Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Improve the ability of deep processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

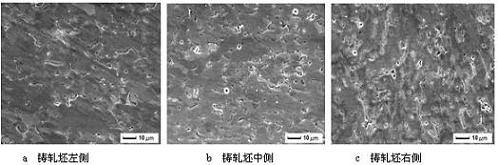

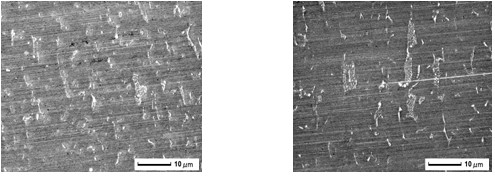

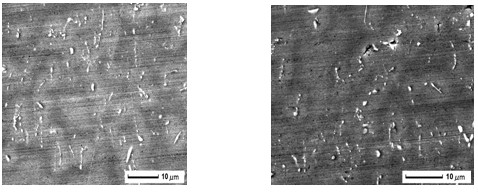

Method for producing wide-amplitude double-zero aluminum foil blank by adopting cast-rolled compact

InactiveCN102492900ASolve the problem of soft tensile propertiesImprove rolling effectMetallurgyCu element

The invention belongs to the technical field of aluminum alloy sheet strip foil material processing, and in particular relates to a method for producing a wide-amplitude double-zero aluminum foil blank by adopting a cast-rolled compact. By adjusting 8079, 1235 and other alloying components and adopting twice intermediate annealing processes, the non-uniform compound scale and distribution, caused by roll cooling intensity difference, of the wide-amplitude cast-rolled compact along the same board plane are eliminated, thus the pinhole degree and performances of the blank foil after rolling are superior to those of 1235; at the same time, through addition of Cu element, the problem of soft tensile property when the wide-amplitude blank is rolled to the double-zero foil after twice annealing is solved; and the rolling performance and foil rolling efficiency of the wide-amplitude blank are improved.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD +1

Fine crystal rare earth oxide molybdenum alloy-doped and its preparation method

InactiveCN1757775AGood mechanical propertiesImprove room temperature fracture toughnessRare earthMuffle furnace

A RE oxide doped fine-crystal Mo-alloy is prepared from MoO2 through doping RE oxide by atomizing method, ball grinding, sieving, reducing in H2 atmosphere in muffle furnace at 800-1100 deg.C, cold isostatic pressing under 150-200 MPa for shaping, segmental sintering in MF induction furnace and mechanical deforming to obtain rod or plate. It has high strength, ductility and toughness.

Owner:山东铭特金属材料科技有限公司

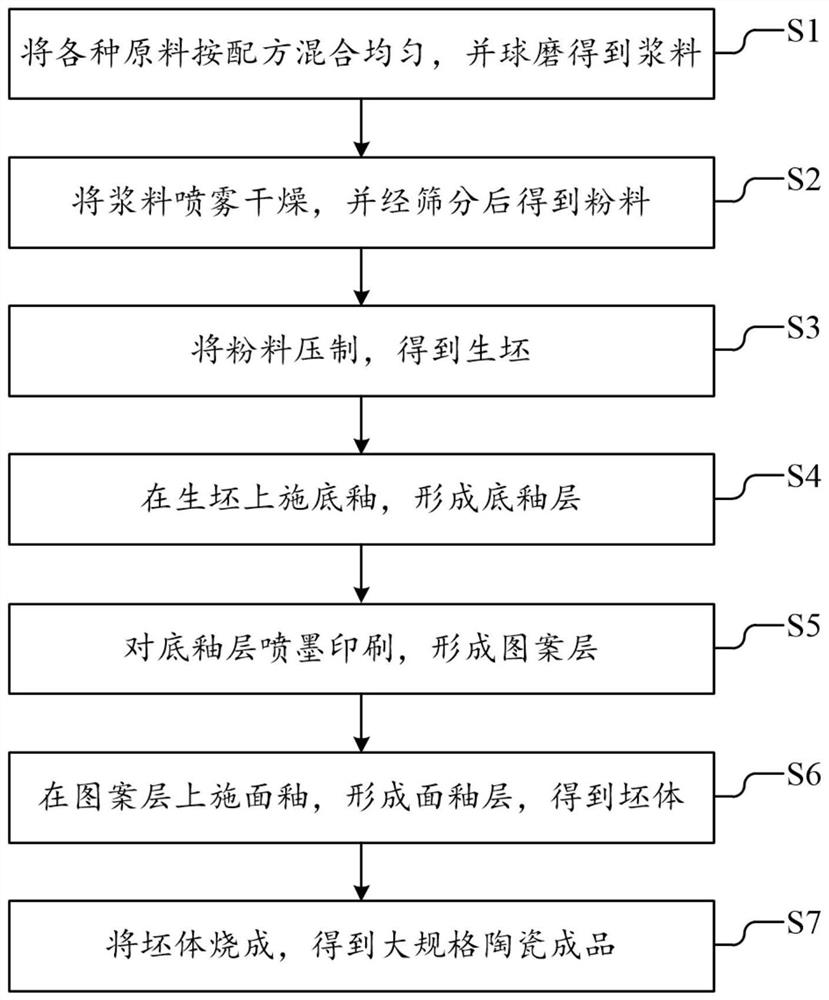

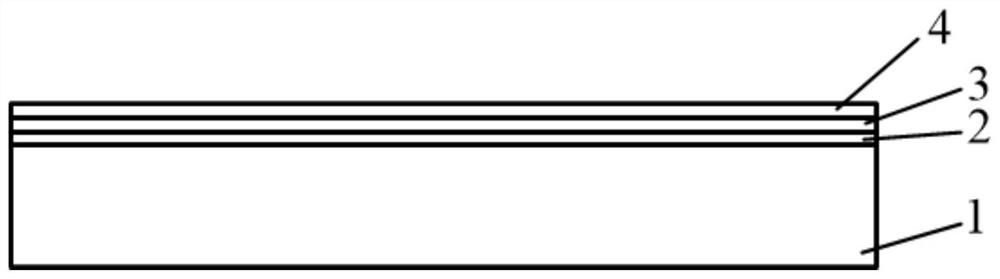

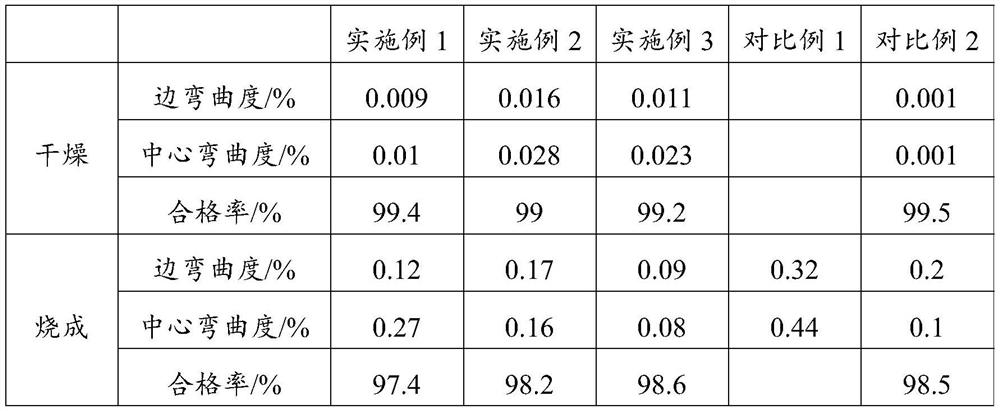

Large-size ceramic rock plate and preparation method thereof

ActiveCN111646788ALess stress buildupRelief of residual stressCovering/liningsPotassium feldsparKaolin clay

The invention discloses a large-size ceramic rock plate which has a surface area of 3-12m<2> and a thickness of 12-30mm. The large-size ceramic rock plate comprises a green body layer, a ground coat layer, a pattern layer and a cover coat layer; wherein the thickness of the green body layer is 11.5-29.5mm; the green body layer is mainly prepared from the following raw materials by weight: 15-20 parts of potassium feldspar, 8-15 parts of albite, 15-20 parts of calcined kaolin, 12-20 parts of black mud, 8-15 parts of white mud, 15-20 parts of pyrophyllite and 1-10 parts of a toughening agent; wherein the sum of the weight parts of the raw materials is 100 parts. The ceramic rock plate can well adapt to a later deep processing technology, can be widely applied to the fields of floors, curtainwalls and veneers, and has the advantages of high strength, high hardness, acid and alkali resistance, high temperature resistance and the like.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

