TIG (Tungsten Inert Gas) welding gun using external magnetic field

A technology of external magnetic field and welding torch, which is applied in the direction of welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of slow flow of liquid metal, prone to pores, cracks, large supercooling, etc., and achieve compact structure and improved The mechanical properties of the weld and the effect of reducing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

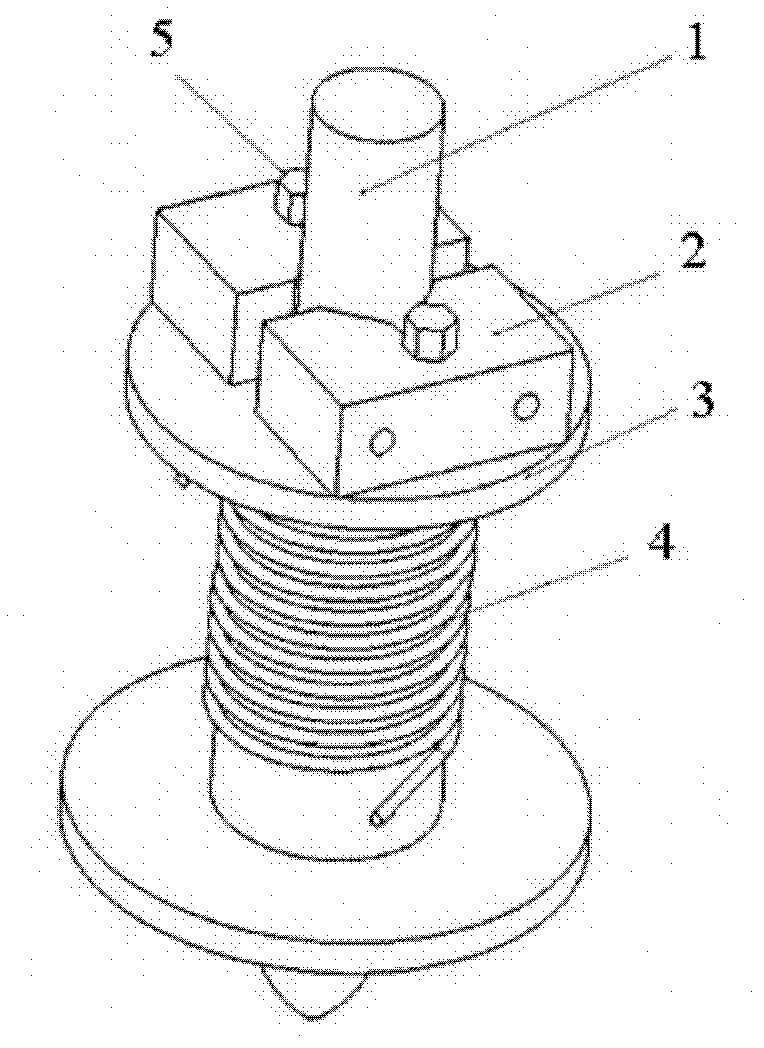

[0010] Attached below figure 1 The present invention is further described. In the present invention, the welding torch 1 is locked by the thread of the bolt 5 and the clamping device 2 and the winding shaft 3, and the entire applied magnetic field is realized by an applied current to realize electromagnetic conversion.

[0011] Judging by the left-hand and right-hand rules, the winding method of the coil 4 will generate a longitudinal magnetic field on the arc. Affected by the longitudinal magnetic field, the arc is "bell-shaped", and its bell surface is a closed curved surface rotating at a high speed; The magnetic field makes the arc temperature distribution diverge, the temperature field is "short and fat", the temperature at the center of the arc drops, and the radial temperature gradient is small; in the longitudinal magnetic field, due to the rotation and expansion of the welding arc, the weld width increases and the penetration depth decreases. Small; the liquid metal i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com