Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Reduce sensible heat loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

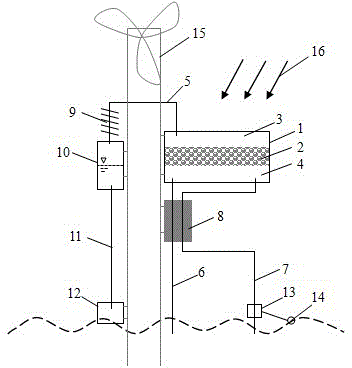

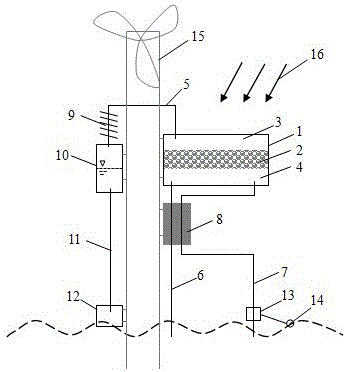

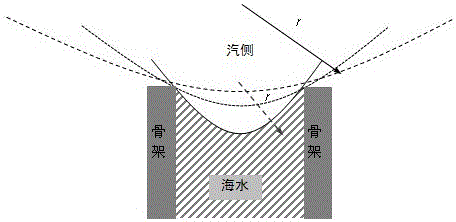

Sea water desalting plant implanted into wind power tower

ActiveCN104528854AAvoid heat lossRaise the evaporation temperatureGeneral water supply conservationSeawater treatmentWater desalinationThermal insulation

The invention relates to a sea water desalting plant implanted into a wind power tower, and belongs to the field of sea water desalination. The sea water desalting plant comprises an evaporator. A porous barrier partitions the evaporator into an upper steam cavity and a lower sea water cavity. The porous barrier is a hydrophilic thermal insulation porous medium, the inner pore diameter is that of a micrometer hole, and the upper side of the porous barrier is coated with a heat absorption coating. The steam cavity is sequentially connected with a condenser, a condensation tank and a fresh water tank through a pipe. One end of the sea water cavity is connected with a sea water pipe to be used for water inputting, and the other end of the sea water cavity is connected with a salt pipe to be used for water outputting. Heat exchange is conducted on the sea water pipe and the salt water pipe through a heat exchanger, and an outlet of the salt water pipe is connected with a piston type water pump to pump out salt water. The center of the porous barrier and the center of the condensation tank are 10 meters away from the sea level in height. By means of the sea water desalting plant, stable and long-time sea water desalting can be achieved without inputting external power and electricity, the thermal utilization efficiency is high, and an effective path is provided for emergency water for ocean working, help seeking and the like or large-scale water contributing.

Owner:深圳润德工程有限公司

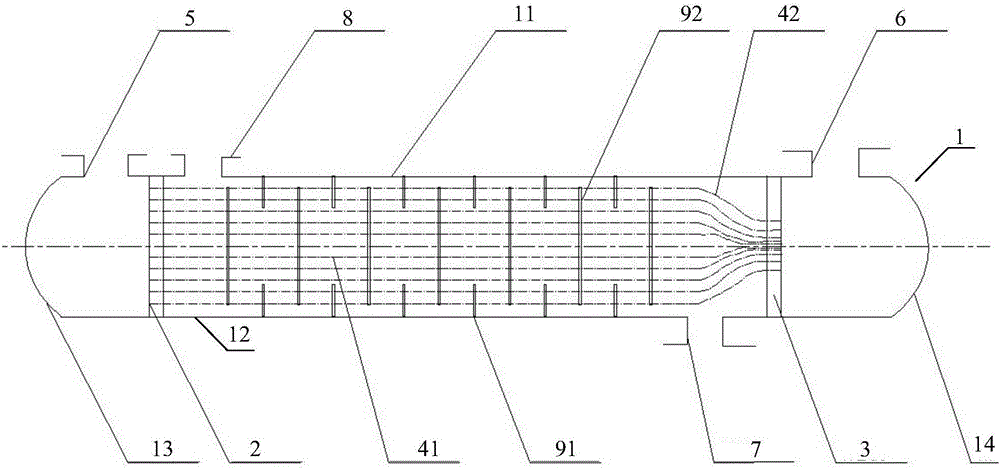

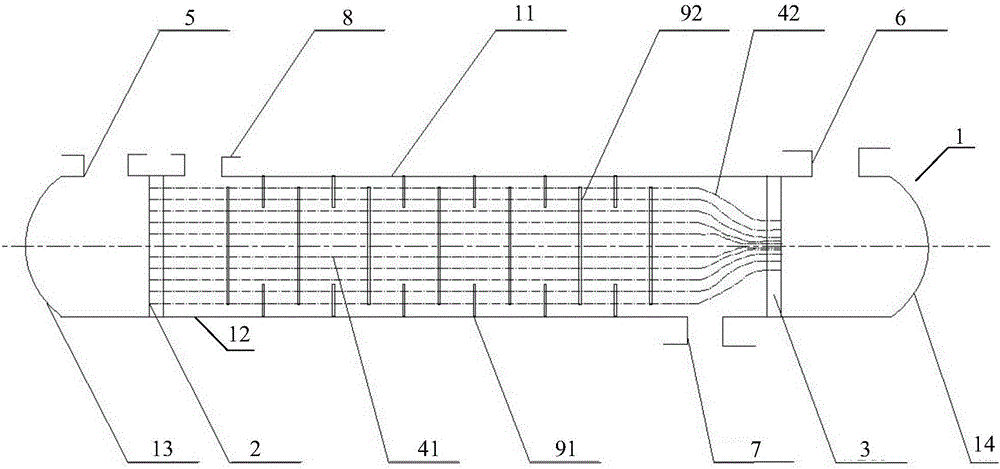

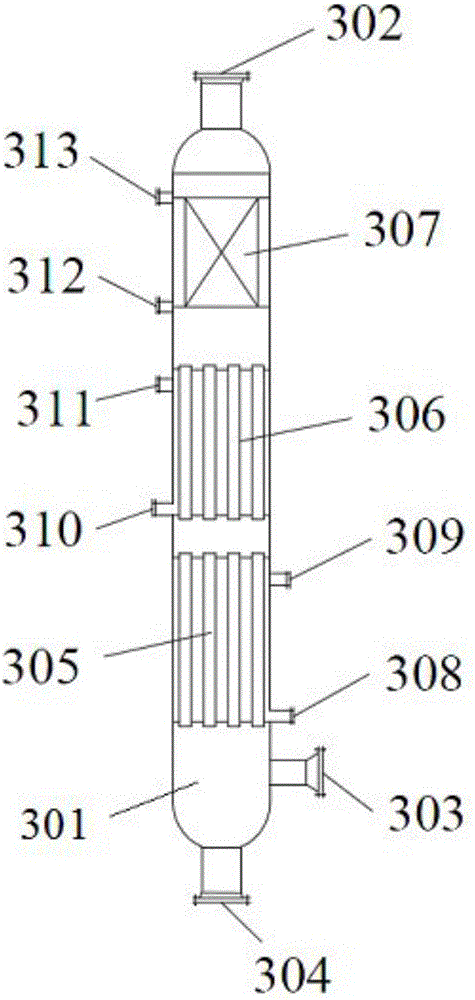

Shell and tube heat exchanger for exchanging heat of fused salts with different temperatures

InactiveCN105674770ASolve the problem of thermal expansionExtended service lifeSolar heating energySolar heat devicesPlate heat exchangerShell and tube heat exchanger

The invention provides a shell and tube heat exchanger for exchanging heat of fused salt with different temperatures. The shell and tube heat exchanger is used for exchanging heat between cold salt and hot salt and at least comprises a shell, a first tube plate and a second tube plate which are respectively mounted at both ends in the shell, and a heat exchange tube fixed between the first tube plate and the second tube plate, wherein the heat exchange tube comprises a straight tube and a spiral tube communicated with the straight tube. The shell and tube heat exchanger further comprises a hot salt inlet, a hot salt outlet, a cold salt outlet and a cold salt inlet formed in the bottom of the shell, which are formed in the top of the shell. According to the shell and tube heat exchanger, one end of the heat exchange tube is provided with the spiral tube, so that the problem of thermal expansion of the heat exchange tube due to high temperature of fused salt can be avoided, so as to prevent movement of the tube plates due to expansion pressure and prolong the service life of the shell and tube heat exchanger; and furthermore, due to the arrangement of the spiral tube, the heat exchange area can be enlarged, and thus the heat exchange effect can be greatly enhanced.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

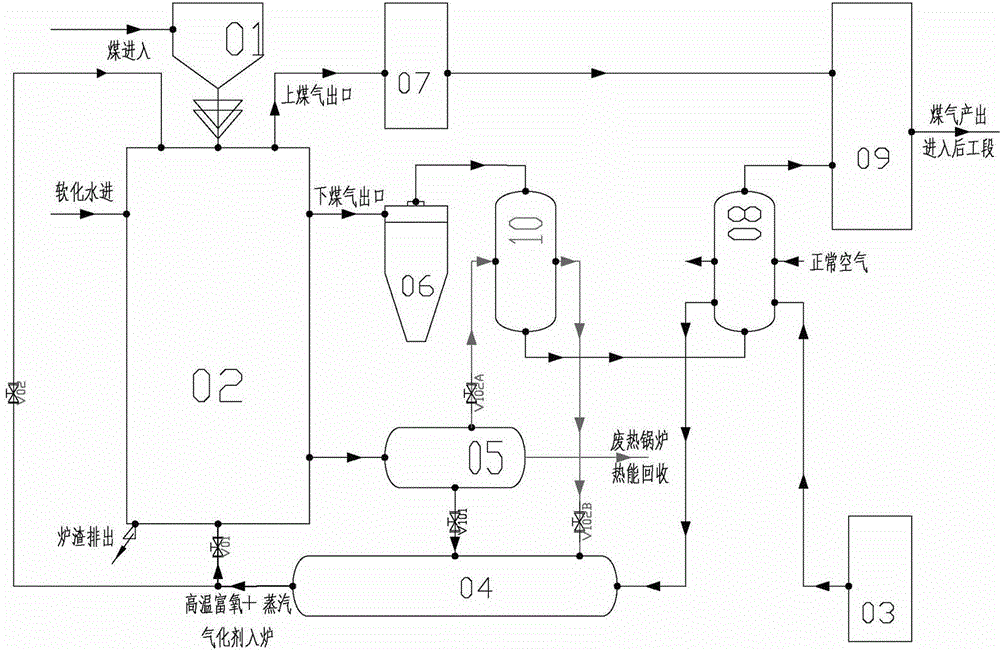

Coal gas production method and device using high-temperature rich oxygen and high temperature steam as gasification agent

ActiveCN103525465AReduce unit consumptionOvercoming technical defects of furnace gas productionCombustible gas productionFixed bedControl valves

The invention belongs to the technical field of chemical coal made gas, and particularly relates to a coal gas production method and device using high-temperature rich oxygen and high temperature steam as a gasification agent. The coal gas production method and device adopt oxygen-enriched air with the oxygen concentration of 25 ~ 30% and with the oxygen temperature of 120 ~ 220 DEG C and the high temperature steam with the temperature of 120 ~ 220 DEG C as the gasification agent for coal gas production; and accordingly, an oxygen-enriched air source and related a heat exchanger, a control valve and pipelines are additionally arranged in an original coal gas production device. The coal gas production method and device well overcome the technical defects of coal gas production by use of a traditional atmospheric-pressure fixed bed gas producer, increase the coal gas producer yield and the coal gas calorific value, reduce the carbon content of ash, and reduce sensible heat loss, and the coal gas unit consumption is reduced by 10 ~ 30%.