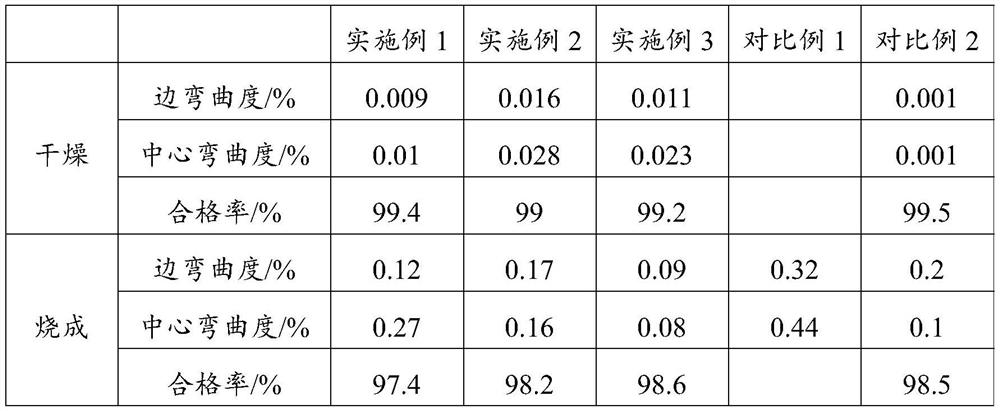

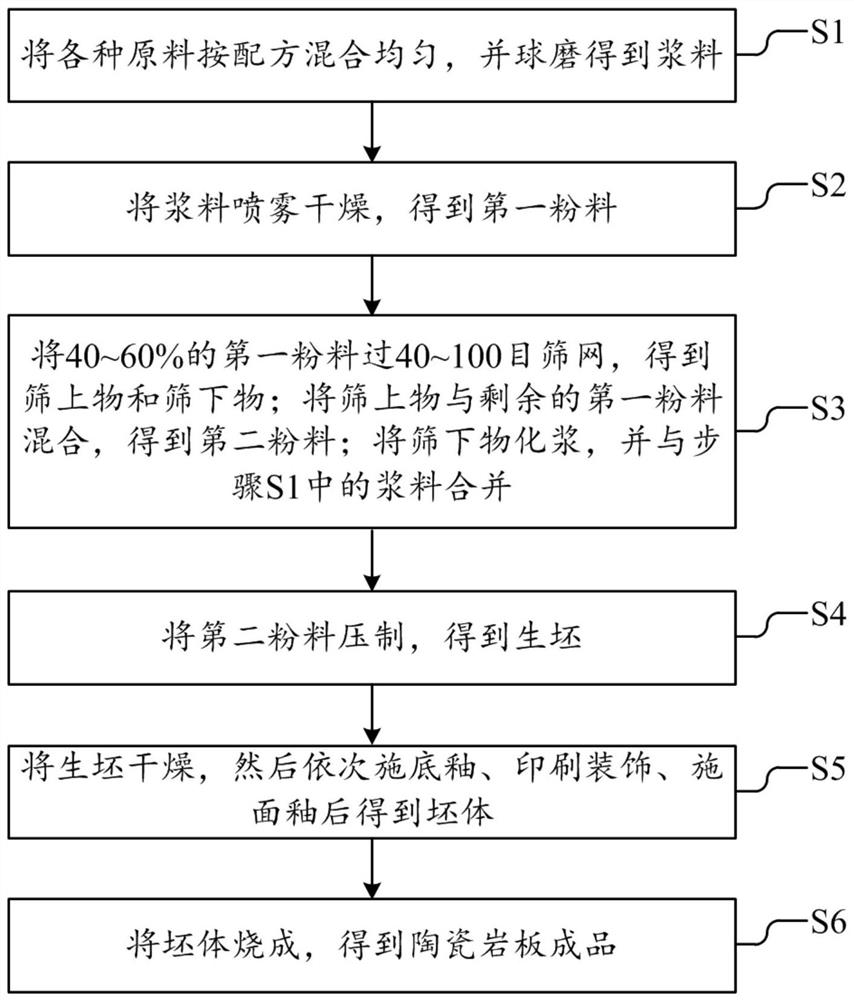

Preparation method of ceramic rock plate and the ceramic rock plate

ActiveCN111704450AImprove machinabilityImprove liquidityCeramic materials productionSpray driedSlurry

The invention discloses a preparation method of a ceramic rock plate, which comprises the following steps: preparing slurry, carrying out spray drying to obtain powder, screening a part of the powder,mixing the screened powder with the remaining powder to obtain pressed powder, pressing the plate, glazing the plate, decorating the plate, and firing the final product. The invention further discloses the ceramic rock plate prepared by adopting the preparation method. The ceramic rock plate can well adapt to a later deep processing technology, can be widely applied to the fields of floors, curtain walls and veneers, and has the advantages of high strength, high hardness, acid and alkali resistance, high temperature resistance and the like.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Ferrotitanium with low silicon and its preparation method

A low-Si ferrotitanium contains Ti (35-75 wt.%), Al (1-12 wt.%), Si (0-1.5 wt.%), C (0-0.05 wt.%), P (0-0.02 wt.%), S (0-0.02 wt.%) and Fe (rest), and is prepared from titanium ore concentrate and waste titanium material through smelting, or from waste steel and pure titanium through resmelting. Its advantage is high purity.

Owner:江苏江南铁合金有限公司

Preparation of nano rare-earth oxide doping molybdenum alloys

The invention discloses a method for preparing a nano rare earth oxide doped molybdenum alloy. In the method, by taking rare earth ammonium dimolybdate crystals as raw materials and adopting the roasting and hydrogen reduction method, molybdenum alloy powder is obtained, the powder after reduction is in press-forming by the isostatic cool pressing with a pressure of between 180 and 200 Mpa, the formed blank materials are presintered in a muffle furnace with a temperature of between 1, 100 and 1, 300 DEG C, and sintered in a vacuum intermediate frequency induction sintering furnace at a temperature of between 1, 600 and 1, 900 DEG C for 10 to 24 hours; the materials sintered can be made by the prior mechanical processing methods into materials and products with different shape such as molybdenum alloy bar materials or plate materials, etc. as required. The molybdenum alloy containing nano rare earth oxide, prepared by the method of the invention, has the advantages of high intensity, ductility and toughness and wide application.

Owner:临沂明华管业有限公司

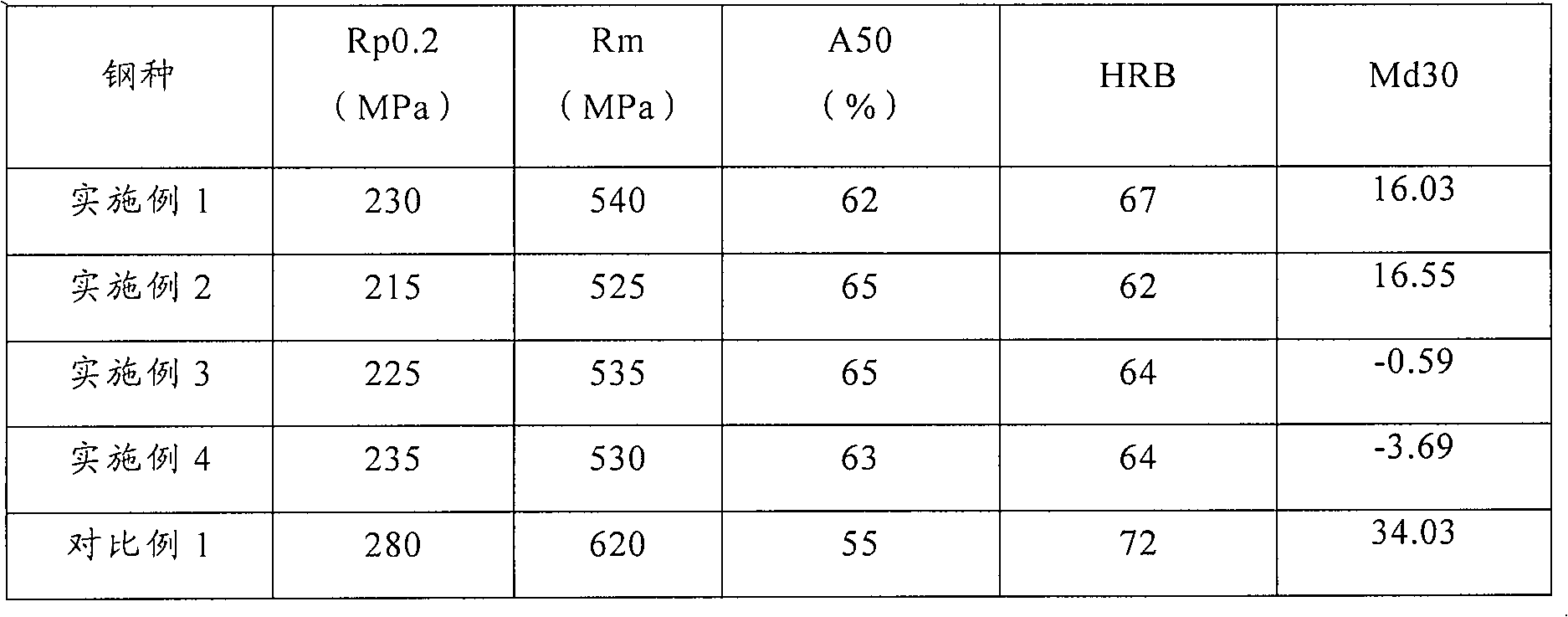

Soft austenitic stainless steel and preparation method thereof

ActiveCN102560285AImprove the ability of deep processingImprove corrosion resistanceProcess efficiency improvementSlagNitrogen

The invention relates to a soft austenitic stainless steel which comprises the following components by weight: less than or equal to 0.025% of C, less than or equal to 0.020% of N, more than or equal to 6C of Ti, 10.00-12.00% of Ni, 18.00-19.00% of Cr, less than or equal to 2% of Mn, less than or equal to 0.40% of Si, less than or equal to 0.015% of S, less than or equal to 0.045% of P, and the balance of Fe and inevitable impurities. The high-temperature ferrite delta content of the austenitic stainless steel is less than 5%. The invention also relates to a preparation method of the soft austenitic stainless steel. The preparation method comprises the following steps of: skimming slags after completing the reduction at a refining station; after skimming slags, adding lime and fluorite in each ton of liquid steel, and performing slagging at least twice, with the N content being controlled within the range of 0.015-0.025%; after two slaggings, adding TiFe powder into each ton of liquid steel till tapping ladle; after tapping, adding low-carbon synthetic slag so as to perform a slag exchanging operation and further absorb TiN impurities; when the liquid steel reaches an LF (ladle furnace) refining furnace for refining, adding a certain quantity of TiFe wires, thereby causing Ti to be more than or equal to 6C; and casting after stirring, wherein the nitrogen content of an end product after being cast is less than or equal to 0.020%. The soft austenitic stainless steel provided by the invention is applied to the field with higher demand on forming property and corrosion resistance.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

