Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Improve temperature field distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

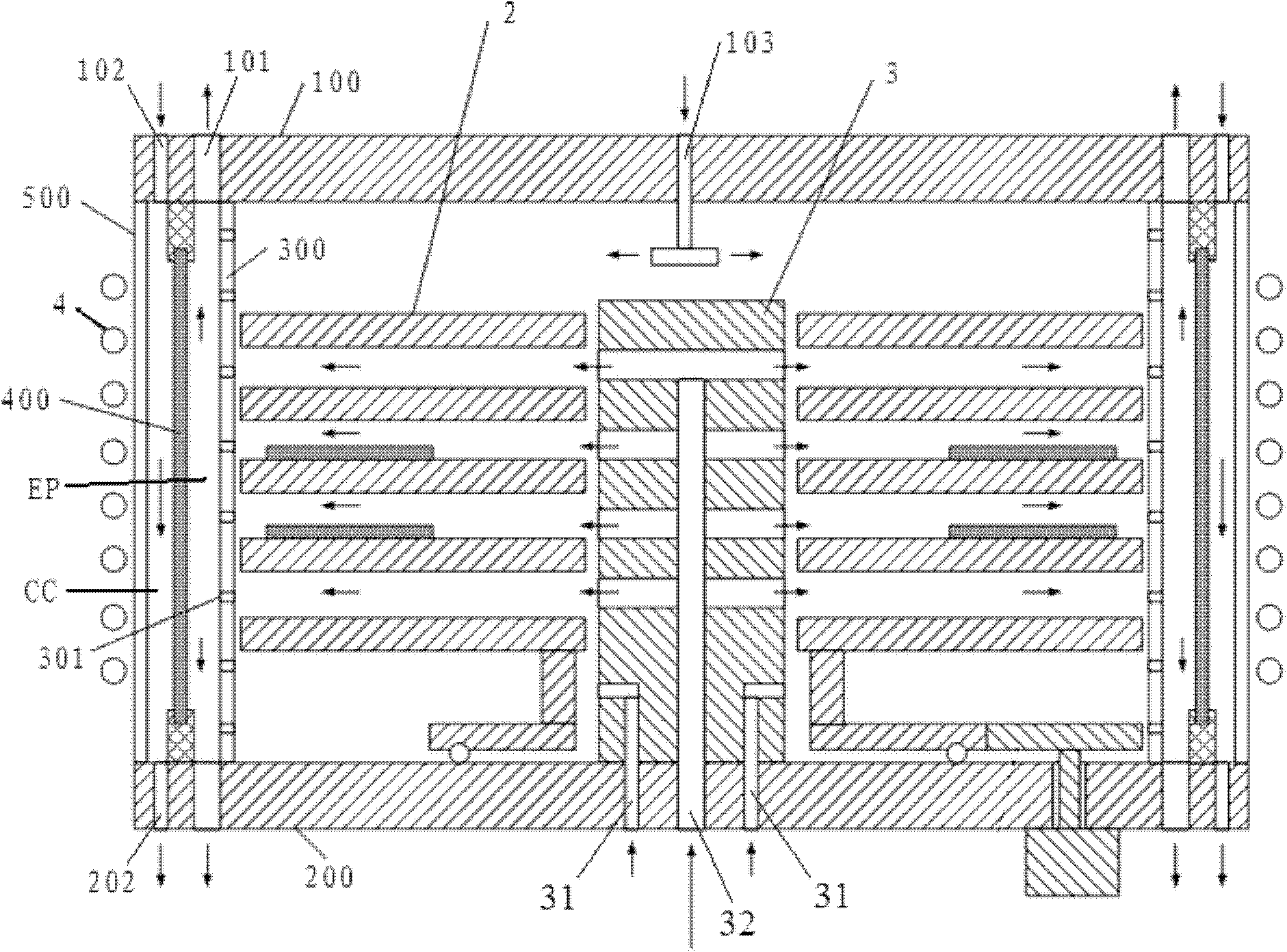

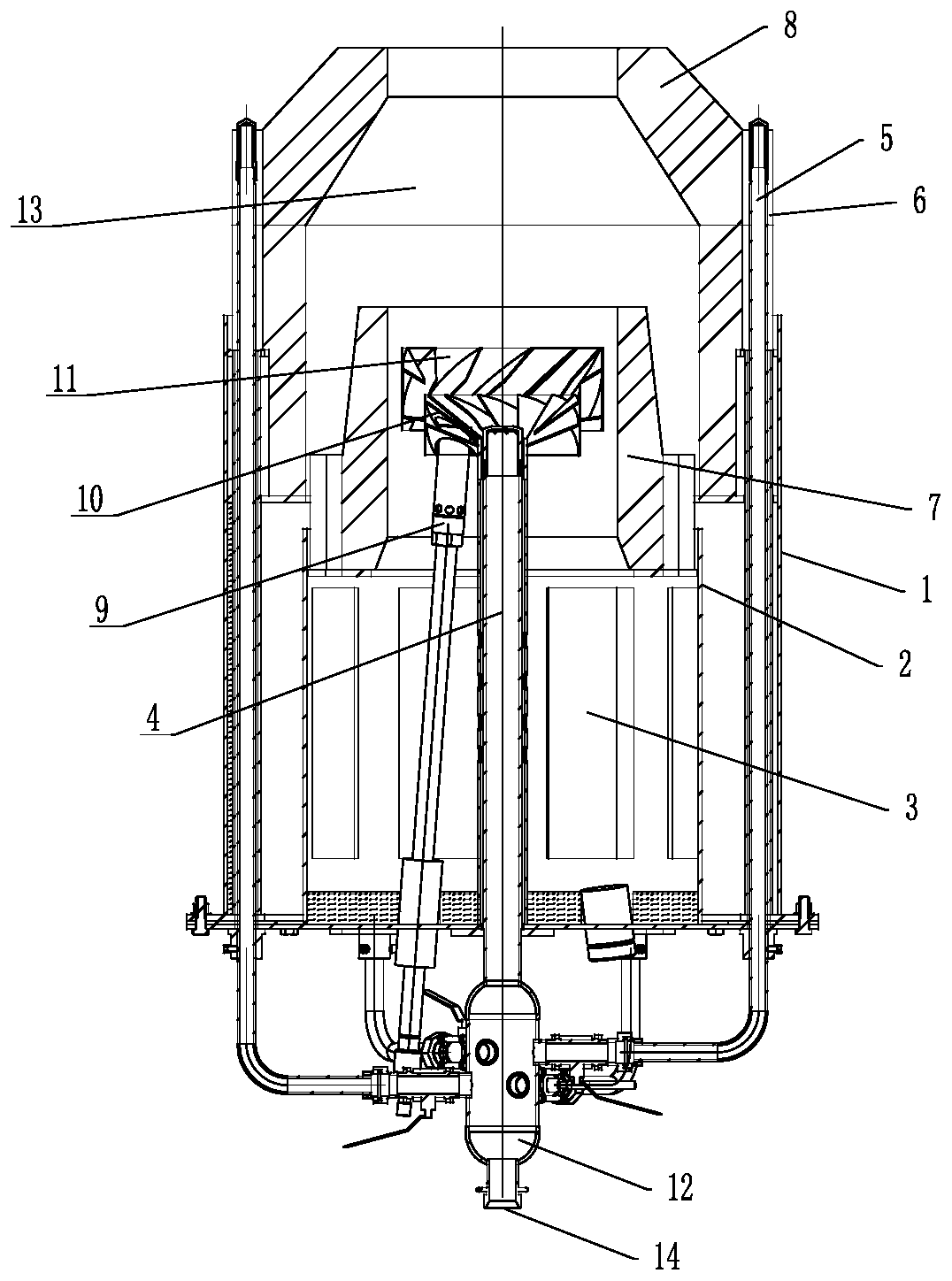

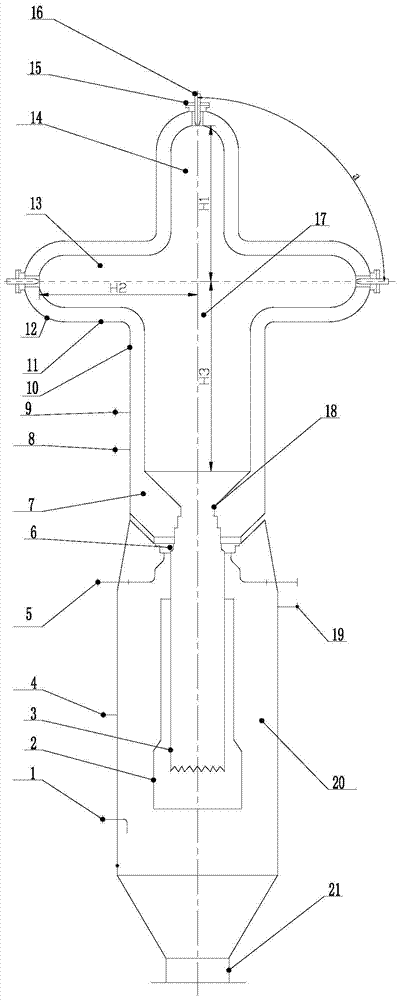

Process chamber device and epitaxial equipment with it

ActiveCN102691100AImprove temperature field distributionReduce maintenance timesSemiconductor/solid-state device manufacturingFrom chemically reactive gasesGraphitePulp and paper industry

The invention discloses a process chamber device and epitaxial equipment with the process chamber device. The process chamber device comprises: a top cap and a bottom cap; an inner quartz tube, which is located between the top cap and the bottom cap and provided with exhaust holes, and defines a process chamber together with the top cap and the bottom cap; a graphite sleeve positioned between the top cap and the bottom cap and sleeved outside the inner quartz tube, with an exhaust path defined between the graphite sleeve and the inner quartz tube, communicated with the outside, and communicated with the process chamber through the exhaust holes; and an outer graphite sleeve positioned between the top cap and the bottom cap and sleeved outside the graphite sleeve, with a cooling channel defined between the outer graphite sleeve and the graphite sleeve and communicated with the outside. According to the process chamber in embodiment of the invention, temperature field distribution in the process chamber can be improved, and ultimately, uniformity of the radial temperature in the process chamber and further in a substrate can be realized. Also, the maintenance frequency and the maintenance cost of the graphite sleeve can be reduced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

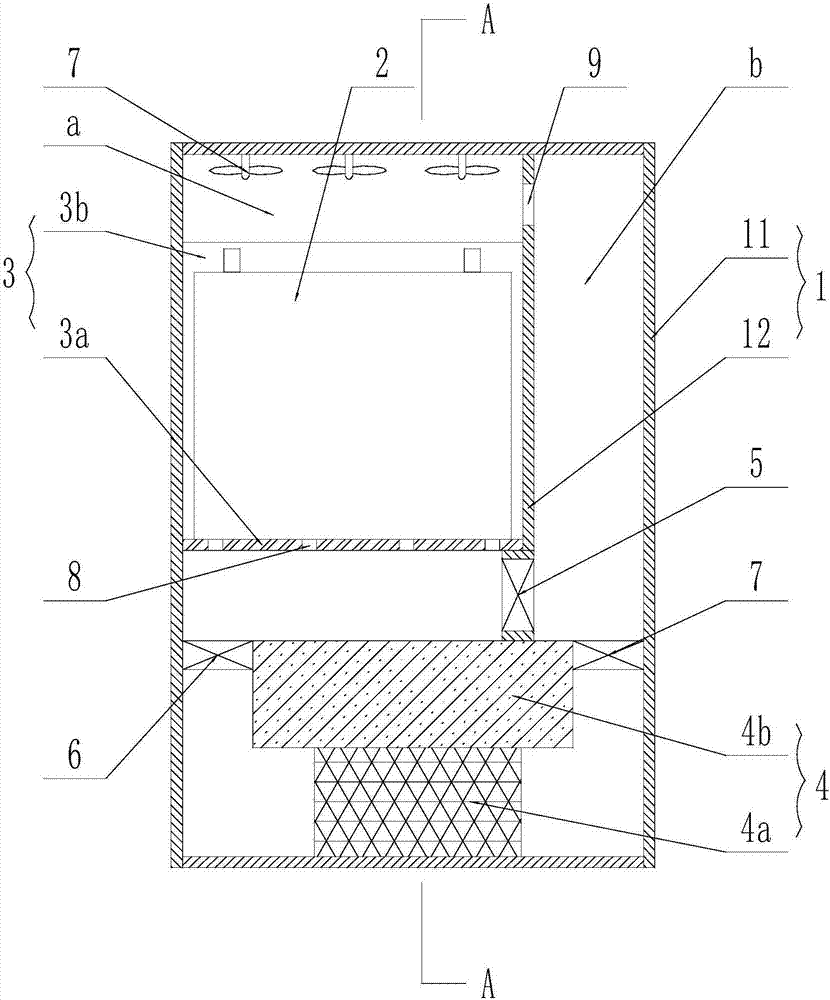

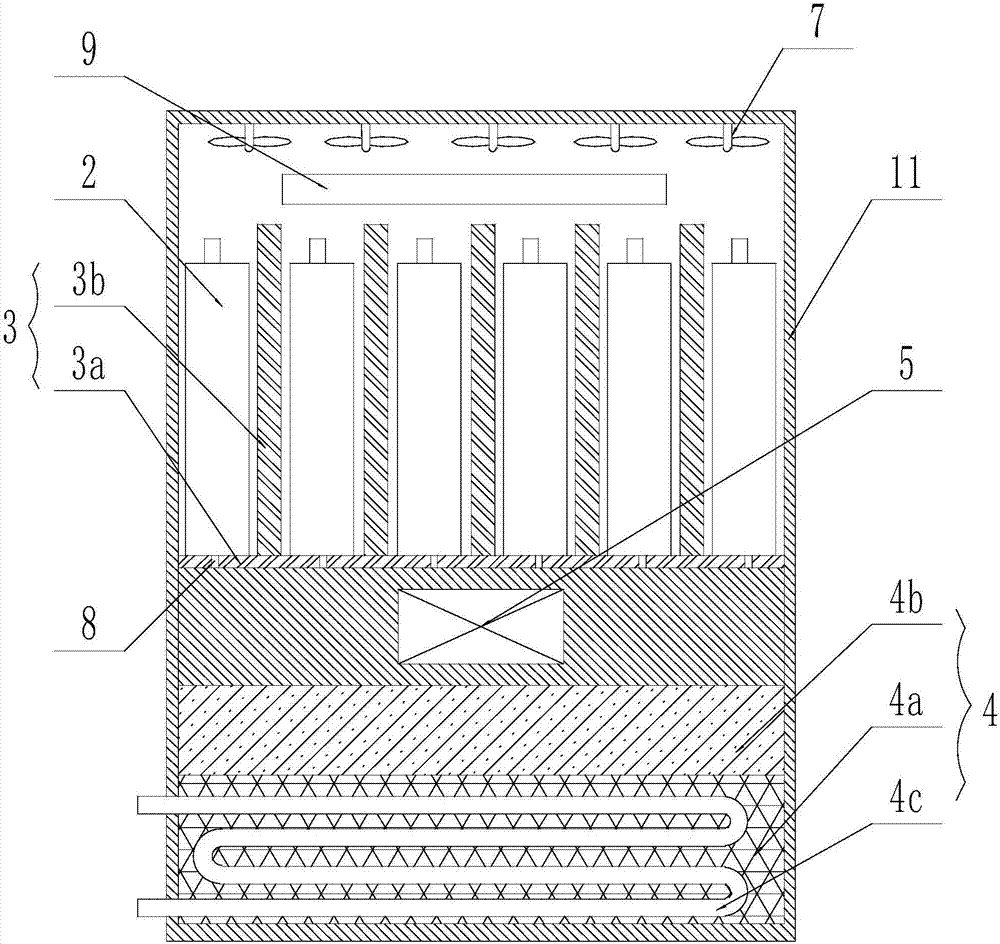

Vehicle-mounted new energy battery pack

InactiveCN107230751ARealize the heat dissipation functionImprove high rate discharge performanceCell electrodesSecondary cellsHigh rateElectrical battery

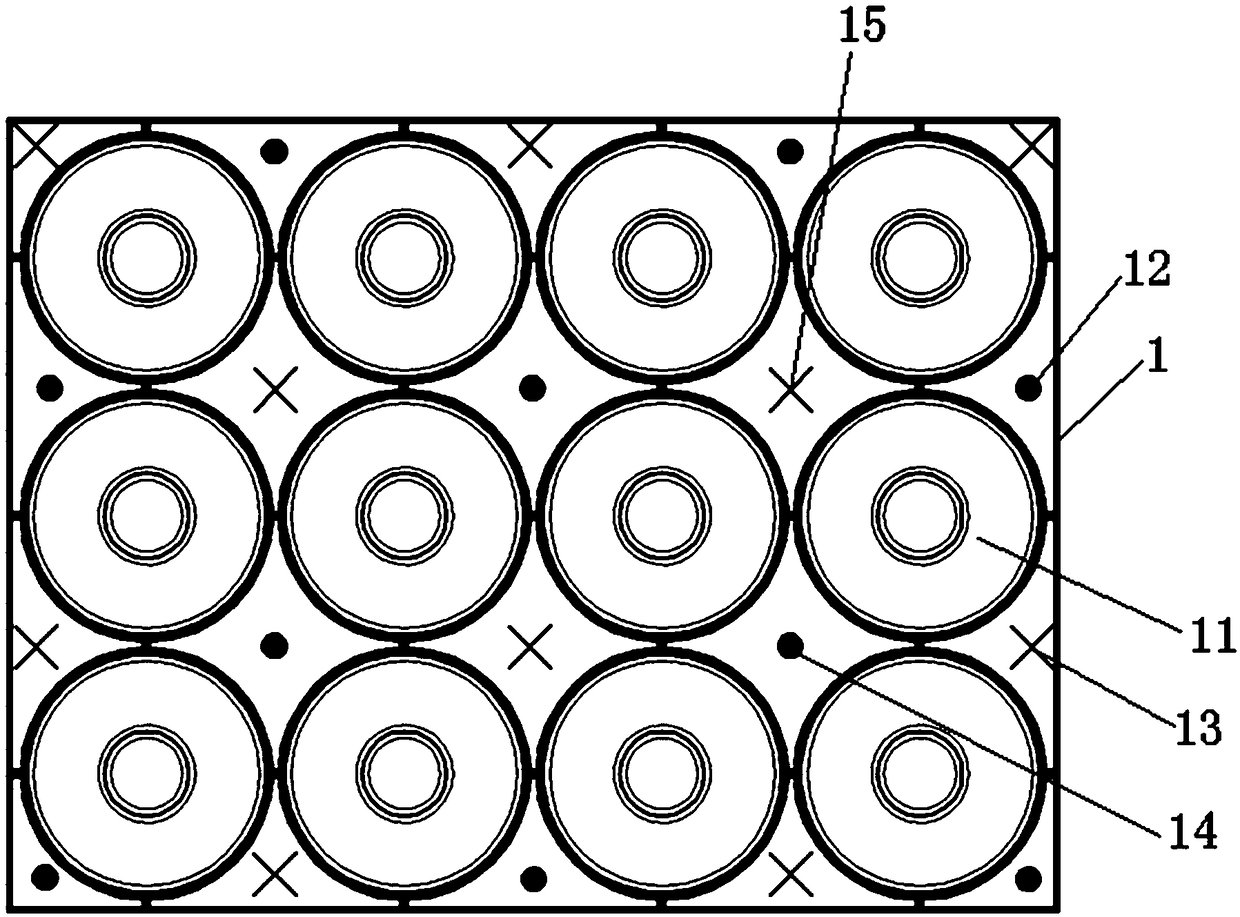

The invention discloses a vehicle-mounted new energy battery pack. The vehicle-mounted new energy battery pack comprises a battery box and multiple battery bodies arranged in the battery box; the battery box comprises a sealed type box body; a space partition plate is vertically arranged in the sealed type box body; the battery box is divided by the space partition plate into a battery placement region and a heat dissipation region; a fan is arranged on the battery box top plate above the battery placement region; a temperature detector is arranged in the battery placement region; multiple ventilating holes are formed in a battery fixation frame in the battery placement region; the ventilating holes are connected with the heat dissipation region to from an air circulation channel; and an air cooling apparatus is arranged in the air circulation channel. Compared with the prior art, the battery pack is arranged in the sealed box body according to the structure of the vehicle-mounted new energy battery pack, so that effects of thermal insulation and waterproofness are realized; by virtue of divisional setting, the temperature field distribution in the battery box can be improved; and by virtue of the battery bodies, the high-rate discharging performance of the lithium battery is improved, and excellent electronic conductivity and ionic conductivity and high high-rate charging-discharging performance are represented.

