Rim sealing structure capable of inhibiting non-uniform multi-scale gas invasion

A sealed structure, multi-scale technology, applied to the supporting elements of the blade, machine/engine, stator, etc., can solve problems such as weakening performance improvement, fuel consumption increase, and overall machine efficiency reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in more detail below in conjunction with accompanying drawing example:

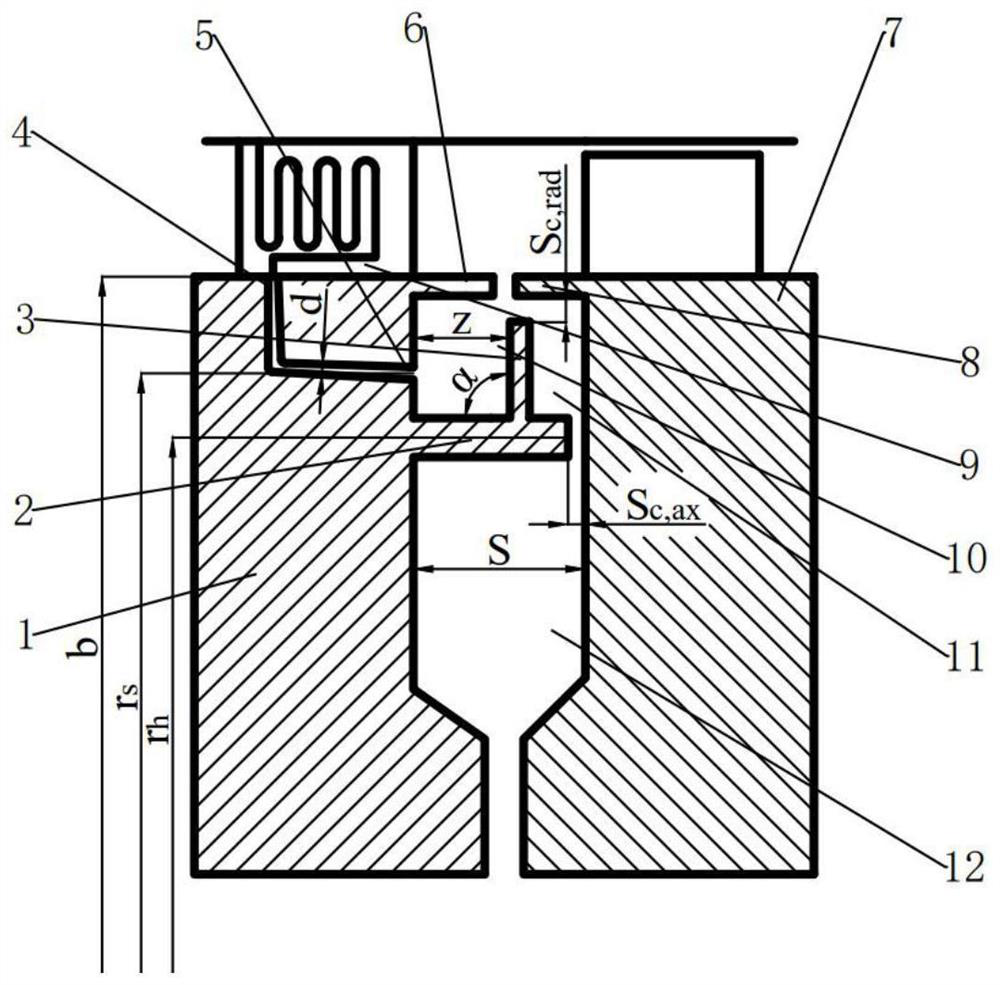

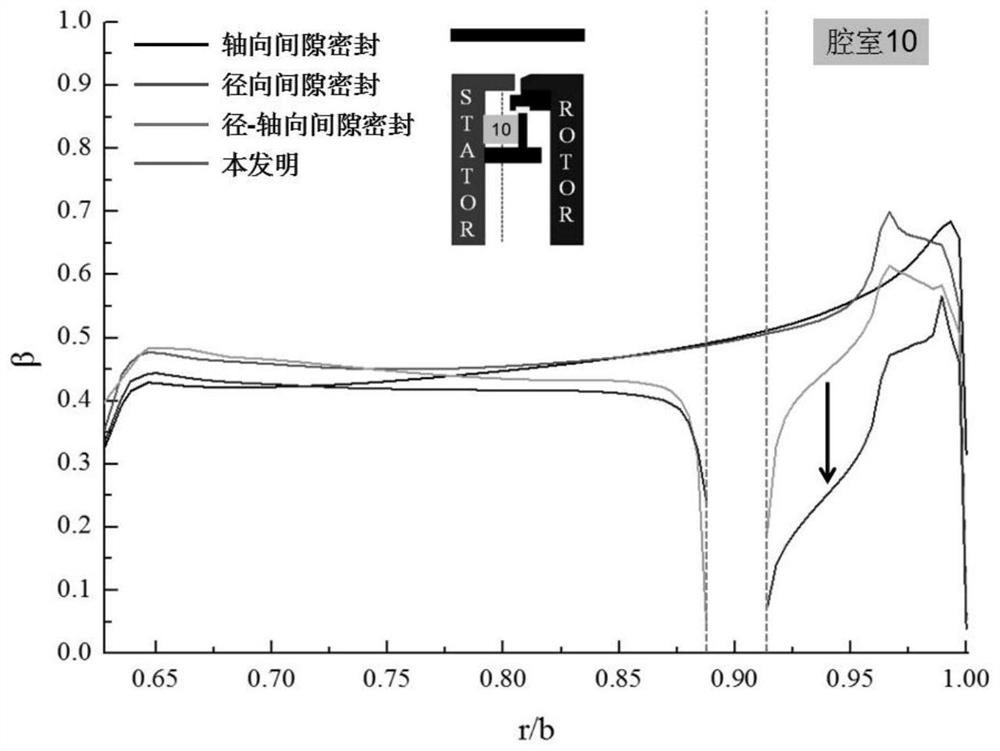

[0027] to combine Figure 1~2 , the gear ring 2 in the static rotating chamber is installed on the turbine static disk or the stator blade guard ring 1, the inner gear ring baffle 3 is installed on the gear ring 2 in the rotating static chamber at a certain angle, the inner gear ring baffle and the rotating The installation angle of the gear ring in the static volume chamber is α. The cold air intake hole 4 of the vane guard ring is located at the outlet of the internal cooling channel of the guide vane, and the cold air intake hole 4 of the vane guard ring is connected with the side jet hole 5 of the wheel rim. The end wall 6 of the trailing edge of the turbine guide vane, the gear ring 2 in the rotating static chamber and the inner gear ring baffle 3 form an approximately closed "quiet" system housing chamber 10, and the gear ring 2 in the rotating static chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com