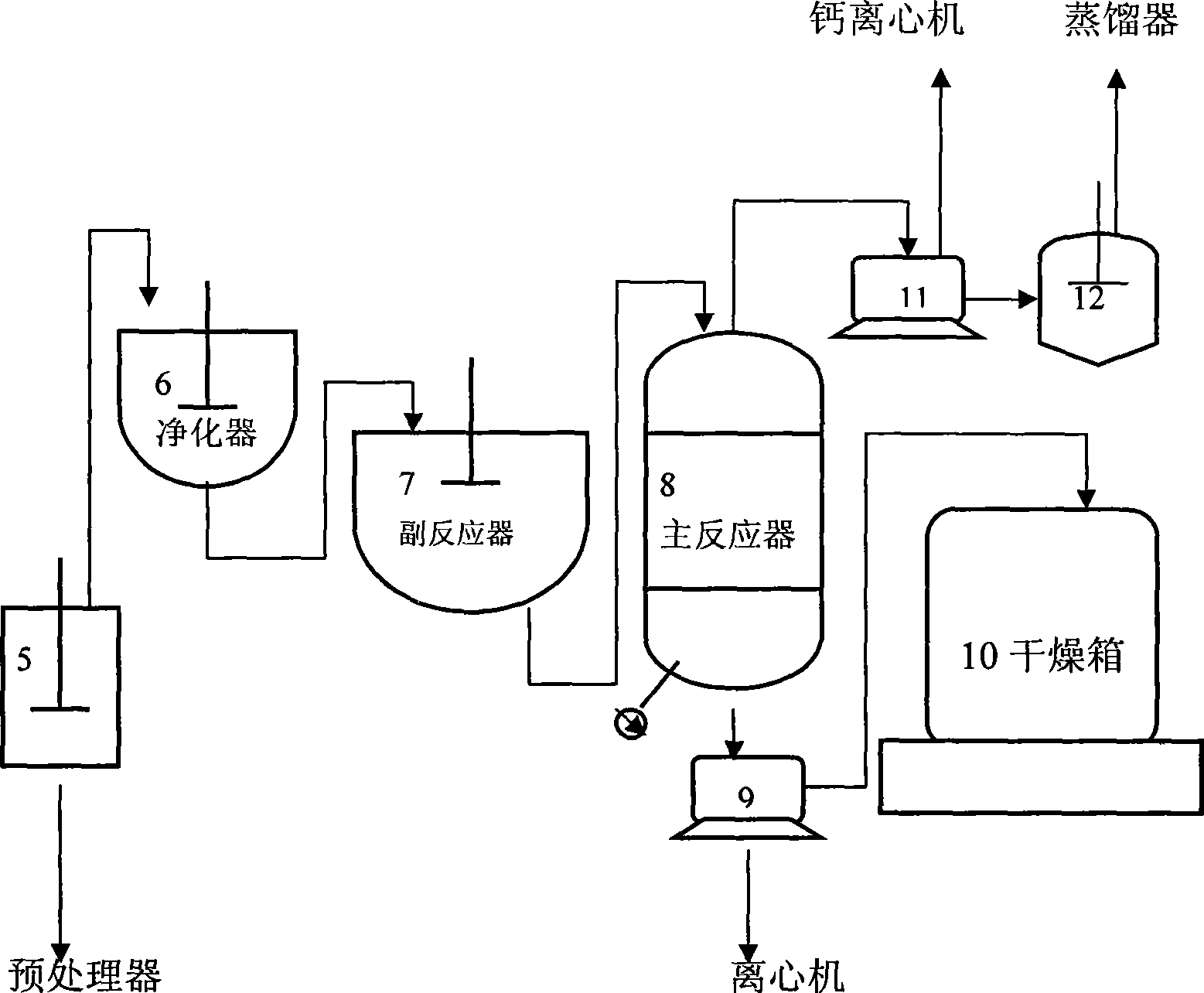

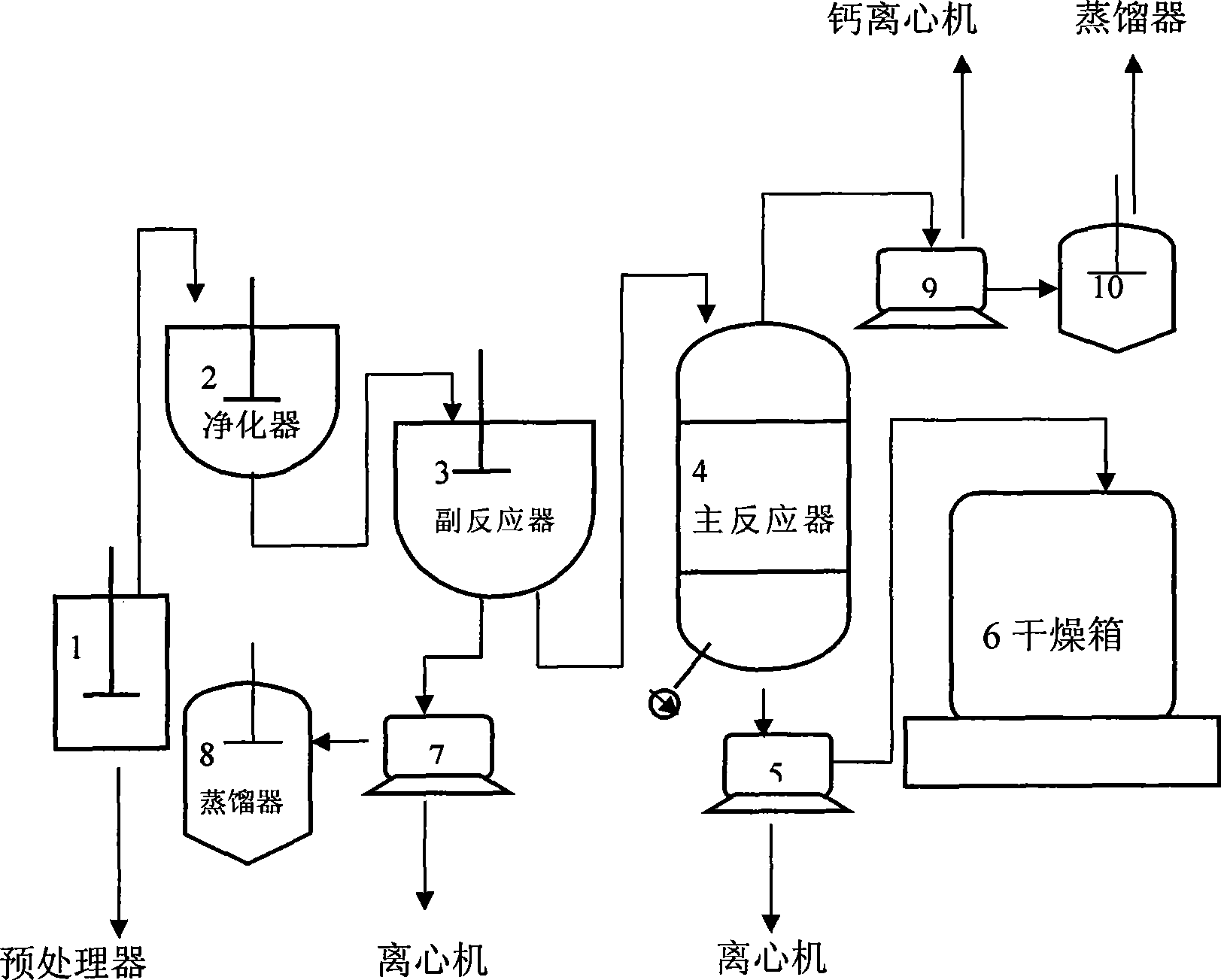

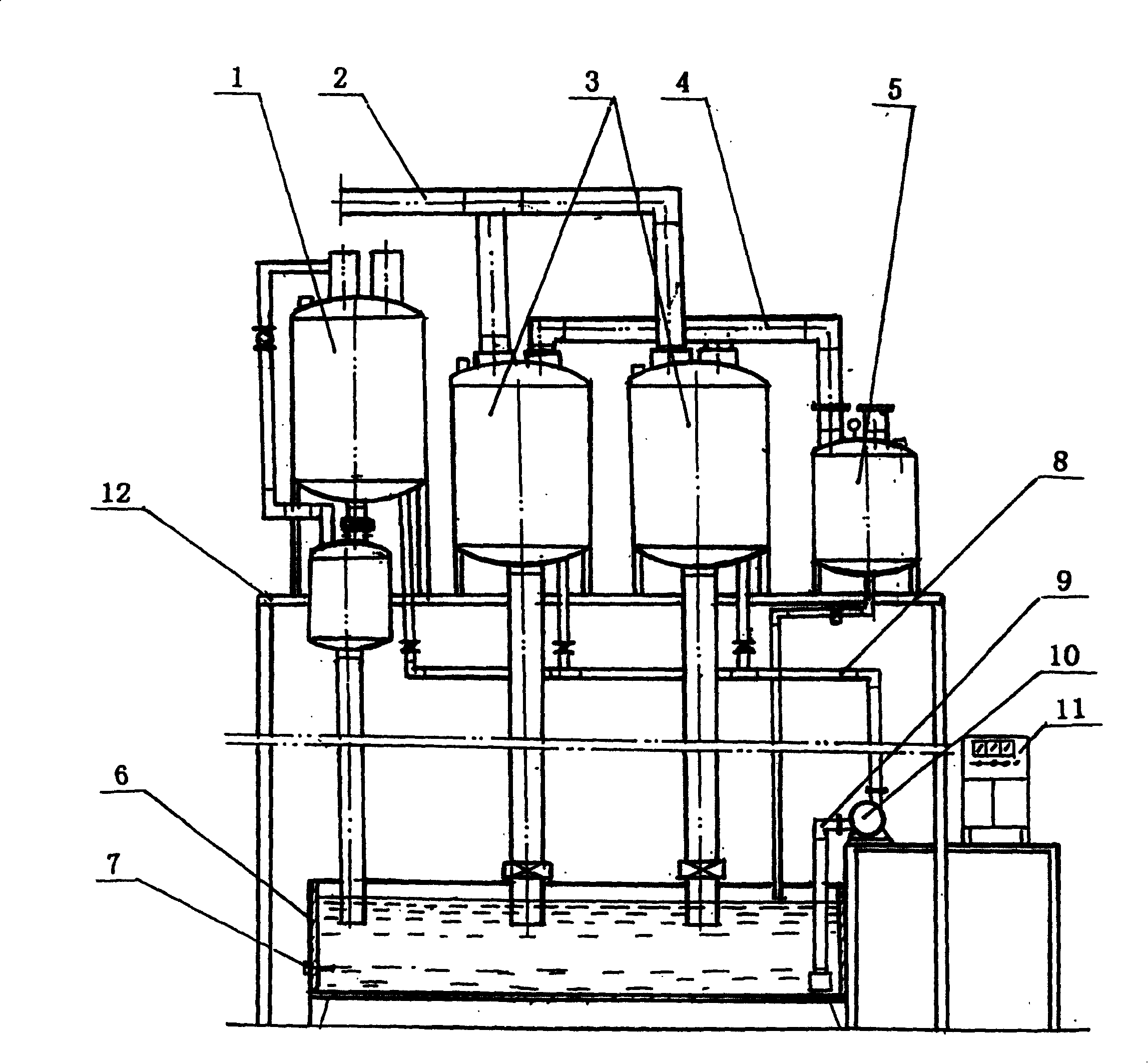

Material circulation system formed by waste carbide mud residue and alkali-chloride industry

InactiveCN101456026ASolve disposal problemsSolve the problem of raw materialsElectrolysis componentsSolid waste disposalElectrolysisCalcium Chloride Hexahydrate

The invention discloses a material circulating system formed by waste acetylene sludge and the chlor-alkali industry. The system comprises: pretreated waste acetylene sludge is reacted with hydrochloric acid, the reaction product is filtered to obtain a calcium chloride solution; the filtrate is reacted with sodium hydroxide generated by electrolysis of a chlor-alkali factory to generate high-purity calvital; the calvital is chloridized, centrifugated, dried and crushed to prepare bleaching powder; and filter cakes are reacted with the hydrochloric acid to generate active carbon. The calcium chloride generated in the reaction can be prepared into calcium chloride dihydrate and anhydrous calcium chloride; and sodium chloride after treatment can be taken as a raw material for electrolysis. The material circulating system effectively solves the problem of treating the waste acetylene sludge and raw material problem in the chlor-alkali industry, embodies recycling economy; and byproducts of the bleaching powder and the active carbon and calcium chloride dihydrate products improve deep processing capacity of an enterprise.

