On-site repair and surfacing method for large-area metal walls

A large-area metal and on-site repair technology, which is applied to metal processing equipment, welding equipment, arc welding equipment, etc., can solve the problems of accumulation forming failure, welding machine ground wire cannot be conveniently pressed, etc., to ensure stability and good stacking The effect of welding layer accumulation morphology and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

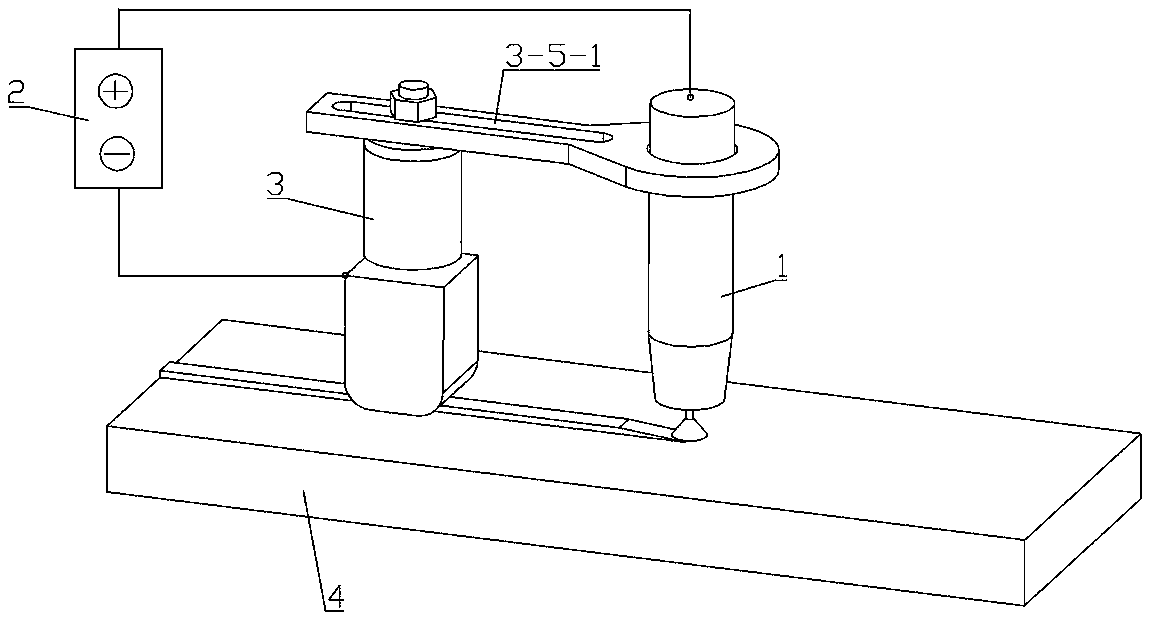

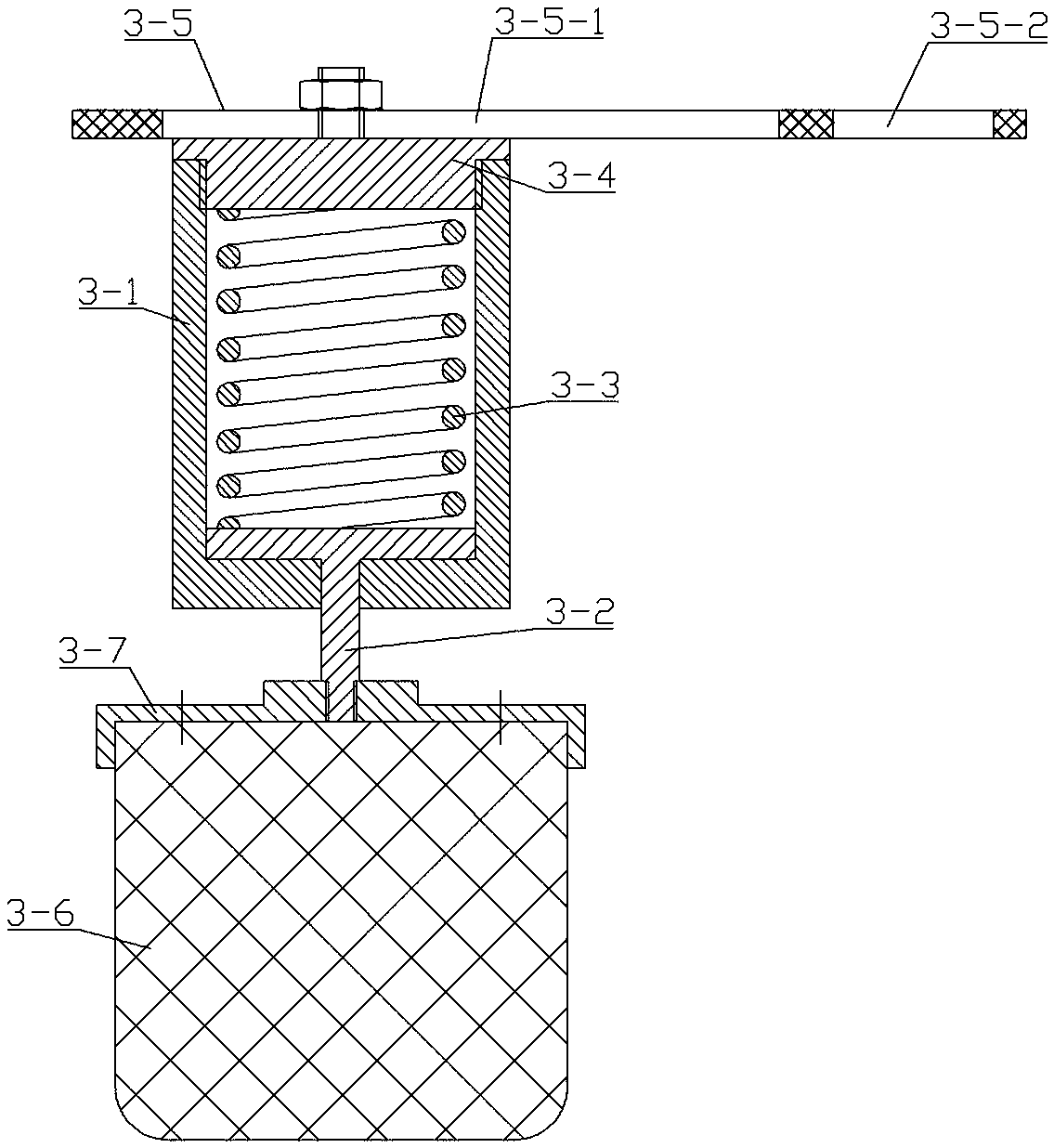

[0043] Such as figure 1 , 2 Shown, a kind of on-the-spot overlay welding method of metal wall surface repair of a large area, install synchronous moving mechanism 3 on the welding torch 1 in the surfacing device, during the surfacing process, the graphite slide block 3-6 on the synchronous moving mechanism 3 is in melting all the time. The rear of the pool, and is pressed on the surfacing layer by the elastic pressing mechanism on the synchronous moving mechanism, and moves together with the welding torch 1. The welding current enters the workpiece from the welding wire of the welding torch through the arc, and then returns to the welding machine from the graphite slider 3-6 Negative pole of power supply 2;

[0044] The specific welding steps are as follows:

[0045] S01, perform simple mechanical polishing on the welding surface of the surfacing workpiece, and remove rust, water and oil;

[0046] S02, the welding torch 1 approaches the workpiece 4 to be surfacing, when the...

Embodiment 2

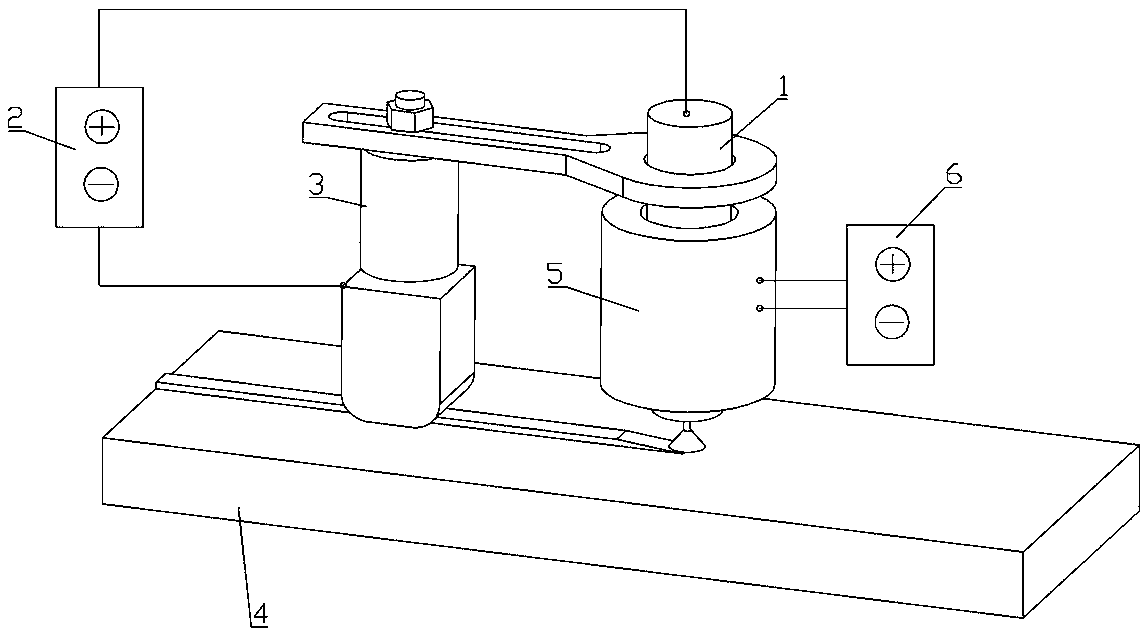