Owner:上海穗杉实业股份有限公司

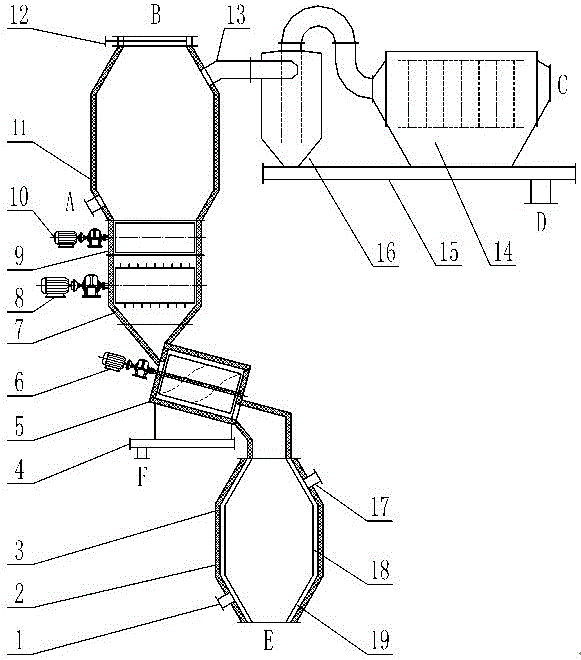

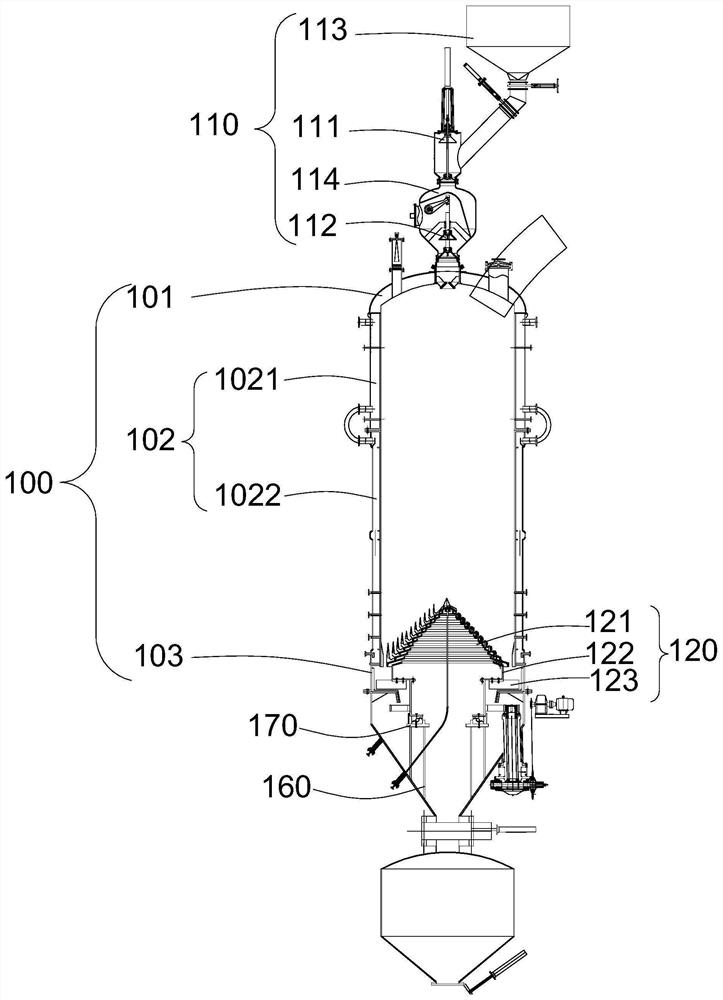

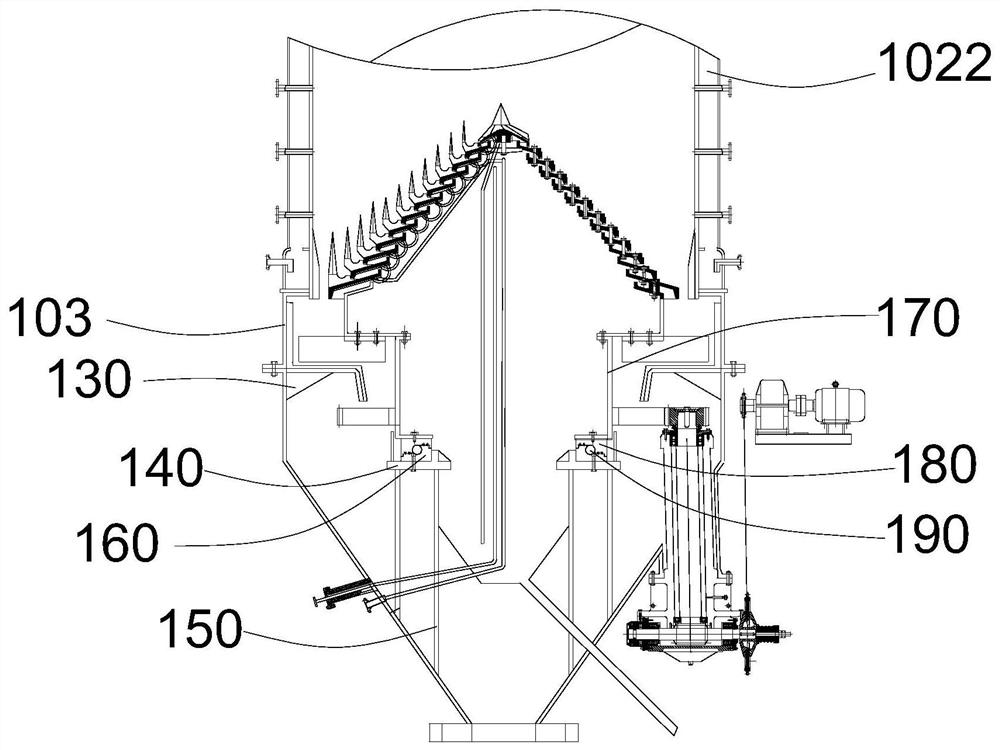

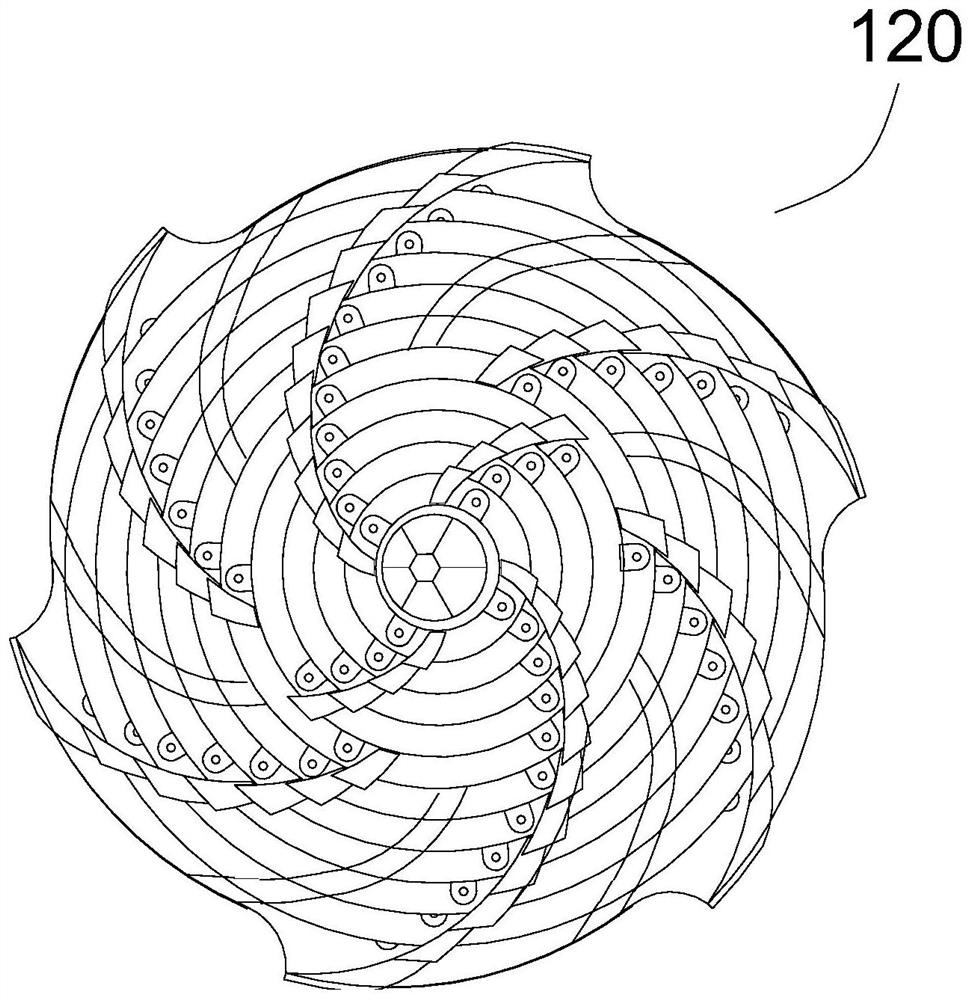

High-temperature coal gas filtering and purifying device and method for static bed

The invention provides a high-temperature coal gas filtering and purifying device and method for a static bed. The device and the method are characterized in that cinder dust or semicoke serves as a filter material. Raw coal gas enters the device from the bottom of the device, and passes through a filter material layer through a coal gas passage of a tower grid, so that motes in the raw coal gas are adsorbed to gaps in the cinder dust and micropores in the surface of the cinder dust, and purified coal gas is output to a user's device through a purified coal gas outlet. When approaching to a saturated condition, the filter material falls down slowly into a water basin, a coal gas box and a water sealing partition rotate slowly as external power is transmitted to a ratchet wheel, and the water basin (containing the filter material), the tower grid and the coal gas box which are welded into a whole, and saturated cinder dust is exhausted out of the device step by step. Moreover, two grades of sealing bell jars of a feeding mechanism are opened and closed alternately to feed a new filter material, so as to maintain the height of the filter material layer. Therefore, the filtering continuity and the purity degree of coal gas are ensured.