Owner:南通宙亚电子科技有限公司

Preparation method of rosinyl magnetic polymer microspheres

InactiveCN102675517AImprove the ability of deep processingIncrease added valueFerroso-ferric oxidesNatural resin chemical modification(Hydroxyethyl)methacrylateOil phase

The invention discloses a preparation method of rosinyl magnetic polymer microspheres, and the method comprises the following steps of: mixing rosinyl hydroxyethyl methacrylate ester, styrene and divinylbenzene with self-made oleic acid modified Fe3O4 to prepare an oil phase; then mixing deionized water with a dispersant to obtain a water phase; mixing the oil phase with the water phase, adding an initiator, agitating uniformly, and rising temperature for reaction; cooling the product to room temperature, washing with distilled water, removing nonmagnetic substances by a magnetic isolation method to obtain brown products; and soaking with diluted hydrochloric acid to remove Fe3O4 not buried in the microspheres, washing with distilled water to be neutral, and performing vacuum drying to obtain the rosinyl magnetic polymer microspheres. The dispersant is gelatin and the initiator is azodiisobutyronitrile. The method provided by the invention has the advantages of easily available raw materials, simple synthetic process, environmental friendliness and no toxicity. Inorganic material Fe3O4 and an organic high polymer are composited to prepare the magnetic microspheres to endow rosin with novel property and function, thereby expanding the application field of the rosin.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

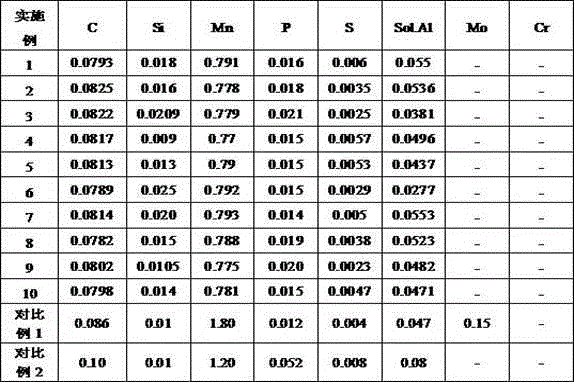

Alloying hot-dip galvanized steel with tensile strength being 390 MPa-level and used for automobile and production method

ActiveCN105063475AV-bend pulverization level reductionSimple production processHot-dipping/immersion processesPre treatmentContinuous annealing

The invention provides alloying hot-dip galvanized steel with tensile strength being 390 MPa-level and used for an automobile. The alloying hot-dip galvanized steel comprises, by weight, 0.07%-0.10% of C, not larger than 0.03% of Si, 0.7%-1.0% of Mn, 0.010%-0.025% of P, not larger than 0.010% of S and 0.020%-0.070% of Als. The production method includes the steps of molten iron preprocessing; smelting with a converter and RH furnace processing; continuous casting, casting blank heating, hot rolling, coiling, acid pickling, cold continuous rolling, continuous annealing, hot galvanizing, alloying, finishing, on-line direct roller painting of self-lubricating paint and drying of a self-lubricating alloying plate. By means of the alloying hot-dip galvanized steel, it can be guaranteed that the yield strength ranges from 290 MPa to 320 MPa, the tensile strength ranges from 390 MP a to 440 MPa, the elongation percentage is not less than 36%, the roughness ranges from 0.4 microns to 1.0 microns, and the PC value is not less than 90; the ingredients and the technology are simple, and the cost is relatively lower; a better plasticity is achieved; meanwhile, through direct roller painting of a self-lubricating film, the pulverization level is upgraded to the first level; the pulverization resisting capability is excellent, and complex automobile inner plates and structural components can be stamped.

Owner:武汉钢铁有限公司

Method for coproduction of bleaching powder and active carbon as well as chlorine-containing compound from carbide slag

InactiveCN101439847AIncrease gross productImprove the ability of deep processingHypochloriteElectrolysisSlag

The invention discloses a method for joint production of activated carbon and compounds containing chlorine by using acetylene sludge to produce bleaching powder. The main technical proposal of the method comprises the following steps: the acetylene sludge is pretreated and then reacts with hydrochloric acid, a calcium chloride solution is obtained through the filtration, a filtrate reacts with sodium hydroxide produced by the electrolysis in a chlor-alkali plant to generate high-purity calcium hydroxide, the calcium hydroxide is chloridized, centrifuged, dried, and crushed to obtain the bleaching powder, and a filter cake reacts with the hydrochloric acid to obtain the activated carbon. Calcium chloride produced during the reaction can be produced into calcium chloride dihydrate and anhydrous calcium chloride; and sodium chloride can be produced into industrial salt. The method can ensure that an enterprise completely throws off the heavy burden of three wastes, make the enterprise achieve the fundamental aim of zero emission, greatly increase the total output value of the enterprise, and improve the economical benefit to a great extent. The method also adjusts a product structure of the enterprise, turns waste materials into bleaching powder and activated carbon products with high added values, improves the capability of deep processing of the enterprise, and has large pushing effect on the development of the enterprise.

Owner:南通宙亚电子科技有限公司

Producing method of dried muskmelon

InactiveCN103976302AImprove the ability of deep processingReduce wasteConfectionerySweetmeatsMusk melonProcess engineering

The invention discloses a producing method of dried muskmelon. The method includes: selecting fresh muskmelon, cleaning, sterilizing, peeling, taking flesh, cutting into slices, hardening, performing color protecting, blanching, performing solute osmosis, drying and reshaping. Beneficial effects of the producing method are that: the producing method overcomes the color browning problem of the muskmelon, preserves the original color and flavor of the muskmelon, enhances the deep processing capability of agricultural and sideline products, adopts rejected muskmelon as the raw material for deep processing of the muskmelon so as to achieve full utilization of raw materials, reduces waste of the muskmelon resource, completes muskmelon industrial production through producing downstream muskmelon products, increases the kinds of the agricultural and sideline products subjected to deep processing in Xinjiang, and enriches the market; and the producing method utilizes the resources reasonably and protects the environment.