Owner:江苏昊科汽车空调有限公司

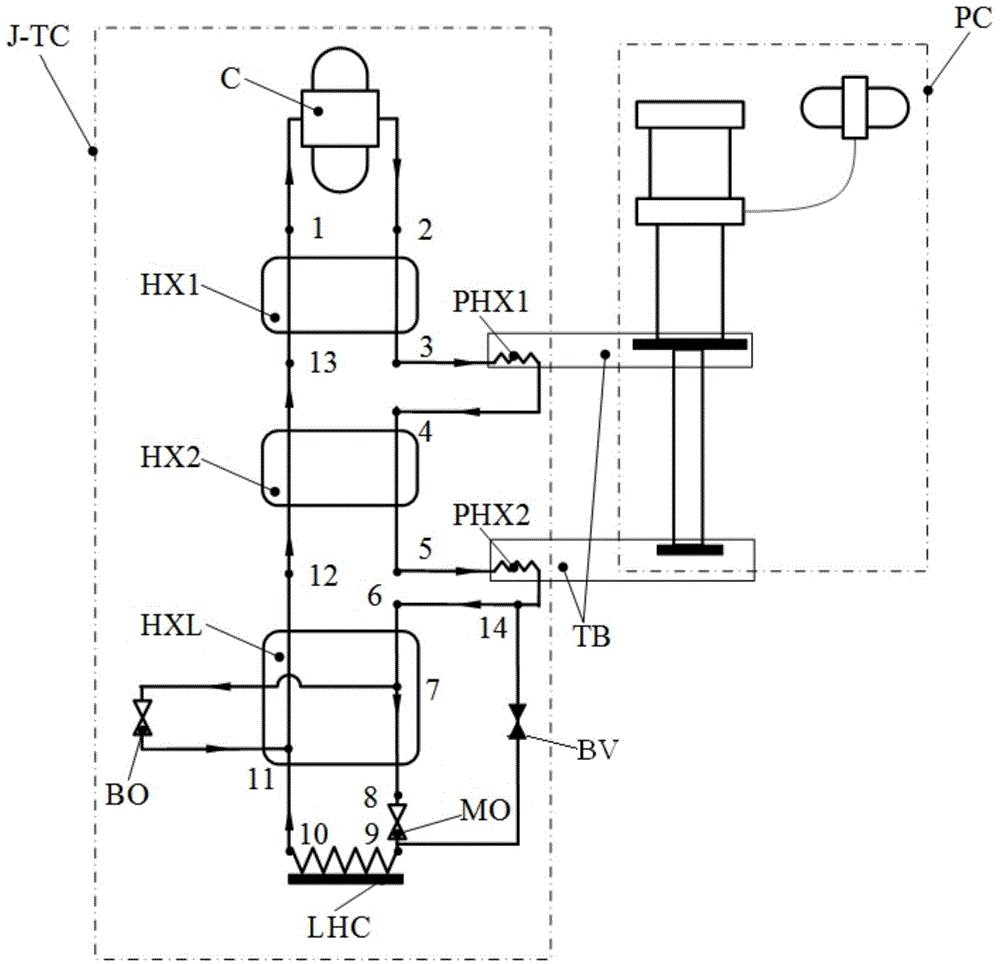

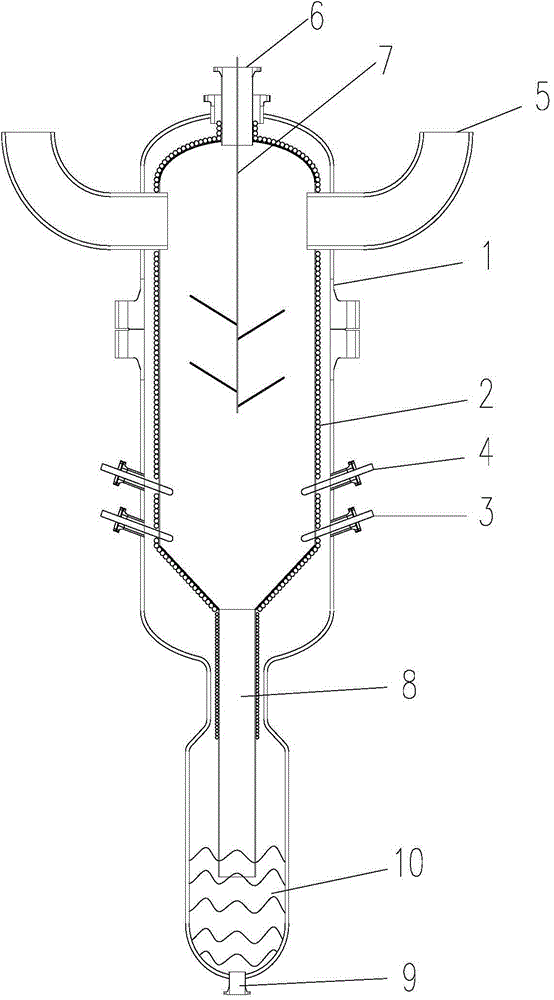

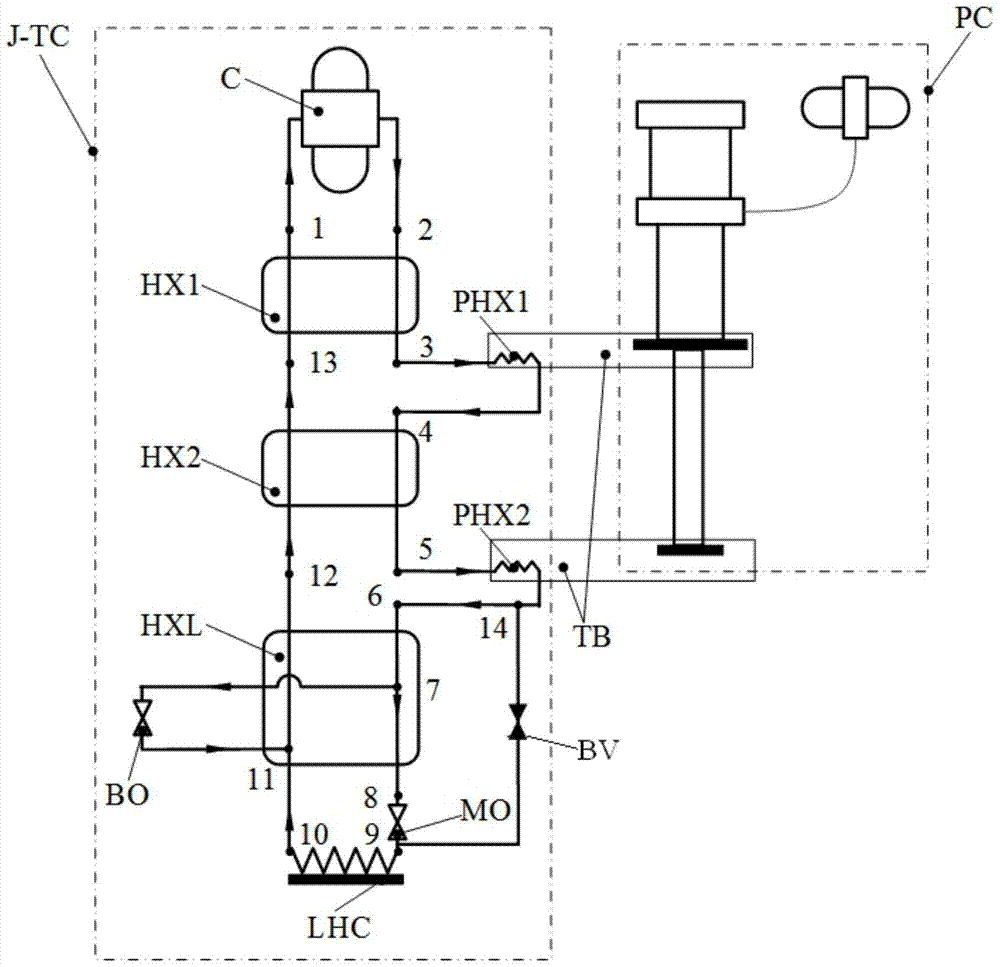

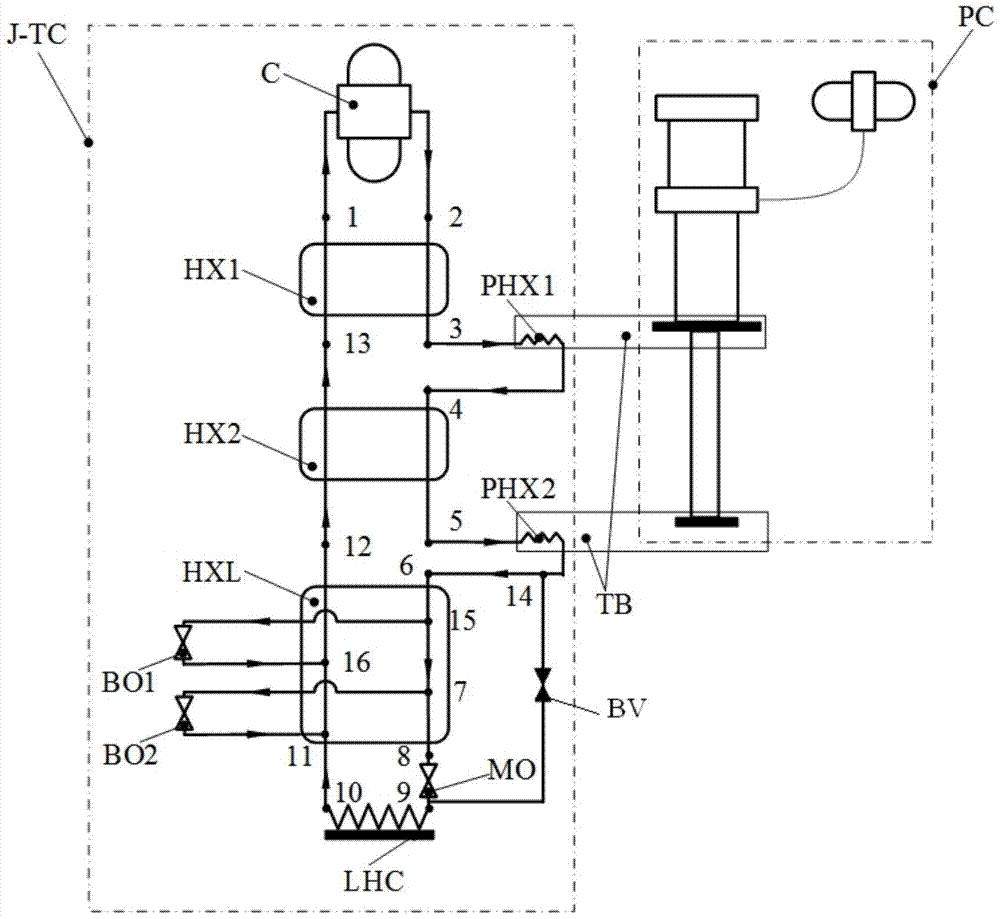

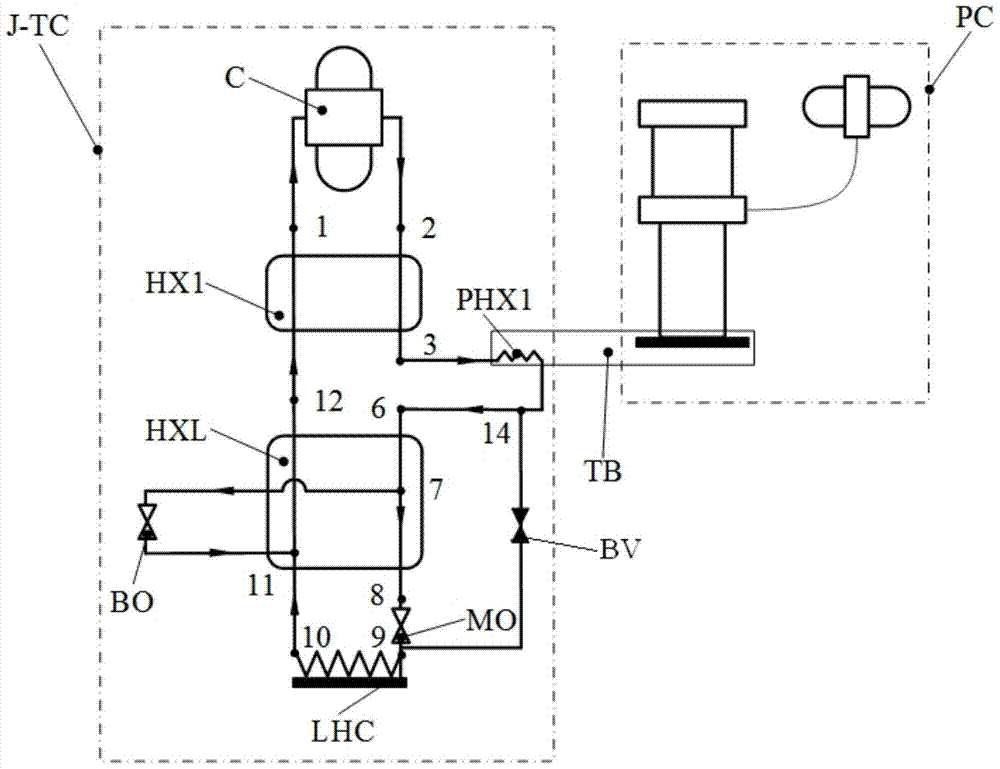

Low-temperature surface type heat exchanger adopting bypass throttling and precooling J-T refrigerator

ActiveCN104879968ASmall temperature differenceImprove temperature field distributionMechanical apparatusEvaporators/condensersRefrigerator carLiquid hydrogen

The invention discloses a low-temperature surface type heat exchanger adopting bypass throttling. The low-temperature surface type heat exchanger comprises a high-pressure side pipeline and a low-pressure side pipeline. The low-temperature surface type heat exchanger is operated in a liquid hydrogen temperature region or a lower temperature region. At least one bypass pipeline communicated with the low-pressure side pipeline is arranged on the high-pressure side pipeline, and an isenthalpic throttling element is arranged on each bypass pipeline. The temperature of a working medium in the low-pressure side pipeline at the outlet of each bypass pipeline is lower than the temperature of a working medium in the high-pressure side pipeline at the inlet each bypass pipeline. The invention further provides a precooling J-T refrigerator. Temperature field distribution of gas in the heat exchanger is changed by adopting bypass throttling, and irreversible loss is reduced. The heat exchanger is applied to the liquid helium temperature region precooling J-T refrigerator, temperature of high-pressure gas before throttling is lowered, refrigerating capacity of the liquid hydrogen temperature region is increased, and overall efficiency is increased.

Owner:ZHEJIANG UNIV

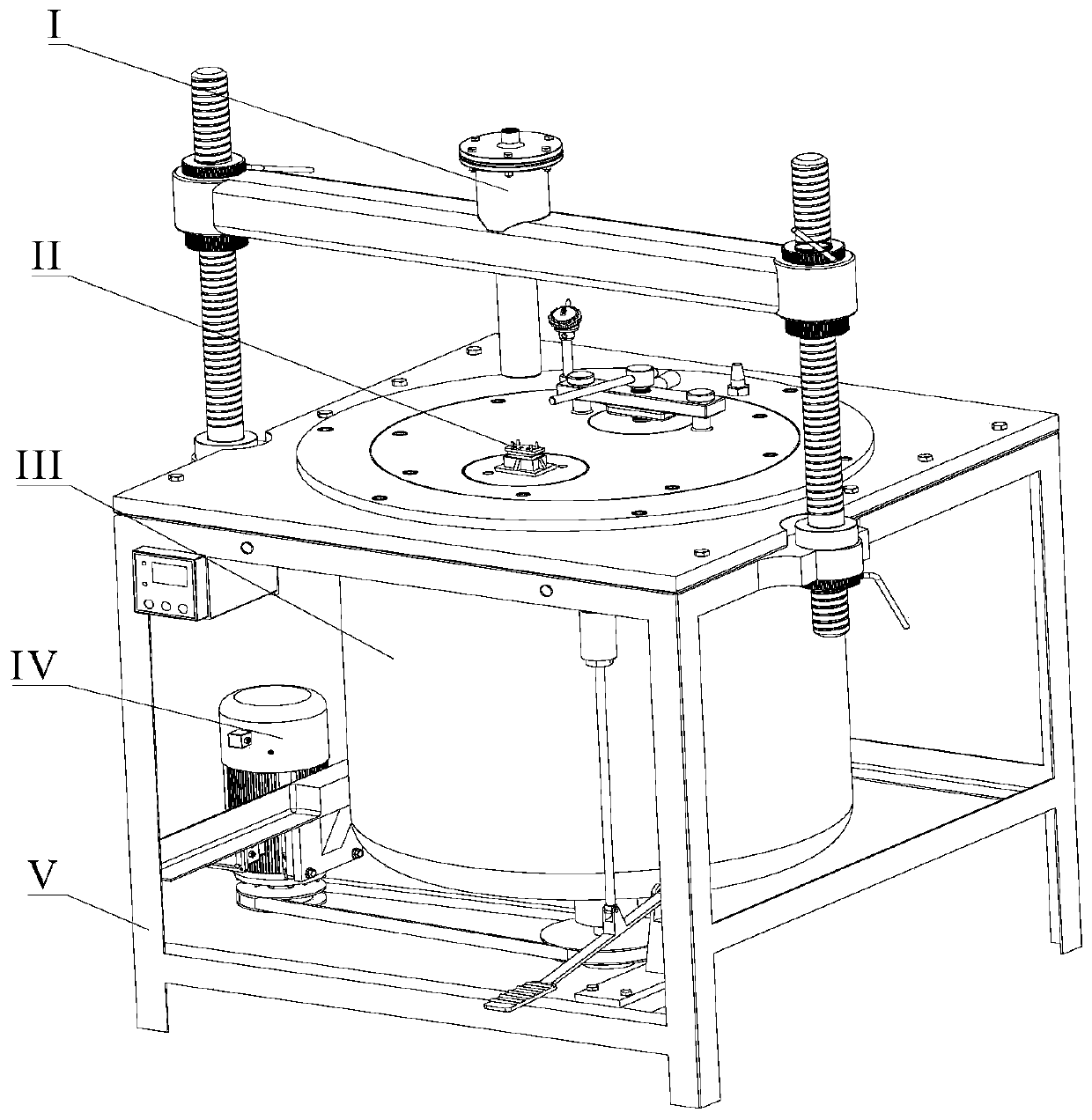

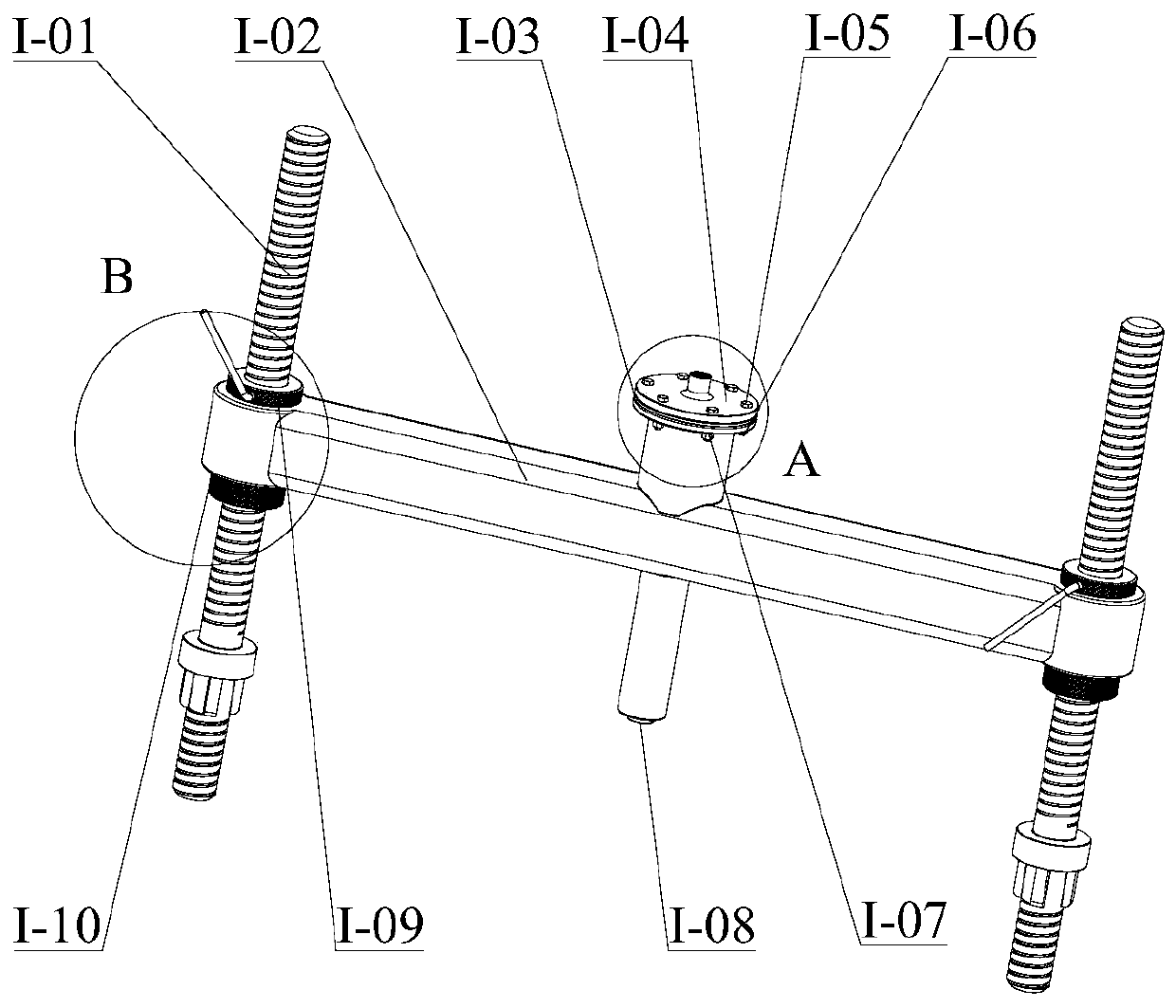

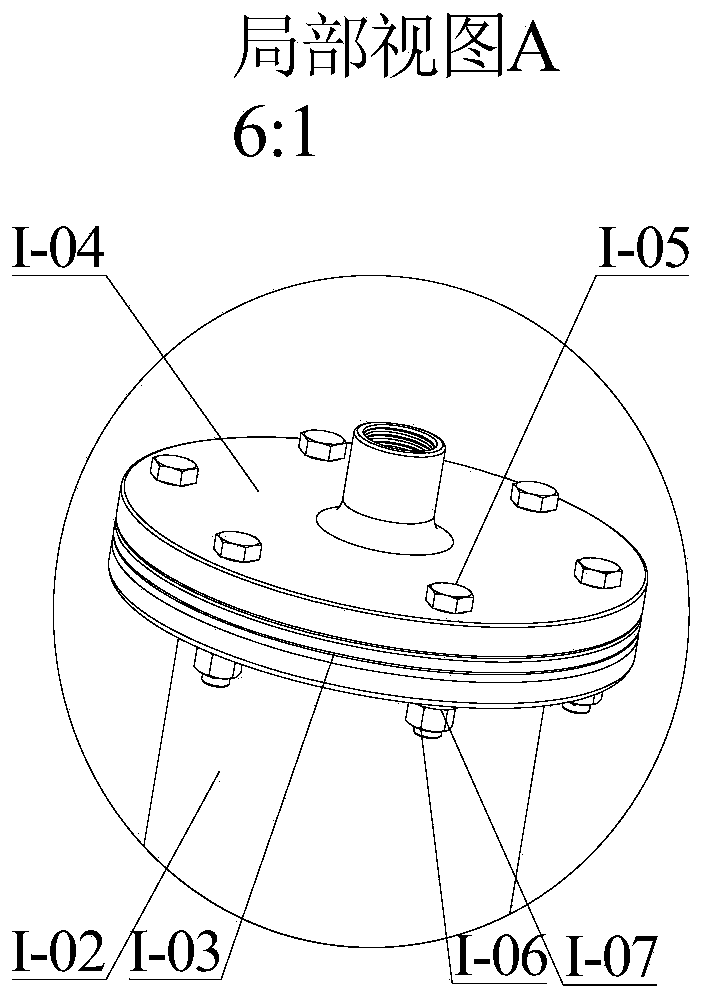

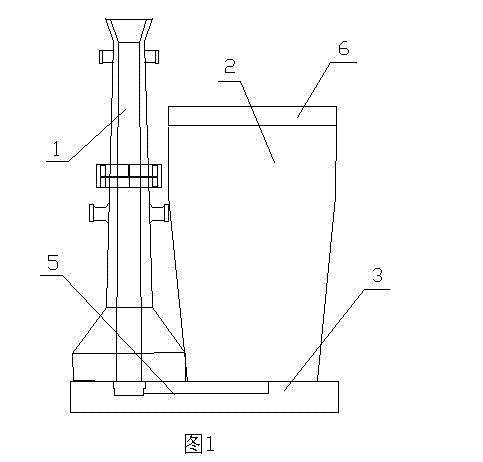

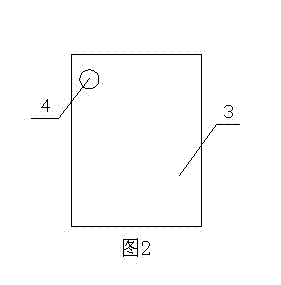

Aluminum oxide ceramic integrated hot-pressing molding machine and working method

InactiveCN111002437AImprove air tightnessReduce frictionFeeding arrangmentsAuxillary shaping apparatusOxide ceramicTemperature control

The invention discloses an aluminum oxide ceramic integrated hot-pressing molding machine and a working method. The aluminum oxide ceramic integrated hot-pressing molding machine comprises a pressingdevice and a hot-pressing device which are fixed to a rack, wherein the hot-pressing device is located below the pressing device, a stirring device is arranged in the hot-pressing device, and a hot-pressing mold is arranged above the hot-pressing device; the pressing device enables one path of high-pressure gas to act on the hot-pressing mold, and enables the other path of high-pressure gas to enter the hot-pressing device to enable slurry to flow into a cavity of the hot-pressing mold; the stirring device is used for stirring the slurry in the hot pressing device so as to enable an aluminum oxide blank to be more uniformly distributed in the slurry; and temperature measuring elements for detecting the temperature of internal oil and the temperature of slurry at the slurry outlet are arranged in the hot-pressing device, the power of an electric heating device is regulated and controlled in real time according to the temperature detected by the temperature measuring elements, and the purpose of accurate temperature control is achieved. Through the mold and the heating device, the temperature field distribution tends to be reasonable, the slurry temperature can be accurately controlled, the heating efficiency is obviously improved, and the distribution of the aluminum oxide powder in liquid paraffin can significantly improve the molding quality of the casting.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

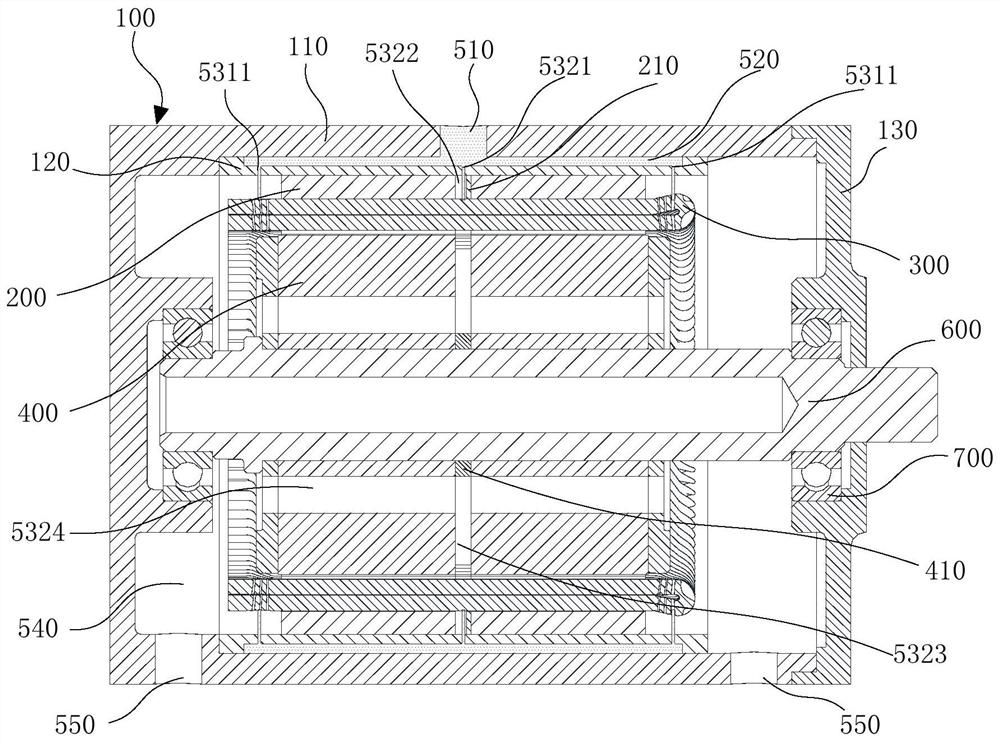

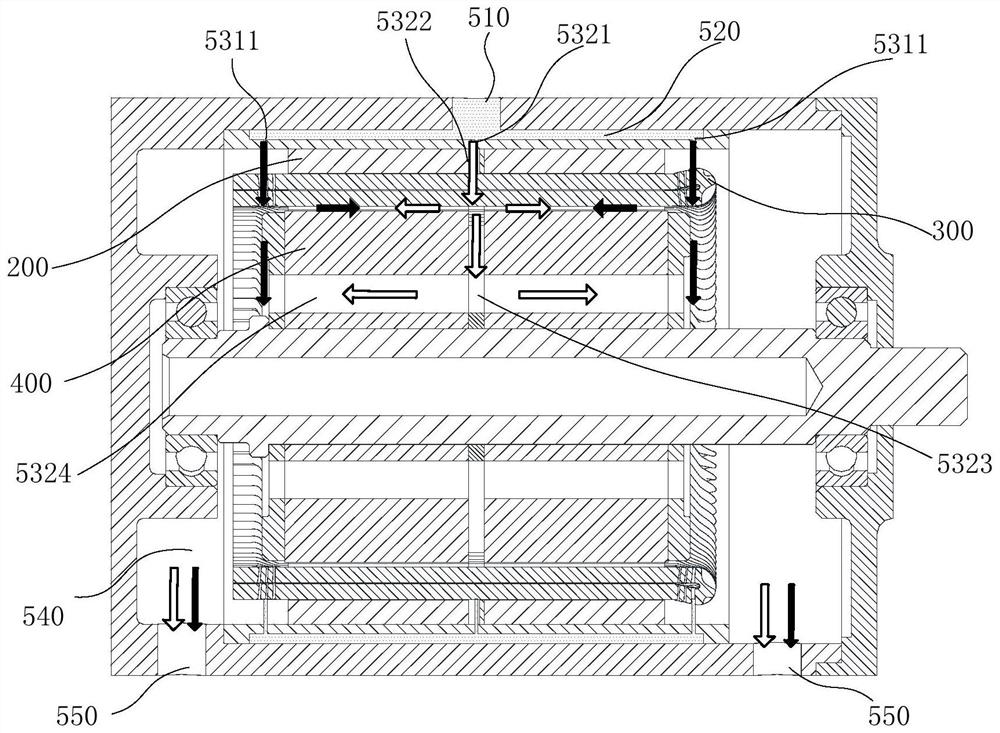

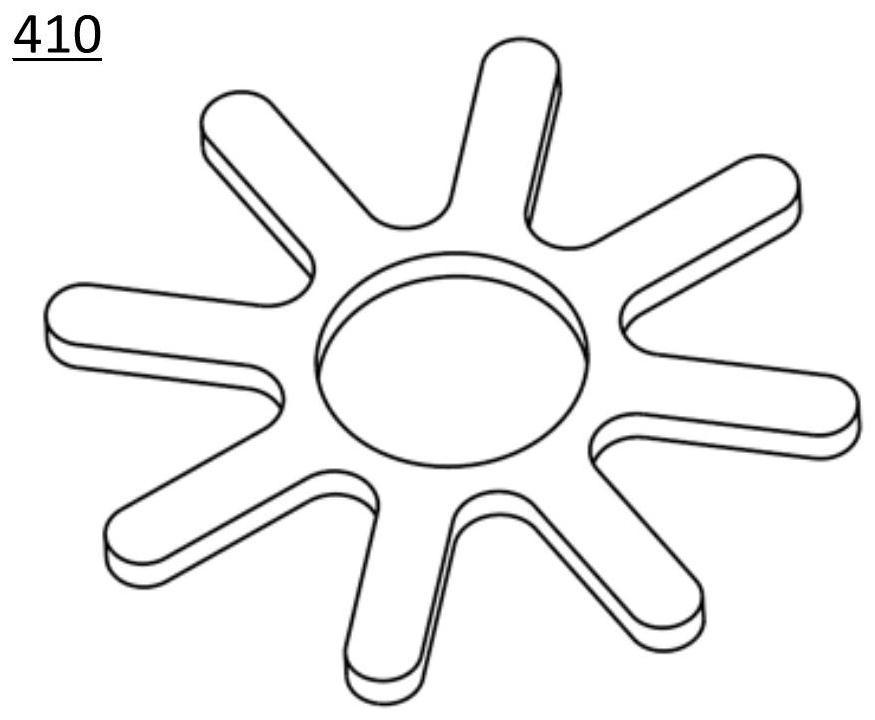

Oil cooling driving motor and automobile

ActiveCN113644784AImprove temperature field distributionUniform distribution of temperature fieldMagnetic circuit rotating partsElectric machinesElectric machineDrive motor