Owner:舒瑞 +1

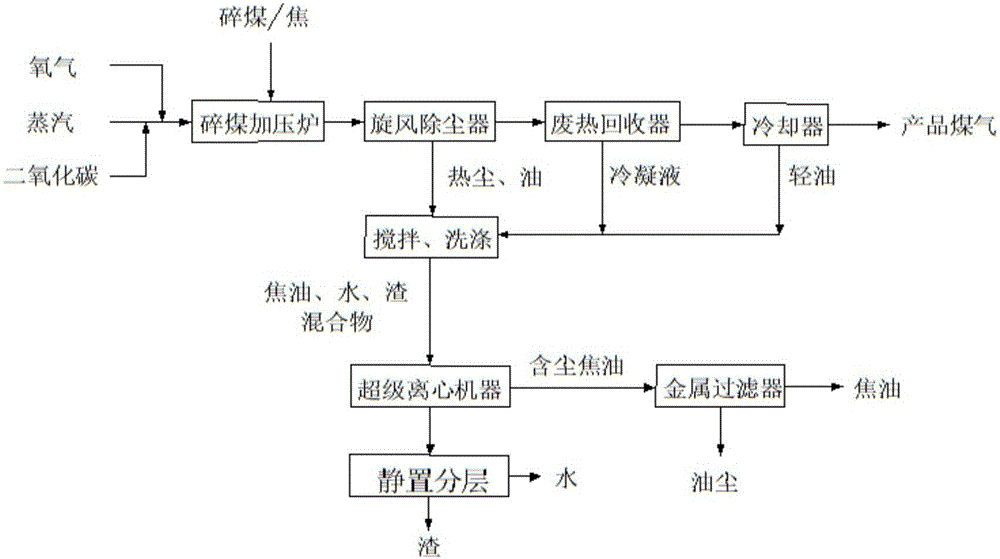

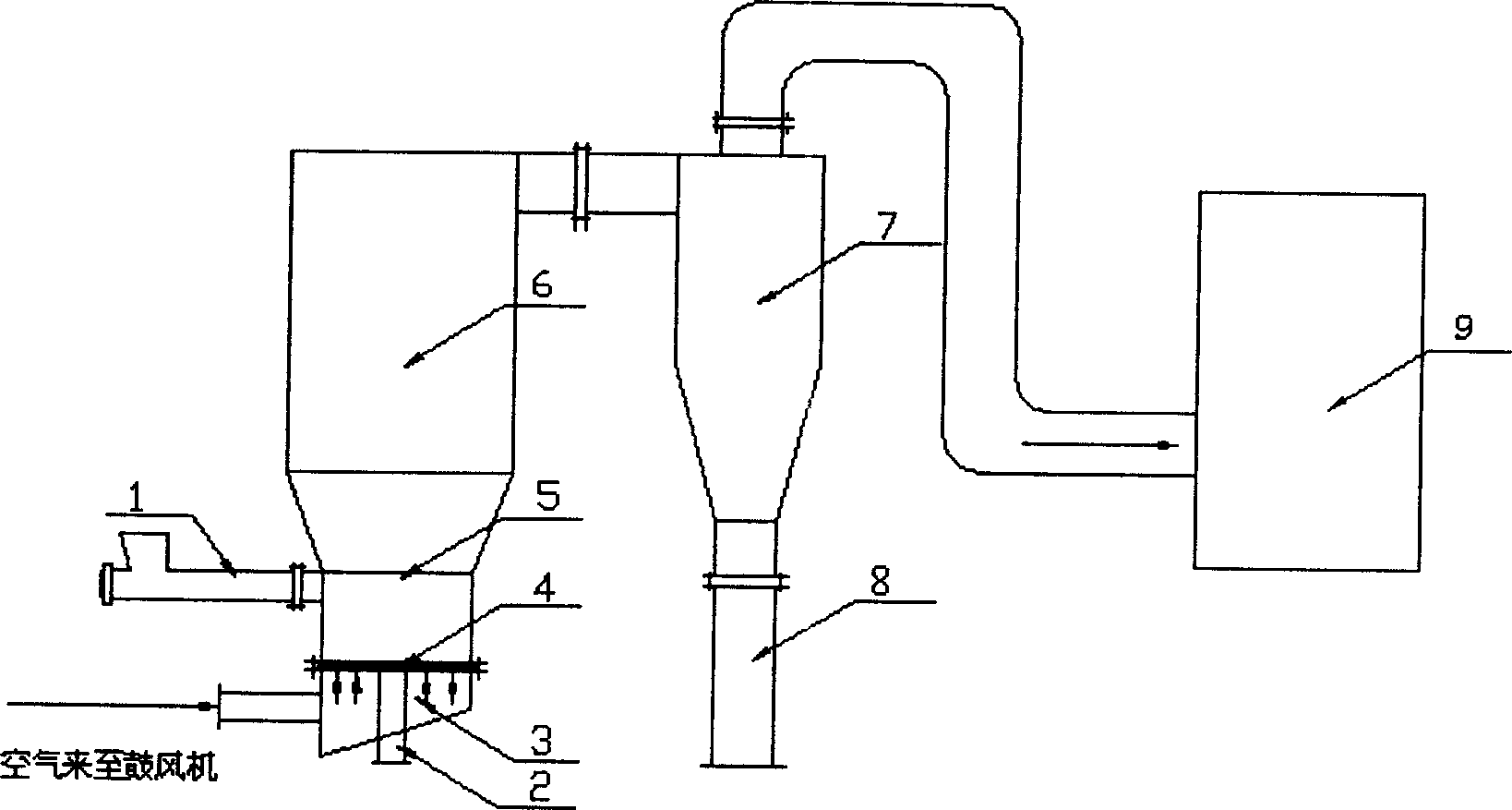

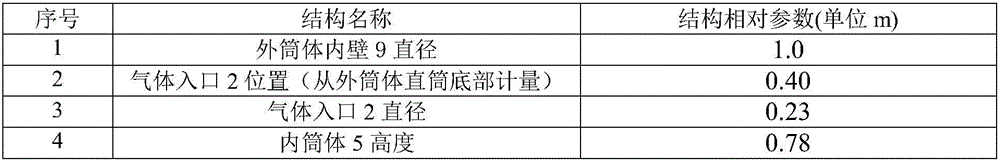

Coke gasification process and device

InactiveCN106190318AShort processReduce energy consumptionEnergy inputGasification processes detailsSuperheaterThree level

A coke gasification process comprises the steps that coarse coal gas carrying oil-containing dust enters a cyclone separator for separation, separated gas is mixed with the coarse coal gas carrying oil-containing dust entering the cyclone separator, re-separation is performed to obtain coarse coal gas and oil-containing dust; the coarse coal gas enters an integrated waste heat recovery device and sequentially passes through an overheater, a heat recovery device II, a heat recovery device I for staged heat recovery and then is discharged to a cooler through a recovered waste heat and coarse coal gas outlet, and recovery heat generates steam at the three levels of low-pressure saturation, middle-pressure saturation and overheating. The coke gasification process has the advantages that no washing coal gas water is produced, coal gas waste heat can be recycled in a staged mode, and meanwhile different levels of steam are produced.