Owner:丁保林

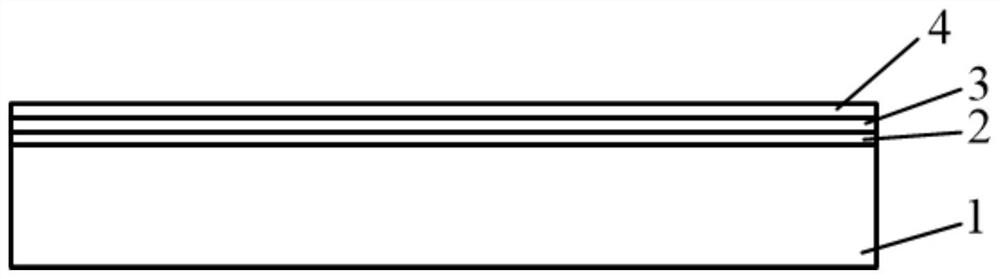

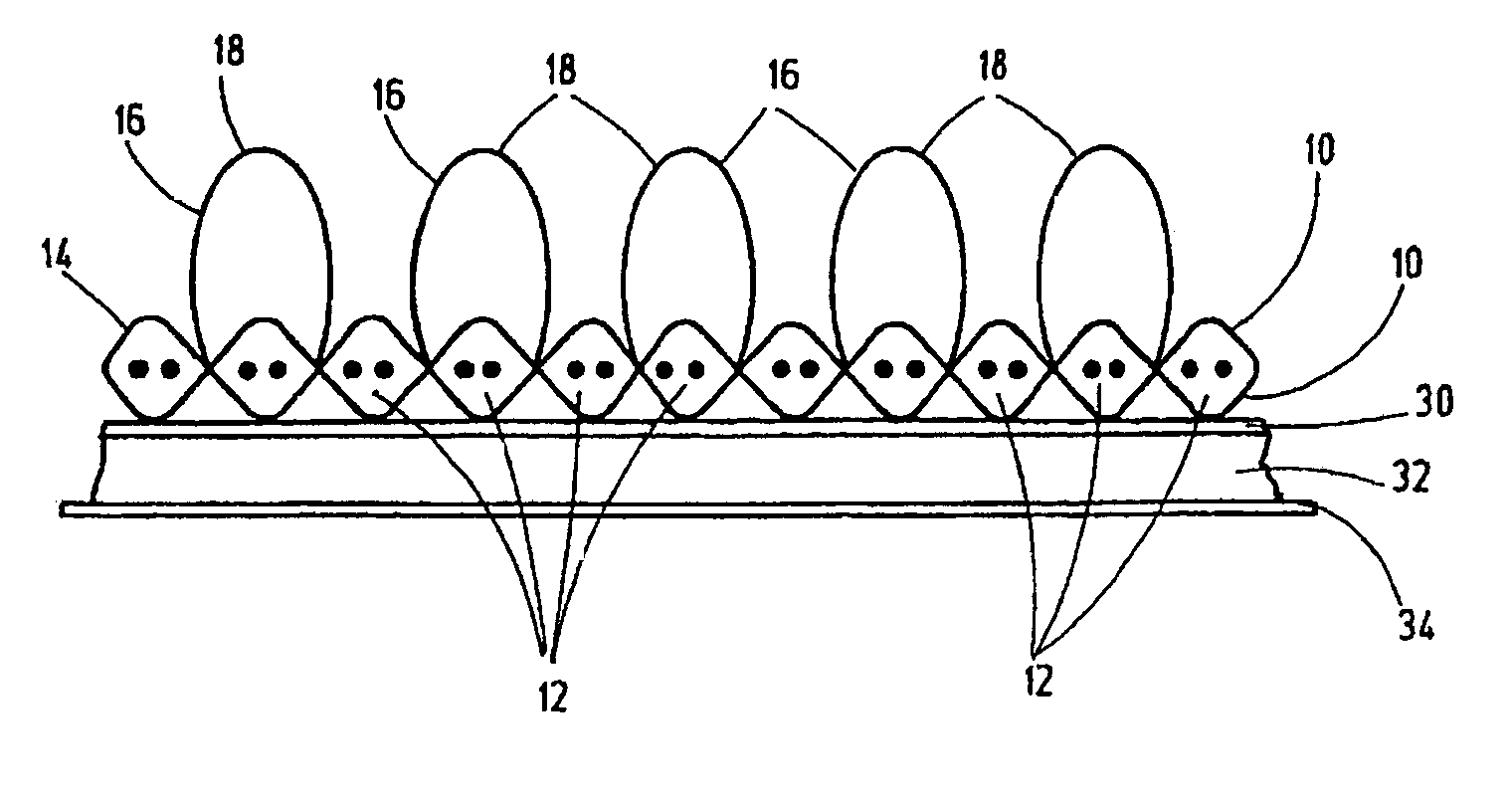

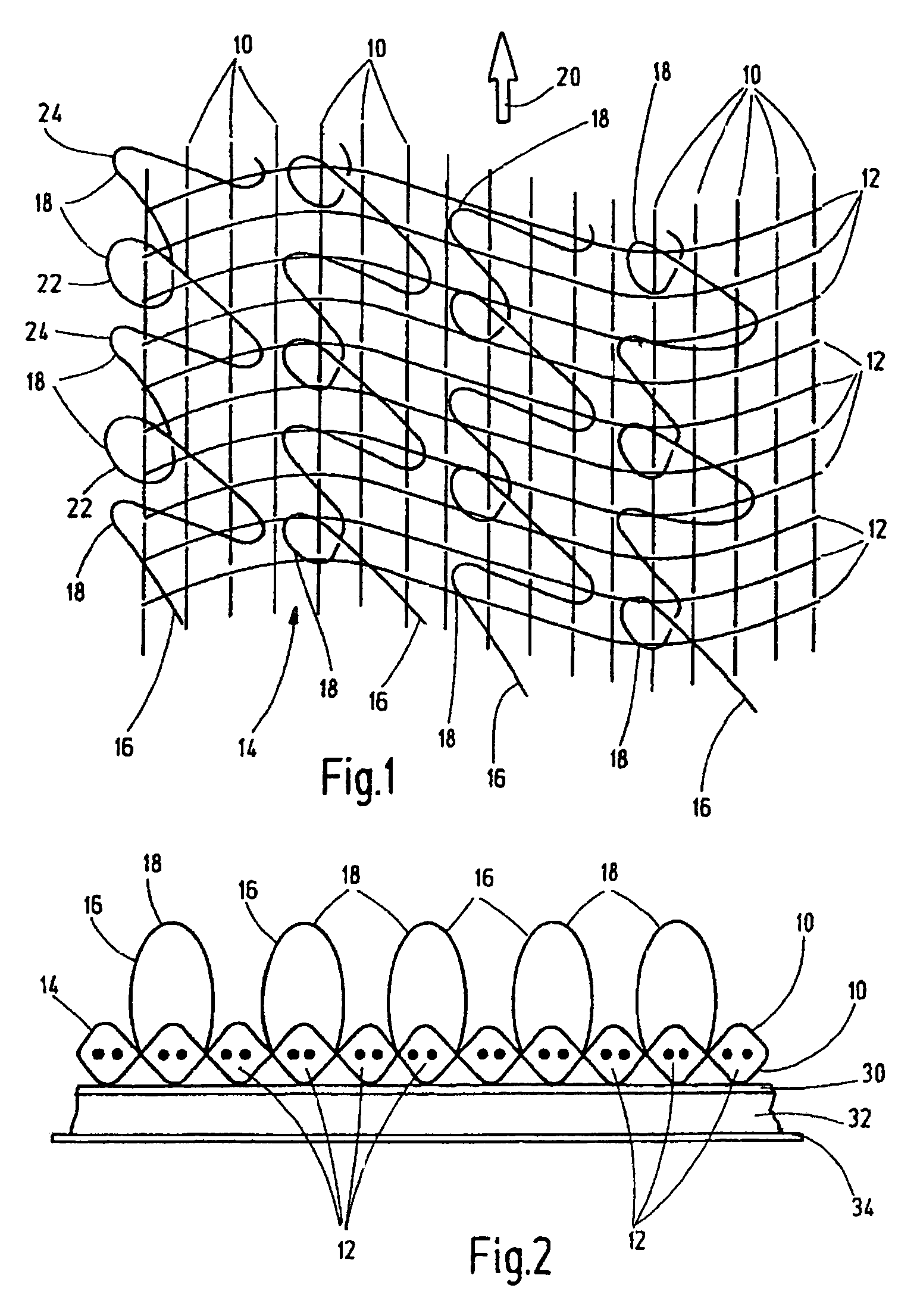

Flame-resistant closure

ActiveUS7670663B2Produced economicallyReduce flammabilityLayered productsWoven fabricsYarnEngineering

A flame-resistant closure includes at least one closing part having at least one two-dimensional backing fabric (14) of warp threads (10) and weft threads (12) and having functional threads (16) on the right side of the backing fabric (14). The functional threads at least partially extend through the backing fabric (14), and form the closing elements (18). The backing fabric (14) is of the non-flame-resistant type. At least some sections of the backing fabric reverse side include a substrate layer (32) with a substantially inflammable medium and / or with an active extinguishing medium. This closure meets even high demands on inflammability.

Owner:GOTTLIEB BINDER

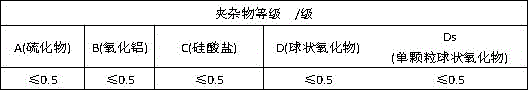

Forging molten steel used for producing spindle and hinged shaft of hydropower station generator and smelting process for forging molten steel

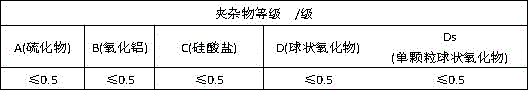

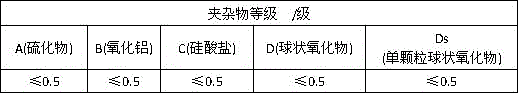

ActiveCN105543651AImprove cleanlinessSafe, long life and efficient operationHydrogenNon-metallic inclusions

The invention discloses forging molten steel used for producing a spindle and a hinged shaft of a hydropower station generator and a smelting process for forging molten steel. The forging molten steel used for producing a spindle and a hinged shaft of a hydropower station generator is prepared from the following chemical components in weight percentage: 0.42-0.46wt% of C, 0.20-0.30wt% of Si, 0.55-0.75wt% of Mn, less than or equal to 0.005wt% of S, less than or equal to 0.015wt% of P, less than or equal to 0.0010wt% of O, less than or equal to 0.0001wt% of H, less than or equal to 0.0045% of N, and the balance of Fe and unavoidable impurities. A preparation method comprises the processing steps of KR-method hot metal pretreatment and deep-desulfuration, converter smelting, LF ladle furnace refining, VD furnace vacuum refining and the like. Molten steel produced according to the invention is high in cleanness, the contents of nonmetallic inclusion and gas of the forging steel produced by adopting the method are relatively low, namely, oxygen content in steel is 0.0005-0.0010wt%, the content of hydrogen in steel is 0.00003-0.0001wt%, and the nonmetallic inclusion is in 0-0.5 grade. The forging molten steel has excellent toughness, low-temperature impact toughness, anti-fatigue performance and fracture toughness, thus meeting the safe, long-life and efficient operation of generators.

