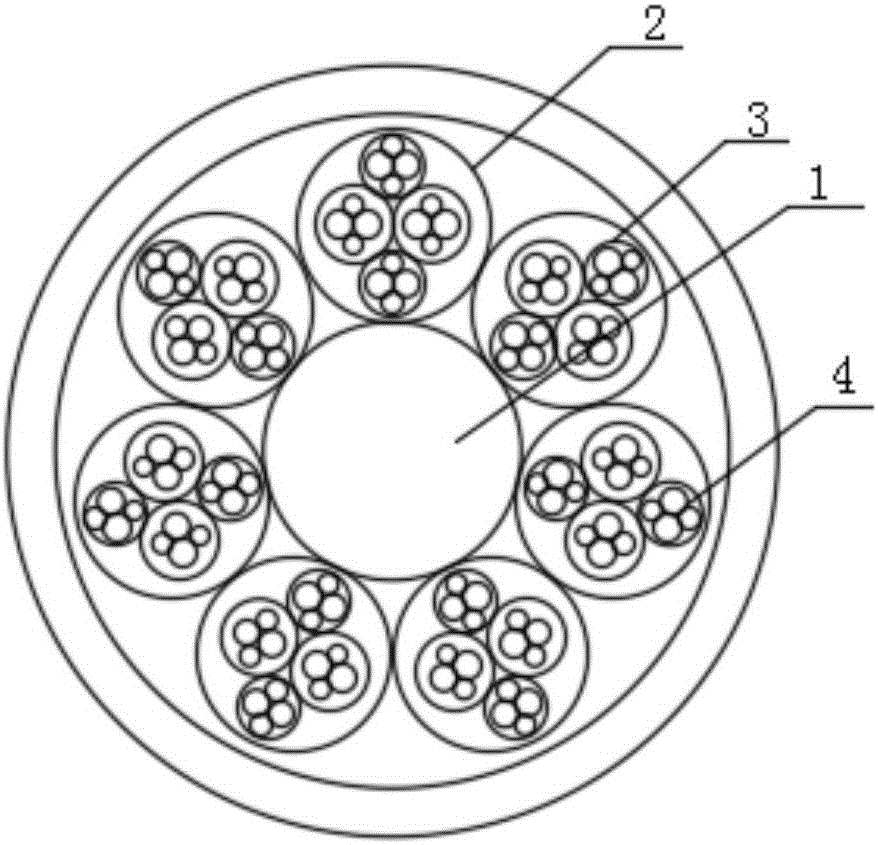

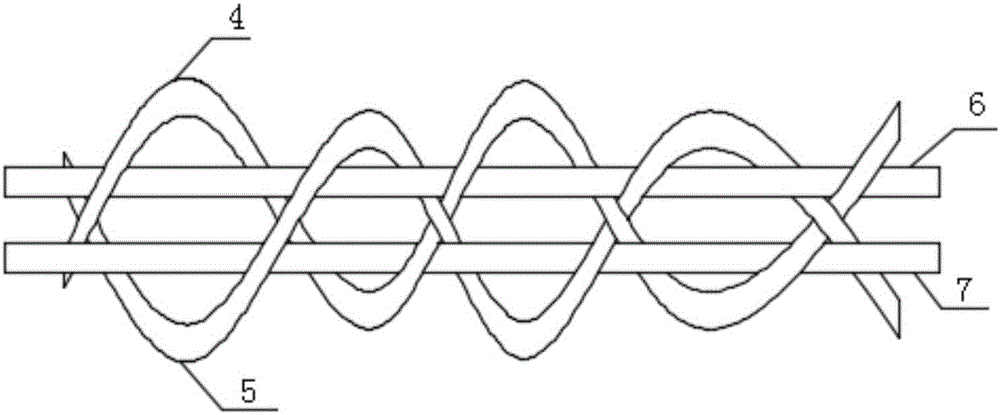

[0016] see Figure 1-2 , the present invention provides a technical solution: a cable-type welding wire applied to a CMT welding system, including a central welding wire 1, a spiral welding wire 2 is provided on the outside of the central welding wire 1, and the spiral welding wire 2 is tightly wound on the central welding wire in a helical manner 1, and the outer side of the spiral welding wire 2 is provided with a protective ring, four sets of sub-welding wire groups 3 are provided inside the spiral welding wire 2, and the sub-welding wire groups 3 are all arranged tangentially, and the sub-welding wire groups 3 The inside of the first welding wire 4, the second welding wire 5, the third welding wire 6 and the fourth welding wire 7 are all provided, and the diameters of the first welding wire 4 and the second welding wire 5 are D, and the third welding wire 6 and the fourth welding wire The diameters of 7 are all d, and d is less than D, the first welding wire 4 and the seco...

Embodiment 2

[0023] see Figure 1-2 , the present invention provides a technical solution: a cable-type welding wire applied to a CMT welding system, including a central welding wire 1, a spiral welding wire 2 is provided on the outside of the central welding wire 1, and the spiral welding wire 2 is tightly wound on the central welding wire in a helical manner 1, and the outer side of the spiral welding wire 2 is provided with a protective ring, four sets of sub-welding wire groups 3 are provided inside the spiral welding wire 2, and the sub-welding wire groups 3 are all arranged tangentially, and the sub-welding wire groups 3 The inside of the first welding wire 4, the second welding wire 5, the third welding wire 6 and the fourth welding wire 7 are all provided, and the diameters of the first welding wire 4 and the second welding wire 5 are D, and the third welding wire 6 and the fourth welding wire The diameters of 7 are all d, and d is less than D, the first welding wire 4 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com