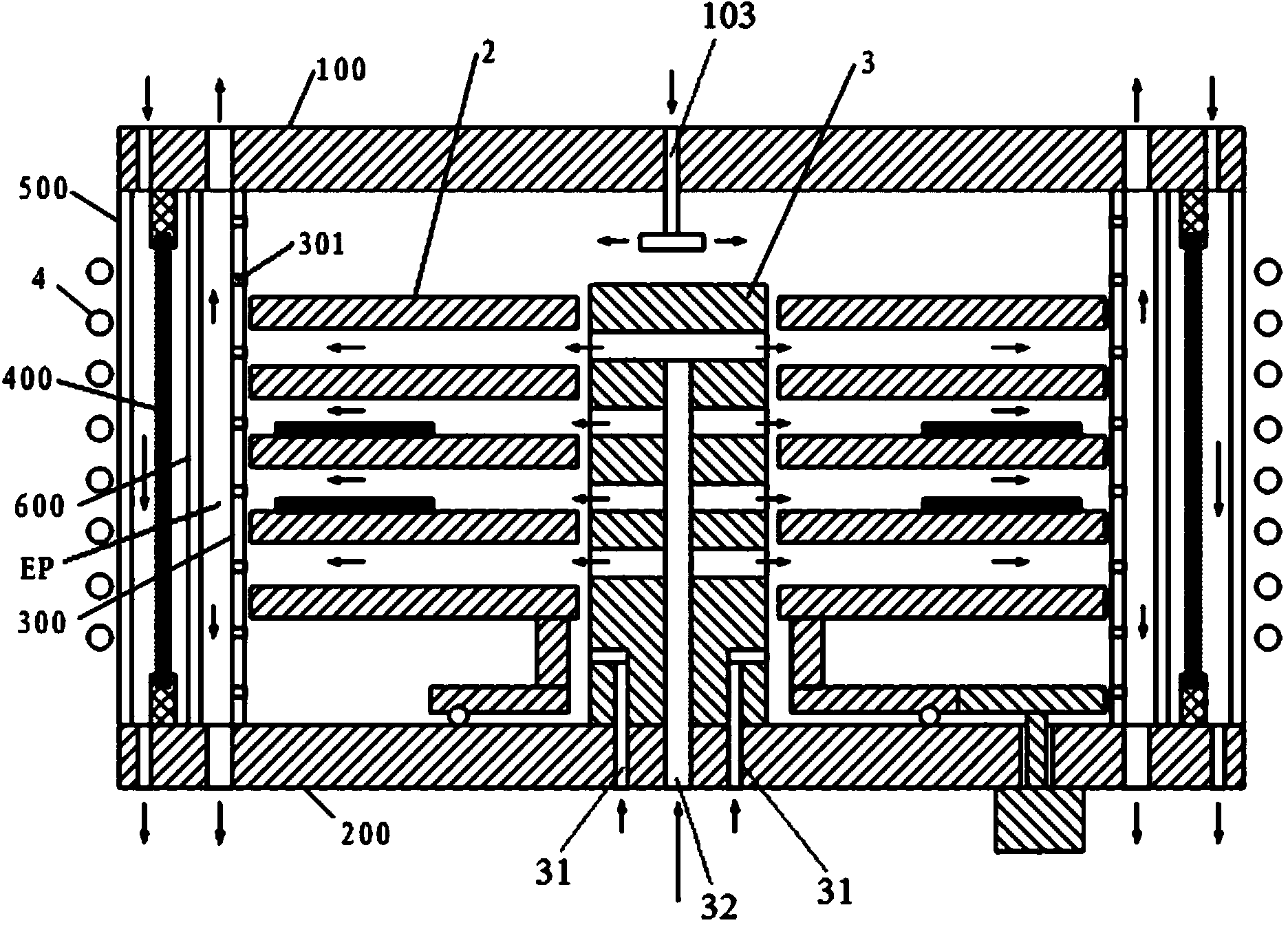

The invention provides an oil cooling driving motor and an automobile, the oil cooling driving motor comprises a shell, a stator core, a stator winding coil and a rotor core which are sequentially arranged from outside to inside, and the oil cooling driving motor further comprises an oil cooling system, at least one stator partition plate and at least one rotor partition plate; the stator partition plate divides the stator core into at least two sections along the axial direction and forms a stator cooling gap; the rotor partition plates divide the rotor core into at least two sections along the axial direction, and the rotor partition plates and the stator partition plates are arranged in one-to-one correspondence; the oil cooling system comprises an oil inlet, a cooling oil cavity, a cooling loop, a motor cavity and an oil outlet; the cooling loop comprises an end cooling loop and a middle cooling loop which are used for cooling the two ends of the stator winding coil, the two ends of the stator iron core and the two ends of the rotor iron core respectively and cooling the middle of the stator winding coil and the middle of the stator iron core respectively. According to the motor provided by the invention, the temperature field distribution of the driving motor is improved, so that the output capability of the motor is improved.

Owner:SAIC MOTOR

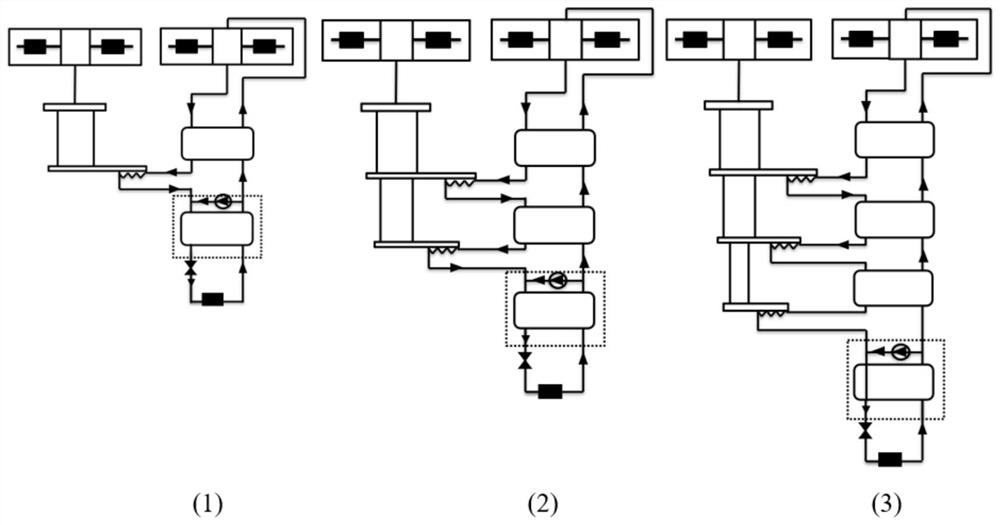

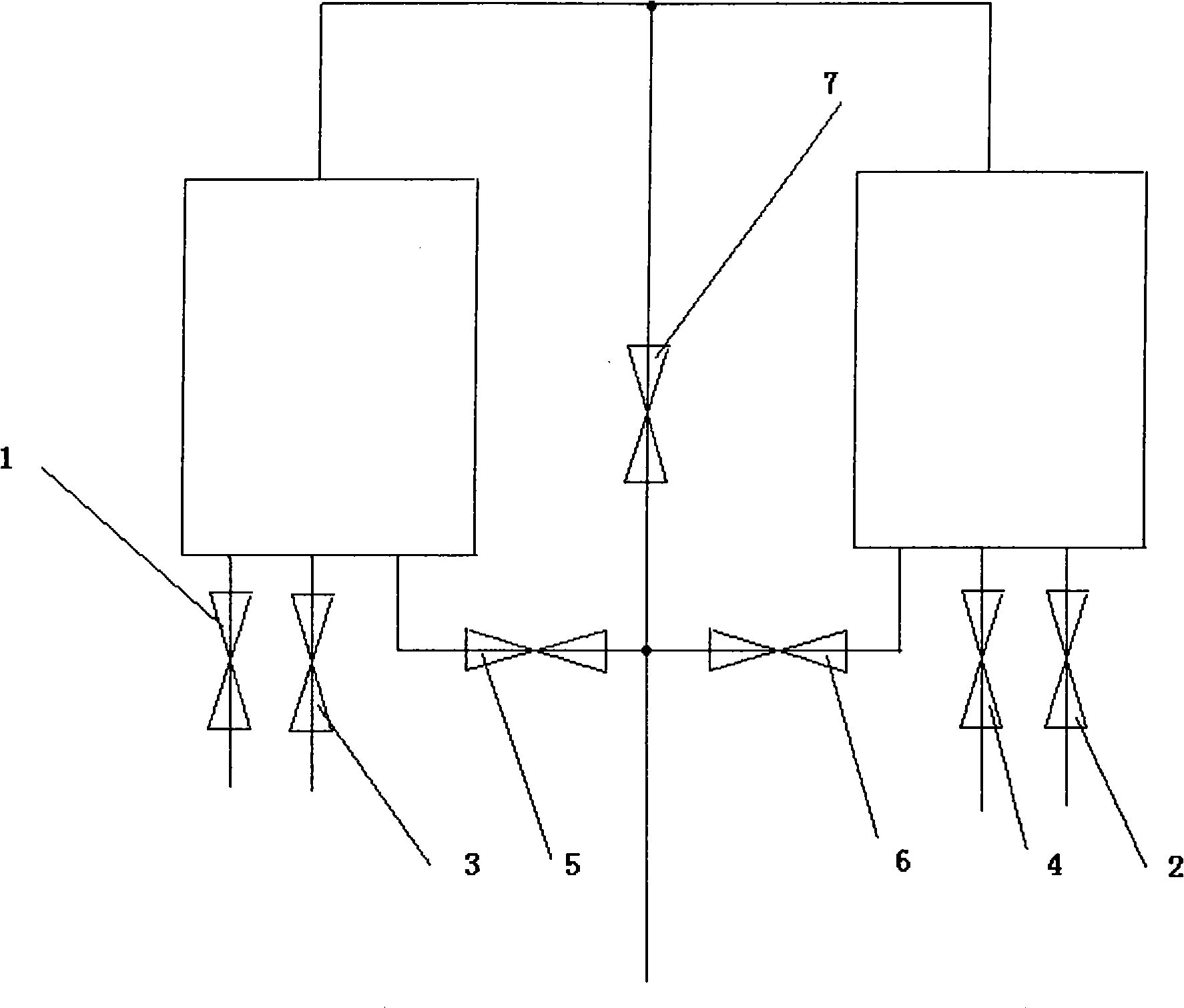

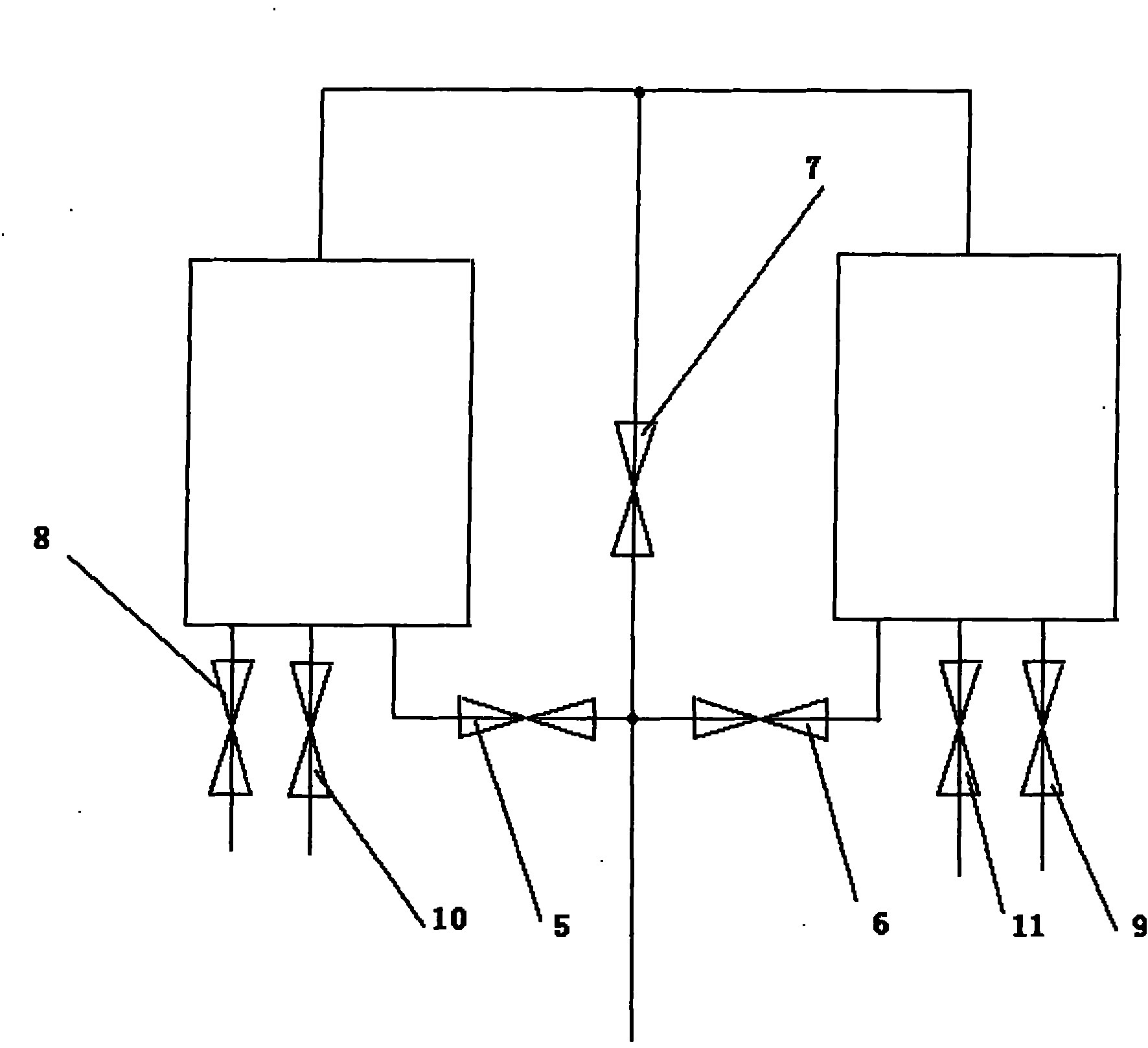

Coupling fixed bed oxygen-enriched continuous gasification process

InactiveCN101475839AReduce sensible heat lossReduce erosionCombined combustion mitigationCombustible gas productionCarbon dioxideProcess engineering

The invention discloses oxygen-rich continuous gasification technology for a coupled fixed bed, wherein a solid raw material comprises coal or coke, and a gas raw material comprises oxygen, air and steam; and the oxygen can be mixed with the air into oxygen-rich air first and then is sent into a gas-making furnace, and can also be sent into the gas-making furnace in the form of single gas. The technology is characterized in that the gas-making furnace is that two common gas furnace bodies (A and B) are connected into a whole by a pipeline and a valve, two furnaces alternately upward blow to make gas, and the gas raw material can also comprise carbon dioxide; and the gas-making process comprises the step of the blowing-off of the A and B furnaces, the step of upward blowing of the A furnace, the step of secondary blowing-off of the A and B furnaces, and the step of upward blowing of the B furnace, and the steps are circulated. The gas-making furnace is that the two common gas furnace bodies are connected into a whole by the pipeline and the valve, and the two furnaces alternately upward blow to make gas, so the technology can optimize the distribution of temperature fields in the gas furnaces, reduce the sensible heat loss of semiwater gas, the erosion to pipelines in subsequent working procedures, and the quantity of carry-overs, improve the condition of gas quality, and reduce gas consumption and coal consumption.

Owner:北京名都厚德科技有限公司

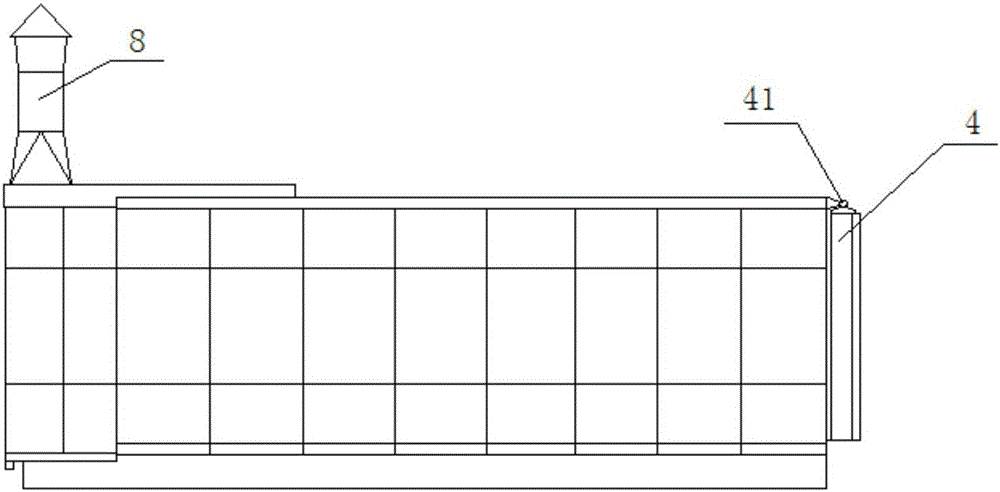

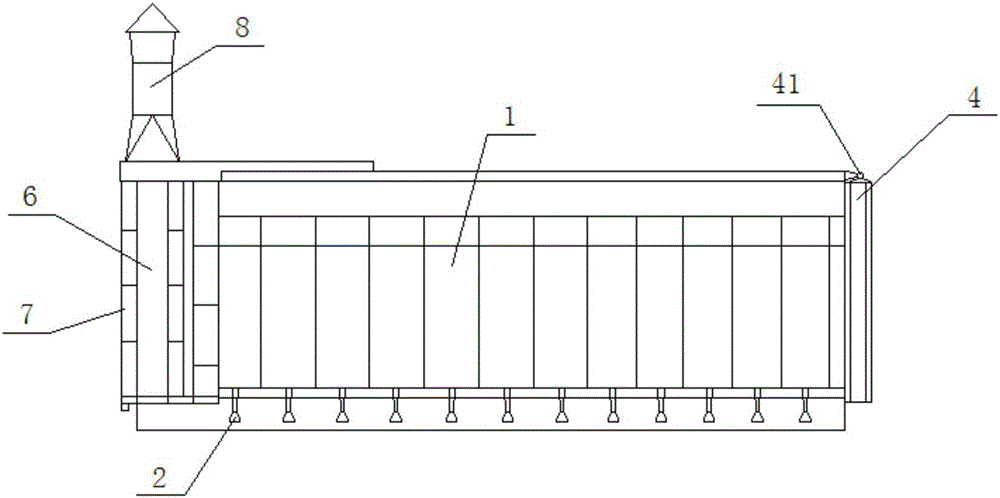

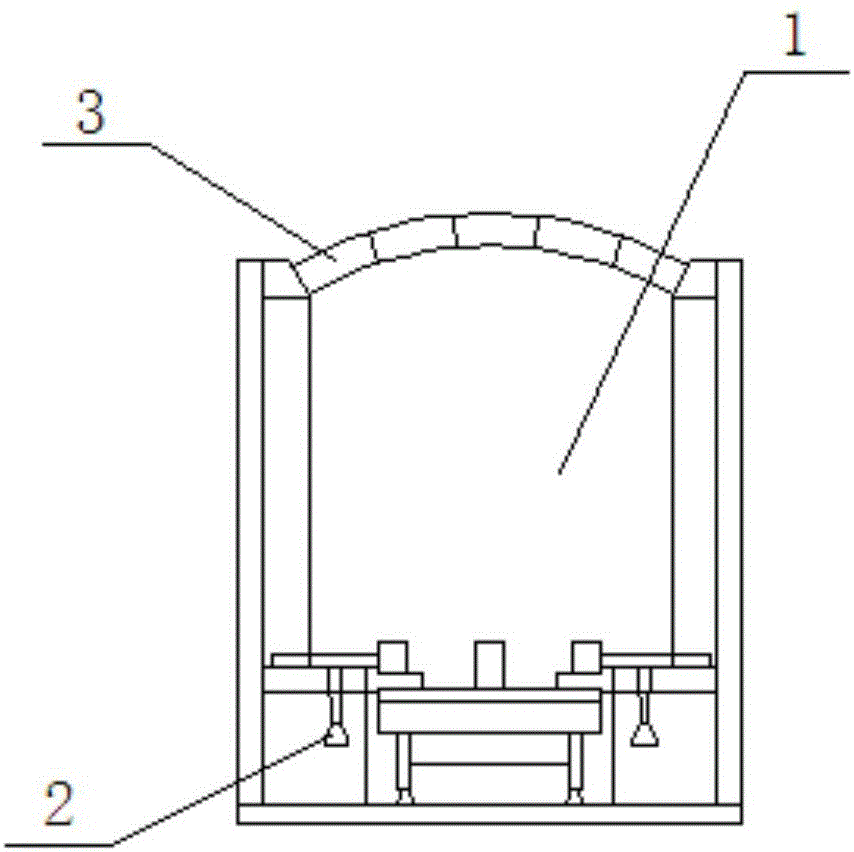

Natural gas shuttle-type energy-saving kiln

InactiveCN106123590AEfficient combustionQuality improvementCharge composition/stateCharge treatment typeCombustion systemCombustion

The invention discloses a natural gas shuttle-type energy-saving kiln. The natural gas shuttle-type energy-saving kiln comprises a kiln top of a hanging type micro arc top structure. A kiln door is of a single arm connection shaft rotary operation structure. A whole kiln frame is of an assembly type integral structure and externally provided with a stoving varnish color board in a sealed mode. A combustion system adopts outer mixed type nozzle design. Smoke adopts a kiln tail smoke discharge mode. According to the natural gas shuttle-type energy-saving kiln, through of body structure light and energy-saving design of the natural gas shuttle-type kiln, natural gas efficient combustion technology and waste heat utilization technology, the natural gas shuttle-type energy-saving kiln and comprehensive utilization of energy are achieved, ceramic product quality is improved, the energy cost is reduced, comprehensive utilization of the energy is achieved, emission is reduced, and clean production is achieved.

Owner:ZHEJIANG TIANFENG CERAMIC

Moving bed gasification furnace

ActiveCN104946310AAvoid damageImprove temperature field distributionGranular/pulverulent flues gasificationFuel gasificationEngineering

The invention provides a moving bed gasification furnace which is used for fuel gasification. The moving bed gasification furnace comprises a furnace body, wherein the inside of the side wall of the furnace body is provided with a water cooling wall through which cooling water can pass, which is used for reducing high temperature generated by gasification of the fuel in the furnace body; a cavity is formed between the side wall and water cooling wall of the furnace body; and the cavity can be filled with inert gas to prevent the furnace body from overhigh temperature. The water cooling wall is arranged inside the moving bed gasification furnace to protect the furnace body of the moving bed gasification furnace, thereby avoiding the damage to the furnace body due to overhigh temperature.