Owner:WUKUN STEEL

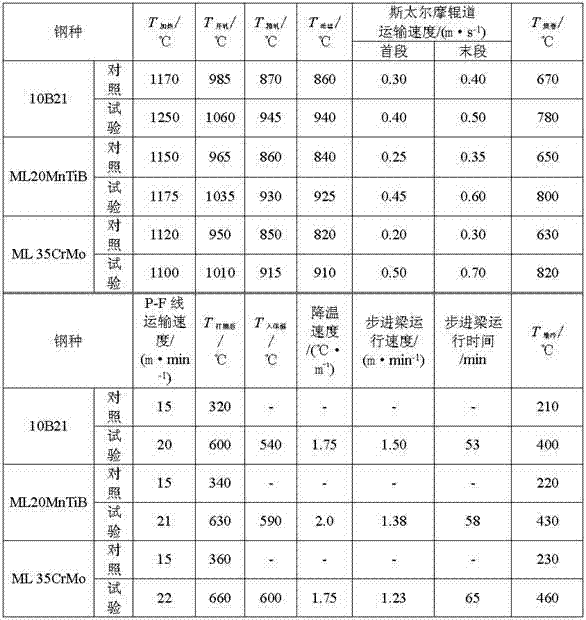

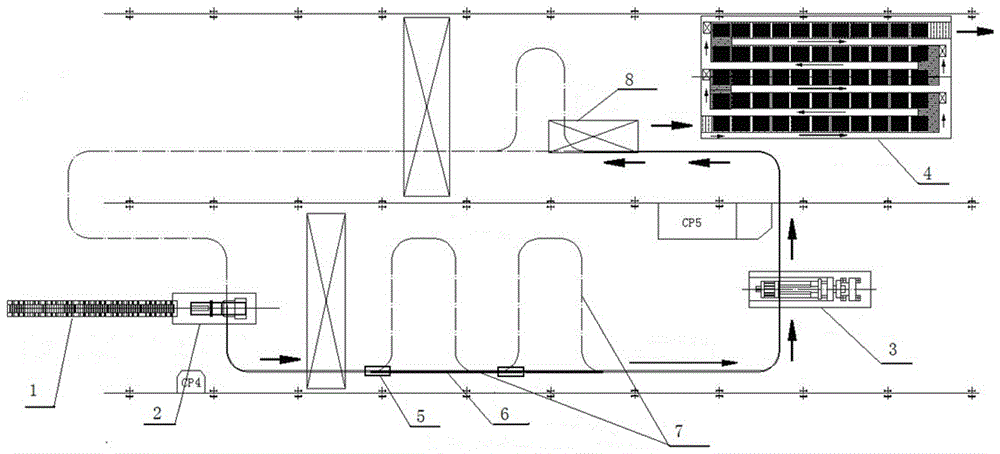

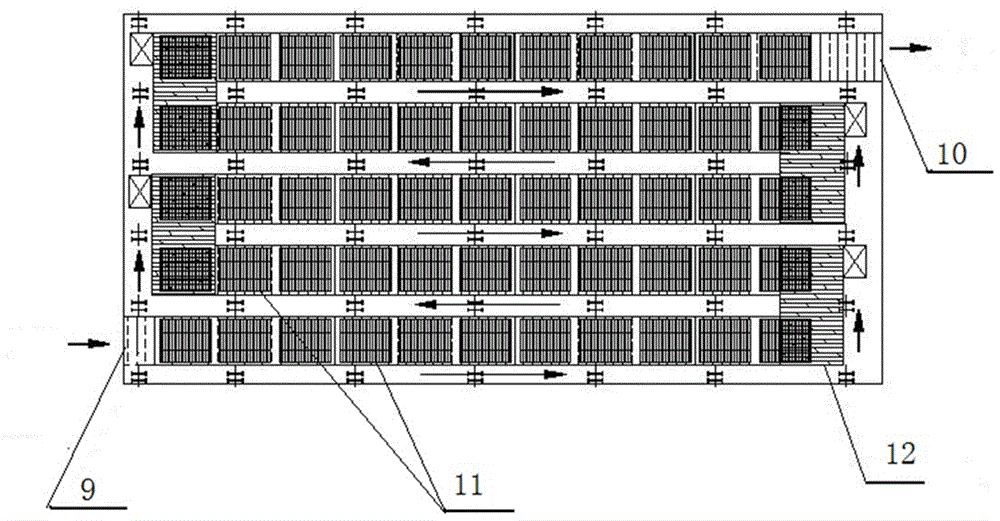

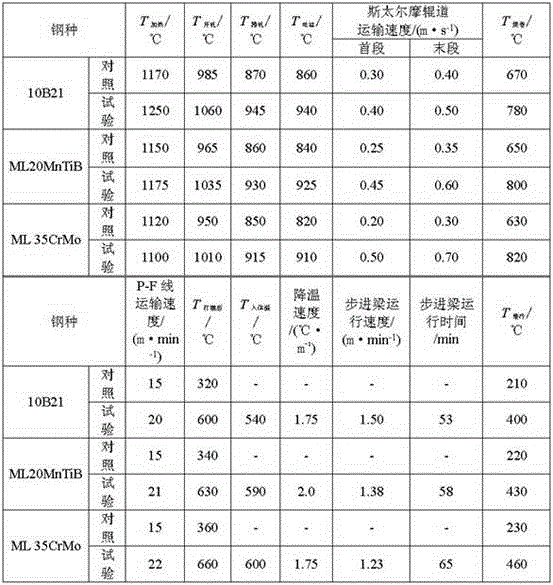

Method for softening and rolling cold forging steel

The invention discloses a method for softening and rolling a cold forging steel. The main process flow comprises the steps of heating, rolling, performing finish rolling, spinning, performing Sitaimoer roller controlled cooling, collecting, transporting, bundling, performing coil discharging, keeping the temperature in a temperature controlled chamber and performing stack cooling, wherein after collecting is finished, the cold forging steel coil is put to a P-F transportation line and the steel coil is rapidly transferred to a bander along a straight line rail; after coil discharging is finished, the steel coil is put to the temperature controlled chamber and slowly operates in the temperature controlled chamber until the temperature is 400-600 DEG C when the steel coil reaches the outlet; and finally stack cooling is performed to achieve room temperature. By adopting the method, the problems of low plasticity of the steel material and easy cracking of the cold forging steel due to integrated inner stress of the rolled cold forging steel are solved, the deep processing capability of the steel material is increased and the non-annealing of the cold forging steel is realized.

Owner:WUKUN STEEL

Method for preparing solid silicic acid from filter residue of boric sludge

InactiveCN102167329AImprove the ability of deep processingMeet the protection requirementsSilicaSilicic acidSludge

The invention discloses a method for preparing solid silicic acid from filter residue of boric sludge. The method comprises the following steps of: heating boric sludge to the temperature of between 60 and 80 DEG C by using steam and keeping the temperature for 1 to 2 hours, throwing to dry by using a centrifugal machine to obtain filter cake boric sludge, reacting the filter cake boric sludge and hydrochloric acid to generate hydrate of magnesium chloride, filtering the hydrate of magnesium chloride to obtain silicon dioxide filter residue, reacting the silicon dioxide filter residue and sodium carbonate to obtain sodium metasilicate nonahydrate aqueous solution, and filtering to remove the insoluble impurities to obtain the clear filtrate; and reacting the clear filtrate and sulfuric acid solution to generate the mixed solution of silicic acid and sodium sulfate, and filtering to obtain filter cake silicic acid jelly and clear filtrate, washing the silicic acid jelly, throwing to dry, freezing, crushing and packing to obtain the silicic acid powder product; and performing inspissation on the filtrate to obtain crystal, washing the crystal, throwing to dry, crushing, and packing to obtain the sodium sulfate crystal product. The waste material of the boric sludge which is polluted again is treated so as to obtain solid silicic acid, and secondary pollution is avoided and economic benefit is created.

Owner:王嘉兴

Austenitic stainless steel material

InactiveCN111254367AImprove the ability of deep processingImprove corrosion resistanceMetallurgySS - Stainless steel

The invention provides an austenitic stainless steel material. The austenitic stainless steel material comprises the following elements of, in percentage by weight, 0.02%-0.03% of C, 10.8%-12.5% of Ni, 20.0%-22.5% of Cr, 0.8%-1.0% of Mn, 0.4%-0.7% of Si, smaller than or equal to 0.036% of P, smaller than or equal to 0.013% of S, and smaller than or equal to 0.05% of N, and the other elements Fe and other impurity component elements.

Owner:泰州市淳强不锈钢有限公司

A stretch-bending straightening process for stainless steel cold-rolled strip

ActiveCN111185494BStraightening straightnessFixed straightnessStructural engineeringSS - Stainless steel

The invention provides a stretch-bending straightening process for stainless steel cold-rolled strips. Using stretch-bending straightening equipment, for stainless steel cold-rolled strips of different sizes and hardnesses, the tension of the braking S-roller group is adjusted to change the entrance of the bending unit. Angle and elongation of the strip can be used to correct the flatness of the strip; compared with the existing technology, this process can meet the technical requirements for the flatness of the stainless steel cold-rolled strip, effectively eliminate the shape defects, and improve the flatness of the strip. Model quality, improve product deep processing performance, thereby greatly improving product yield.

Owner:天津冶金集团天材科技发展有限公司

Seamless steel tube for cold rolling bearing ring sleeve and preparation method of seamless steel tube

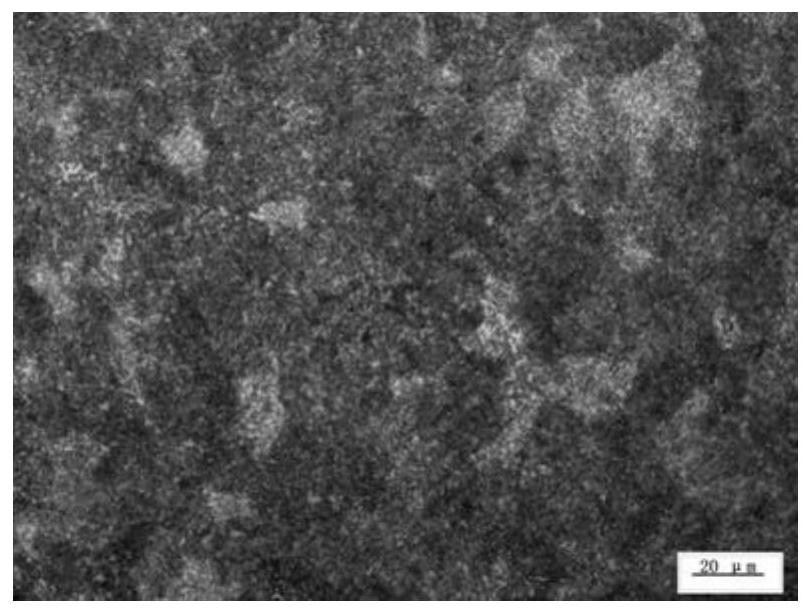

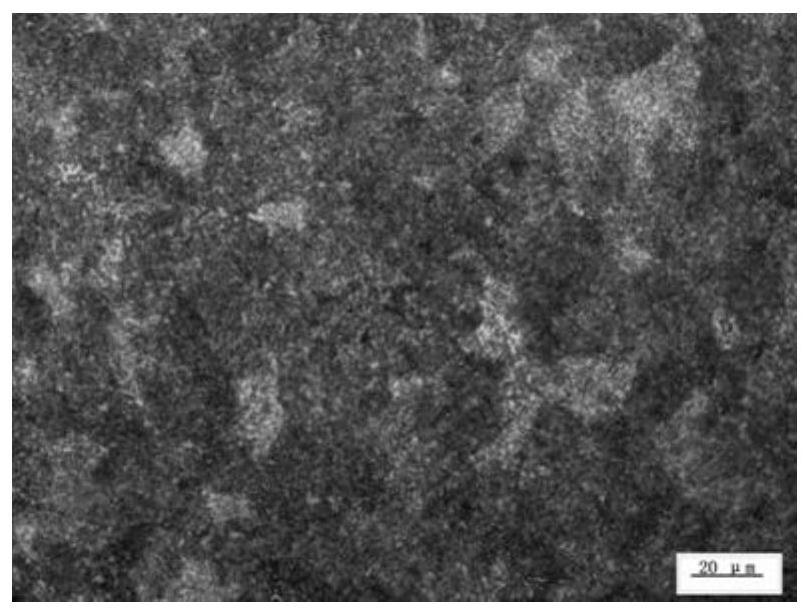

InactiveCN111218615AImprove the ability of deep processingEnsure safetyTemperature control deviceSteel tubeMicrostructure

The invention discloses a seamless steel tube for a cold rolling bearing ring sleeve. The seamless steel tube is prepared from the following chemical components in percentage by mass: 0.98-1.03% of C,0.15-0.35% of Si, 0.30-0.45% of Mn, 1.45-1.60% of Cr, greater than or equal to 0.020% of P, less than or equal to 0.010% of S, and the balance of iron and trace impurity elements. The invention further discloses a preparation method of the seamless steel tube. According to the seamless steel tube for the cold rolling bearing ring sleeve, the tubular body hardness after spheroidizing annealing is190 HBW-205 HBW, the annealing microstructure level is level 2, materials have good deep processing performance after annealing, a microstructure of the materials can meet the technological requirements of user quenched-tempered heat treatment, and the safety of using the materials is guaranteed.