Owner:SEDIN ENG

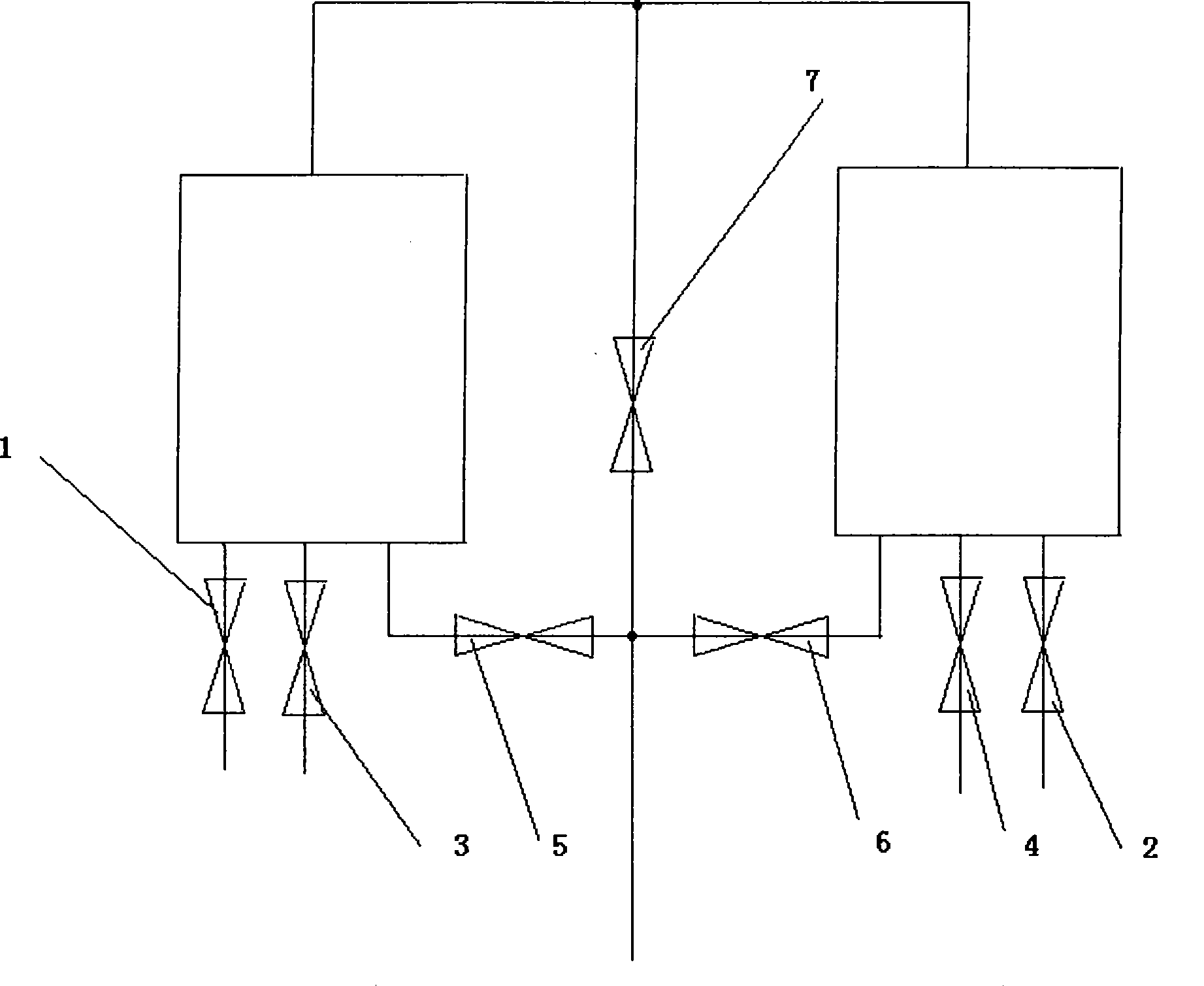

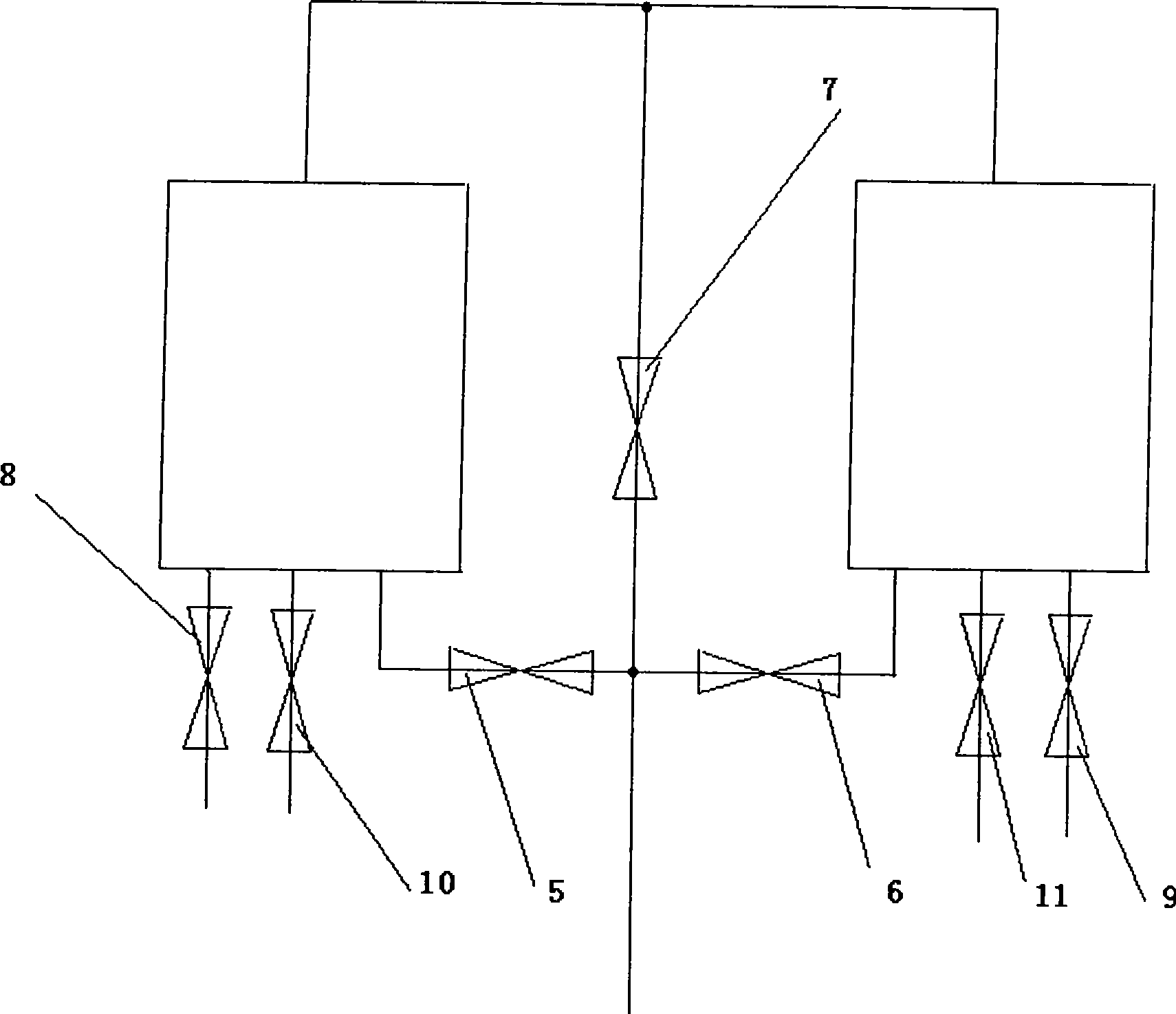

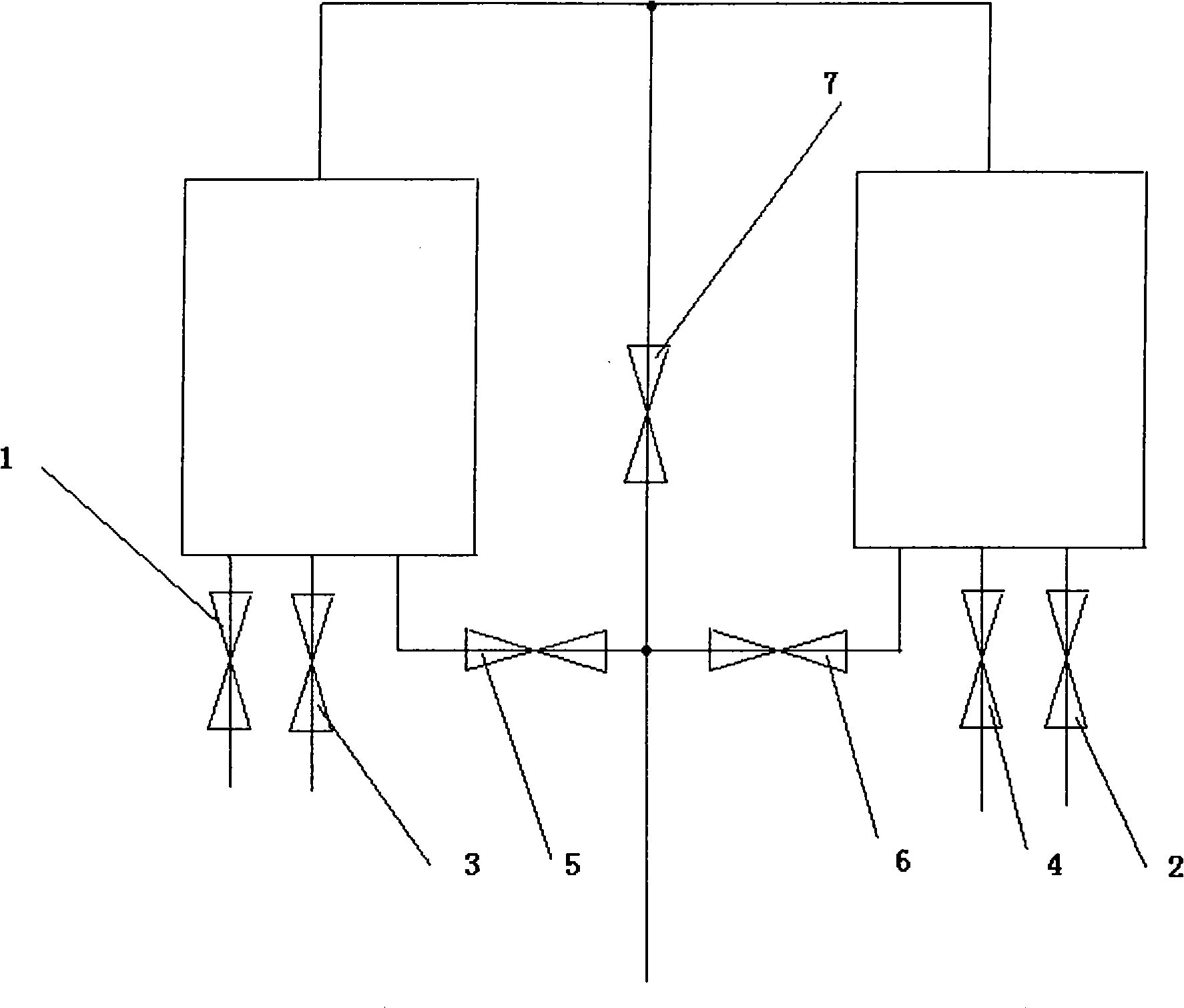

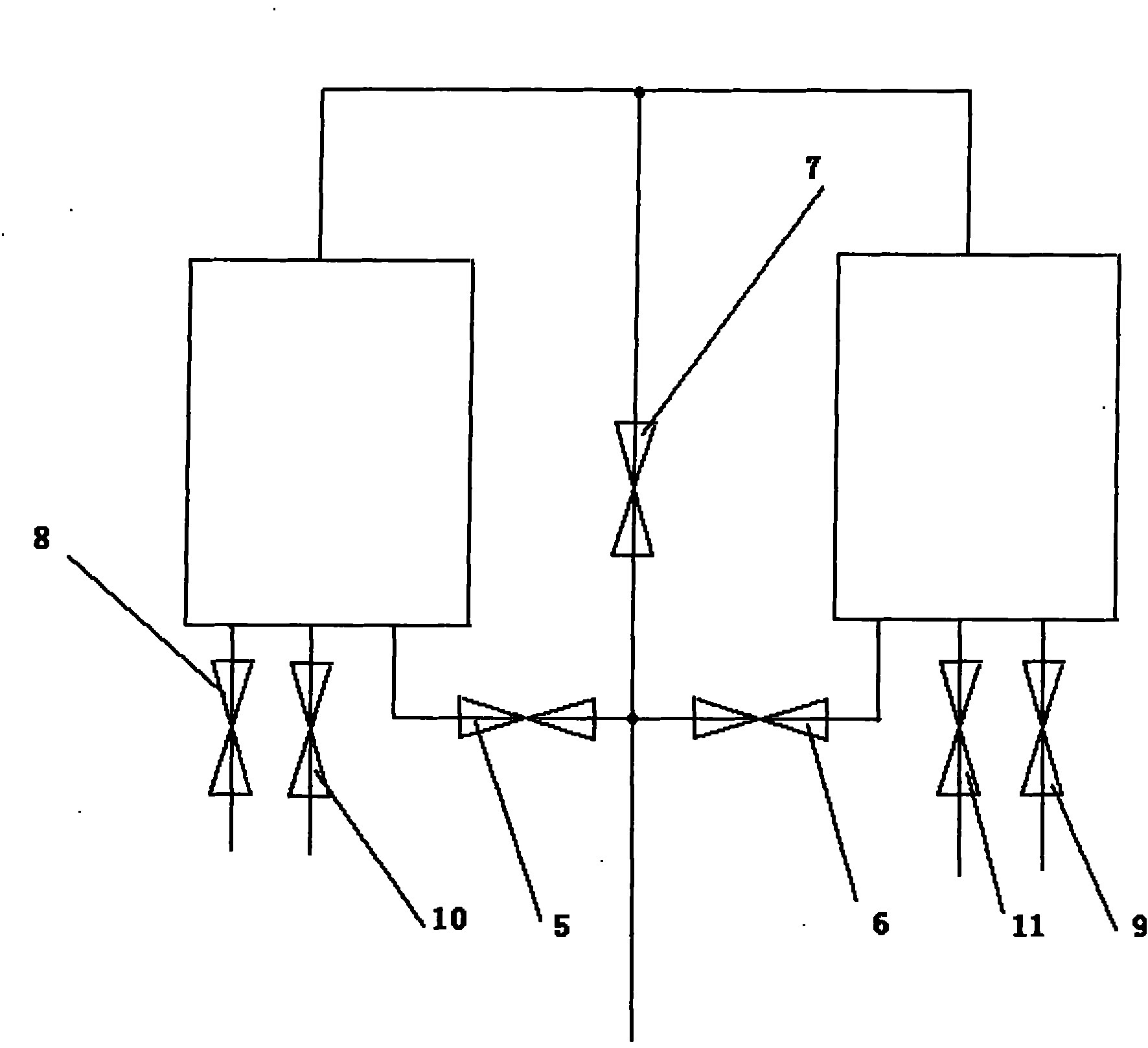

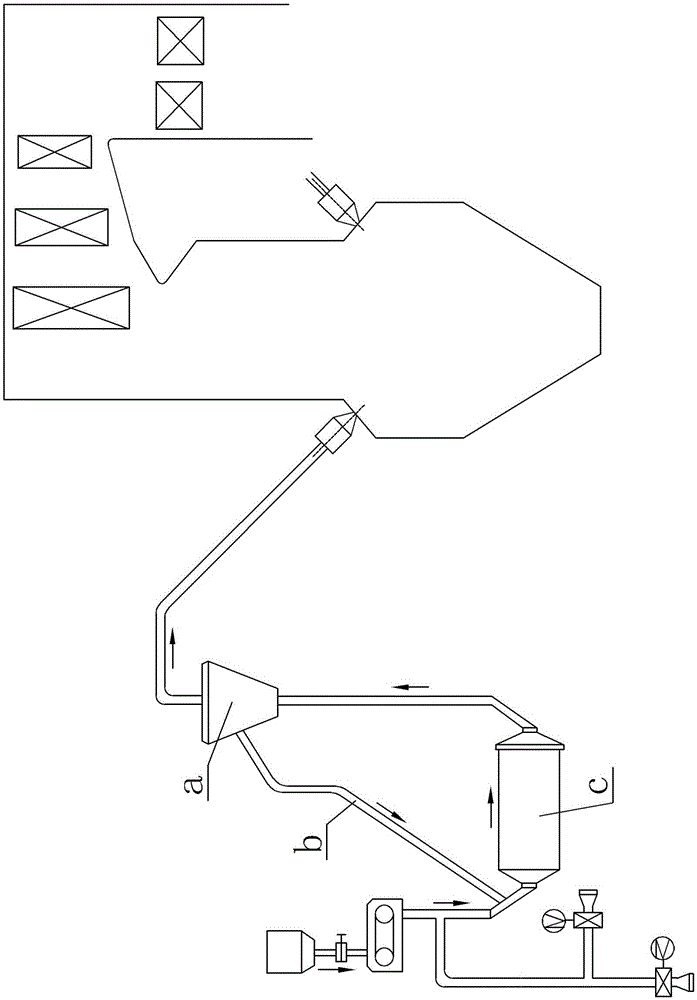

Coupling fixed bed oxygen-enriched continuous gasification process

InactiveCN101475839AReduce sensible heat lossReduce erosionCombined combustion mitigationCombustible gas productionCarbon dioxideProcess engineering

The invention discloses oxygen-rich continuous gasification technology for a coupled fixed bed, wherein a solid raw material comprises coal or coke, and a gas raw material comprises oxygen, air and steam; and the oxygen can be mixed with the air into oxygen-rich air first and then is sent into a gas-making furnace, and can also be sent into the gas-making furnace in the form of single gas. The technology is characterized in that the gas-making furnace is that two common gas furnace bodies (A and B) are connected into a whole by a pipeline and a valve, two furnaces alternately upward blow to make gas, and the gas raw material can also comprise carbon dioxide; and the gas-making process comprises the step of the blowing-off of the A and B furnaces, the step of upward blowing of the A furnace, the step of secondary blowing-off of the A and B furnaces, and the step of upward blowing of the B furnace, and the steps are circulated. The gas-making furnace is that the two common gas furnace bodies are connected into a whole by the pipeline and the valve, and the two furnaces alternately upward blow to make gas, so the technology can optimize the distribution of temperature fields in the gas furnaces, reduce the sensible heat loss of semiwater gas, the erosion to pipelines in subsequent working procedures, and the quantity of carry-overs, improve the condition of gas quality, and reduce gas consumption and coal consumption.