Owner:SHANGHAI BEINENG CHEM TECH

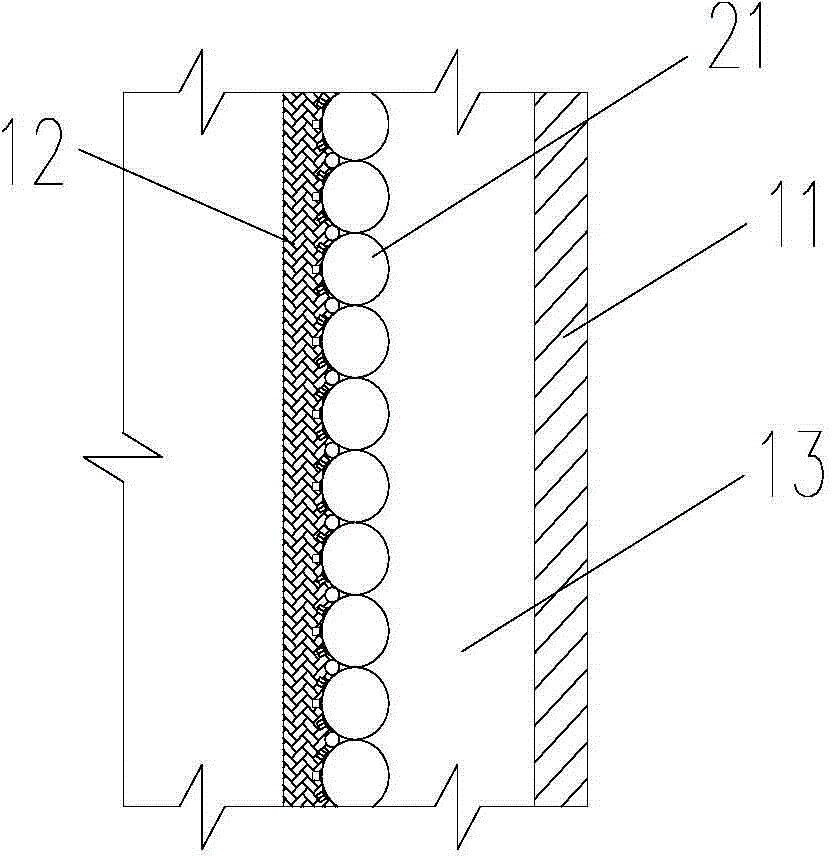

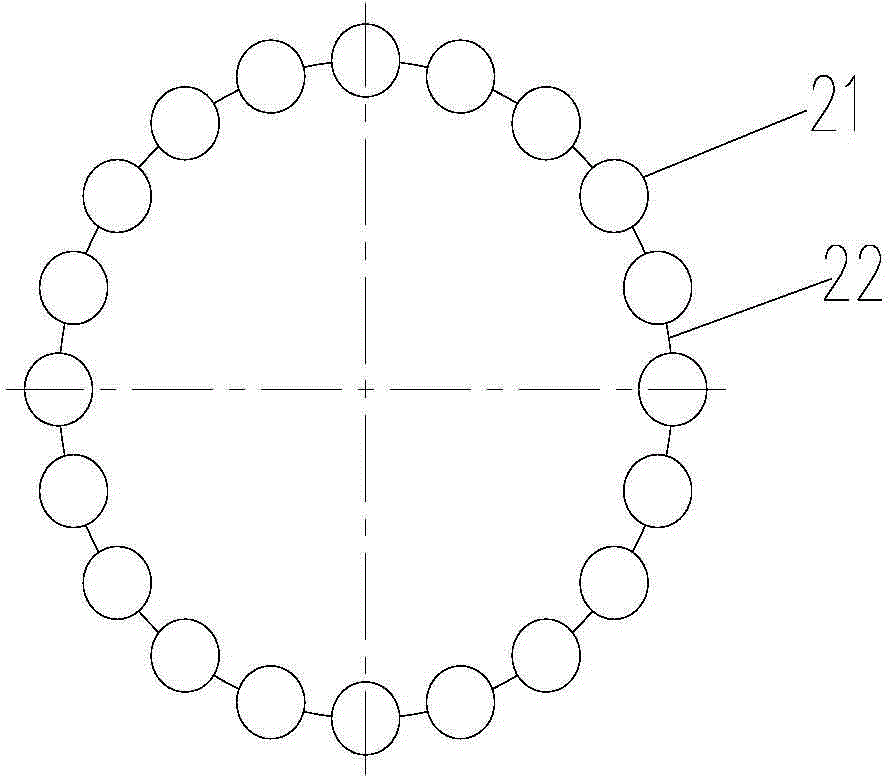

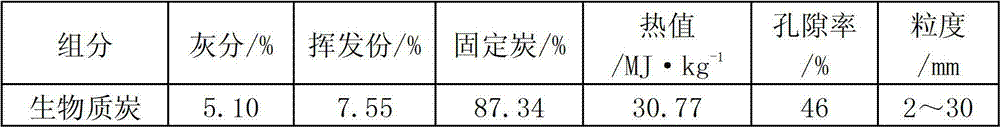

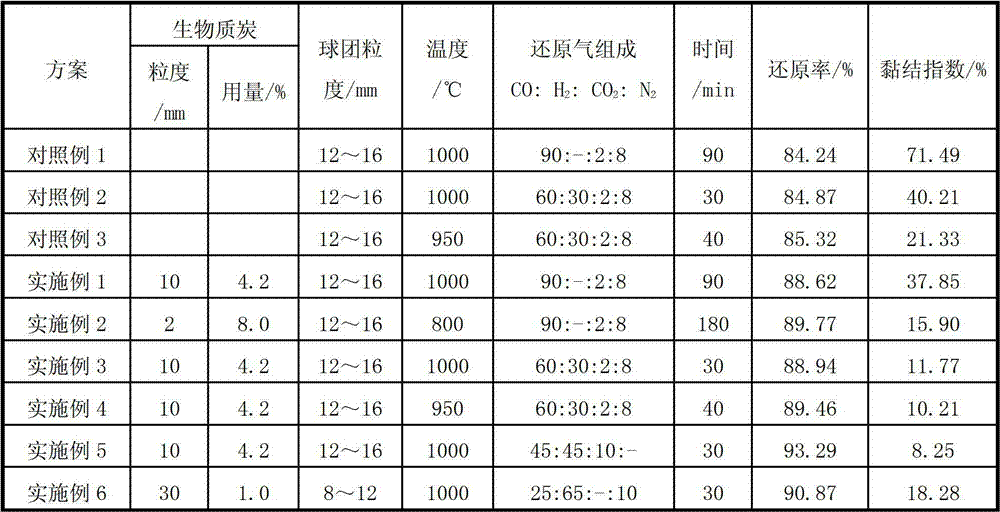

Gas base shaft-furnace direct reduction method for strengthening iron ore pellets

InactiveCN102864266AReduce stickingHarm mitigationShaft furnaceProcess efficiency improvementReduction rateShaft furnace

The invention discloses a gas base shaft-furnace direct reduction method for strengthening iron ore pellets. The method comprises the following steps of (1) evenly mixing iron ore oxidation pellets and biomass charcoal ingredients, and enabling ingredients in a mixing material by weight to be 92%-99% of iron ore pellets and 1%-8% of biomass charcoal; and (2) adding the mixing material in a shaft furnace, conducting gas base direct reduction for 0.5 to 3 hours at the temperature of 800 DEG C-1000DEG C to obtain metallized pellets. The gas base reduction of the biomass strengthening iron ore pellets is adopted, bonding degree of the pellets in a reduction process is effectively reduced while reduction rate is improved, and utilization efficiency and running states of the shaft furnace are greatly improved.

Owner:CENT SOUTH UNIV

Liquid steel casting equipment

The invention discloses liquid steel casting equipment. The liquid steel casting equipment comprises an ingot mold, wherein the upper part of the ingot mold is provided with a hot top; the ingot mold is arranged on an ingot mold base plate; a steel flow channel is formed in the ingot mold base plate, is communicated with a central casting pipe arranged on one side of an ingot mold body and is communicated with casting gates at the bottom of the ingot mold; and at least one casting gate is formed at the position which is deviated from the bottom center of the ingot mold. The liquid steel casting equipment can prevent the phenomenon of slag entrainment in the process of casting liquid steel by changing the position and the quantity of the ingot mold casting gates, deviating the casting gates from the bottom center or increasing a plurality of casting gates, changes the flow field distribution and the temperature field distribution of the liquid steel inside the ingot mold in the process of casting the liquid steel or after the casting, overcomes the defects of center segregation and loosing of steel ingots and can change the segregation positions of the steel ingots to make a segregation off center close to a steel ingot rolling surface at the same time.

Owner:郭秀梅

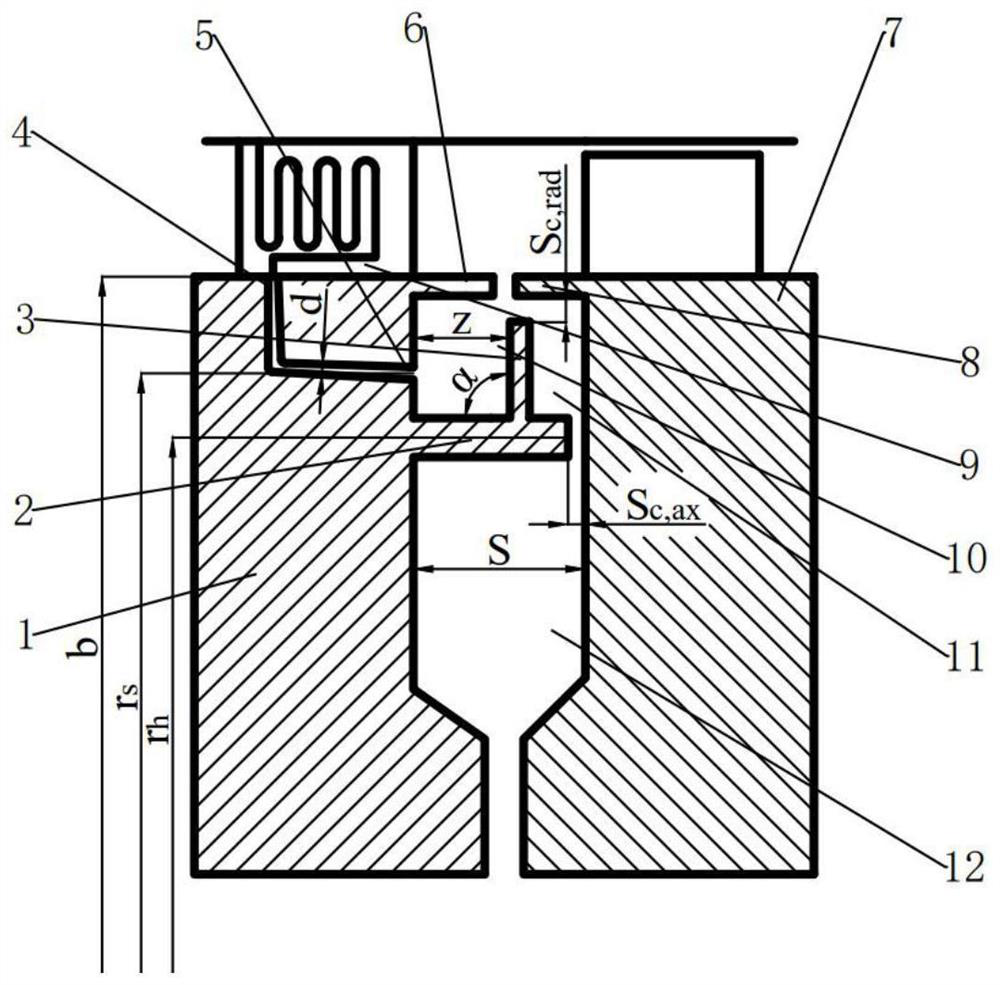

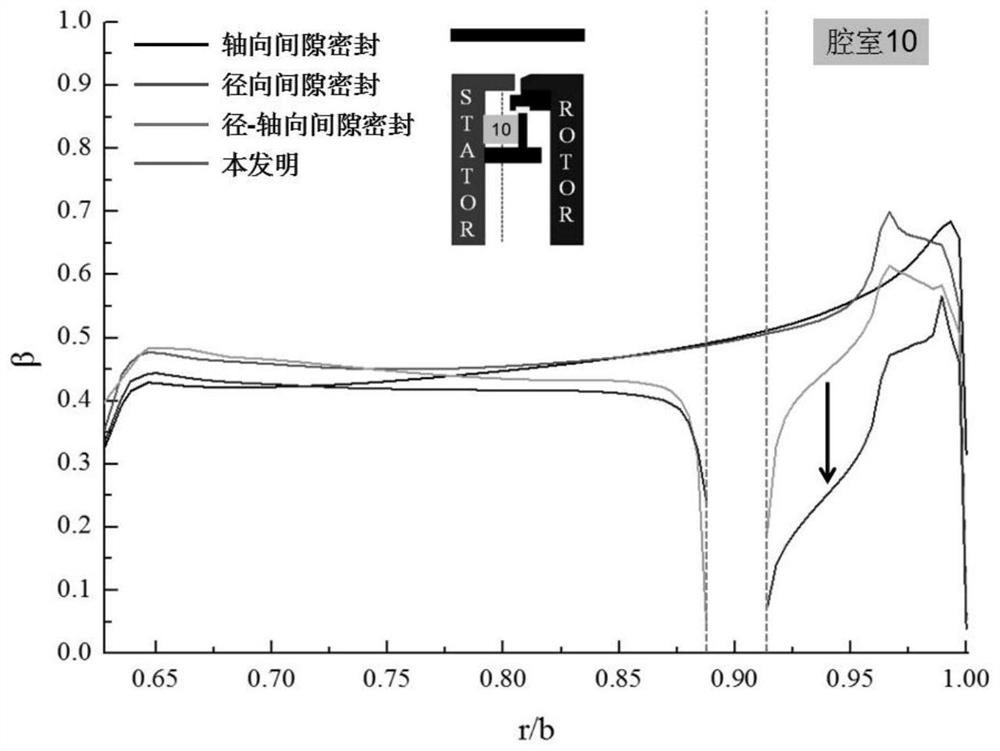

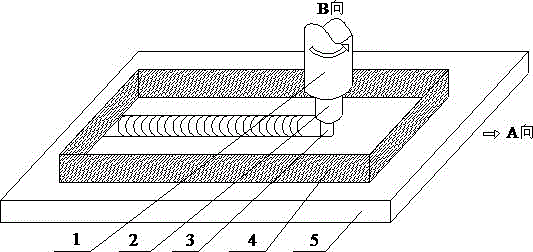

Rim sealing structure capable of inhibiting non-uniform multi-scale gas invasion

PendingCN112431639AReduce intrusionImprove temperature field distributionBlade accessoriesLeakage preventionCold airJet flow

The invention discloses a rim sealing structure capable of inhibiting non-uniform multi-scale gas invasion. The structure comprises a high-pressure turbine guide vane end wall, a rotating static containing cavity inner gear ring, an inner gear ring baffle and a rim lateral jet hole. According to the rim sealing structure, the flow resistance of gas invasion flow is increased through a combined gap, a rotating static disc cavity is divided through the rotating static containing cavity inner gear ring, then high-temperature invasion gas is limited at a high-radius position, and the circumstancethat a wheel disc is ablated due to the fact that the high-temperature invasion gas goes deep into a disc center is avoided. A static-static system containing cavity is constructed through the inner gear ring baffle so as to reduce the tangential speed ratio of the invasion flow, the high-temperature and high-speed invasion flow is buffered, and the sealing efficiency is improved. In addition, therim lateral jet hole forms high-pressure cold air outflow, so that the sealing efficiency is improved, thermal stress distribution of the inner gear ring and the inner gear ring baffle is improved, the thermal operation deformation of a turbine disc is reduced, rubbing of a rotating static component is avoided, and the reliability of the sealing structure is improved.

Owner:BEIJING UNIV OF CHEM TECH

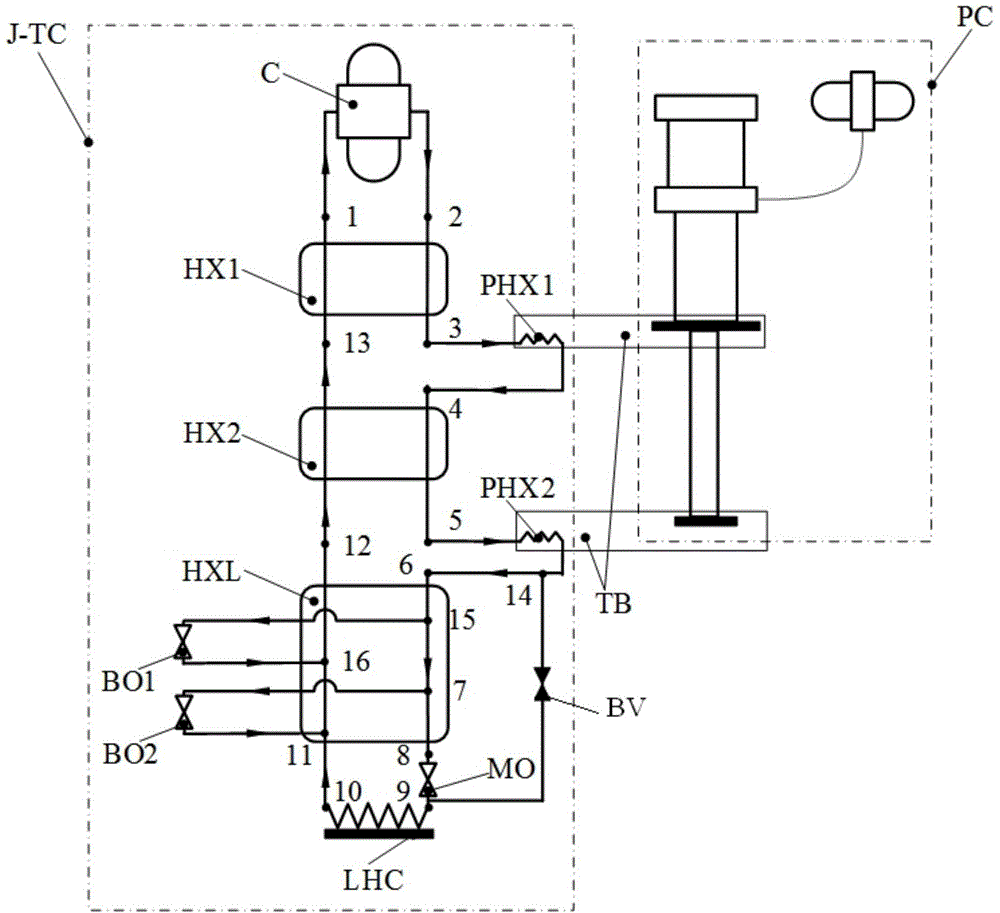

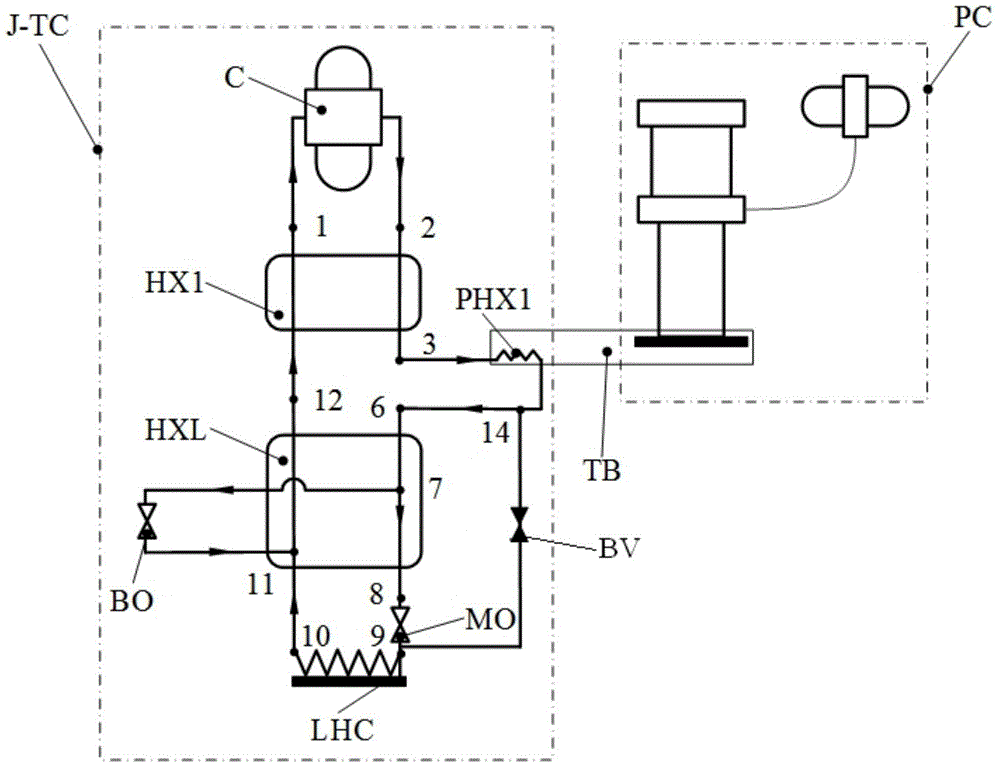

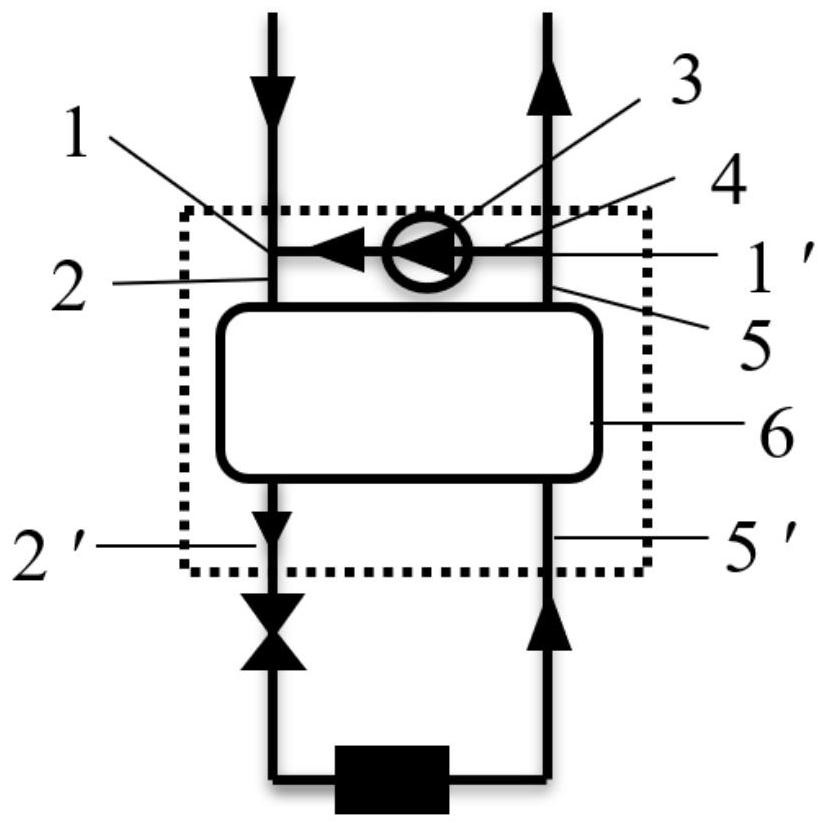

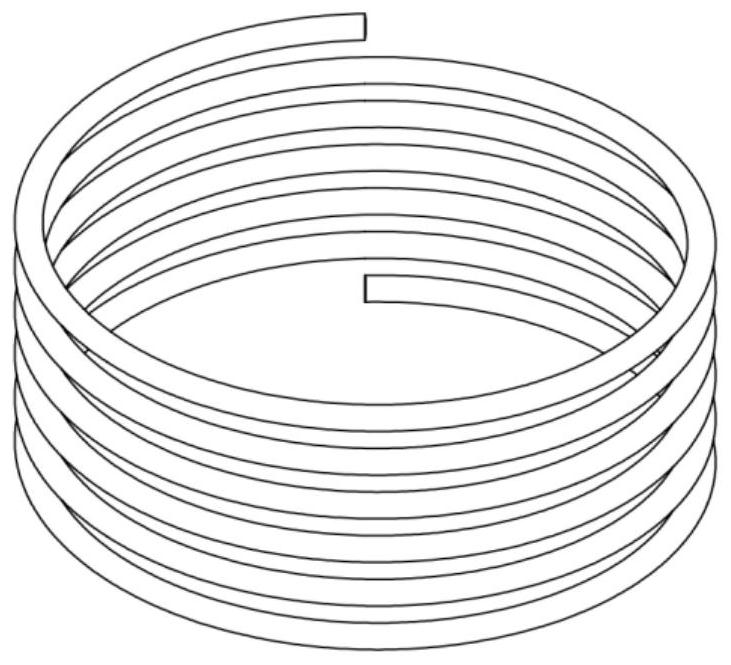

Bypass type low-temperature negative-pressure heat exchanger for pre-cooling type JT refrigerator and design method

ActiveCN112212719AIncrease the cooling capacity of the final stageImprove efficiencyCompression machinesStationary tubular conduit assembliesRefrigeration temperatureMechanical engineering

The invention discloses a bypass type low-temperature negative-pressure heat exchanger for a pre-cooling type JT refrigerating machine and a design method. The heat exchanger is composed of a high-pressure side pipeline, a low-pressure side pipeline, a bypass pipeline, a bypass element, a three-way element and a low-temperature negative-pressure dividing wall type heat exchanger. According to theinvention, the temperature and flow distribution of a fluid in the low-temperature negative-pressure heat exchanger are changed through the bypass pipeline, the irreversible loss of the pipeline and the pressure drop loss of the low-pressure pipeline side are reduced, the low-pressure pressure of the pre-cooling type JT refrigerating machine after throttling is reduced, and the final-stage refrigerating temperature of the pre-cooling type JT refrigerating machine is reduced; the flow velocity of a high-low pressure pipeline fluid in the low-temperature negative-pressure dividing wall type heatexchanger is increased, so that the heat exchange efficiency of the low-temperature negative-pressure heat exchanger is improved; the fluid temperature before throttling is reduced, and the refrigerating capacity of the pre-cooling type JT refrigerating machine is increased; and the overall efficiency of the pre-cooling type JT refrigerating machine is improved. The bypass type low-temperature negative-pressure heat exchanger for the pre-cooling type JT refrigerator and the design method have very positive significance for application of the pre-cooling type JT refrigerator in special fieldssuch as extremely low temperature areas, aerospace and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