Owner:BAOTOU IRON & STEEL GRP

Pyrolysis carbon black carbonized by high-temperature pyrolysis gas and preparation method thereof

InactiveCN111808446AImprove the ability of deep processingAchieve hybridPigmenting treatmentChemical industryHeat carrierMetallurgy

The invention discloses pyrolysis carbon black carbonized by high-temperature pyrolysis gas and a preparation method thereof. According to the invention, a microwave generator is used as a heating source of a pyrolysis carbon black carbonization furnace, carbonization of the carbon black is realized through high temperature, and the deep processing performance of the carbon black is improved; high-temperature gas serves as a carrier to realize mixing of a high-temperature heat carrier and a carbon black material; uniform and rapid heating of the carbon black material is achieved through high thermal conductivity of the high-temperature heat carrier, the overall carbonization time of the carbon black material is shortened, and carbonization efficiency is improved; and the waste heat of thepyrolysis gas is used for providing heat for the carbonization furnace, so the heat of high-temperature pyrolysis gas is fully utilized, and energy-saving effect is obvious.

Owner:安徽省克林泰迩再生资源科技有限公司

Production method of dried melon

InactiveCN103976302BImprove the ability of deep processingReduce wasteConfectionerySweetmeatsProcess engineeringMusk melon

The invention discloses a producing method of dried muskmelon. The method includes: selecting fresh muskmelon, cleaning, sterilizing, peeling, taking flesh, cutting into slices, hardening, performing color protecting, blanching, performing solute osmosis, drying and reshaping. Beneficial effects of the producing method are that: the producing method overcomes the color browning problem of the muskmelon, preserves the original color and flavor of the muskmelon, enhances the deep processing capability of agricultural and sideline products, adopts rejected muskmelon as the raw material for deep processing of the muskmelon so as to achieve full utilization of raw materials, reduces waste of the muskmelon resource, completes muskmelon industrial production through producing downstream muskmelon products, increases the kinds of the agricultural and sideline products subjected to deep processing in Xinjiang, and enriches the market; and the producing method utilizes the resources reasonably and protects the environment.

Owner:丁保林

A kind of soft rolling method of cold heading steel

Owner:WUKUN STEEL

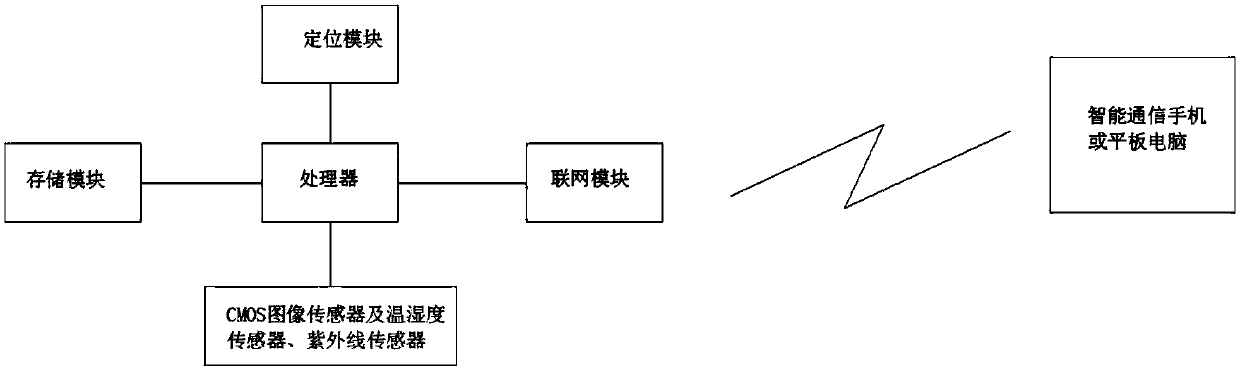

Screen-free interactive automobile data recorder capable of realizing remote monitoring and remote monitoring method

InactiveCN107945310ASolve the need for real-time remote access to the image information of the driving recorder terminal equipmentSolve remote monitoringRegistering/indicating working of vehiclesTransmissionComputer moduleInterconnection

The invention discloses a screen-free interactive automobile data recorder capable of realizing remote monitoring and a remote monitoring method. The automobile data recorder is a screen-free automobile data recorder which comprises a positioning module, a camera module, a processor and a storage module; the positioning module, the camera module and the storage module are connected with the processor in a communication manner; the screen-free interactive automobile data recorder further comprises a 4G module and a remote terminal; the 4G module is connected with the processor in a communication manner; the remote terminal is connected with the automobile data recorder through the 4G module in a communication manner; the screen-free automobile data recorder is powered through an OBD interface; the OBD interface can support communication between the screen-free automobile data recorder and the remote terminal through the 4G module, to realize human-machine interaction. The comprehensiveperformance of the automobile data recorder can be improved; the automobile data recorder can be improved from single driving safety to a multipurpose vehicle-mounted safety product integrating parking safety, network interconnection and remote monitoring.

Owner:深圳市中和联创智能科技有限公司

Fine crystal rare earth oxide molybdenum alloy-doped and its preparation method

A RE oxide doped fine-crystal Mo-alloy is prepared from MoO2 through doping RE oxide by atomizing method, ball grinding, sieving, reducing in H2 atmosphere in muffle furnace at 800-1100 deg.C, cold isostatic pressing under 150-200 MPa for shaping, segmental sintering in MF induction furnace and mechanical deforming to obtain rod or plate. It has high strength, ductility and toughness.

Owner:山东铭特金属材料科技有限公司

Preparation of nano rare-earth oxide doping molybdenum alloys

The invention discloses a method for preparing a nano rare earth oxide doped molybdenum alloy. In the method, by taking rare earth ammonium dimolybdate crystals as raw materials and adopting the roasting and hydrogen reduction method, molybdenum alloy powder is obtained, the powder after reduction is in press-forming by the isostatic cool pressing with a pressure of between 180 and 200 Mpa, the formed blank materials are presintered in a muffle furnace with a temperature of between 1, 100 and 1, 300 DEG C, and sintered in a vacuum intermediate frequency induction sintering furnace at a temperature of between 1, 600 and 1, 900 DEG C for 10 to 24 hours; the materials sintered can be made by the prior mechanical processing methods into materials and products with different shape such as molybdenum alloy bar materials or plate materials, etc. as required. The molybdenum alloy containing nano rare earth oxide, prepared by the method of the invention, has the advantages of high intensity, ductility and toughness and wide application.

Owner:临沂明华管业有限公司

Method for preparing sodium metasilicate nonahydrate from filter residue obtained by treating boric sludge

InactiveCN102167341AImprove the ability of deep processingImprove economic efficiencyAlkali metal silicatesChemistryCorrosion resistant

Owner:王嘉兴

Method for preparing water glass by using boron mud residue

InactiveCN105399104AImprove the ability of deep processingMeet the protection requirementsAlkali metal silicatesChemical reactionSilicon dioxide

The invention relates to a method for preparing water glass by using boron mud residue. The method comprises: heating boron mud with steam to achieve a temperature of 58-82 DEG C, maintaining for 1-2 h, carrying out centrifuge drying with a centrifuge to achieve liquid-solid separation so as to obtain filter cake boron mud, carrying out a chemical reaction of the filter cake boron mud and hydrochloric acid in a first corrosion-resistant reactor under slow stirring according to a pure mass ratio of 1:1.61-2.05 to generate a magnesium chloride hydrate, filtering the magnesium chloride hydrate to obtain the clarified filtrate and the silicon dioxide filter residue, carrying out a reaction of the silicon dioxide filter residue and sodium carbonate in a sealed second reactor under heating pressurization and slow stirring according to a pure mass ratio of 1:1.52-1.95 to generate a sodium metasilicate nonahydrate aqueous solution, and filtering to remove insoluble impurities to obtain a clarified filtrate, wherein the filtrate is the water glass product. According to the present invention, the re-pollution waste material of the boron mud waste material is treated, the water glass is prepared, the secondary pollution is avoided, and the economic benefits are created.

Owner:常德市金佰特节能环保科技有限公司

Method for extracting oligosaccharide from water-chestnut

The invention discloses a method for extracting oligosaccharide from water-chestnut. The method comprises the following steps: (1) dissolving water-chestnut powder in an ethanol solution, and carryingout ultrasonic extraction and centrifuging so as to obtain an extract liquid; (2) subjecting the extract liquid obtained in the step (1) to vacuum concentration and removing ethanol from the extractliquid so as to obtain a concentrated liquid; (3) filtering the concentrated liquid obtained in the step (2) by adopting an ultrafiltration membrane, fitering the obtained permeated liquid through a nanofiltration membrane so as to obtain a retentate; and (4) subjecting the retentate obtained in the step (3) to vacuum concentration until a brix degree is 55 to 65, and carrying out freeze-drying soas to obtain water-chestnut oligosaccharide. The method provided by the invention has the advantages of no pollution, no solvent residue, no generation of phase transition, high extraction efficiency, simple operation, convenience in control, etc.