Owner:北京名都厚德科技有限公司

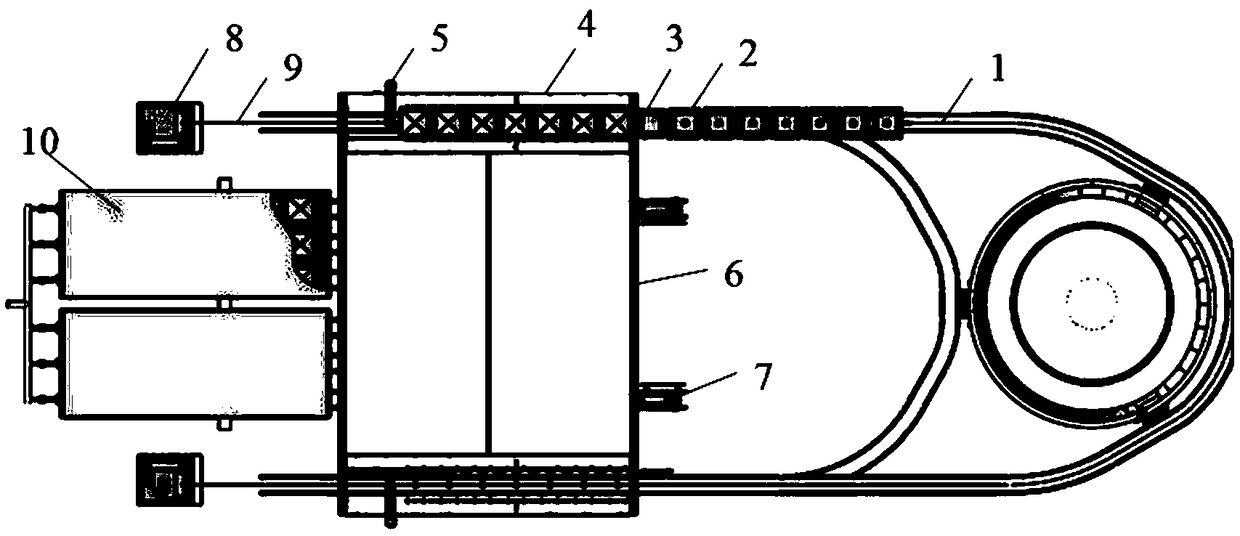

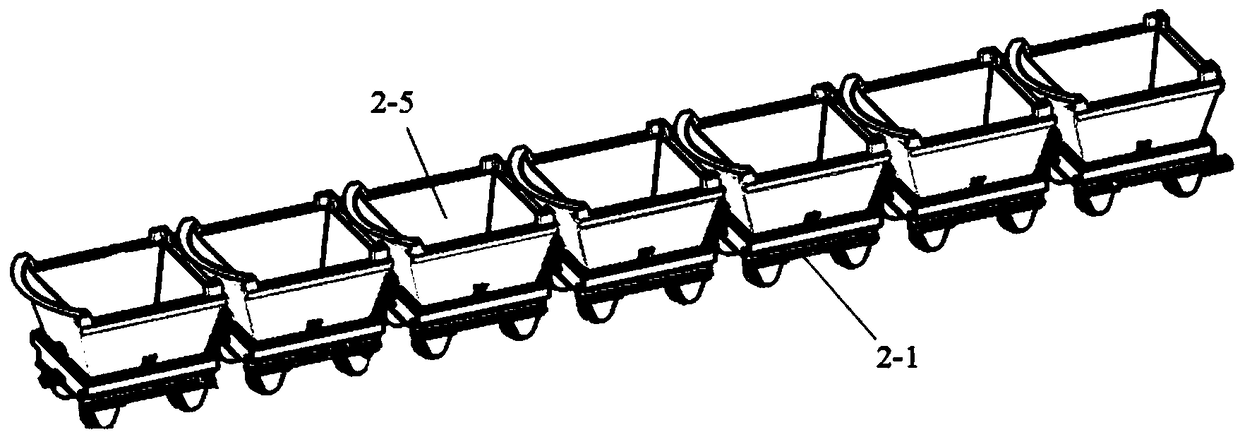

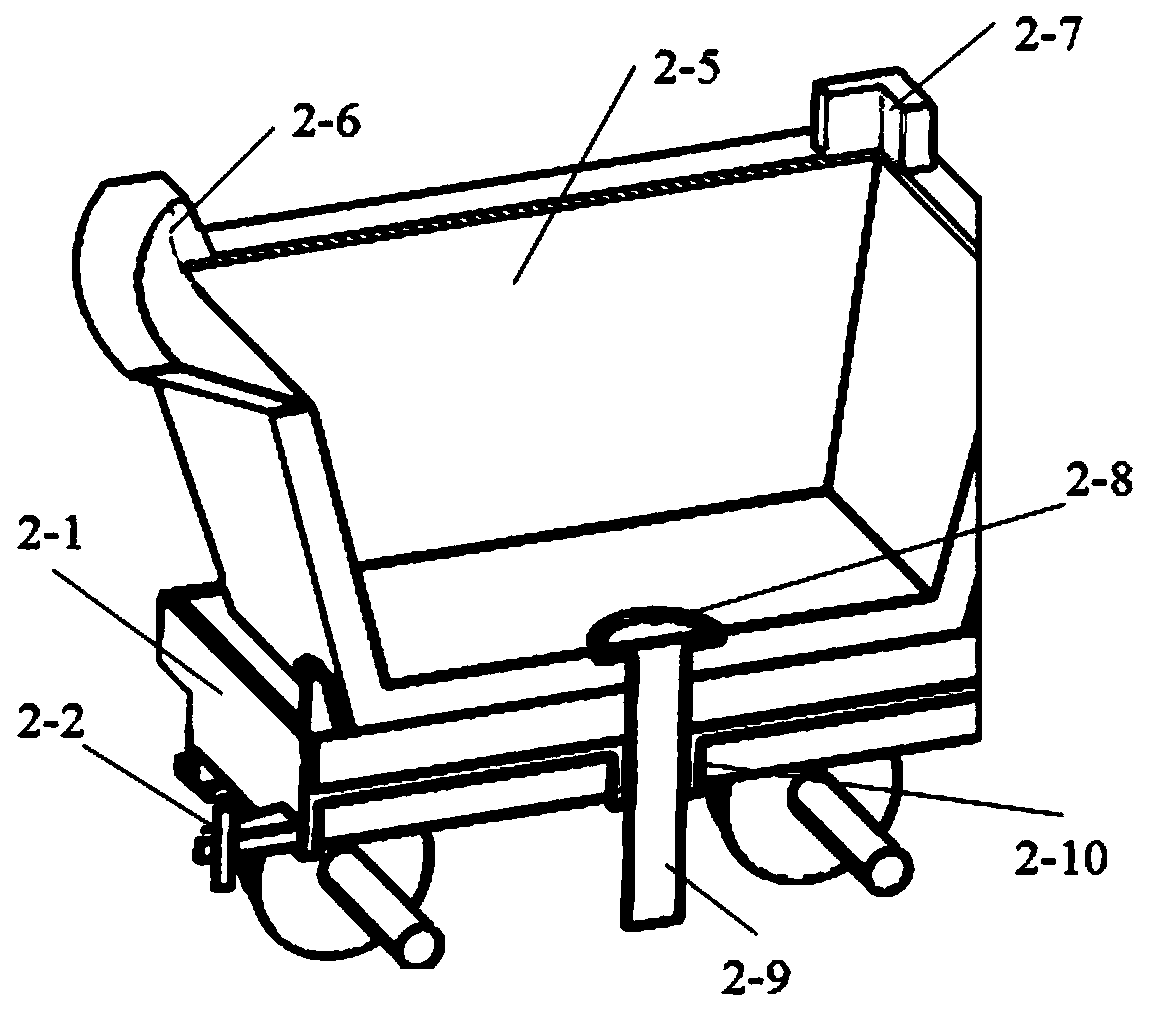

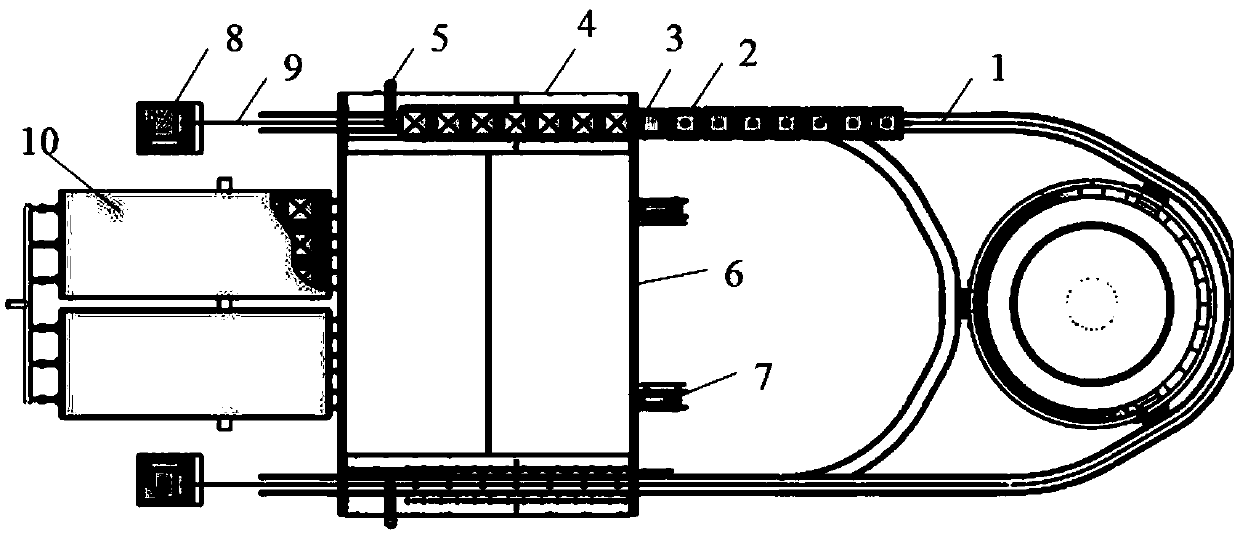

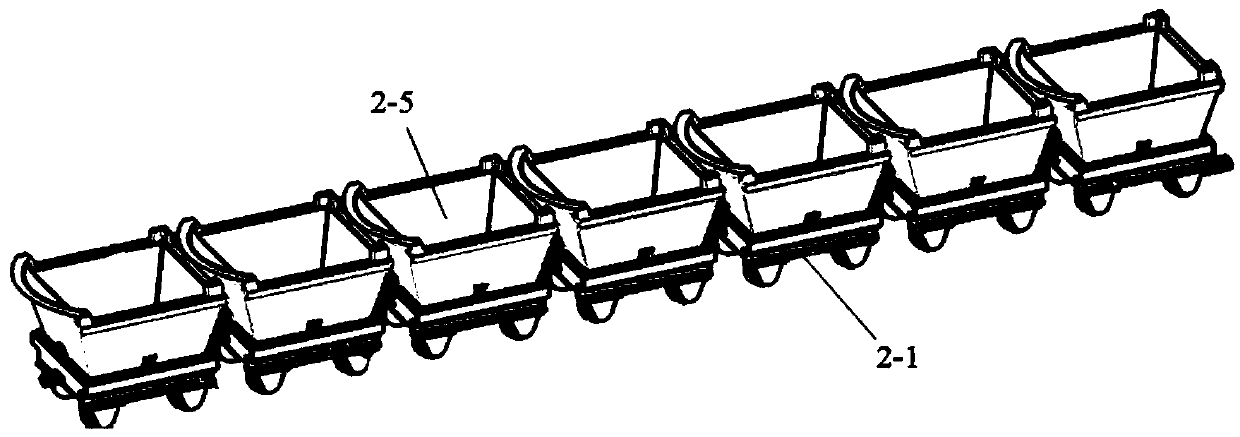

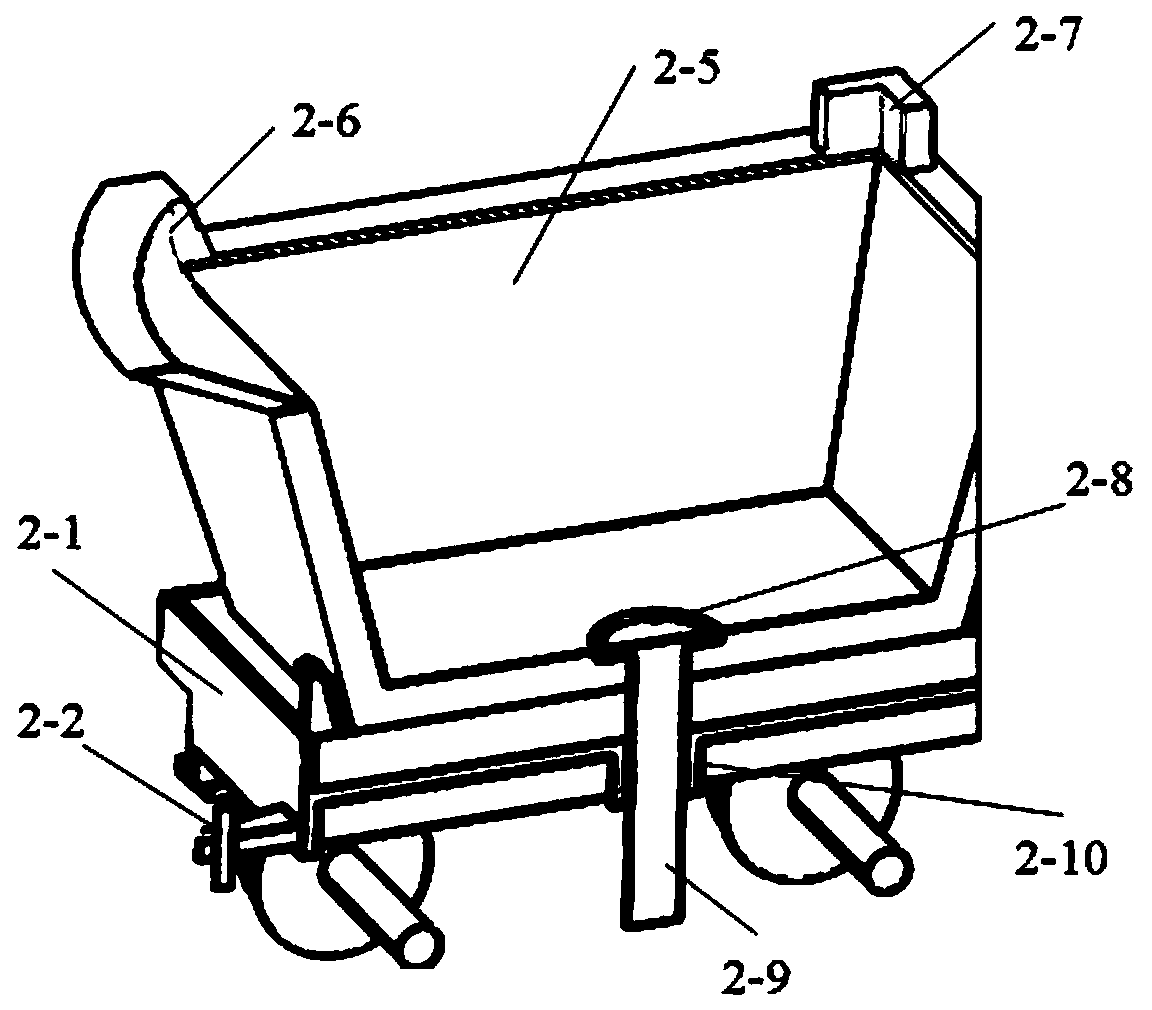

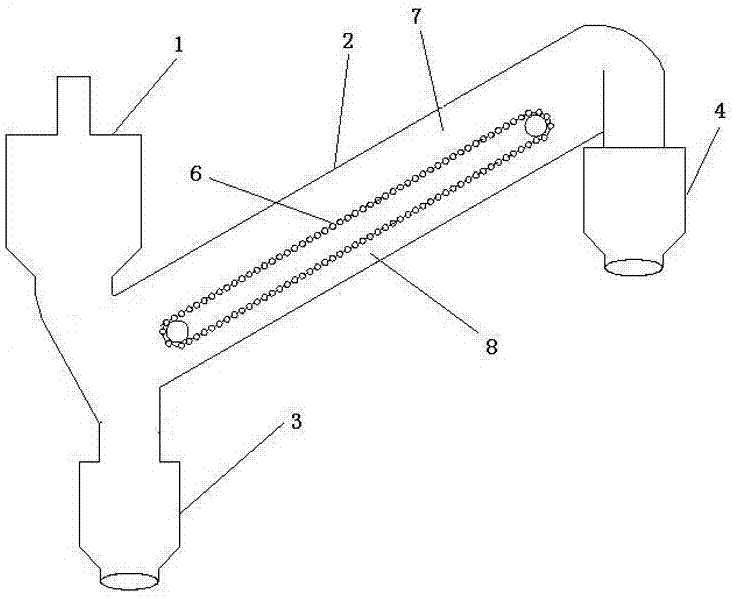

Furnace discharging system for calcium carbide sensible heat power generation

ActiveCN109084588AAchieve seamless connectionPrecise positioningCharge manipulationTunnel kilnReciprocating motion

The invention discloses a furnace discharging system for calcium carbide sensible heat power generation. The furnace discharging system comprises a conveying track, a furnace discharging trolley set,a moving platform, a mechanical arm, a traction track, traction trolleys, winches and a tunnel kiln. The moving platform is connected with the conveying track and the traction track. The front end andthe rear end of the furnace discharging trolley set are connected with one ends of two steel wire ropes correspondingly. The other ends of the two steel wire ropes are connected with the winches correspondingly. Under driving of the winches, the furnace discharging trolley set reciprocates on the conveying track. The mechanical arm is located on the outer side of the moving platform so that the front end or the rear end of the furnace discharging trolley set can be disconnected from and connected with the steel wire ropes. The traction trolleys are located on a traction trolley track on the outer side of the traction track. The tunnel kiln is internally provided with a track corresponding to the moving platform. The winches are located on the two sides of the tunnel kiln. The furnace discharging system has the beneficial effects that continuous conveying and unloading can be achieved, efficiency is high, running is automatic, operation is simple, the running cost is low, and running is stable.