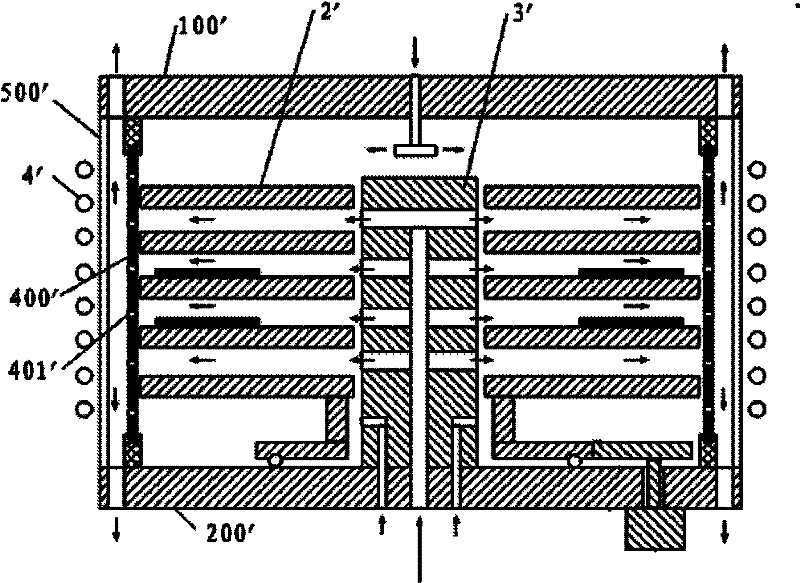

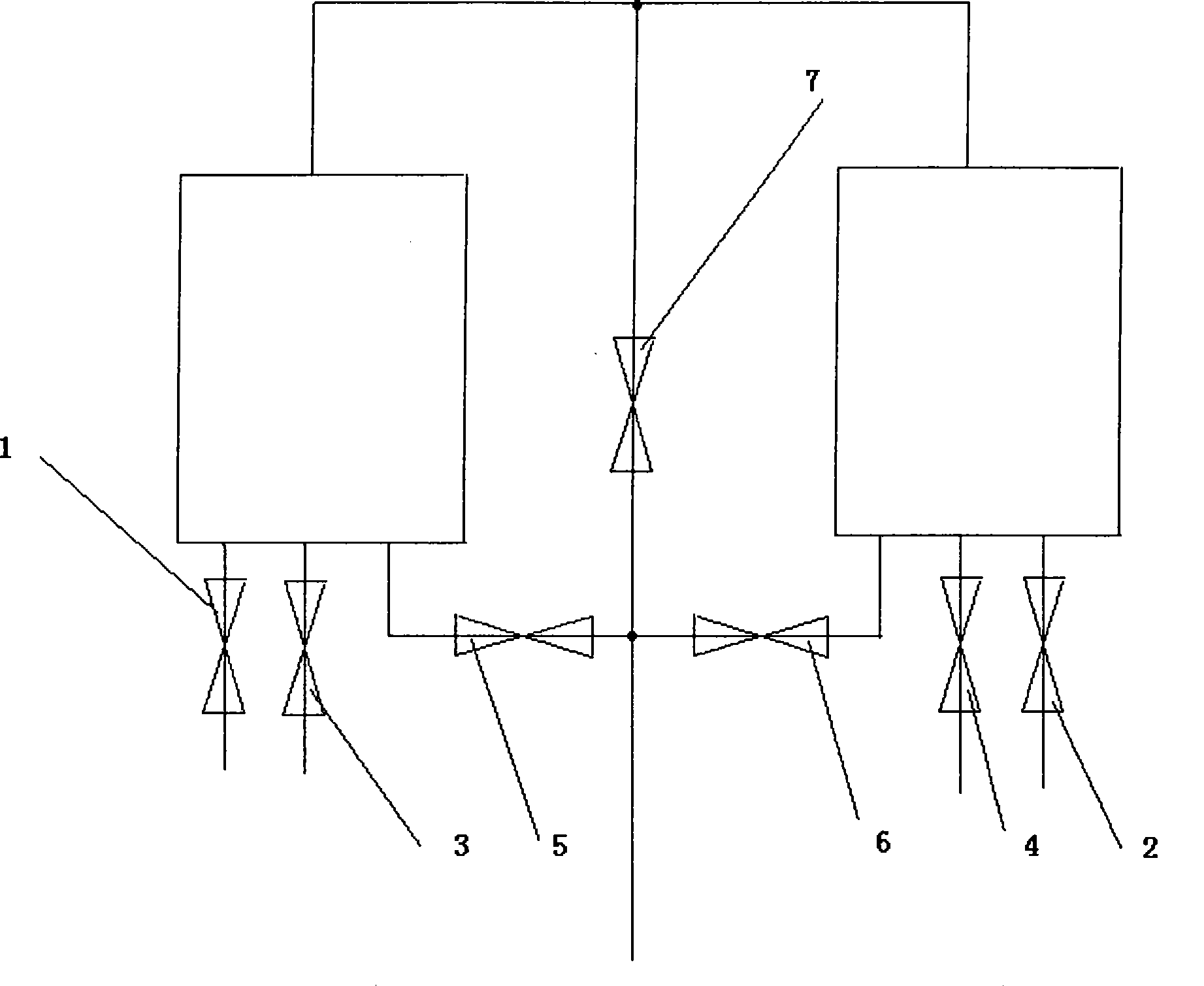

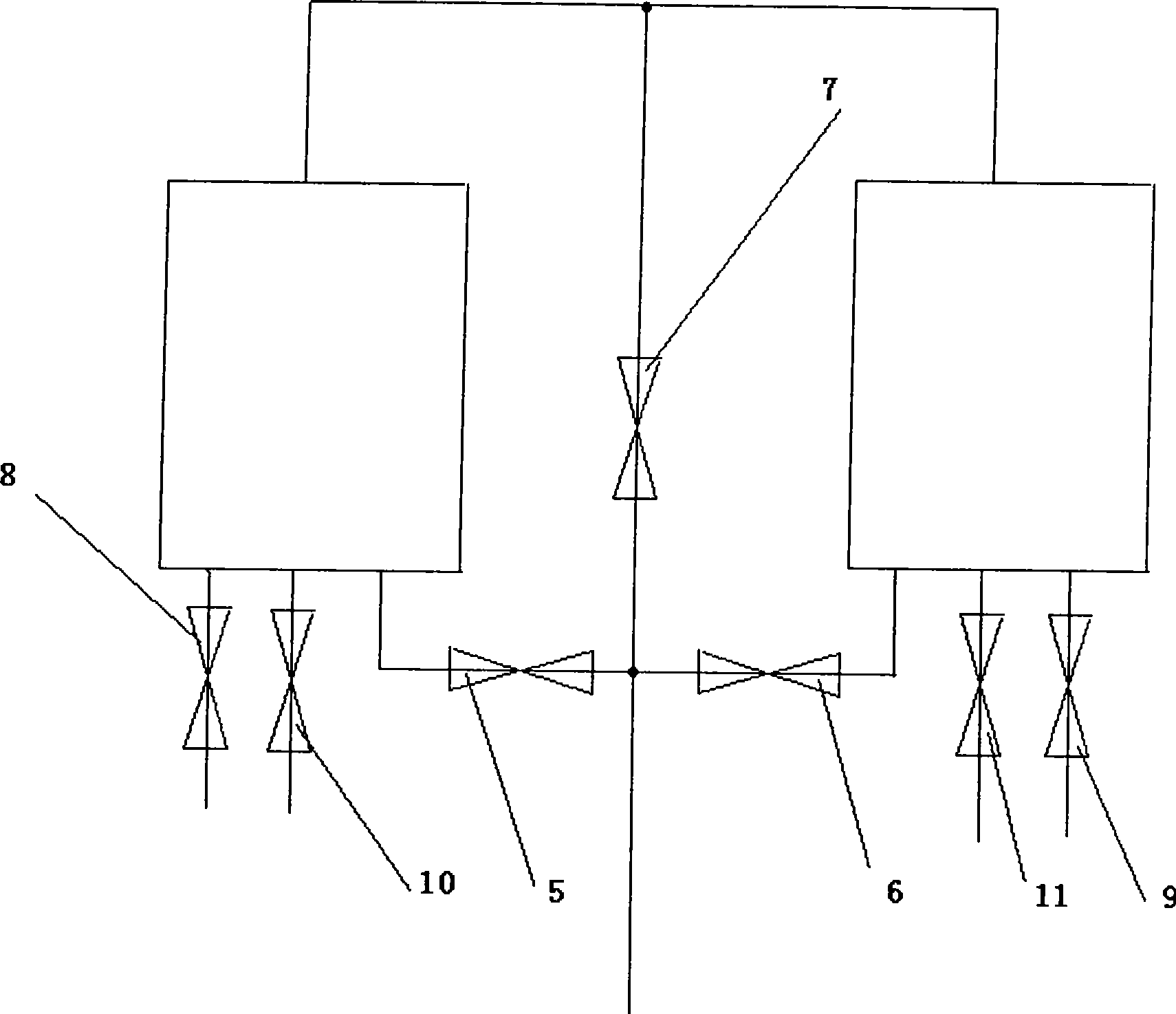

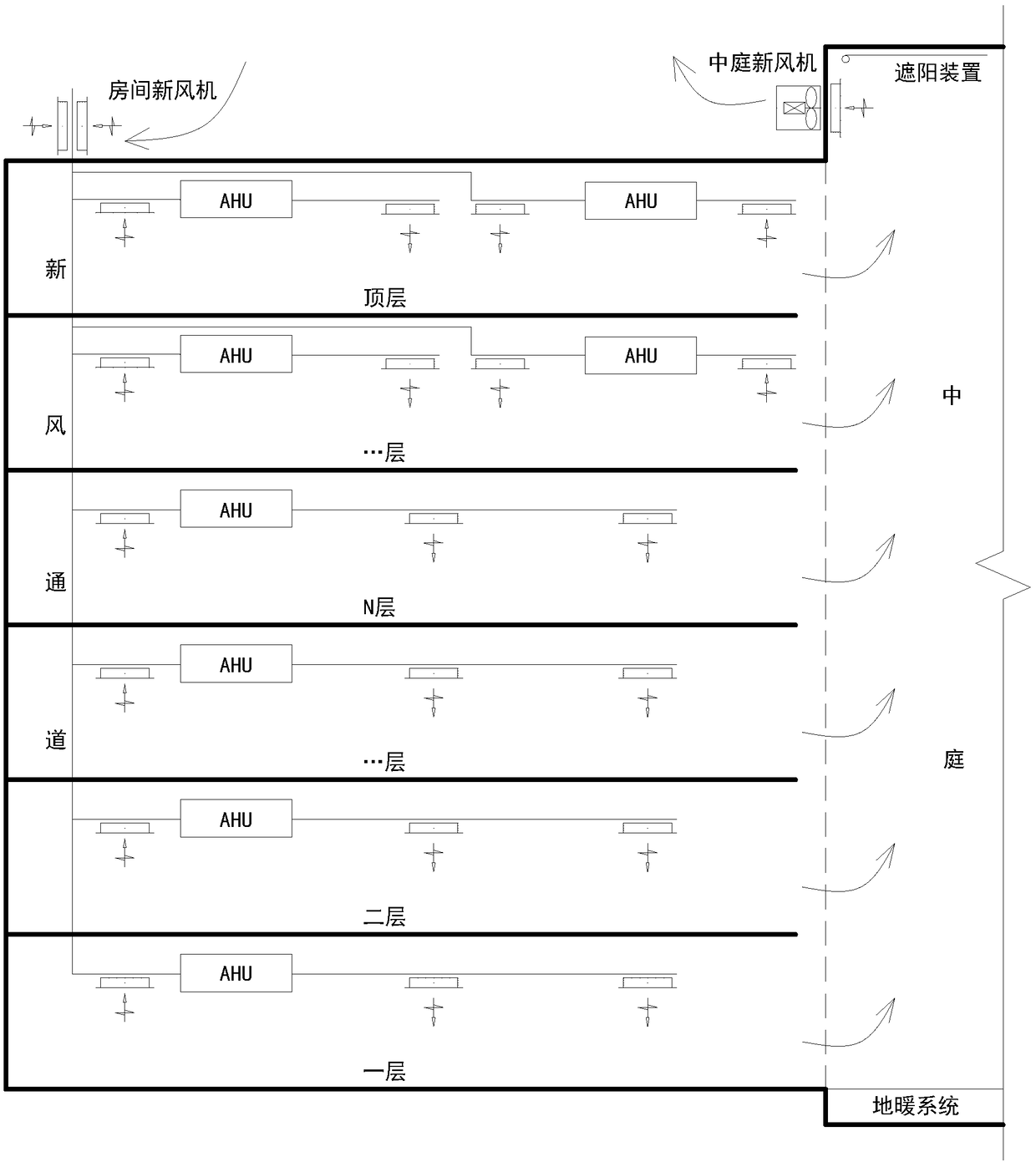

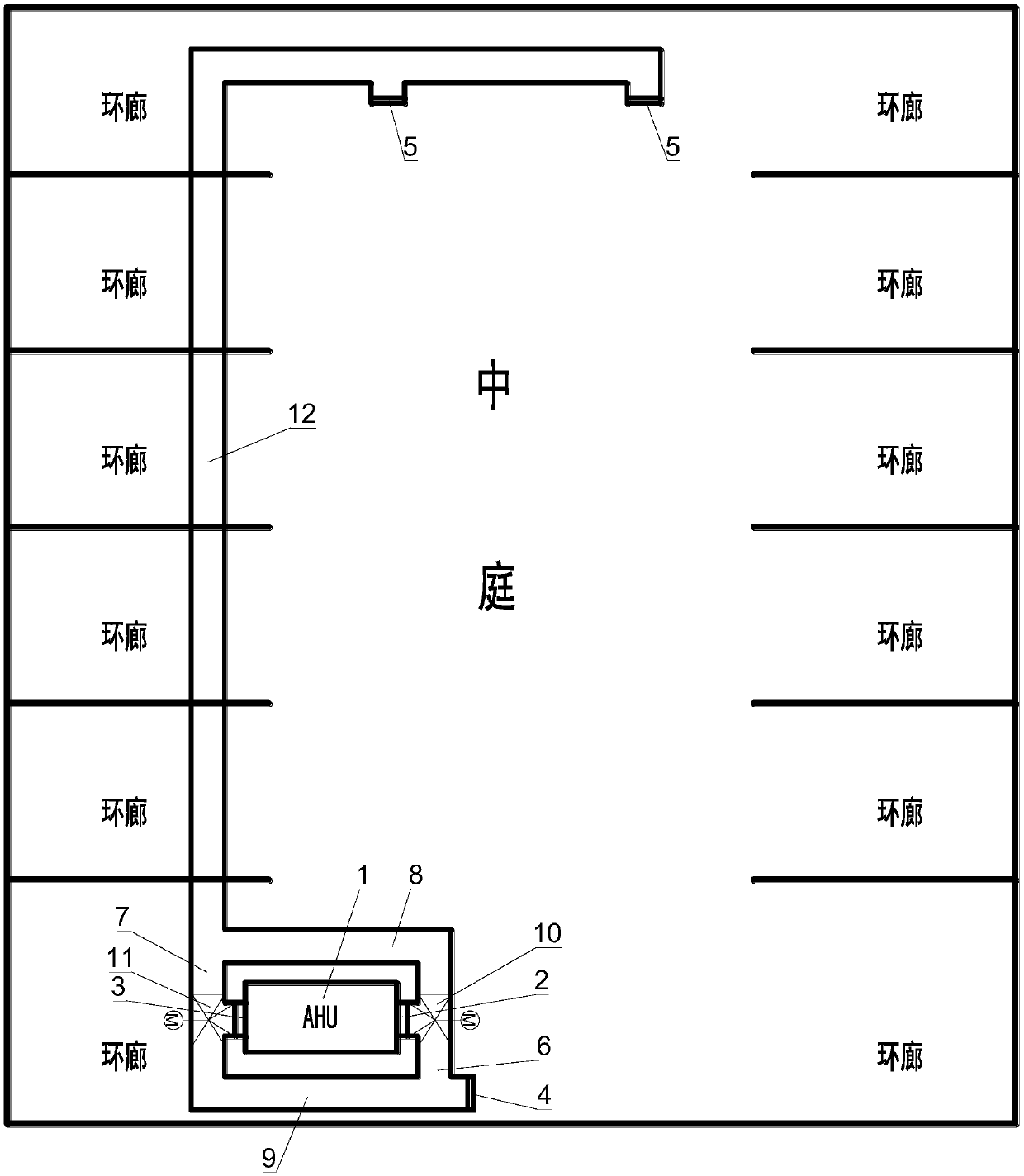

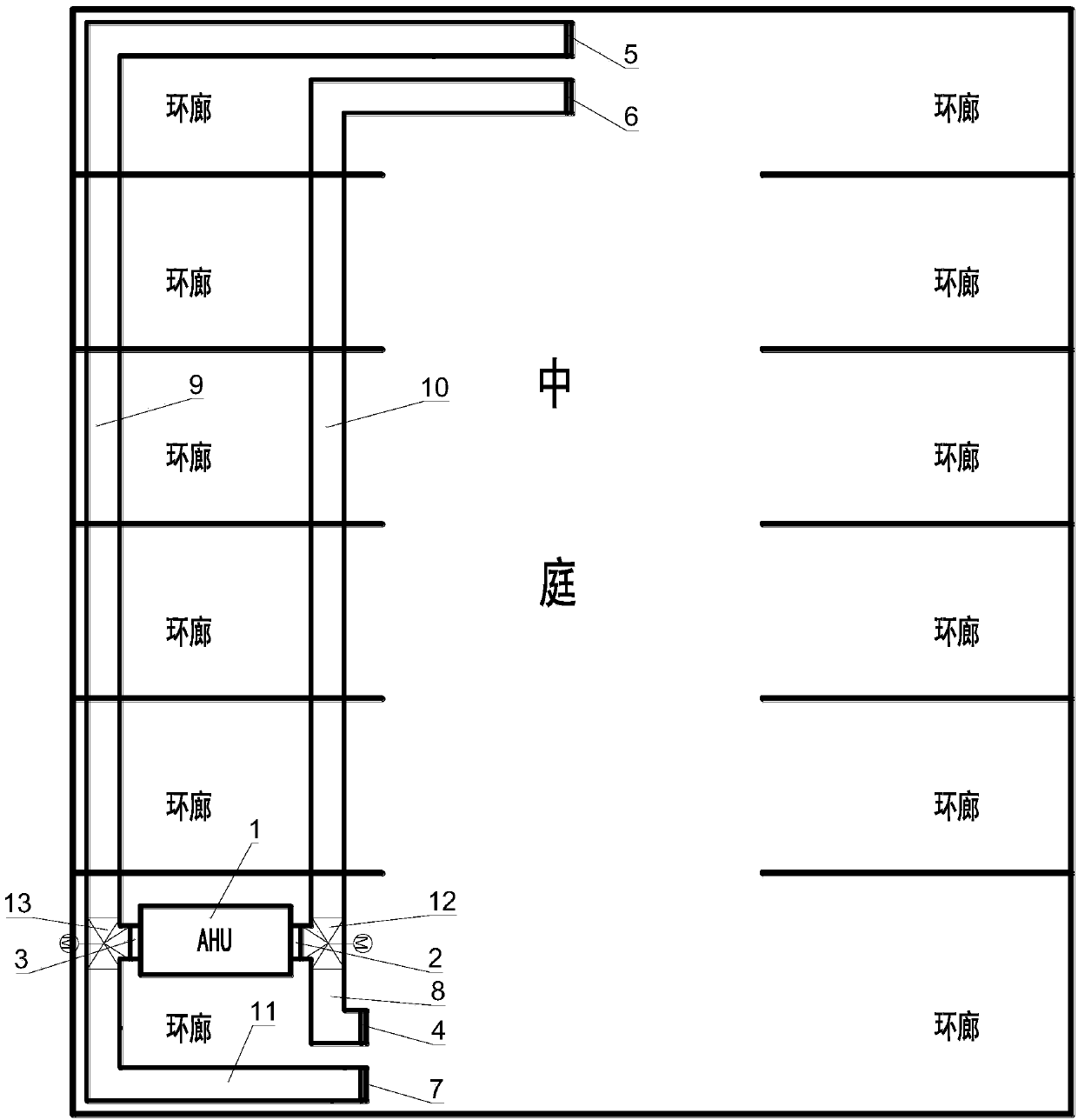

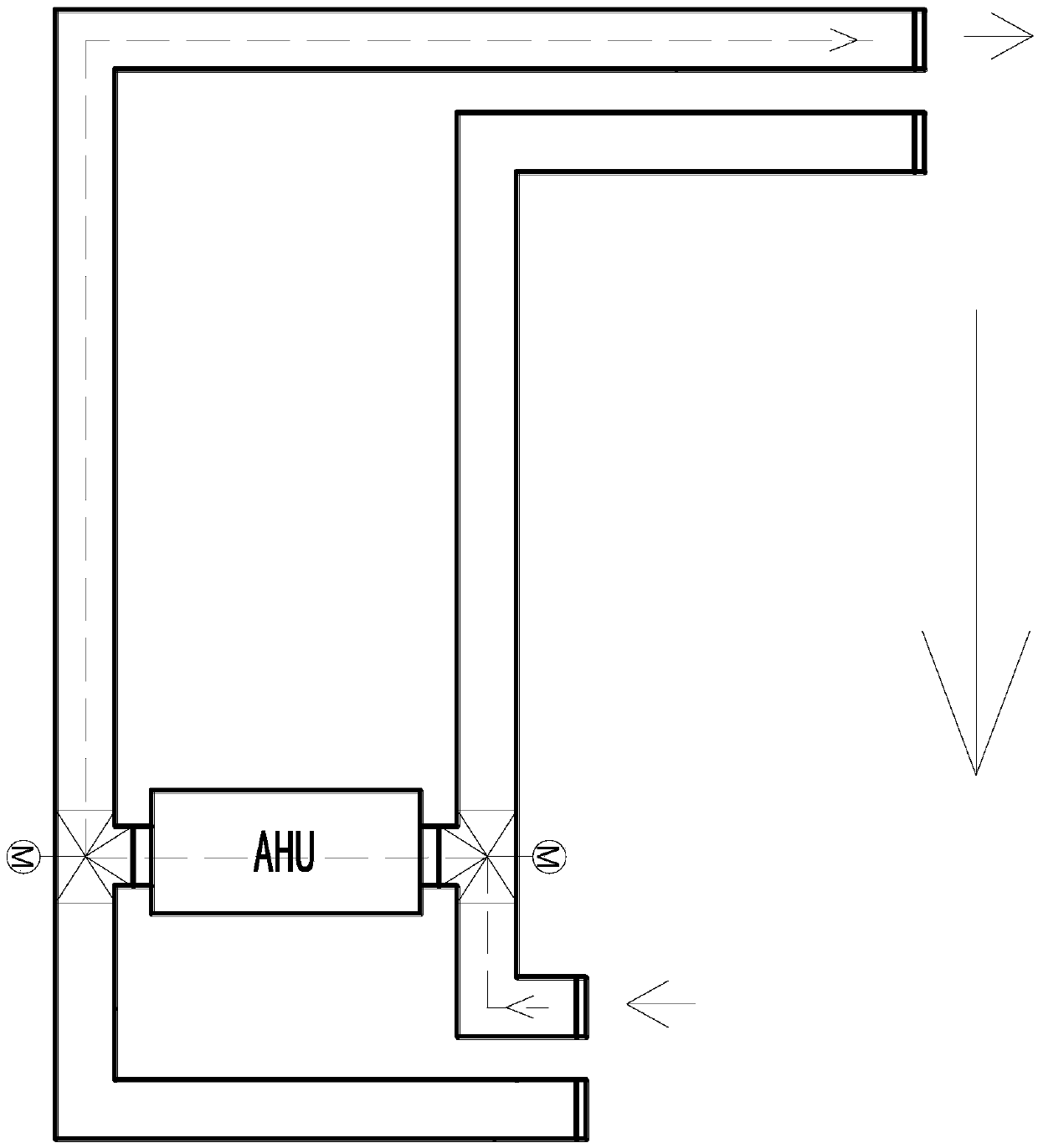

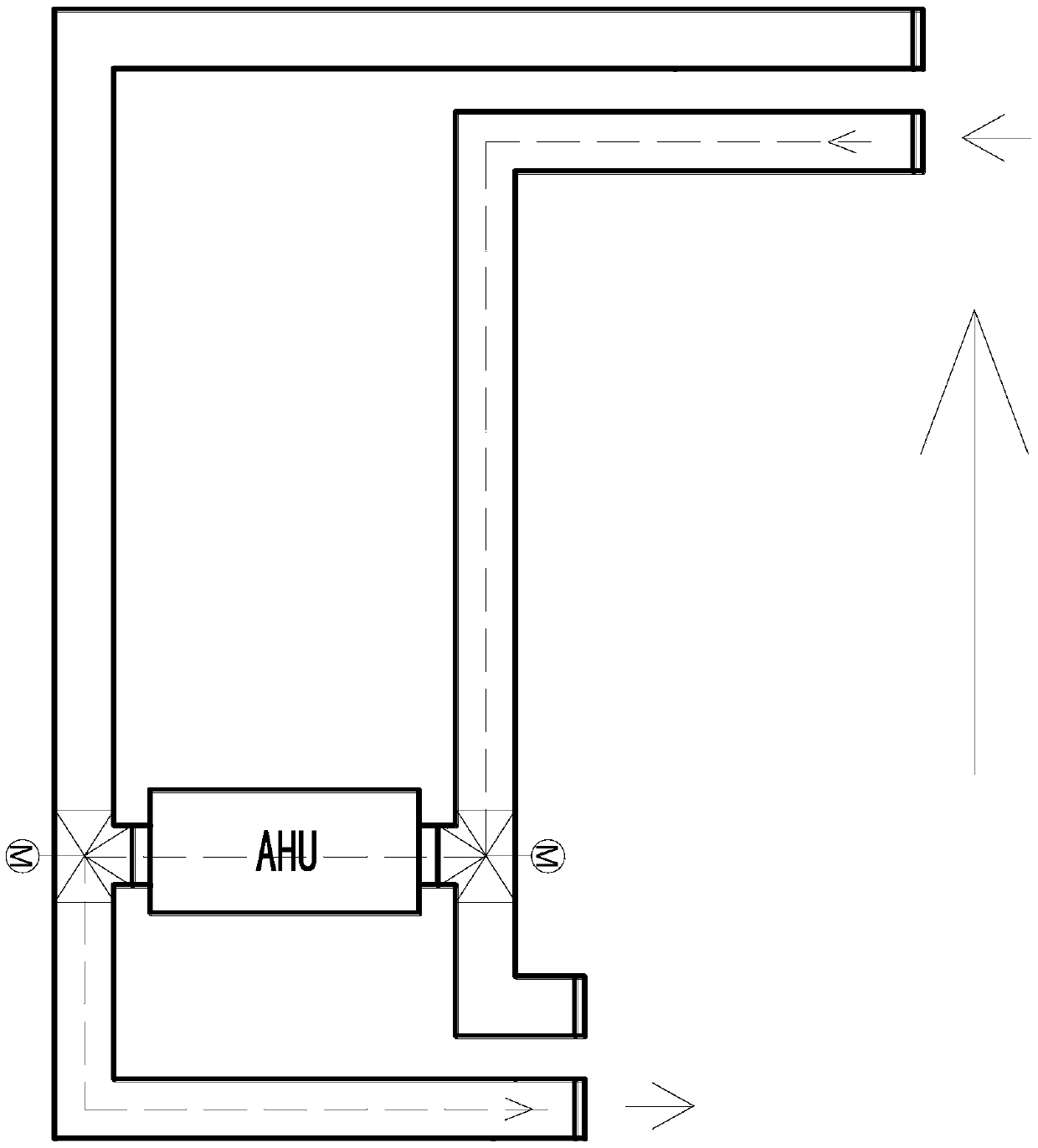

Air conditioning duct system capable of evenly regulating temperature field of building atrium

InactiveCN109140649AReasonable load distributionGuaranteed comfortMechanical apparatusSpace heating and ventilation safety systemsDevice formFresh air

The invention discloses an air conditioning duct system capable of evenly regulating a temperature field of a building atrium. Firstly, rooms and the atrium communicate with the outside, and the roomsand the atrium communicate mutually to form an air flowing channel; and secondly, the rooms or the atrium is provided with a fresh air device forming the air pressure, so that the air pressure difference is formed between the rooms and the atrium. The air conditioning duct system capable of evenly regulating the temperature field of the building atrium is provided for solving the problem that thelarge vertical temperature gradient of the atrium space cannot be solved by an existing air conditioning system. The temperature field of the atrium space can tend to uniform in the vertical direction through the air conditioning duct system.

