Water plunger type vacuum pump and compressor

A vacuum pump and compressor technology, applied in non-displacement pumps, pumps, jet pumps, etc., can solve the problems of great influence of water temperature, unstable working performance, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

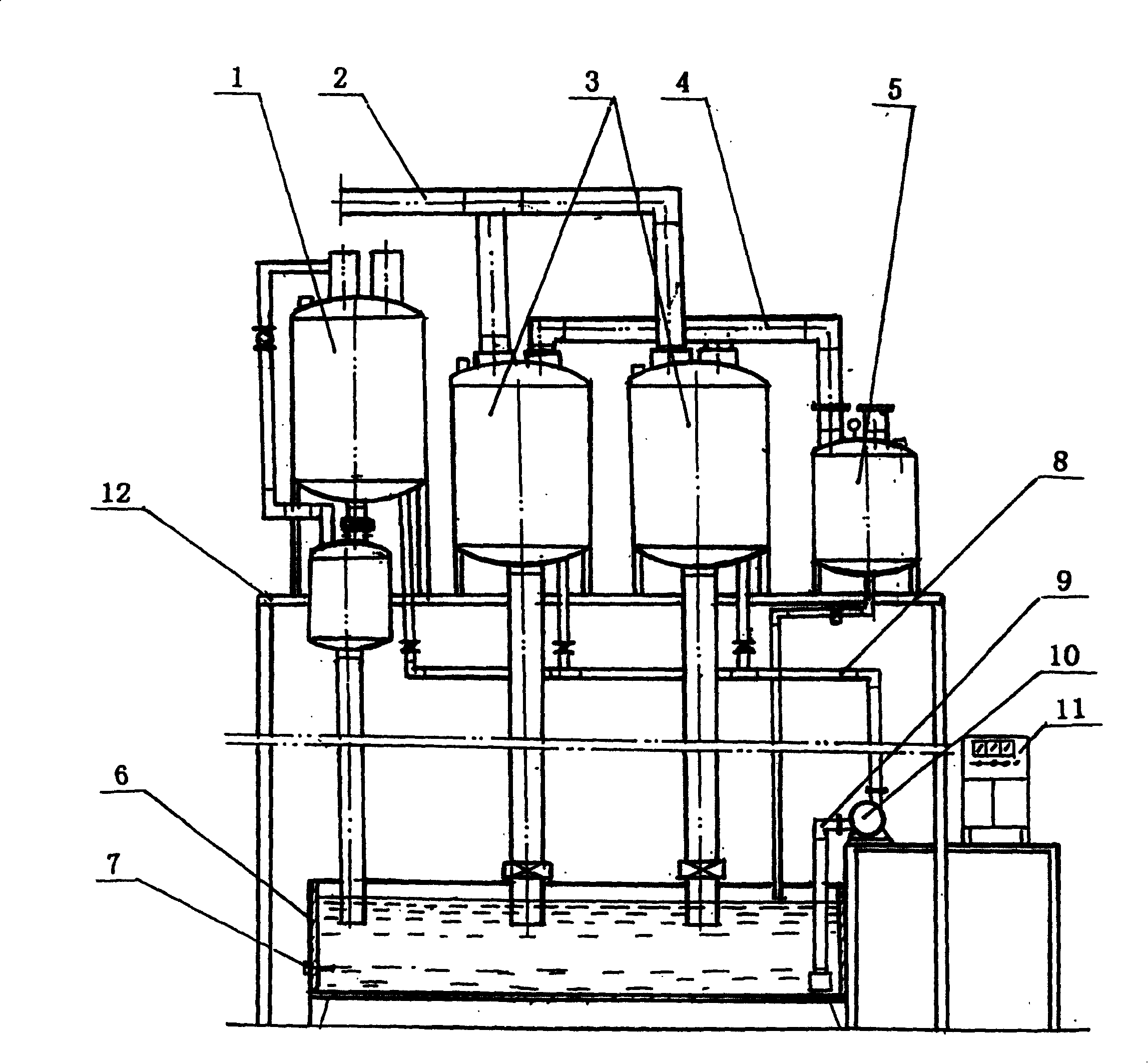

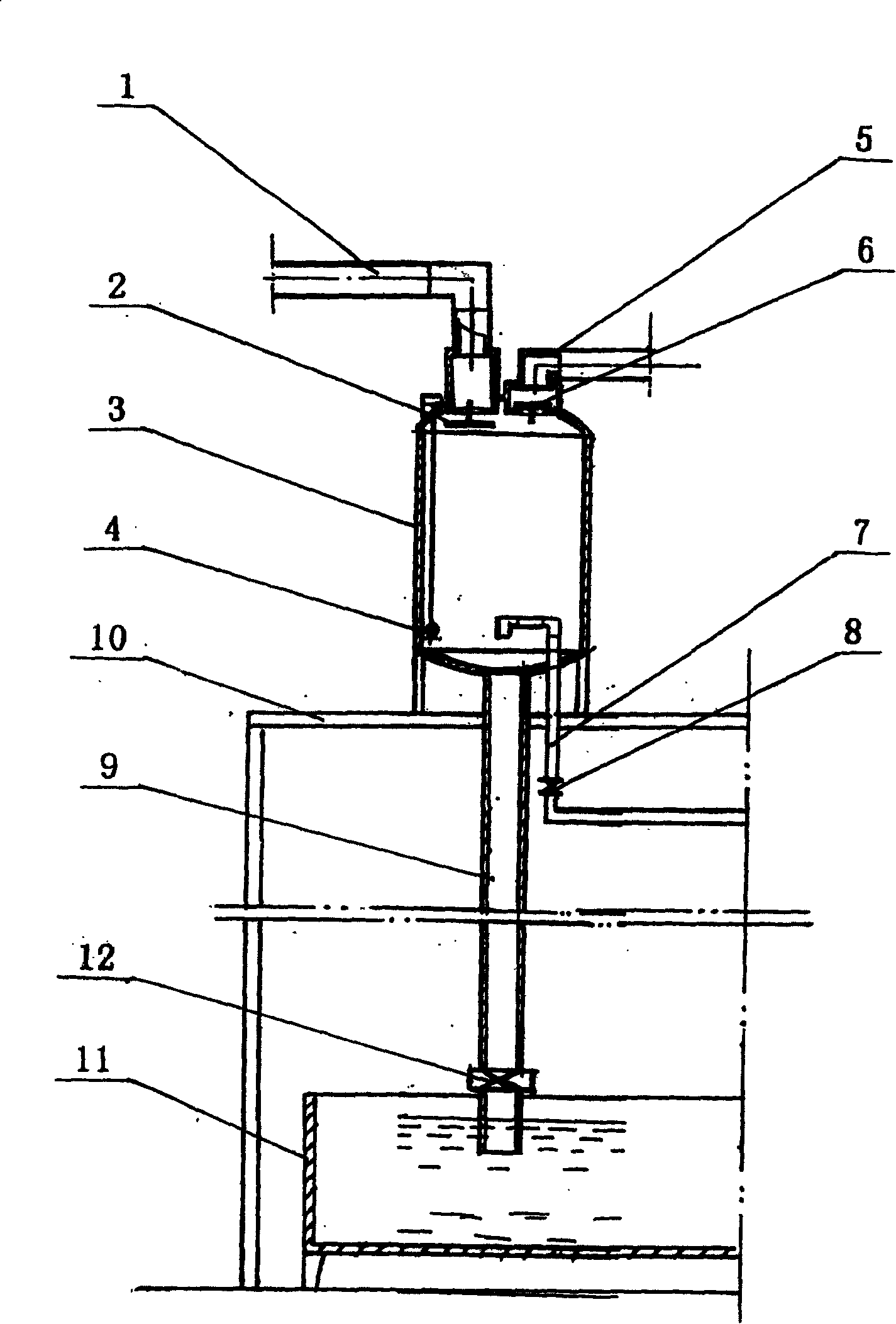

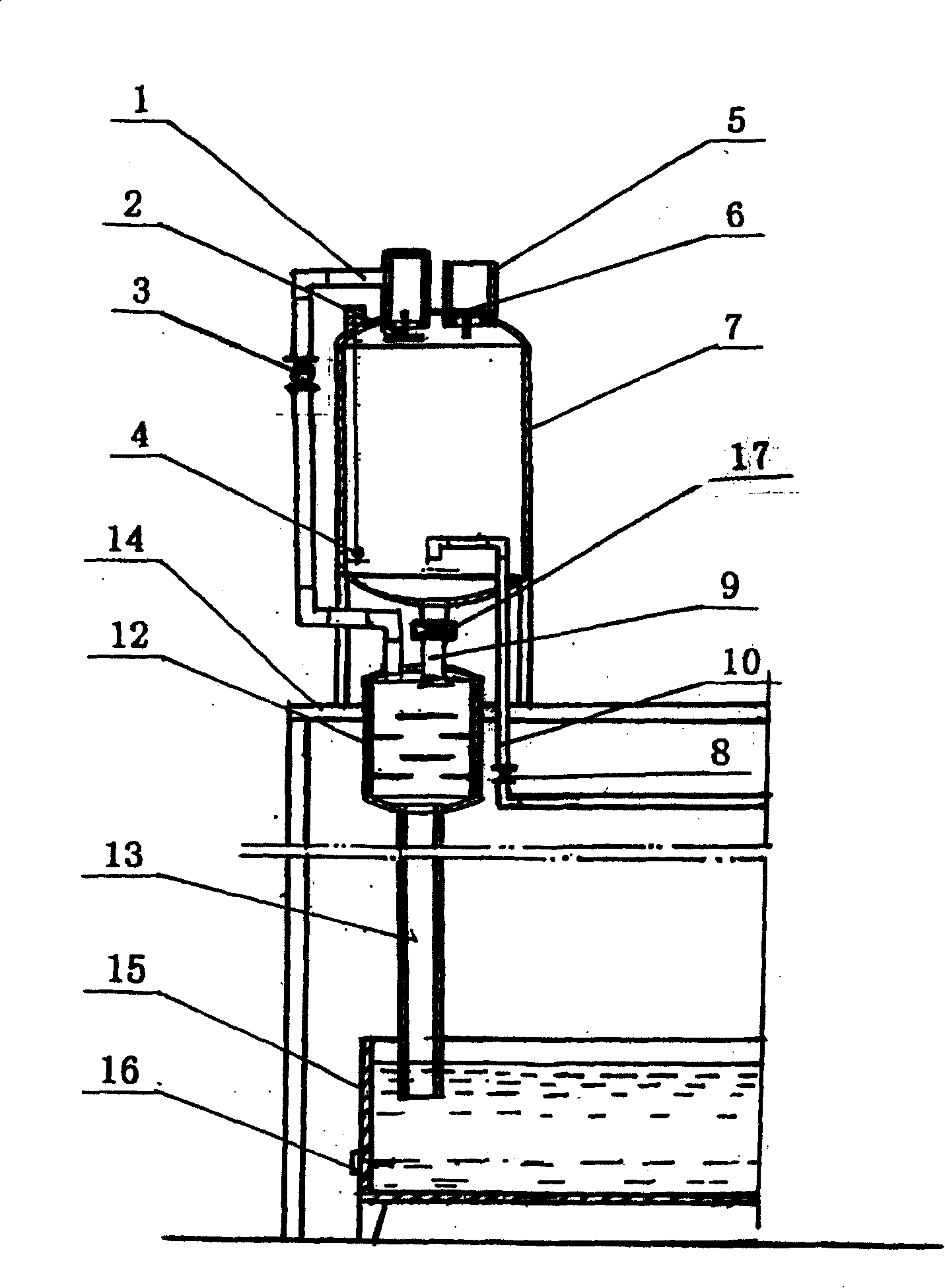

[0018] Below in conjunction with accompanying drawing 1, dynamic operation of the present invention is described:

[0019] Through the control of the water level sensors in various vacuum obtainers 3, the electric water inlet valve on the water delivery pipe of the vacuum obtainer 3 and the electric water discharge valve on the tail pipe are alternately closed or opened, so that each vacuum The obtainer 3 continuously completes the work of extracting gas to obtain vacuum; after connecting the exhaust port of the pressure gas conveyer with the gas collection system, the work of pressure conveying gas can be completed; through the temperature sensor installed in the circulating water tank 6 7 and the control of the water level sensor installed inside the vacuum refrigerator 1, so that the electric water discharge valve on the water discharge pipeline of the vacuum refrigerator 1, the electric water inlet valve on the water delivery pipeline and the electric vacuum valve on the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com