Method for reducing residual stress of metal structure material fusion welding joint

A welding joint and residual stress technology, applied in the direction of metal processing equipment, abrasive feeding devices, abrasives, etc., can solve the problems of increased surface roughness of workpieces, uncontrollable stress distribution, and reduced residual stress, so as to reduce residual stress , The effect of eliminating the residual tensile stress of components and relieving stress corrosion cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0030] One, embodiment (one):

[0031] The processing method of the present embodiment comprises the following steps:

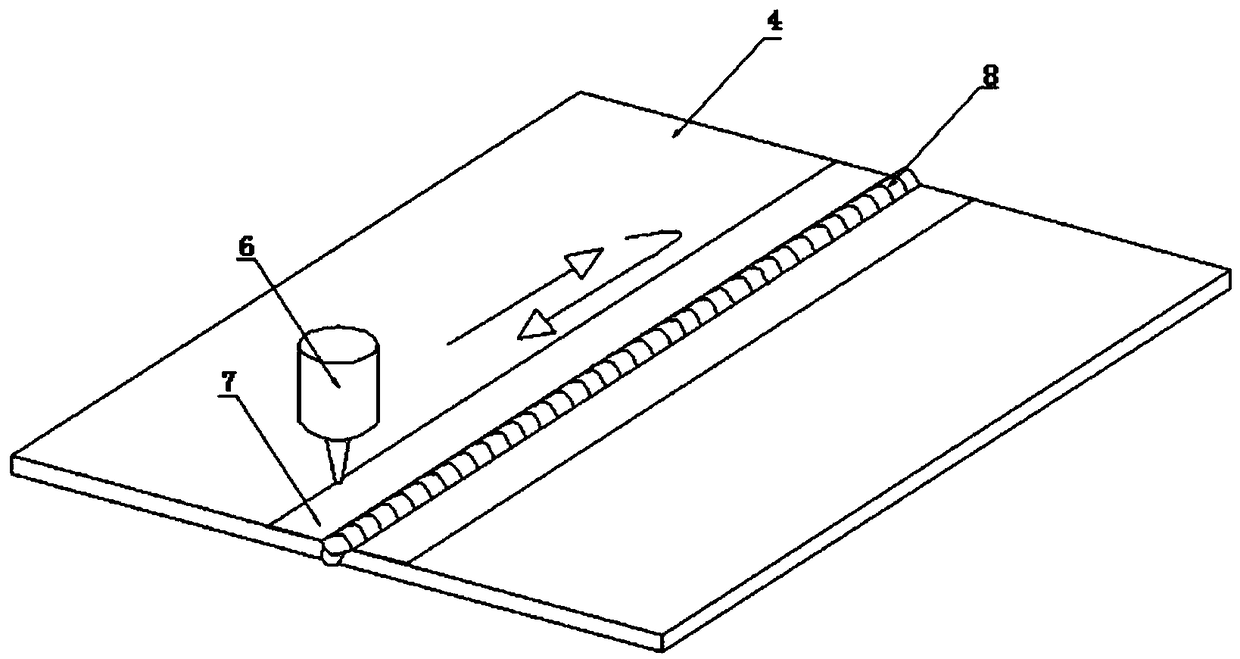

[0032] (1) Grind the 2219 aluminum alloy plate (300mm×150mm×8mm) VPTIG weld seam with 70#-400# sandpaper, and remove oil stains with acetone or alcohol. The area to be treated is the entire weld seam and the two sides of the weld seam respectively. Base metal extends 20mm;

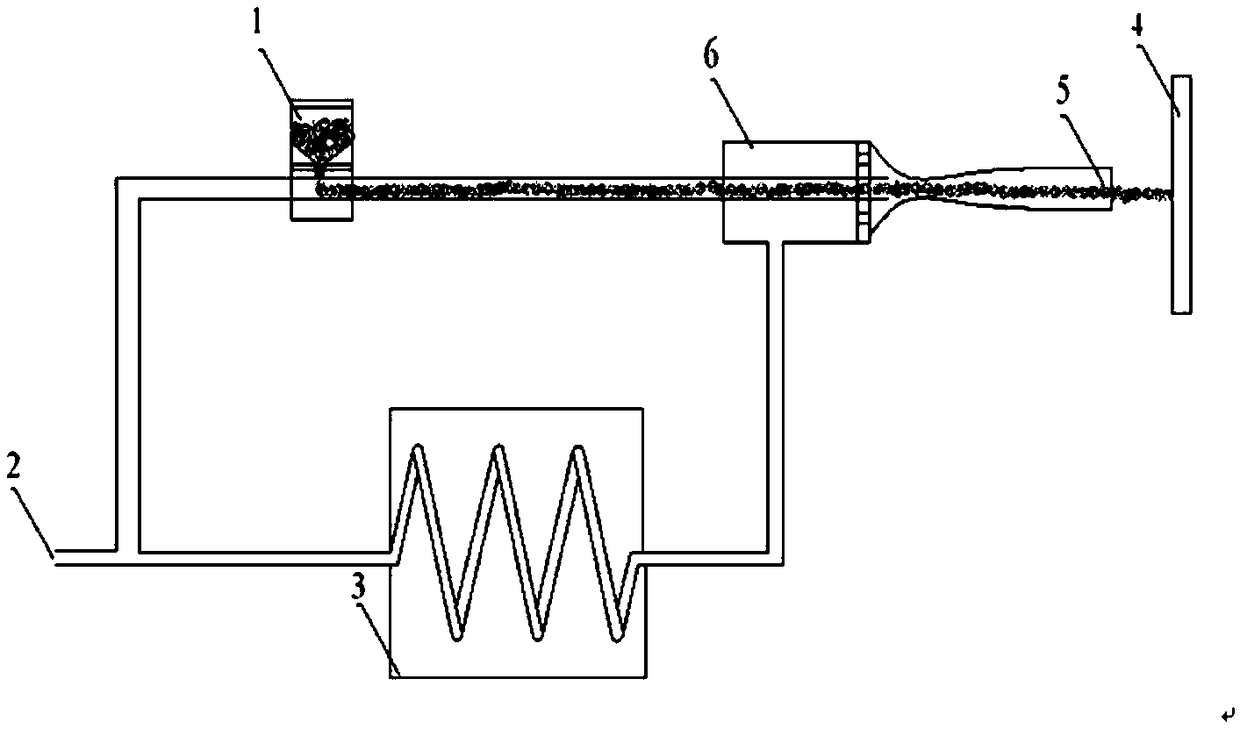

[0033] (2) Parameter selection: the metal particles are Cu particles, the gas pressure is 2.6MPa, the preheating temperature is 400°C, and the acceleration gas is nitrogen;

[0034] (3) Cu particles are loaded into the powder feeder, connected to the high-pressure gas source, and the nitrogen pressure reaches 2.6MPa, and a part of the nitrogen gas is passed into the powder feeder through the hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com