Owner:DALAD BANNER BRANCH OF INNER MONGOLIA YILI ENERGYCO

A furnace discharge system for calcium carbide sensible heat power generation

ActiveCN109084588BAchieve seamless connectionPrecise positioningCharge manipulationTunnel kilnReciprocating motion

The invention discloses a furnace discharging system for calcium carbide sensible heat power generation. The furnace discharging system comprises a conveying track, a furnace discharging trolley set,a moving platform, a mechanical arm, a traction track, traction trolleys, winches and a tunnel kiln. The moving platform is connected with the conveying track and the traction track. The front end andthe rear end of the furnace discharging trolley set are connected with one ends of two steel wire ropes correspondingly. The other ends of the two steel wire ropes are connected with the winches correspondingly. Under driving of the winches, the furnace discharging trolley set reciprocates on the conveying track. The mechanical arm is located on the outer side of the moving platform so that the front end or the rear end of the furnace discharging trolley set can be disconnected from and connected with the steel wire ropes. The traction trolleys are located on a traction trolley track on the outer side of the traction track. The tunnel kiln is internally provided with a track corresponding to the moving platform. The winches are located on the two sides of the tunnel kiln. The furnace discharging system has the beneficial effects that continuous conveying and unloading can be achieved, efficiency is high, running is automatic, operation is simple, the running cost is low, and running is stable.

Owner:DALAD BANNER BRANCH OF INNER MONGOLIA YILI ENERGYCO

Molten salt heat exchanger for intelligently controlling heat exchange flowing speed

InactiveCN105841522ASolve problems that don't match wellRealize intelligent controlHeat exchanger casingsStationary tubular conduit assembliesMolten saltEngineering

The invention provides a molten salt heat exchanger with intelligent control of heat exchange flow rate, which is used for heat exchange between cold salt and hot salt. The molten salt heat exchanger at least includes: an outer shell; The first tube sheet and the second tube sheet at both ends; the heat exchange tube fixed between the first tube sheet and the second tube sheet, the heat exchange tube includes a straight tube and a spiral tube communicating with the straight tube ; The hot salt inlet, hot salt outlet and cold salt outlet arranged on the top of the shell; there are also cold salt inlets arranged at the bottom of the shell, several cold salt passages arranged between the cold salt inlet and the cold salt outlet, and the Intelligent control valves at both ends of each cold salt channel and temperature sensing devices arranged on the cold salt channel and heat exchange tubes. The molten salt heat exchanger of the present invention can realize intelligent control through an intelligent control valve and a temperature sensing device, and can well match the heat exchange flow rate of hot salt and cold salt to achieve better heat exchange effect.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

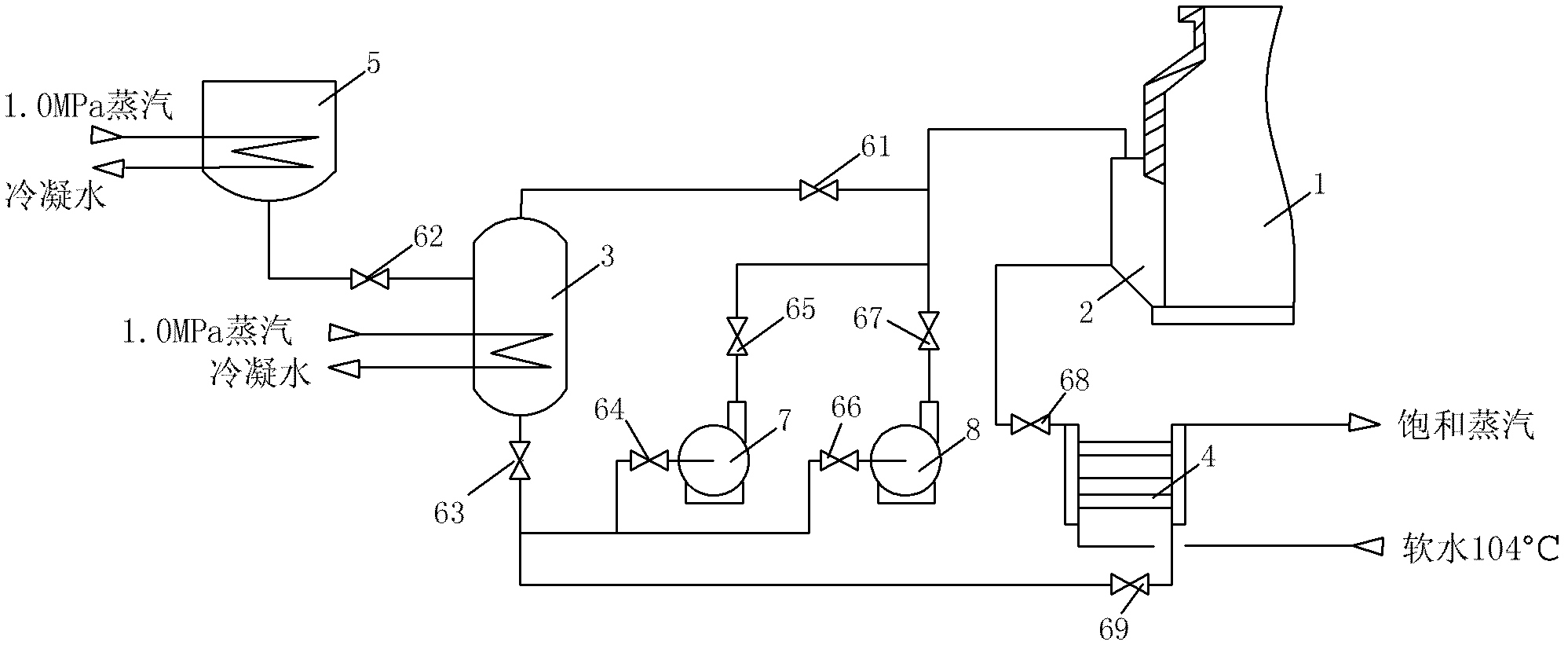

Gas-making furnace jacket fused salt heat exchanging system

InactiveCN102304389AImprove the cold wall effectIncrease productionCombustible gas productionLiquid stateSoftware engineering

The invention relates to a gas-making furnace jacket fused salt heat exchanging system. The system comprises a gas-making furnace and also comprises a fused salt storage tank, wherein the outlet of the fused salt storage tank is connected with the inlet of a fused salt pump; the outlet of the fused salt pump is connected with the inlet of a jacket boiler; the outlet of the jacket boiler is connected with the inlet of a heat exchanger; the outlet of the heat exchanger is connected with the inlet of the fused salt pump; and the medium in the fused salt storage tank is liquid-state fused salt. The technical scheme shows that the liquid-state fused salt in the fused salt storage tank is cycled through the fused salt pump and then fed to the gas-making furnace jacket boiler for further cycle heating, and then heats soft water by the heat exchanger to generate saturated steam, and then the steam is self-used by overheating or externally supplied; and the fused salt is adopted to replace the soft water to be used as a heat-transfer medium, so that the temperature in the jacket boiler is increased, thereby reducing the heat taken away by the heat-transfer medium in the jacket boiler, reducing the loss of sensible heat in the gas-making furnace, improving gasification efficiency and greatly improving the cold wall effect of the gas-making furnace jacket boiler.

Owner:ANHUI HUAIHUA

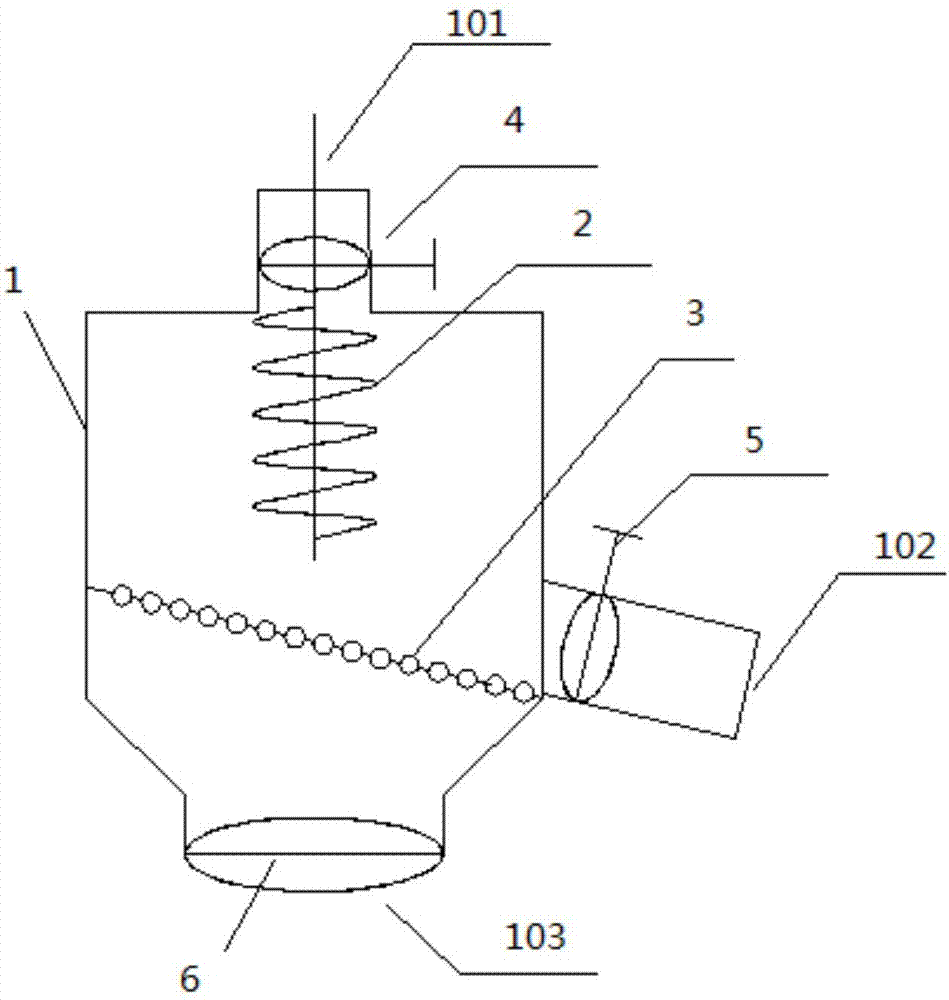

Method for preparing combustable gas using peltate yam waste slag

InactiveCN1648203AImprove efficiencyReduce coal consumptionSpecial form destructive distillationDirect combustionSlag

The method of preparing combustible gas with waste peltate yam dreg includes feeding waste peltate yam dreg with one spiral feeder into one gasifying apparatus, and pyrolyzing waste peltate yam dreg at high temperature into combustible gas via controlling the ratio between air and the waste dreg and the staying time of the waste dreg inside the gasifying apparatus. The said method converts waste peltate yam dreg into combustible gas, and can reduce energy source waste and reduce environmental pollution caused by discarded waste dreg.

