A kind of btzc15 bearing steel produced by adopting the second fire forming process and its production method

A technology of bearing steel and technology, which is applied in the field of BTZC15 bearing steel and its production, can solve the problems that the product is difficult to maintain the survival and sustainable development of the enterprise, and achieve good deep processing performance, reduce production cost, and good safety in use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

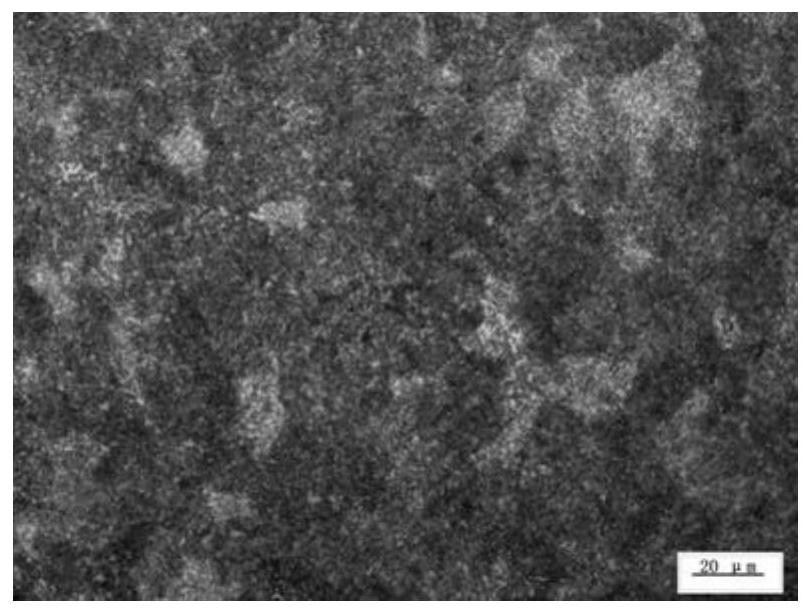

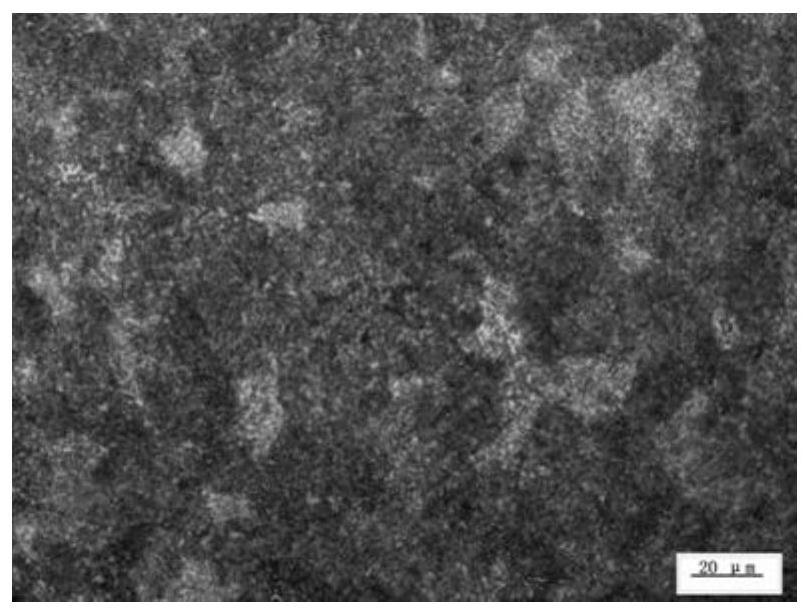

Image

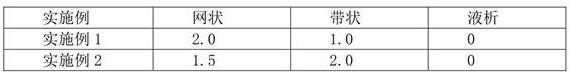

Examples

Embodiment Construction

[0021] The technical features and advantages of the present invention will be described in more detail below in conjunction with the embodiments.

[0022] A production method of BTZC15 bearing steel produced by a second-fire process, including primary heating of a steel billet, billet rolling, billet heating, and continuous hot rolling of seamless steel pipes;

[0023] The total heating time of the steel billet is 7 hours for one heating, the temperature of the preheating section is 780°C, the temperature of the heating section is 1100-1230°C, the temperature of the soaking section is 1180-1220°C, and the temperature is raised slowly when burning steel to ensure uniform heating temperature of the billet and reduce the temperature difference. The billet temperature difference is not greater than 50°C.

[0024] Rolling at a constant speed during rolling; cooling water is not poured directly on the rolled piece; the billet is not straightened by a leveler;

[0025] The total hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com