Owner:SICHUAN LIJIU INTPROP SERVICE CO LTD

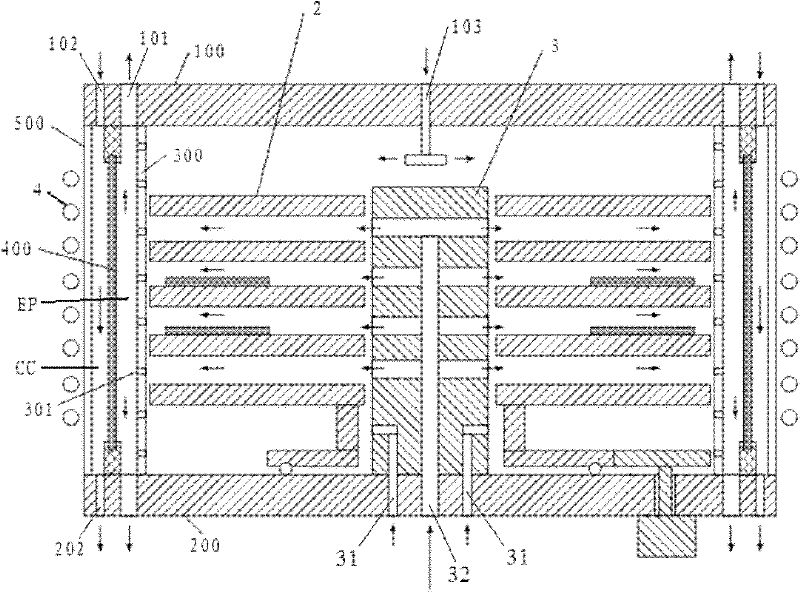

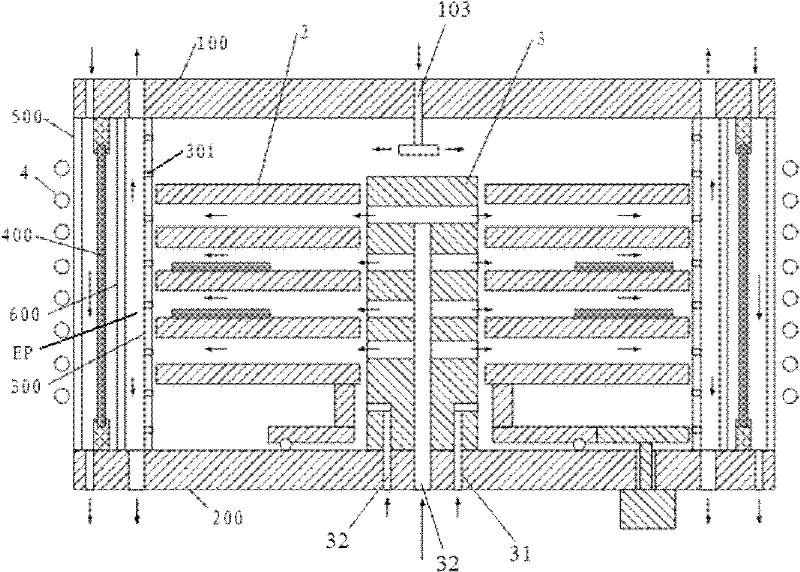

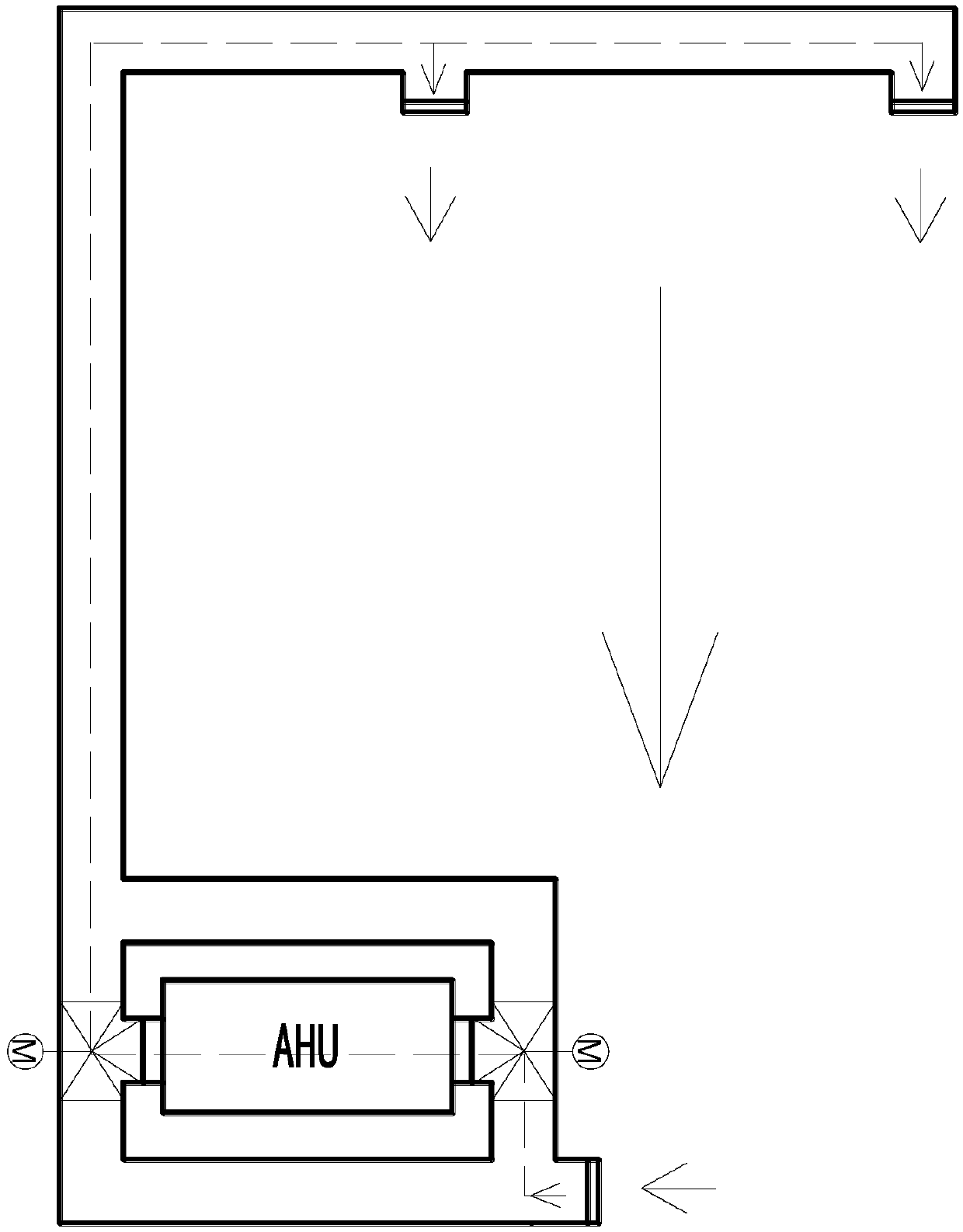

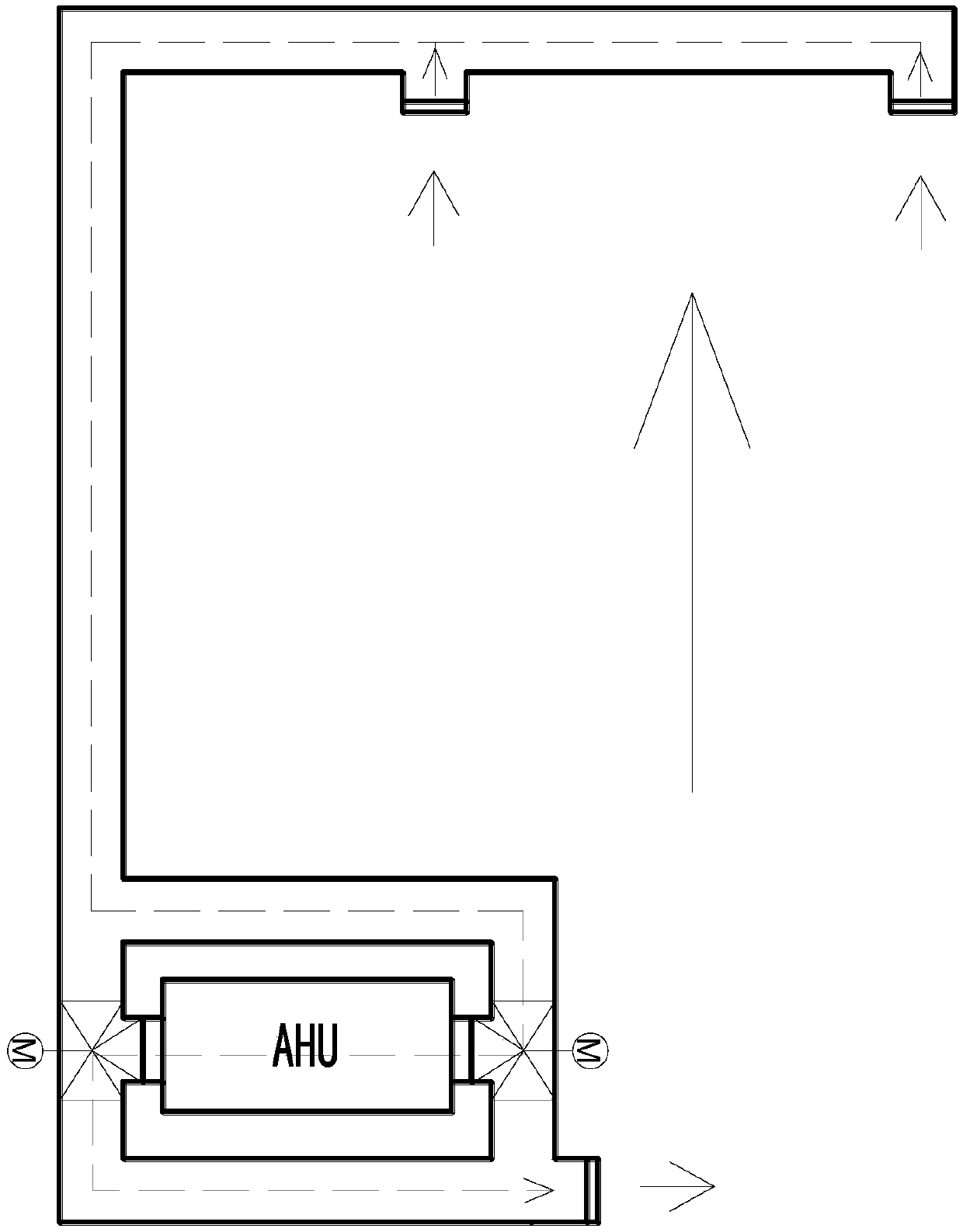

Atrium air conditioning wind system based on air treatment unit and operation method thereof

InactiveCN109099529AImprove temperature field distributionEasy to useDucting arrangementsMechanical apparatusWind systemAir treatment

The invention discloses an atrium air conditioning wind system based on an air treatment unit. The atrium air conditioning wind system based on the air treatment unit comprises the air treatment unit,a bottom air port and a top air port, and the bottom air port and the top air port are used in summer and winter. An operation method of the atrium air conditioning wind system comprises the follow steps that in summer, air at the bottom of an atrium passes through the bottom air port, the air treatment unit and the top air port in sequence, and finally enters the top of the atrium; and in winter, air at the top of the atrium passes through the top air port, the air treatment unit and the bottom air port in sequence, and finally enters the bottom of the atrium. The atrium air wind conditioning system based on the air treatment unit and the operation method thereof are provided for solving the problem existing in an existing atrium air conditioning system that the existing atrium air conditioning system can not adjust the vertical temperature gradient of atrium space of a building in winter and summer. In winter and summer, the operation of the air conditioning wind system can enable the temperature field of the atrium space to tend to be uniform vertically.

Owner:SICHUAN LIJIU INTPROP SERVICE CO LTD

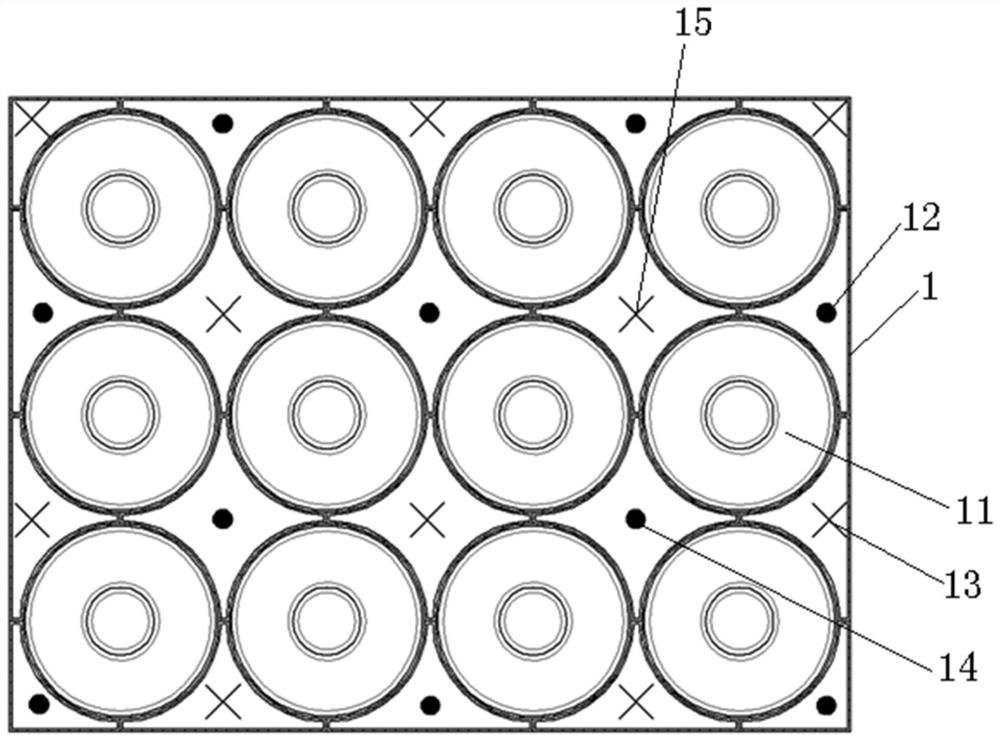

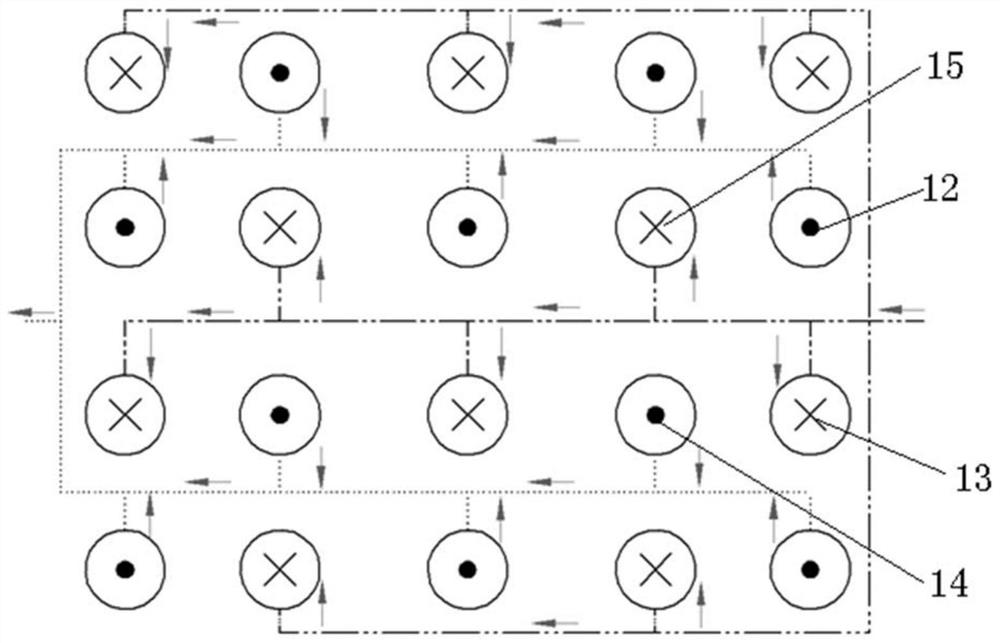

Constant temperature control system of electric automobile battery pack and control method

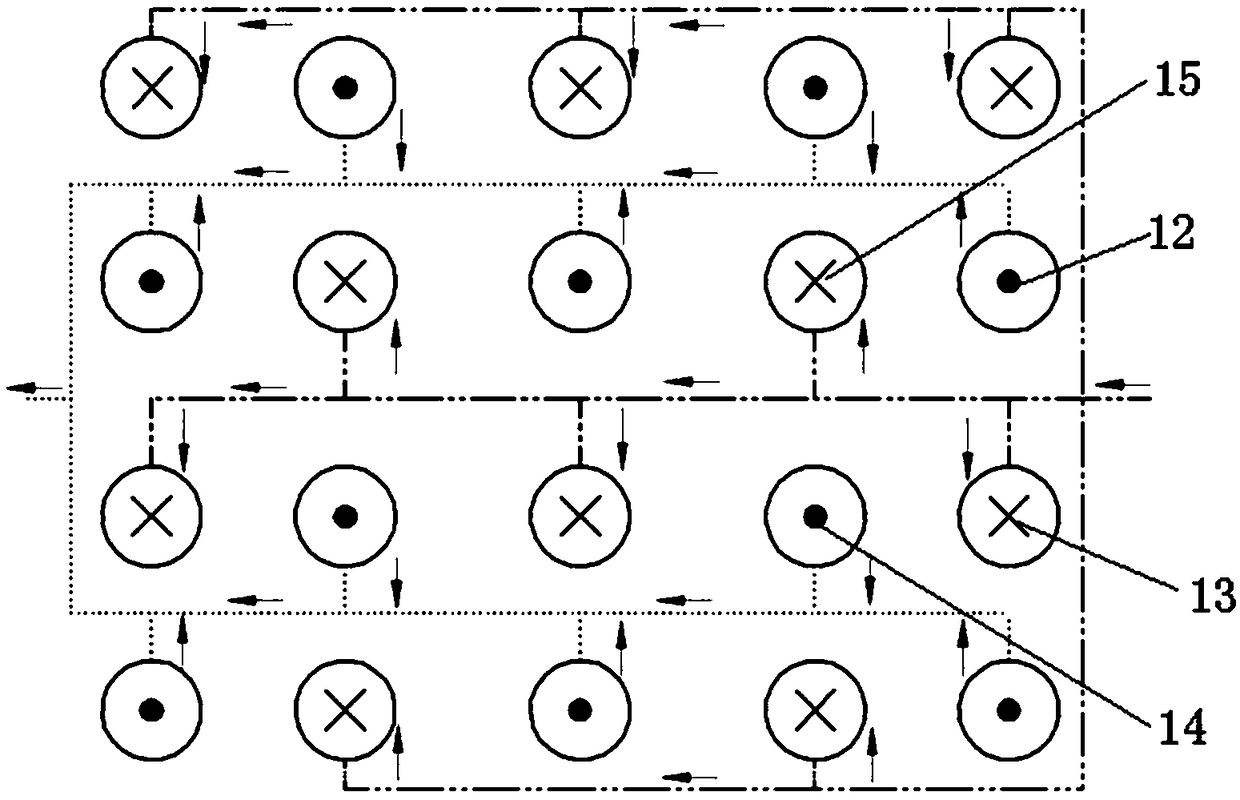

ActiveCN109494429AImprove temperature field distributionAvoid concentrationSecondary cellsTemperature controlAutomotive battery

The invention relates to a constant temperature control system of an electric automobile battery pack and a control method. The constant temperature control system of the electric automobile battery pack comprises a battery pack, a battery pack front end cooling plate and a battery pack rear end cooling plate. The battery pack is installed between the battery pack front end cooling plate and the battery pack rear end cooling plate. The battery pack front end cooling plate is provided with a front end cooling liquid inlet and a front end cooling liquid outlet. Each of battery pack front end inlet and battery pack rear end inlet is provided with a solenoid valve. The solenoid valve is connected with a controller by an electric signal. In the technical scheme, the periphery of each battery cell comprises four cooling liquid flow paths in adverse flowing directions, circulating and alternating occurrence of cooling liquid is realized, and a convection current is formed in the battery cell,so temperature field distribution around the battery cell is improved, and the high-temperature or low-temperature cooling liquid is avoided from being concentrated at a certain end of the battery cell while the flowing directions of all cooling liquid are the same.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Process chamber device and epitaxial equipment with it

ActiveCN102691100BImprove temperature field distributionReduce maintenance timesSemiconductor/solid-state device manufacturingFrom chemically reactive gasesGraphitePulp and paper industry

The invention discloses a process chamber device and epitaxial equipment with the process chamber device. The process chamber device comprises: a top cap and a bottom cap; an inner quartz tube, which is located between the top cap and the bottom cap and provided with exhaust holes, and defines a process chamber together with the top cap and the bottom cap; a graphite sleeve positioned between the top cap and the bottom cap and sleeved outside the inner quartz tube, with an exhaust path defined between the graphite sleeve and the inner quartz tube, communicated with the outside, and communicated with the process chamber through the exhaust holes; and an outer graphite sleeve positioned between the top cap and the bottom cap and sleeved outside the graphite sleeve, with a cooling channel defined between the outer graphite sleeve and the graphite sleeve and communicated with the outside. According to the process chamber in embodiment of the invention, temperature field distribution in the process chamber can be improved, and ultimately, uniformity of the radial temperature in the process chamber and further in a substrate can be realized. Also, the maintenance frequency and the maintenance cost of the graphite sleeve can be reduced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