[0055] Such as image 3 As shown, the only difference between this embodiment and embodiment 1 is that the longitudinal magnetic field coil 5 is installed on the welding torch 1, and the longitudinal magnetic field coil 5 is connected with the longitudinal magnetic field AC power supply 6, and the frequency of the AC power supply is 7-15 Hz. The longitudinal magnetic field coil 5 generates a longitudinal magnetic field in the molten pool area, and the longitudinal magnetic field forms rotating electromagnetic stirring on the molten pool, and the stirring flow impacts the crystallization front, fuses the dendrites, and refines the grains.

Embodiment 3

[0057] Such as Figure 4~6 As shown, the difference between this embodiment and Embodiment 1 is only that a transverse magnetic field generating device is installed on the connecting plate 3-5 of the synchronous moving mechanism 3, and the coil 8-2 of the transverse magnetic field generating device is connected with the DC power supply 7, A constant transverse magnetic field pointing to the right side of the welding traveling direction is generated during the surfacing process, and the strength of the transverse magnetic field is between 100 and 200 gauss. The transverse magnetic field promotes the backward transport of the melt, improves the acceptability of the molten pool to the droplet, and makes the arc deflect in the direction opposite to the direction of the welding torch. dramatically decrease.

[0058] The transverse magnetic field generating device includes a DC power supply 7, a first iron core 8-1, a second iron core 8-4, a transverse magnetic field coil 8-2 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com