Owner:HEZHOU UNIV

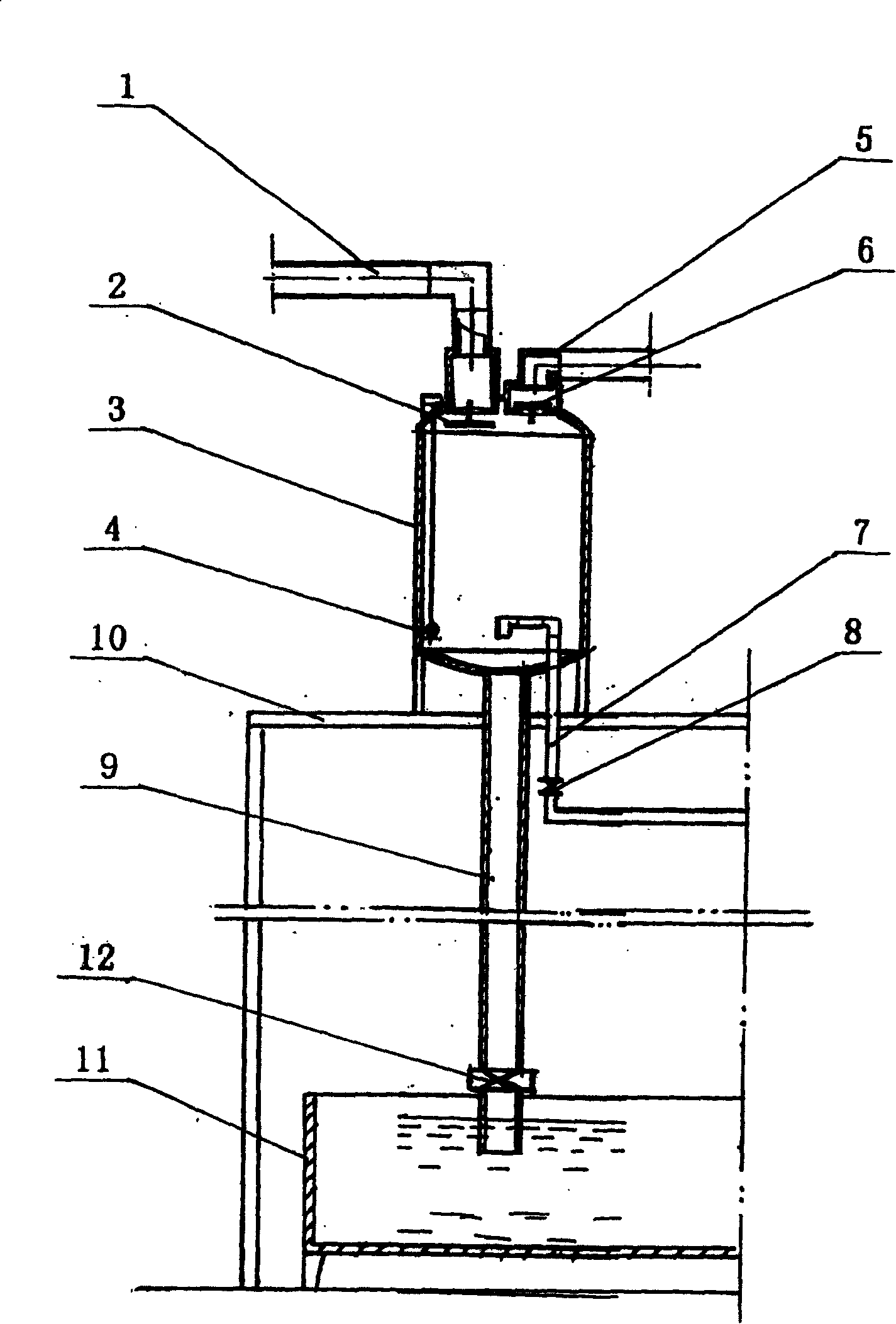

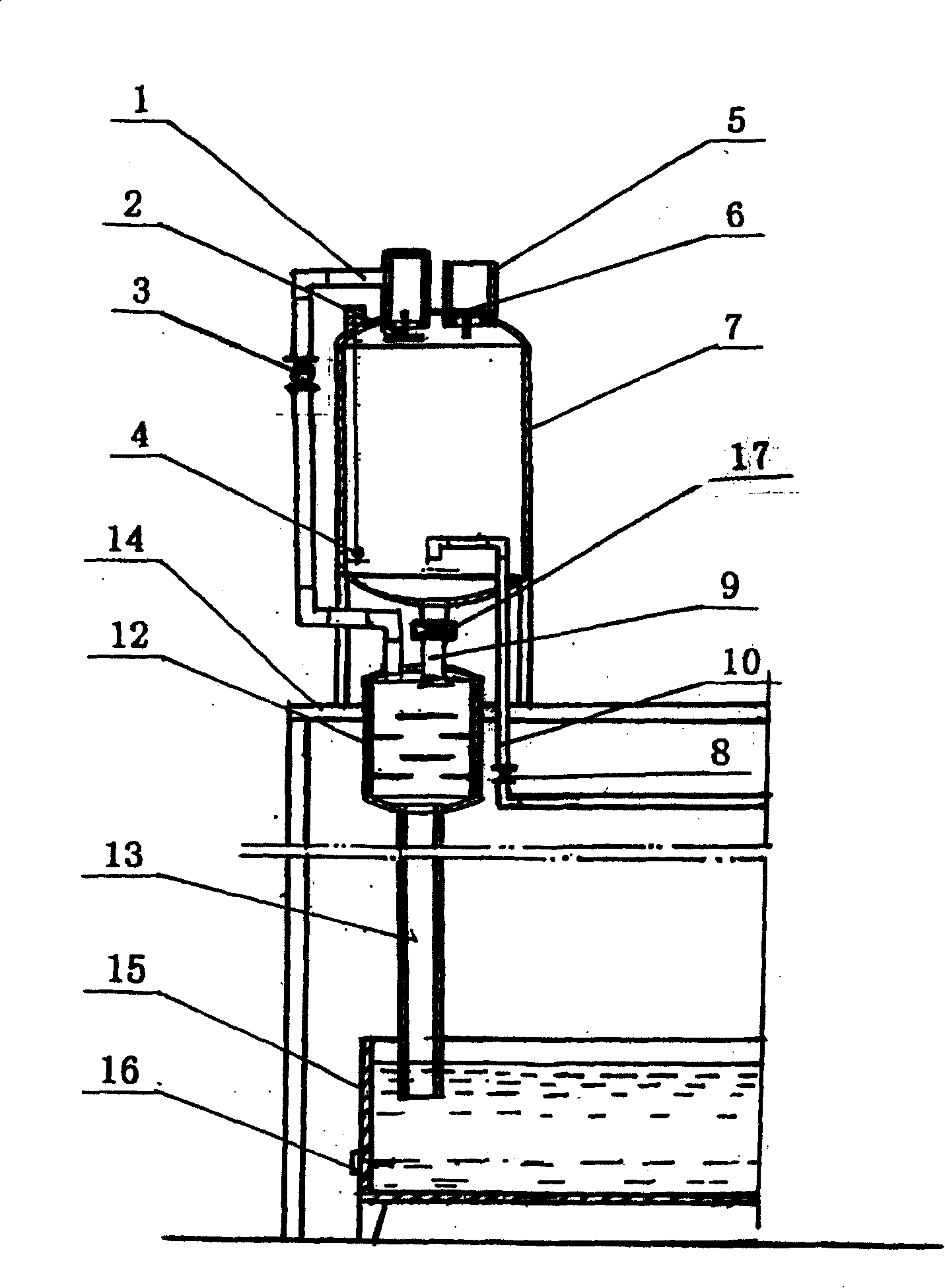

Water plunger type vacuum pump and compressor

InactiveCN100402866CEfficient extractionImprove the ability of deep processingJet pumpsMachines/enginesRefrigerated temperatureMotive power

A water planger type vacuum pump and compressor system for pumping out combustible and explosive gas and steam and compressing them for delivery is composed of vacuumizing unit, vacuum refrigerator, pressure gas delivering unit, water pump, electric controller and working platform. The pressure water tream from water pump is used as the power of vacuumizing unit and vacuum refrigerator to obtain vacuum and cool the circulating water.

Owner:张庆玉

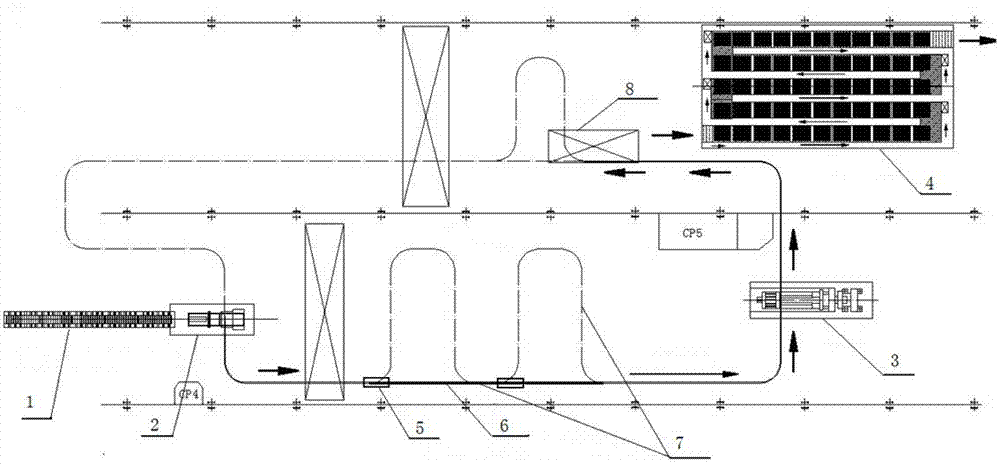

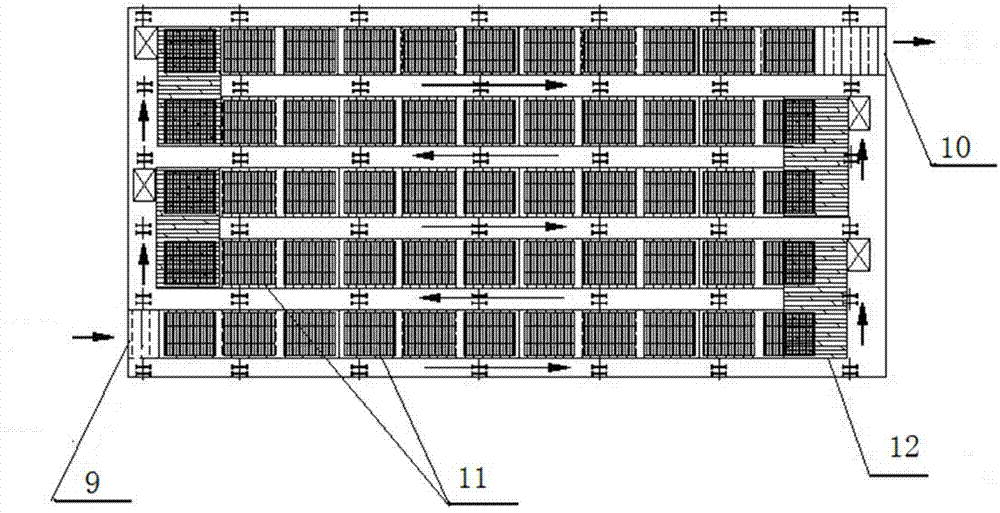

A kind of btzc15 bearing steel produced by adopting the second fire forming process and its production method

ActiveCN111349855BSimple production processReduce manufacturing costWork heating devicesMetal rolling arrangementsChemical compositionPipe

The invention discloses a BTZC15 seamless bearing steel pipe produced by adopting a two-fired rolling process. The mass percentages of its chemical components are: C 0.96-1.05%, Si 0.15-0.35%, Mn 0.30-0.45%, Cr 1.45 ~1.60%, Ce 0.0005~0.0015%, P≤0.020%, S≤0.010%, Pb≤0.002%, Ti≤0.005%, and the rest are iron and trace impurity elements. At the same time, its production method is provided. The BTZC15 seamless bearing steel pipe produced by this method meets the requirements of material composition, non-metallic inclusions and microstructure, and at the same time has high production efficiency and low metal consumption.

Owner:BAOTOU IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com