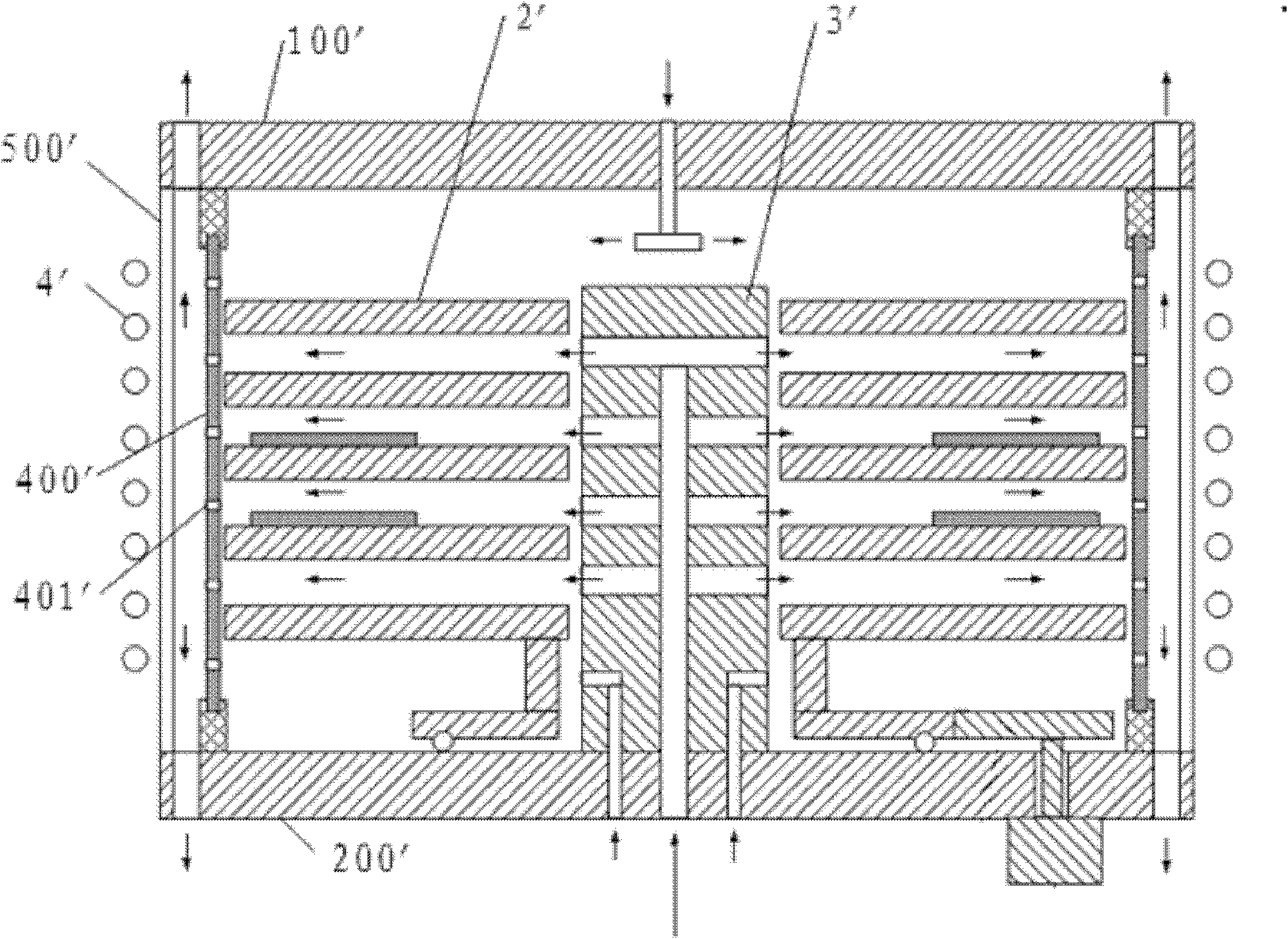

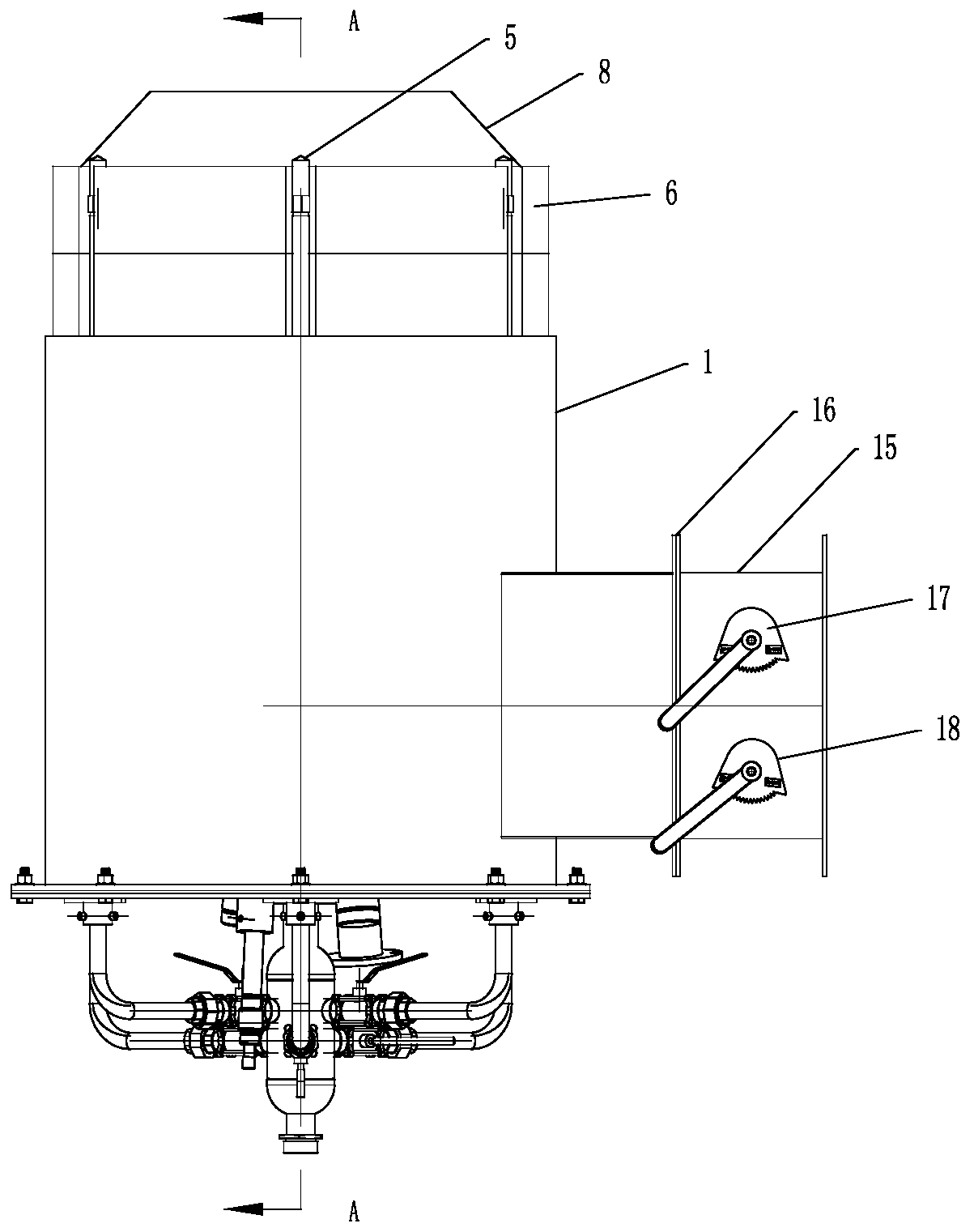

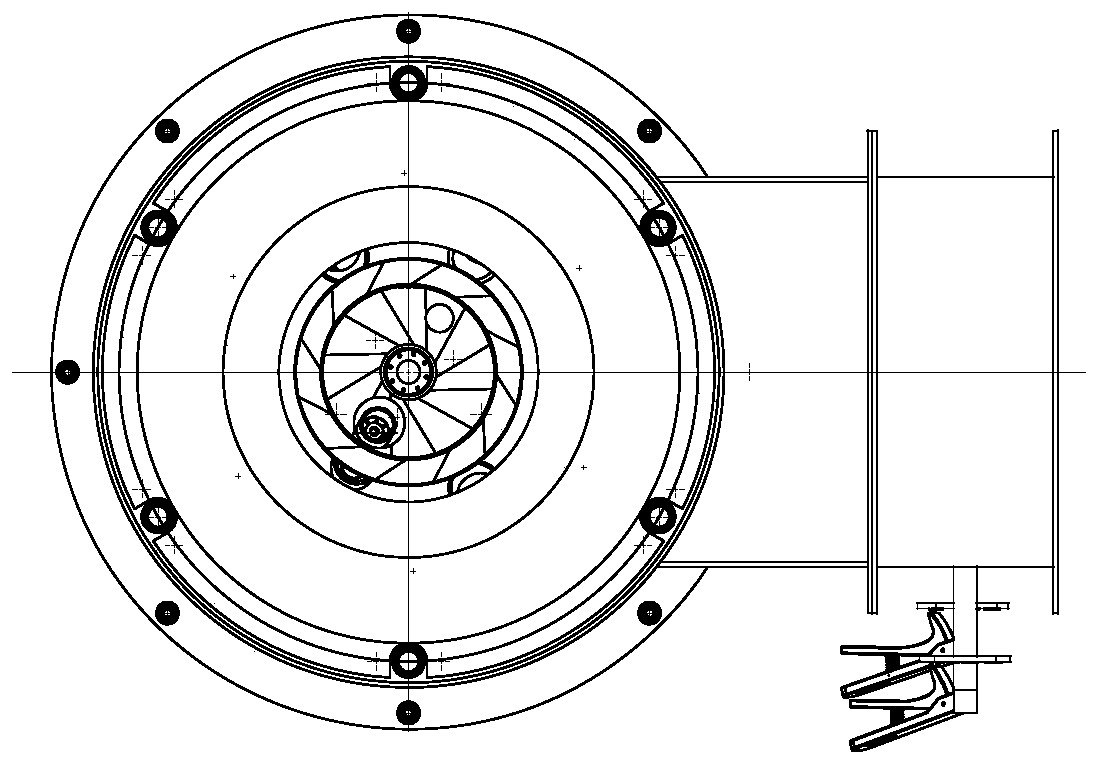

A kind of thermoplastic friction stir welding device and welding method

InactiveCN103660282BGood formabilitySolve the problem of excessive temperature gradientThermoplasticFriction welding

The invention discloses a thermoplastic plastic friction stir welding device which comprises a stirring head clamping part, a shaft shoulder and a tool pin, an open container and a liquid medium, wherein the tool pin is used for carrying out friction stir to enable a weldment to emit heat; the shaft shoulder is fixed with the tool pin to form a stirring head; the stirring head is fixed by the stirring head clamping part; the open container is fixed on the surface of the weldment; the liquid medium is contained in the open container; and the contact part of the open container and the surface of the weldment is sealed and fixed. The device has a simple and small structure, is convenient to install, can effectively solve the problem of excessively large temperature gradient in the thermoplastic plastic friction stir welding process and improves distribution of a temperature field of a welding region; materials can be sufficiently mixed at the welding position and forming performance of the weldment is optimized; and in the welding process and after welding, the cooling speed of the weldment can be effectively controlled and intensity of the thermoplastic plastic friction stir welding joint is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

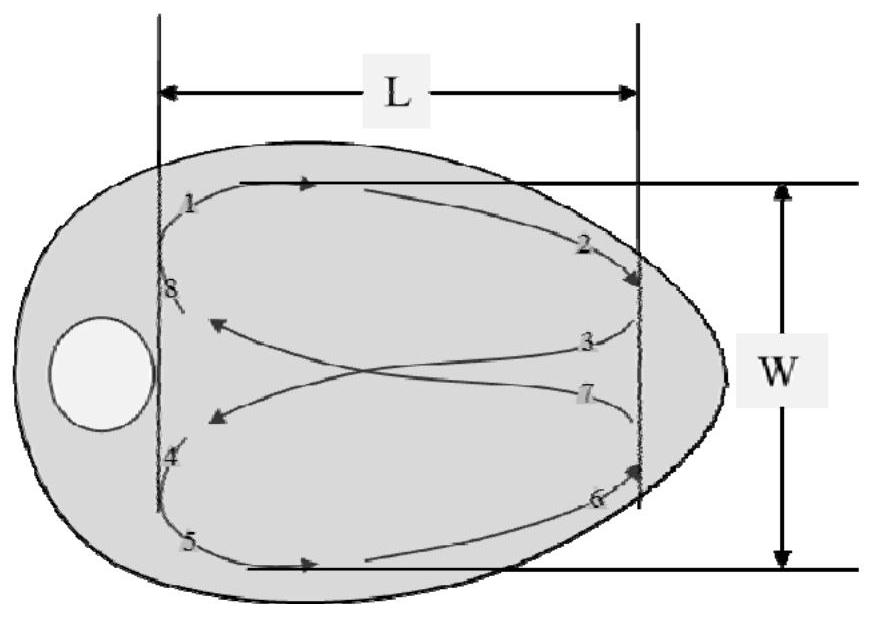

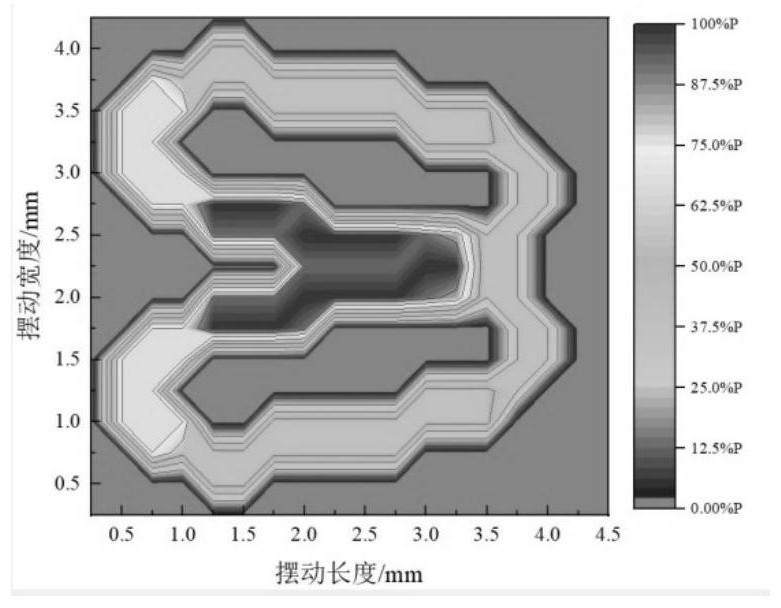

Double-beam swing welding method for inhibiting high-strength titanium alloy welding cracks

ActiveCN111673274APromote escapePrecise temperature controlLaser beam welding apparatusLight beamTitanium

The invention discloses a double-beam swing welding method for inhibiting high-strength titanium alloy welding cracks and relates to the field of material machining engineering. The method aims at solving the problems of welding cracks and air hole defects of high-strength titanium alloys, especially the problem that an existing swing laser welding method cannot be used for solving the problems ofwelding cracks and air hole defects of high-strength titanium alloys. By means of the method, a light path is designed for achieving double-beam laser welding, one beam is fixed, the other beam swings to serve as the auxiliary part, and a track and energy distribution synchronous optimization manner is used for inhibiting the above welding defects. Compared with common swing laser welding, the method can better conform to the flowing trend of a molten pool, convection of the molten pool is better enhanced, and air hole and cracking defects are reduced; the swing amplitude is larger, the temperature gradient is reduced, melt supplementation is driven at the solidification front of the tail portion of the molten pool, and solidification cracks are prevented; and light beam energy distribution and swing tracks are combined, temperature field distribution is improved, connector stress and deformation are reduced, and crack initiation is inhibited. The method is applied to the field of material machining.

Owner:HARBIN INST OF TECH

Novel high-efficiency low-NOx-emission combustor

The invention provides a novel high-efficiency low-NOx-emission combustor. The novel high-efficiency low-NOx-emission combustor comprises a housing, a main fuel spray gun, secondary fuel spray guns, afire pan brick, a convergent brick and incandescent lights; an inner cylinder and a flame path brick of which the inside parts are each of a hollow structure are arranged inside the housing; a plurality of secondary fuel spray guns are uniformly distributed on the outer wall of the flame path brick; the inner side of the flame path brick is provided with the convergent brick which is internally provided with a hollow structure; a combustion chamber for combustion of gases is formed in the inner side of the convergent brick; the sidewall of the inner cylinder is provided with a plurality of air inlets and incandescent lights; the fire pan brick is arranged inside the convergent brick; a cavity inside the fire pan brick communicates with a combustion air passage; the main fuel spray gun isarranged inside the cavity inside the fire pan brick; and the bottom end of the main fuel spray gun and the bottom ends of the secondary fuel spray guns both penetrate out of the bottom of the housingand communicate with a fuel distributor of which the bottom is provided with a fuel inlet. The novel high-efficiency low-NOx-emission combustor can effectively reduce emission of NOx, improves the heating efficiency of a heating furnace and is beneficial for reducing the height of flame and improving the distribution of a temperature field of a radiation chamber.

Owner:洛阳蔚蓝能源科技发展有限公司

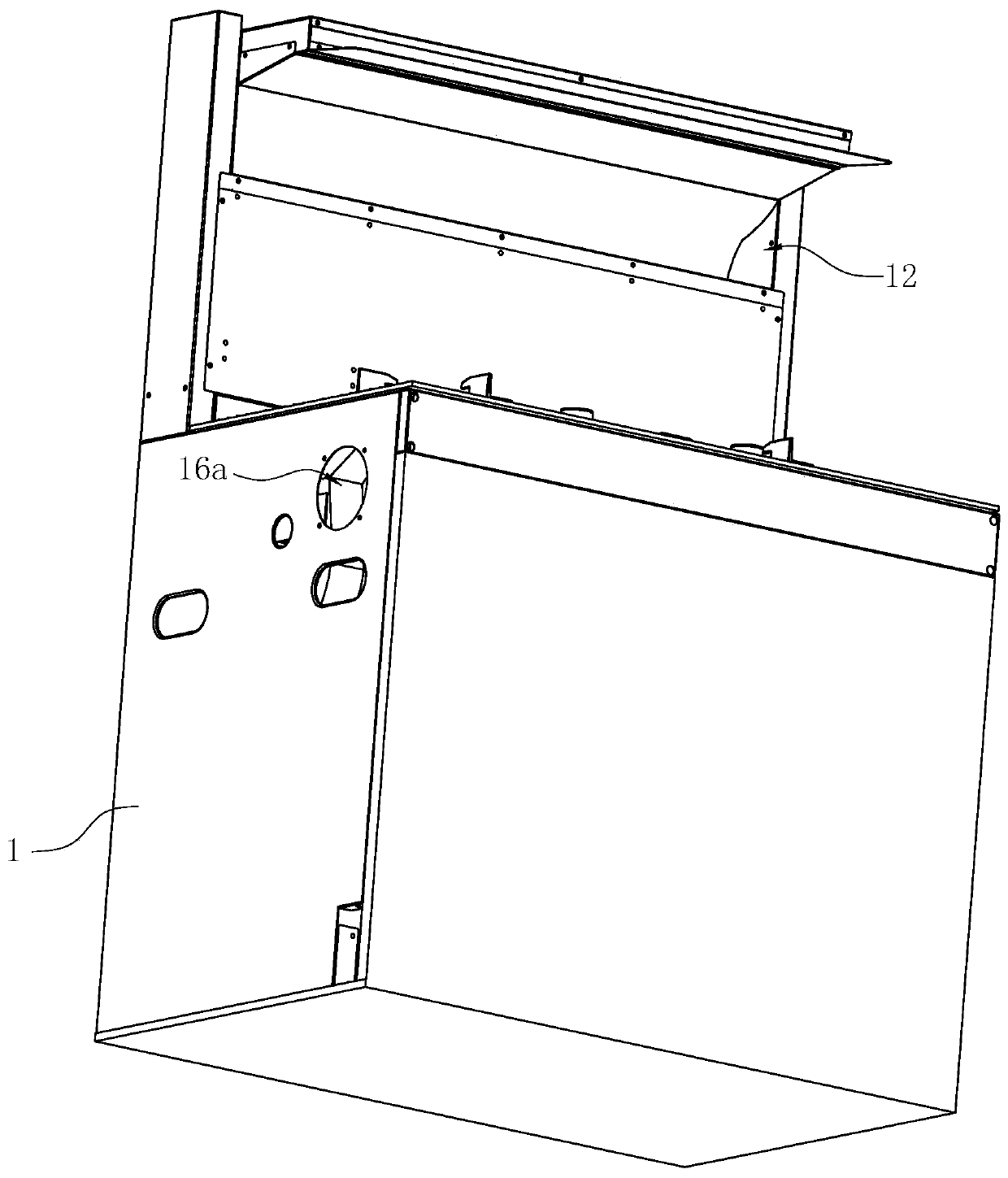

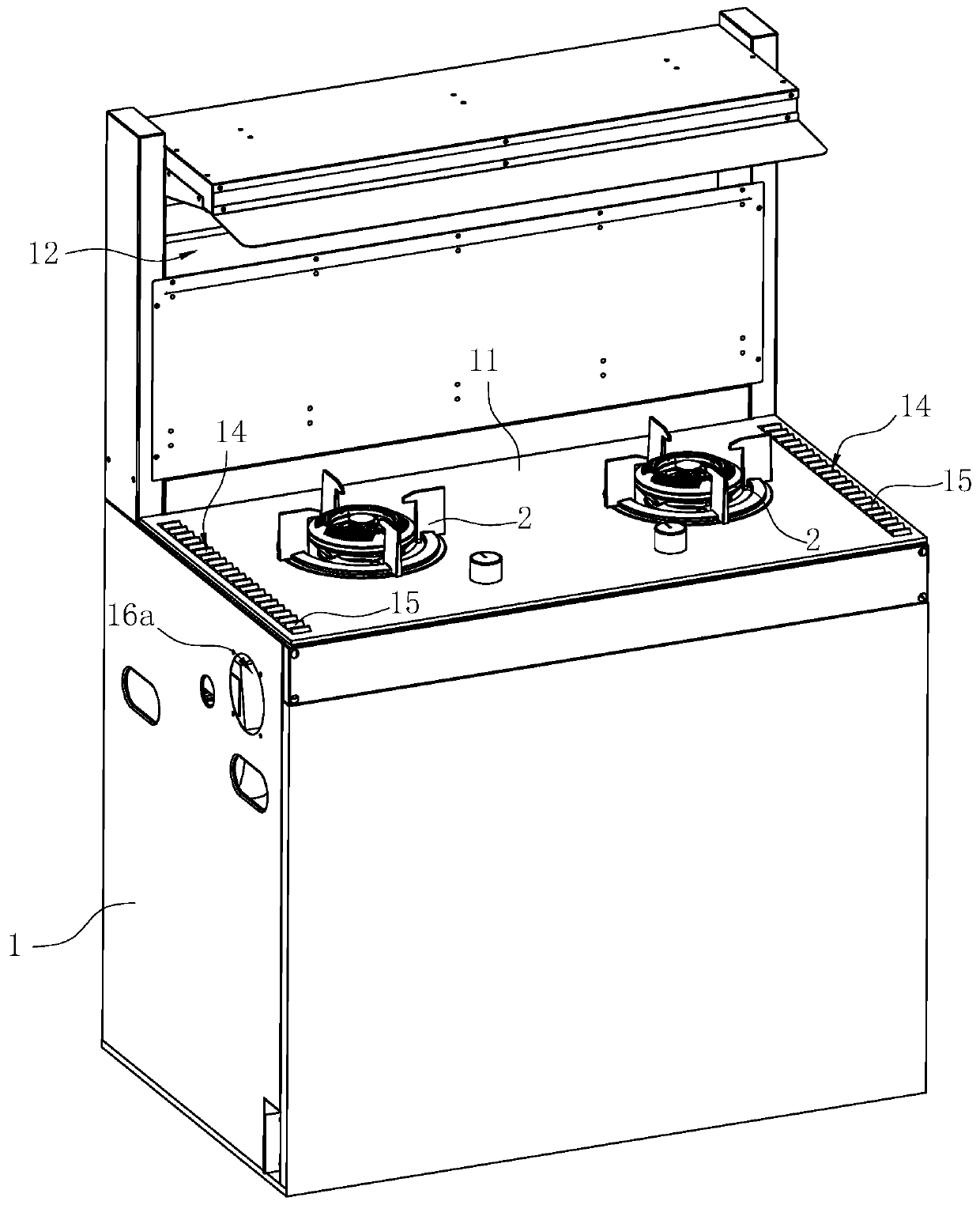

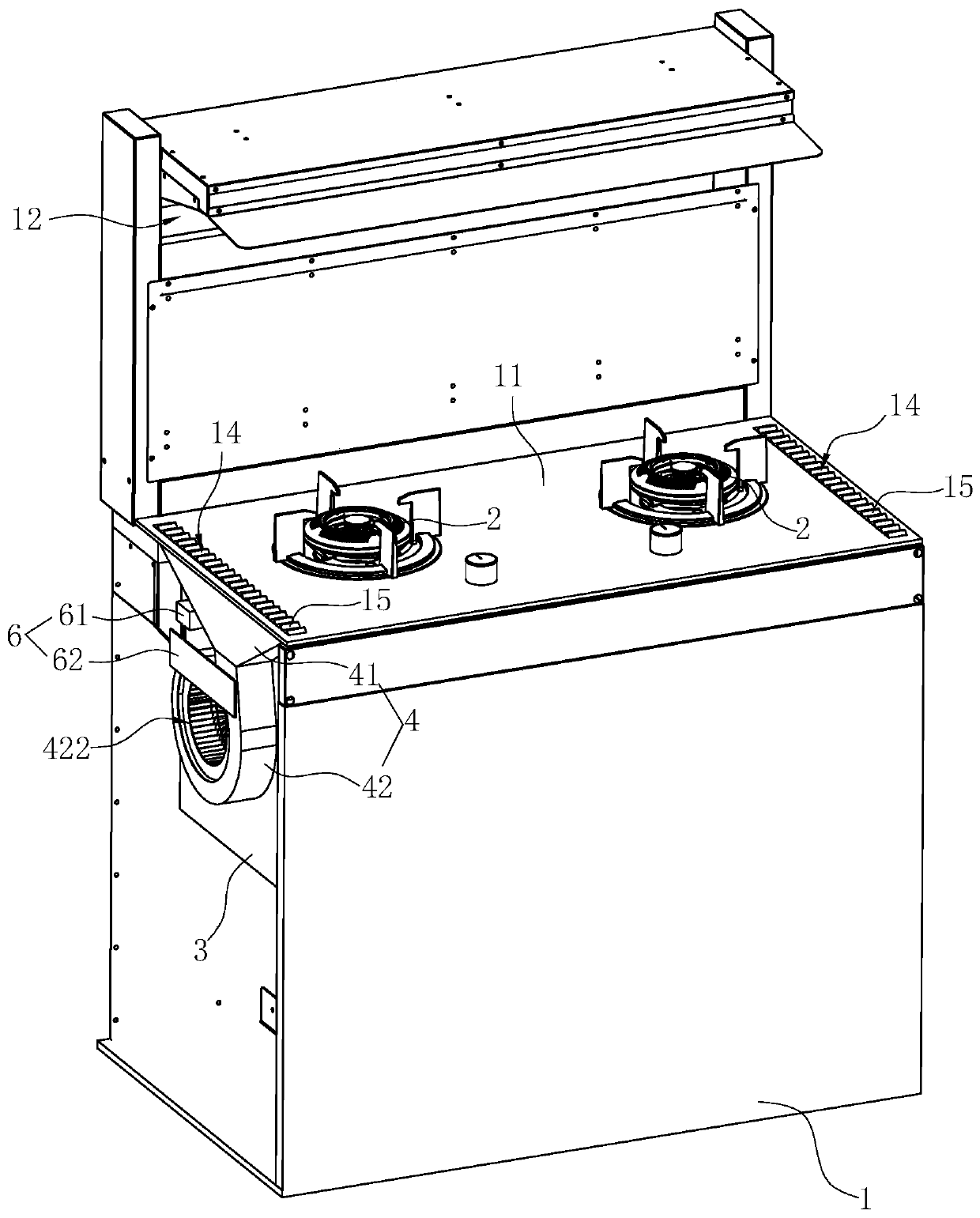

Integrated stove and working control method thereof

ActiveCN111189077AImprove cooling effectImprove temperature field distributionDomestic stoves or rangesLighting and heating apparatusThermodynamicsIndustrial engineering

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

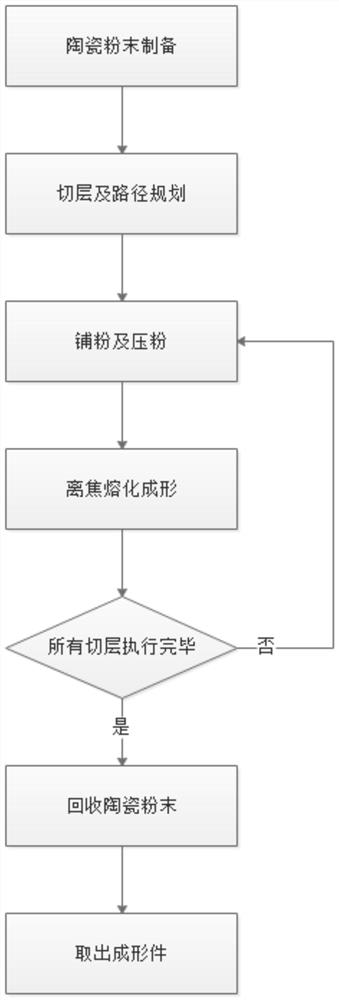

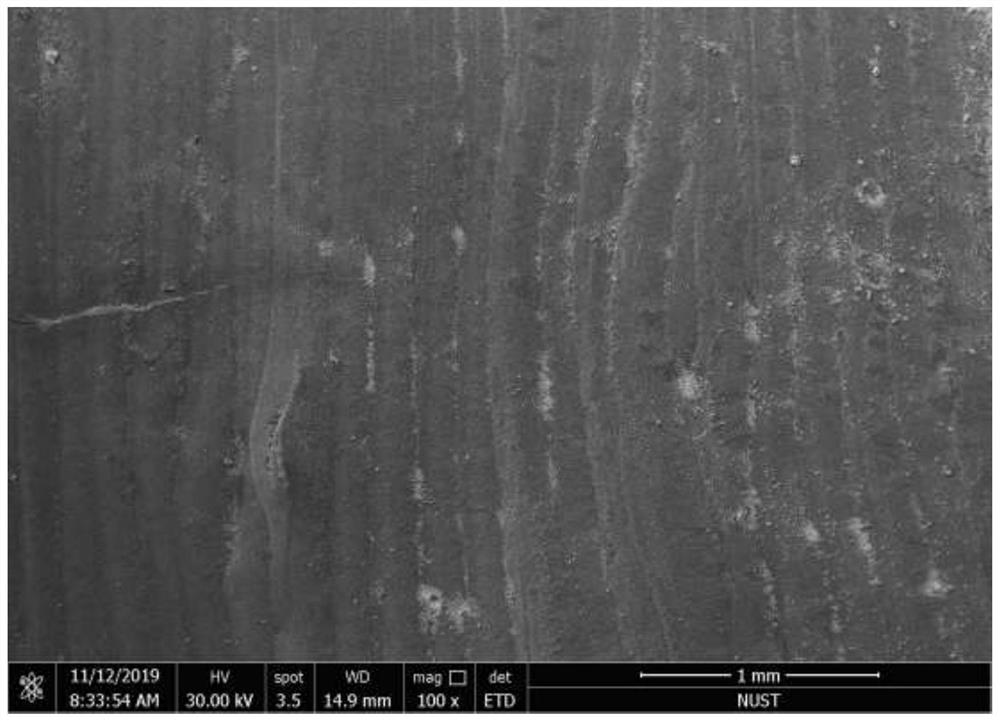

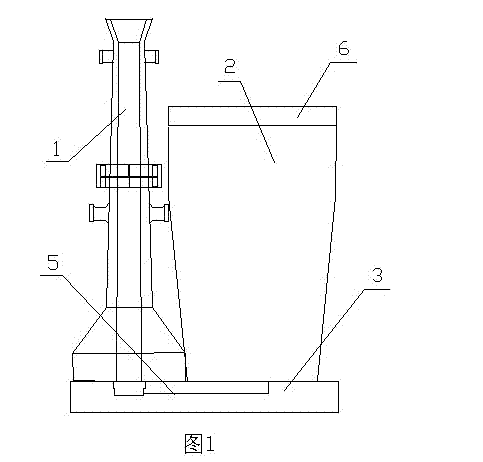

Preparation and defocusing forming method of low-cost ceramic powder for selective laser melting

ActiveCN111689764AImprove temperature field distributionReduce temperature gradientAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingPowder mixture

The invention relates to a preparation and defocusing forming method of low-cost ceramic powder for selective laser melting. The preparation and defocusing forming method comprises the following steps: preparing powder or a powder mixture of a ceramic material; design import and layer cutting of a CAD model; using a roller for carrying out powder laying and powder pressing procedures on the prepared powder or powder mixture of the ceramic material, and obtaining a powder layer blank; controlling the forming cylinder to ascend and descend, and putting the powder layer blank in a defocusing state; heating the specific area of the powder layer blank to the highest temperature through a melting heat source, and integrating solidification and densification after melting and cooling; judging whether all cutting layers are completed or not; recovering the powder raw material and taking out the formed part. According to the method, the low-cost irregular ceramic powder is fully utilized so that the raw material cost can be saved; the temperature field distribution of the molten pool is optimized through defocusing printing, and the temperature gradient is reduced. With application of the method, the problems of high requirements on SLM ceramic powder, harsh processing conditions, complex and cumbersome process and post-treatment, high part preparation cost, insufficient performance andthe like are solved.

Owner:NANJING UNIV OF SCI & TECH

Liquid steel casting equipment

The invention discloses liquid steel casting equipment. The liquid steel casting equipment comprises an ingot mold, wherein the upper part of the ingot mold is provided with a hot top; the ingot mold is arranged on an ingot mold base plate; a steel flow channel is formed in the ingot mold base plate, is communicated with a central casting pipe arranged on one side of an ingot mold body and is communicated with casting gates at the bottom of the ingot mold; and at least one casting gate is formed at the position which is deviated from the bottom center of the ingot mold. The liquid steel casting equipment can prevent the phenomenon of slag entrainment in the process of casting liquid steel by changing the position and the quantity of the ingot mold casting gates, deviating the casting gates from the bottom center or increasing a plurality of casting gates, changes the flow field distribution and the temperature field distribution of the liquid steel inside the ingot mold in the processof casting the liquid steel or after the casting, overcomes the defects of center segregation and loosing of steel ingots and can change the segregation positions of the steel ingots to make a segregation off center close to a steel ingot rolling surface at the same time.

Owner:郭秀梅

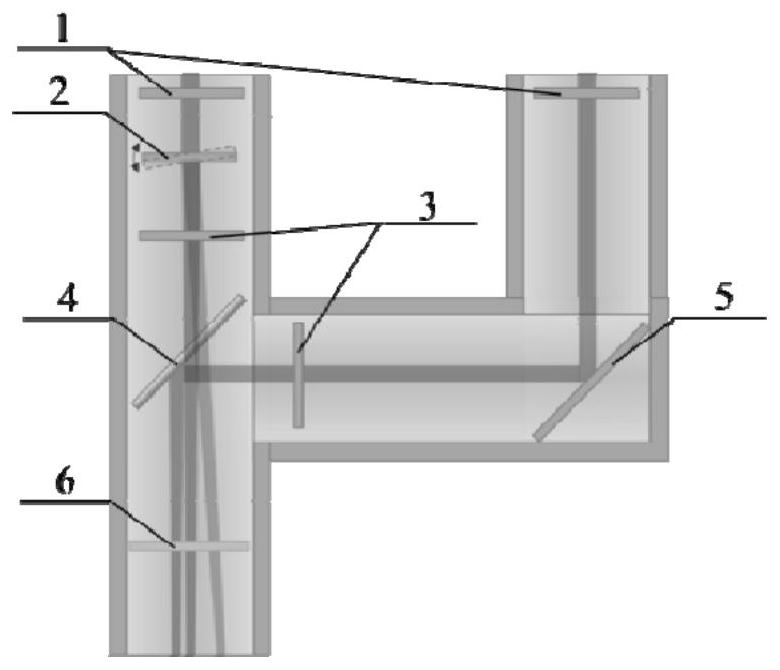

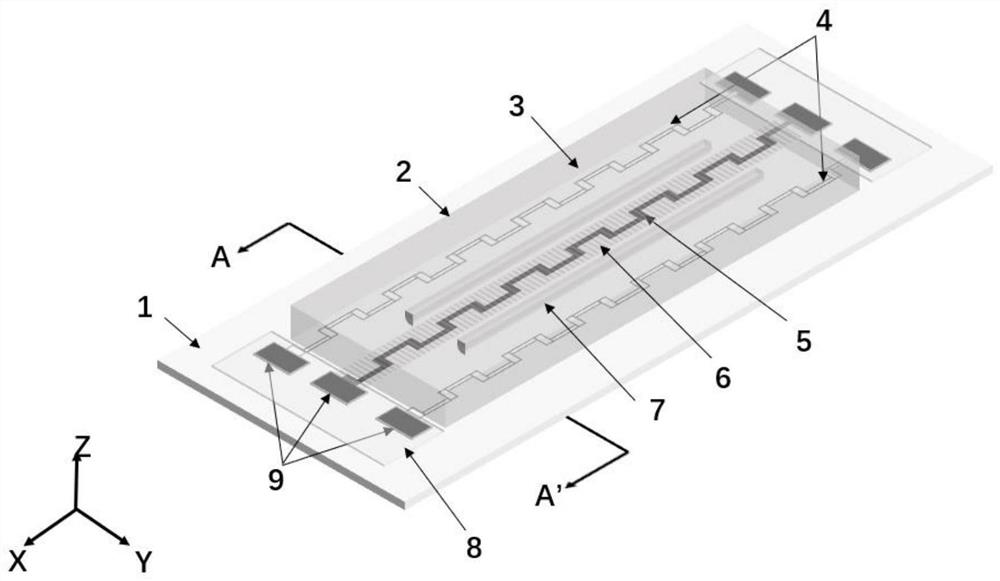

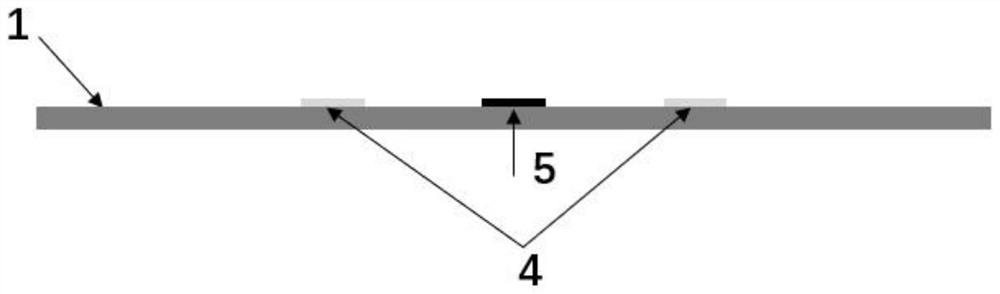

A kind of flexible thermal convection type acceleration sensor and preparation method thereof

ActiveCN113325198BImprove bendabilityHigh speedAcceleration measurement using interia forcesDuplicating/marking methodsAccelerometerThermal insulation

The invention discloses a flexible thermal convection type acceleration sensor and a preparation method thereof. The sensor includes a flexible substrate, a flexible sealing top cover, an S-shaped heating element, an S-shaped temperature sensing element and a heat-absorbing thin layer; the flexible top cover is arranged on a flexible On the substrate, a sealed cavity is formed between the two; the S-shaped heating element is fixed in the center of the flexible substrate in the sealed cavity; two S-shaped temperature sensing elements are fixed on the flexible substrate in the sealed cavity, and are symmetrically distributed Both sides of the S-shaped heating element; the heat-absorbing thin layer is closely attached to the S-shaped heating element inside the sealed cavity; among them, the flexible sealing top cover has a thermal insulation island structure, and the two thermal insulation island structures are symmetrical along the long axis Distributed on the inner surface of the top of the flexible sealing top cover, and distributed above between the S-shaped heating element and the S-shaped temperature sensing element. The acceleration sensor of the invention is suitable for flexible devices and has the characteristics of high sensitivity, fast response time and low power consumption. The preparation method is simple, the cost is low, and it can be prepared on a large scale.

Owner:SOUTHEAST UNIV

Coupling fixed bed oxygen-enriched continuous gasification process

InactiveCN101475839BReduce sensible heat lossReduce erosionCombined combustion mitigationCombustible gas productionFixed bedProcess engineering

The invention discloses oxygen-rich continuous gasification technology for a coupled fixed bed, wherein a solid raw material comprises coal or coke, and a gas raw material comprises oxygen, air and steam; and the oxygen can be mixed with the air into oxygen-rich air first and then is sent into a gas-making furnace, and can also be sent into the gas-making furnace in the form of single gas. The technology is characterized in that the gas-making furnace is that two common gas furnace bodies (A and B) are connected into a whole by a pipeline and a valve, two furnaces alternately upward blow to make gas, and the gas raw material can also comprise carbon dioxide; and the gas-making process comprises the step of the blowing-off of the A and B furnaces, the step of upward blowing of the A furnace, the step of secondary blowing-off of the A and B furnaces, and the step of upward blowing of the B furnace, and the steps are circulated. The gas-making furnace is that the two common gas furnace bodies are connected into a whole by the pipeline and the valve, and the two furnaces alternately upward blow to make gas, so the technology can optimize the distribution of temperature fields in the gas furnaces, reduce the sensible heat loss of semiwater gas, the erosion to pipelines in subsequent working procedures, and the quantity of carry-overs, improve the condition of gas quality, and reduce gas consumption and coal consumption.

Owner:北京名都厚德科技有限公司

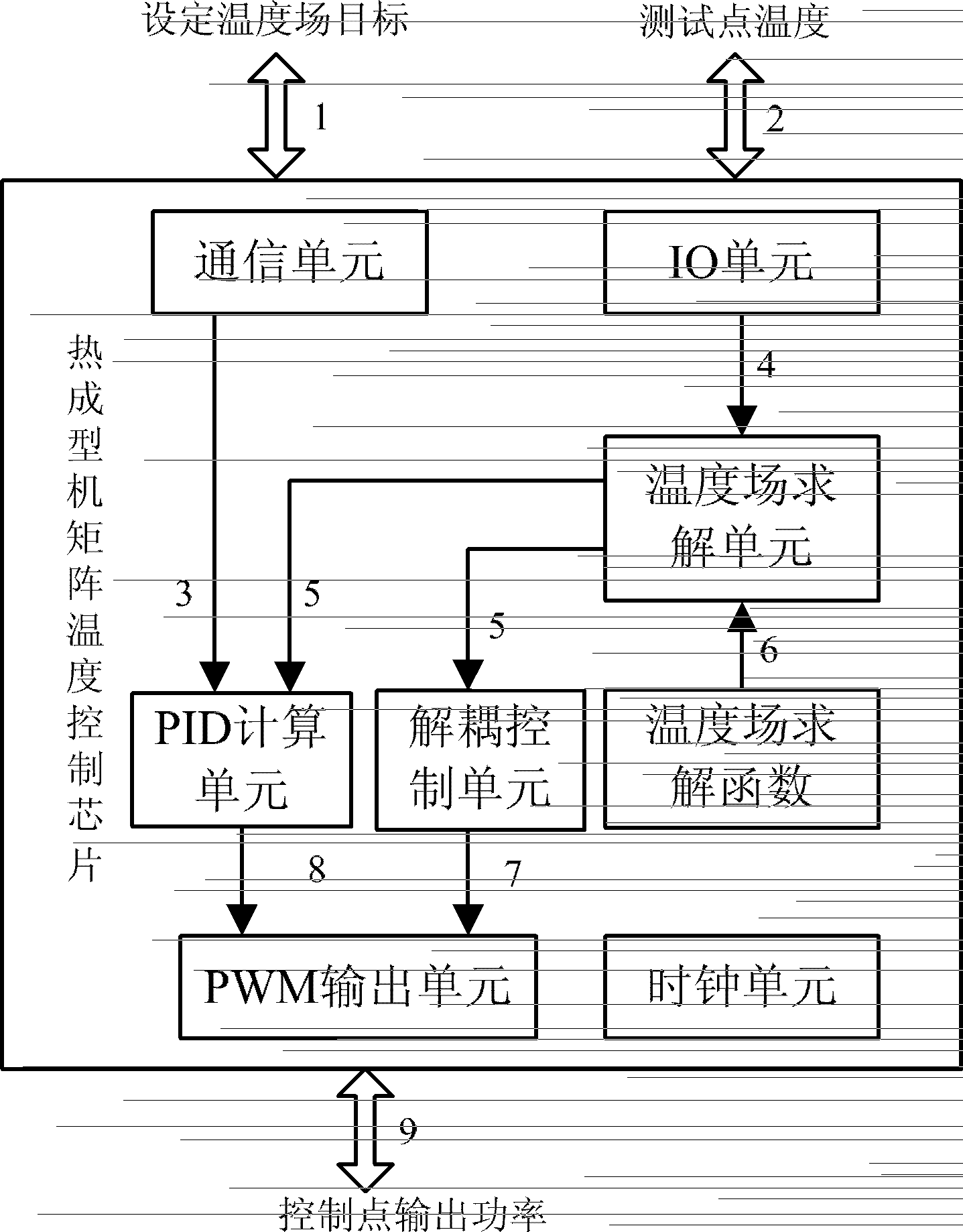

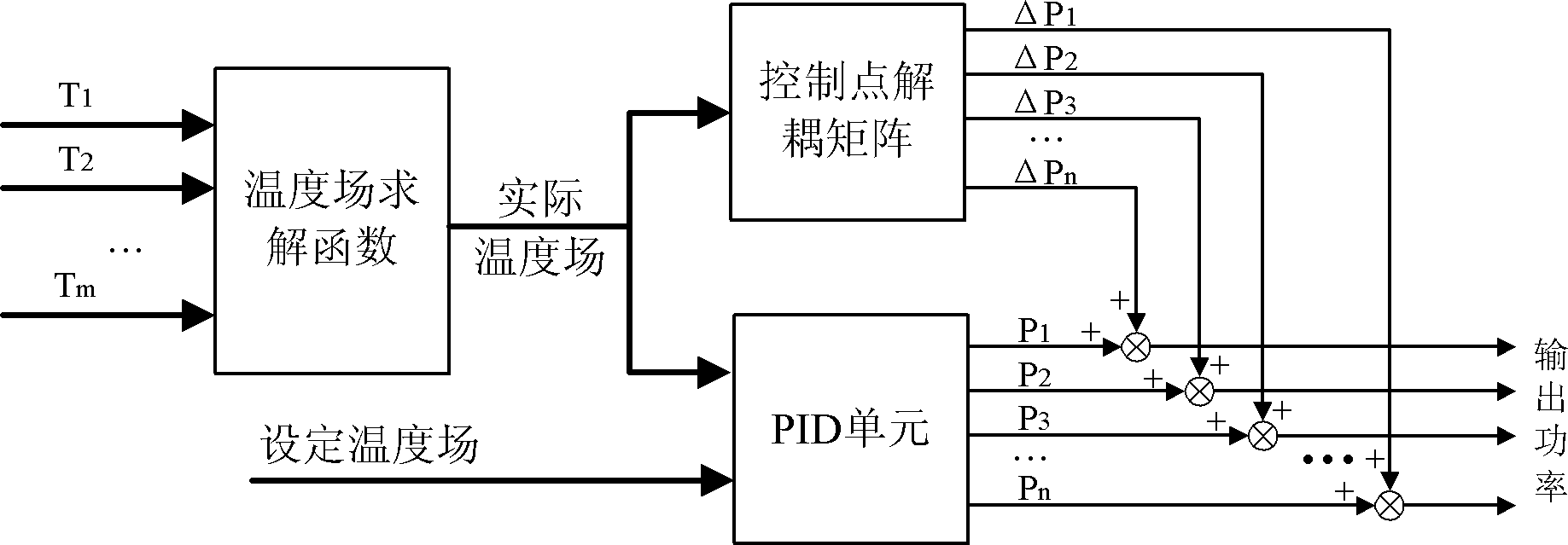

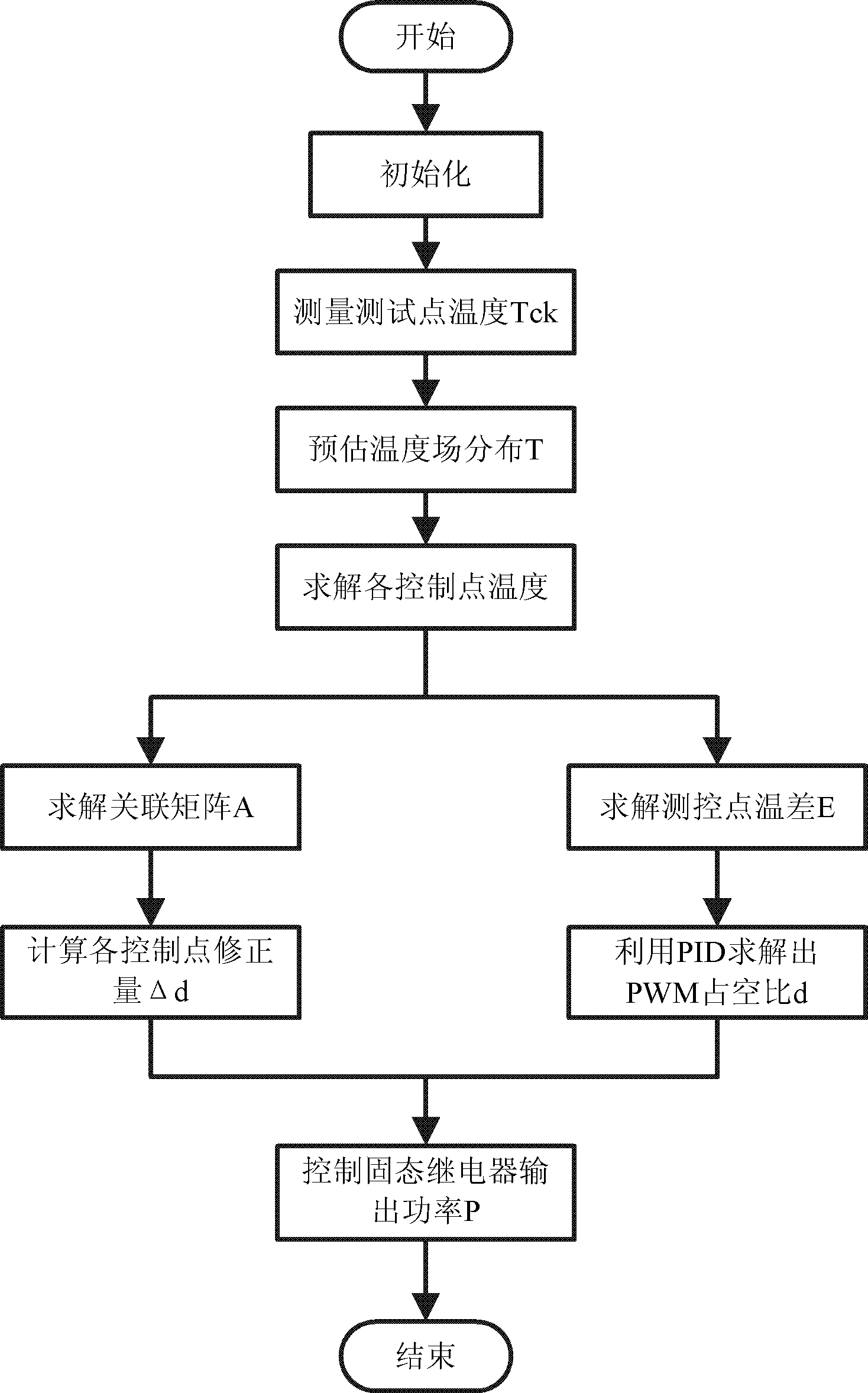

Matrix temperature control chip of thermal forming machine

InactiveCN102555197BReduce usageReduce manufacturing costTemperatue controlTemperature controlCommunication unit

The invention discloses a matrix temperature control chip of a thermal forming machine, and relates to the technical field of temperature control of a sheet / plate thermal forming machine. The chip can be subdivided into seven processing units which mutually operate in parallel: an IO (Input Output) unit, a clock unit, a communication unit, a temperature field solving unit, a matrix decoupling control unit, a PID (Proportion Integration Differentiation) calculation unit and a PWM (Pulse Width Modulation) output unit, wherein the temperature field solving unit is used for pre-estimating overall temperature field distribution by using a priori temperature field solving function and a few of test point temperature values, so that the number of temperature test points can be effectively reduced; the PID calculation unit is used for calculating output of each control point by using a set temperature field and a test temperature field; and the matrix decoupling control unit is used for eliminating thermal transfer influence between each control point and the exterior and providing output correction for each control point, so that the control accuracy and the anti-interference property of the temperature field can be effectively improved. According to the chip, each unit program can be processed in parallel through an internal hardware circuit, the calculation speed is high, and the matrix temperature control chip is reliable in use.

Owner:XI AN JIAOTONG UNIV +1

An electric vehicle battery pack constant temperature control system and control method

ActiveCN109494429BImprove temperature field distributionAvoid concentrationSecondary cellsTemperature controlElectric-vehicle battery

The invention relates to a constant temperature control system of an electric automobile battery pack and a control method. The constant temperature control system of the electric automobile battery pack comprises a battery pack, a battery pack front end cooling plate and a battery pack rear end cooling plate. The battery pack is installed between the battery pack front end cooling plate and the battery pack rear end cooling plate. The battery pack front end cooling plate is provided with a front end cooling liquid inlet and a front end cooling liquid outlet. Each of battery pack front end inlet and battery pack rear end inlet is provided with a solenoid valve. The solenoid valve is connected with a controller by an electric signal. In the technical scheme, the periphery of each battery cell comprises four cooling liquid flow paths in adverse flowing directions, circulating and alternating occurrence of cooling liquid is realized, and a convection current is formed in the battery cell,so temperature field distribution around the battery cell is improved, and the high-temperature or low-temperature cooling liquid is avoided from being concentrated at a certain end of the battery cell while the flowing directions of all cooling liquid are the same.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

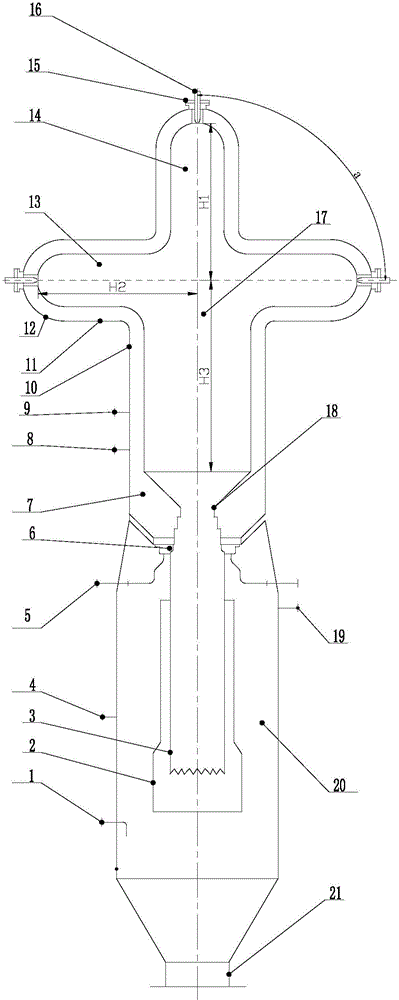

Protrusion type partition reactor

ActiveCN104927924AIncrease production capacityAdapt to the needs of industrial productionHydrogen separationCombined combustion mitigationHydrogenNuclear engineering

The invention relates to a protrusion type partition reactor. The protrusion type partition reactor comprises a reaction chamber 17 and a cooling chamber 20, the reaction chamber 17 is communicated with the cooling chamber 20 through a slag port 18, and the reaction chamber 17 and the cooling chamber 20 have the joint central axis. Compared with an existing gasifier, the protrusion type partition reactor has the advantages of being large in coal feeding amount, high in gasification efficiency, long in service life of a refractory lining and the like. Synthesis gas produced by utilizing the protrusion type partition reactor can be used as chemical engineering raw material gas and fuel gas, can be used for preparing hydrogen and synchronizing liquid fuels and the like, and is extremely wide in application.

Owner:XIAN ORIGIN CHEM TECH

Low-temperature partition wall heat exchanger and pre-cooling j-t refrigerator with bypass throttling

ActiveCN104879968BSmall temperature differenceImprove temperature field distributionMechanical apparatusCompression machinesLiquid hydrogenCooling capacity

The invention discloses a low-temperature partition heat exchanger adopting bypass throttling, which includes a high-pressure side pipeline and a low-pressure side pipeline. The low-temperature partition heat exchanger works in a liquid hydrogen temperature zone and a lower temperature zone. The high-pressure side pipeline is provided with at least one bypass pipeline connected with the low-pressure side pipeline, and an isenthalpic throttling element is arranged on the bypass pipeline; the working medium in the low-pressure side pipeline at the outlet of the bypass pipeline The temperature is lower than the temperature of the working fluid in the high-pressure side pipeline at the inlet of the bypass pipeline. The invention also provides a precooling type J-T refrigerator. The invention adopts the bypass throttling to change the temperature field distribution of the gas in the heat exchanger and reduce the irreversible loss. The heat exchanger is used in the pre-cooling J-T refrigerator in the liquid helium temperature zone, which reduces the temperature of the high-pressure gas before throttling, increases the cooling capacity in the liquid helium temperature zone, and improves the efficiency of the whole machine.

Owner:ZHEJIANG UNIV

Atrium air conditioning air system based on air treatment unit and operation method thereof

InactiveCN109099534AImprove temperature field distributionEasy to useDucting arrangementsMechanical apparatusProduct gasEngineering

The invention discloses an atrium air conditioning air system based on an air treatment unit, which comprises an air treatment unit. The atrium air conditioning air system based on an air treatment unit further comprises a bottom air inlet and a top air outlet for summer use; and the atrium air conditioning air system based on an air treatment unit further comprises a top air inlet and a bottom air outlet for winter use. For the operation method of the atrium air conditioning air system, in summer, the gas at the bottom of the atrium orderly passes through the bottom air inlet, the air treatment unit and the top air outlet and finally enters the top of the atrium; and in winter, the gas at the top of the atrium orderly passes through the top air inlet, the air treatment unit and the bottomair outlet and finally enters the bottom of the atrium. The invention aims at providing an atrium air conditioning air system based on an air treatment unit and an operation method thereof for the problem that the vertical temperature gradient of the building atrium space cannot be adjusted in both winter and summer, which exits in the existing atrium air conditioning system. In winter and summer, the operation of the air conditioning air system can make the temperature field in the atrium space tend to be uniform in the vertical direction.

Owner:SICHUAN LIJIU INTPROP SERVICE CO LTD

A raised zone reactor

ActiveCN104927924BIncrease production capacityAdapt to the needs of industrial productionHydrogen separationCombined combustion mitigationHydrogenNuclear engineering

Owner:XIAN ORIGIN CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com