Owner:HUAZHONG NORMAL UNIV

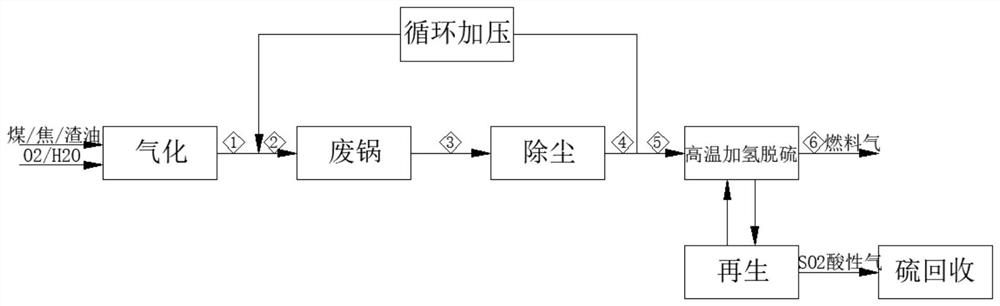

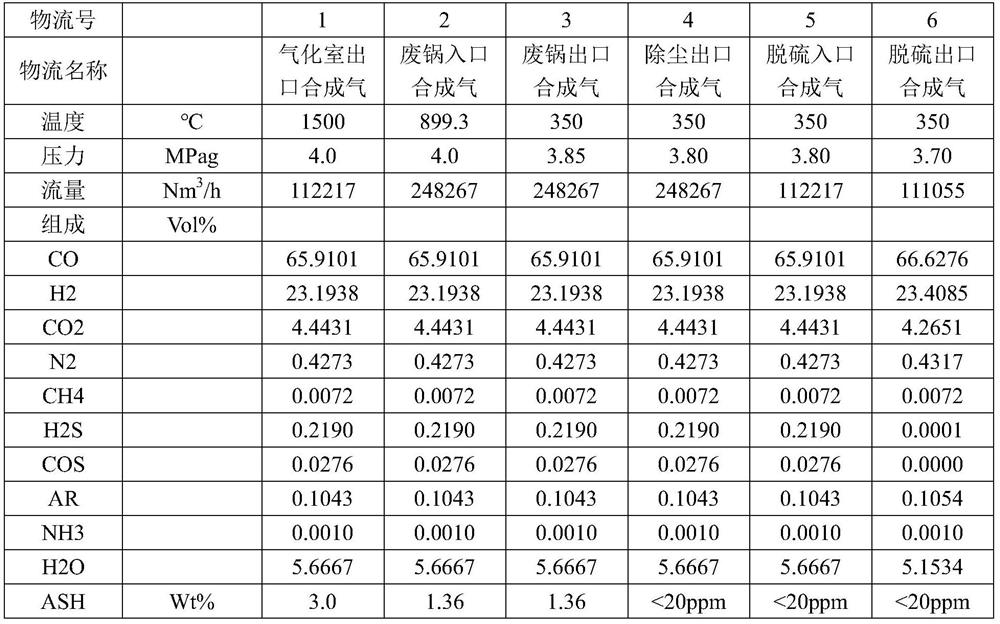

Process for preparing fuel gas from gasified synthesis gas through high-temperature hydrodesulfurization

InactiveCN112480972AReduce sensible heat lossImprove thermal efficiencyGaseous fuelsEnergy inputHydrodesulfurizationSorbent

The invention relates to a process for preparing fuel gas from gasified synthesis gas through high-temperature hydrodesulfurization. The process is free of a synthesis gas washing process, a COS hydrolysis unit and a synthesis gas cooling unit, the process flow is shortened, and the investment is reduced. The high-temperature synthesis gas does not need to be washed and cooled, the sensible heat loss of the synthesis gas is small, the heat efficiency is relatively high, and energy conservation and consumption reduction are facilitated. The COS hydrogenation reduction removal process is considered in desulfurization, the removal rate of sulfides is increased, and the purification effect is guaranteed. Compared with the process that gasified high-temperature synthesis gas directly enters a waste boiler cooler, the process adopts a post-dust-removal gas circulating chilling process, so that the risk of slagging and ash deposition of a waste boiler is reduced. Compared with a gas circulation chilling process after water washing, the gas circulation chilling process after dust removal has the advantages that water carried by the synthesis gas can be reduced to the maximum extent, the influence of water components on the performance of a desulfurization adsorbent is reduced, and the heat value of the fuel gas can be increased.

Owner:SINOPEC NINGBO ENG +2

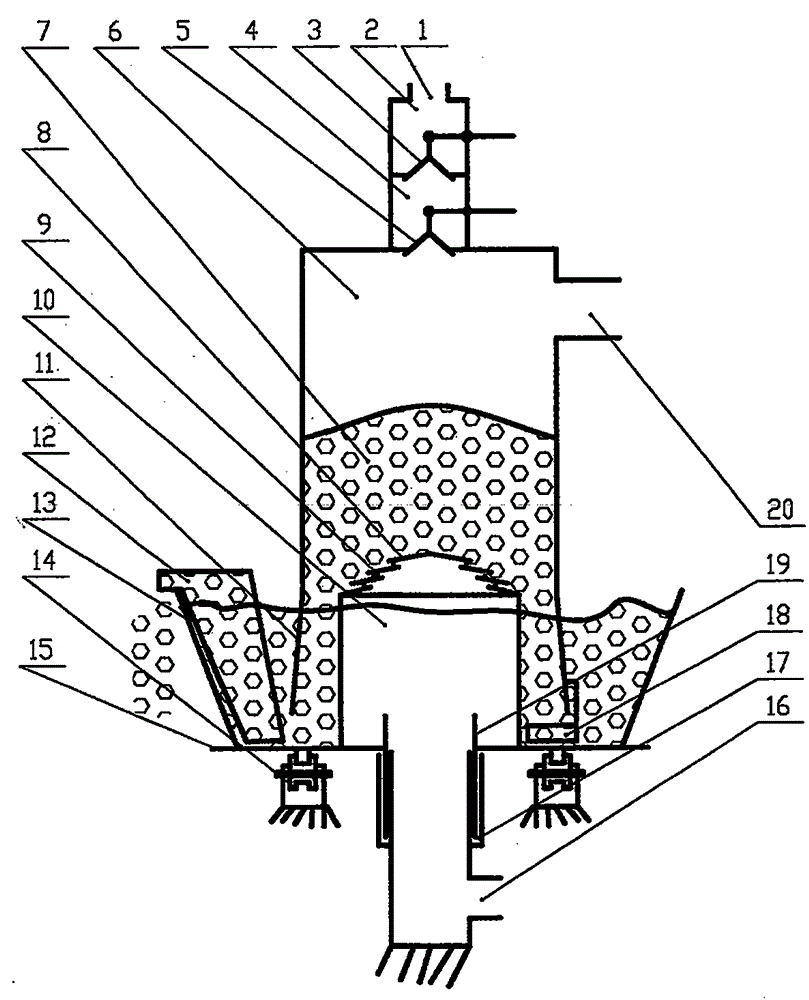

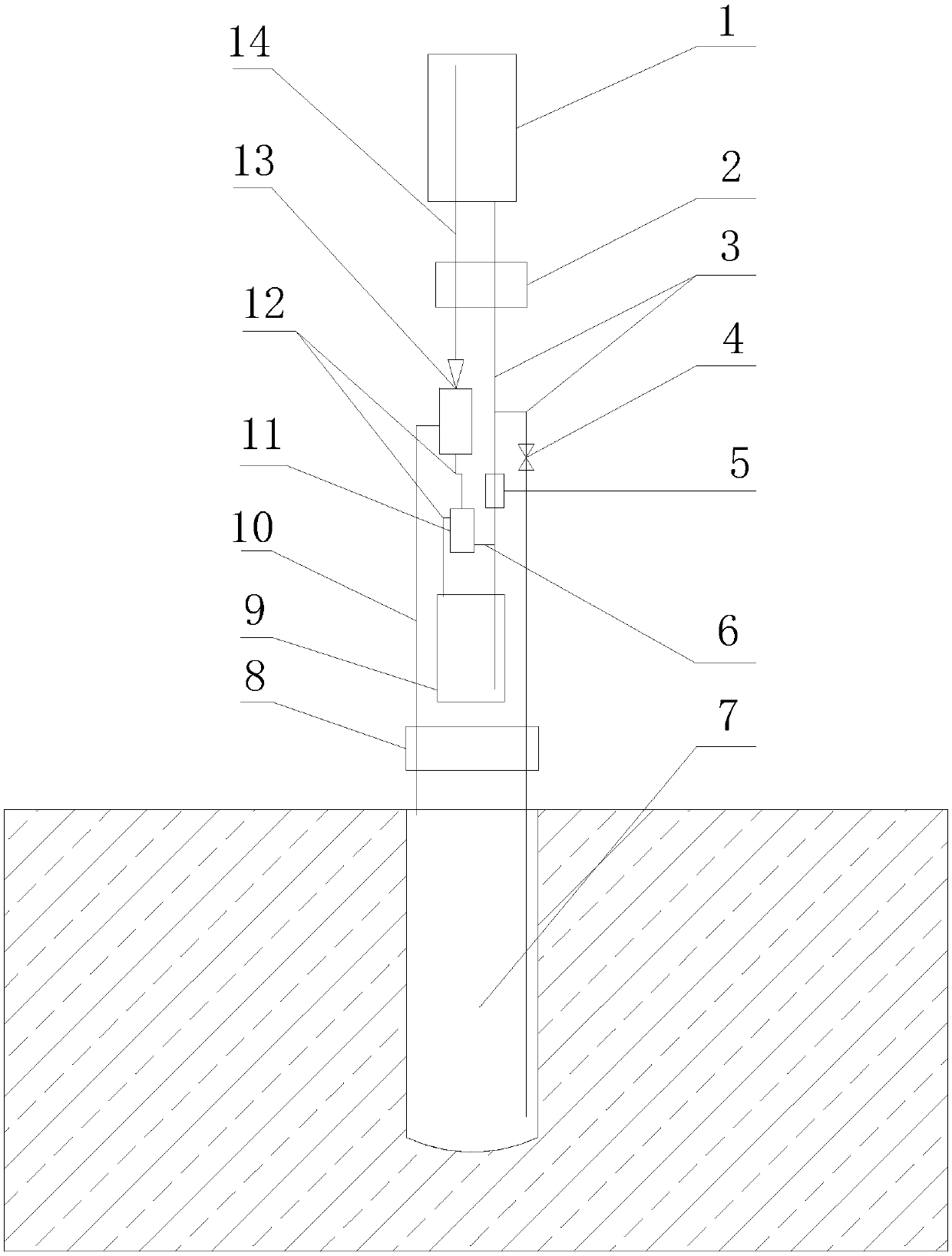

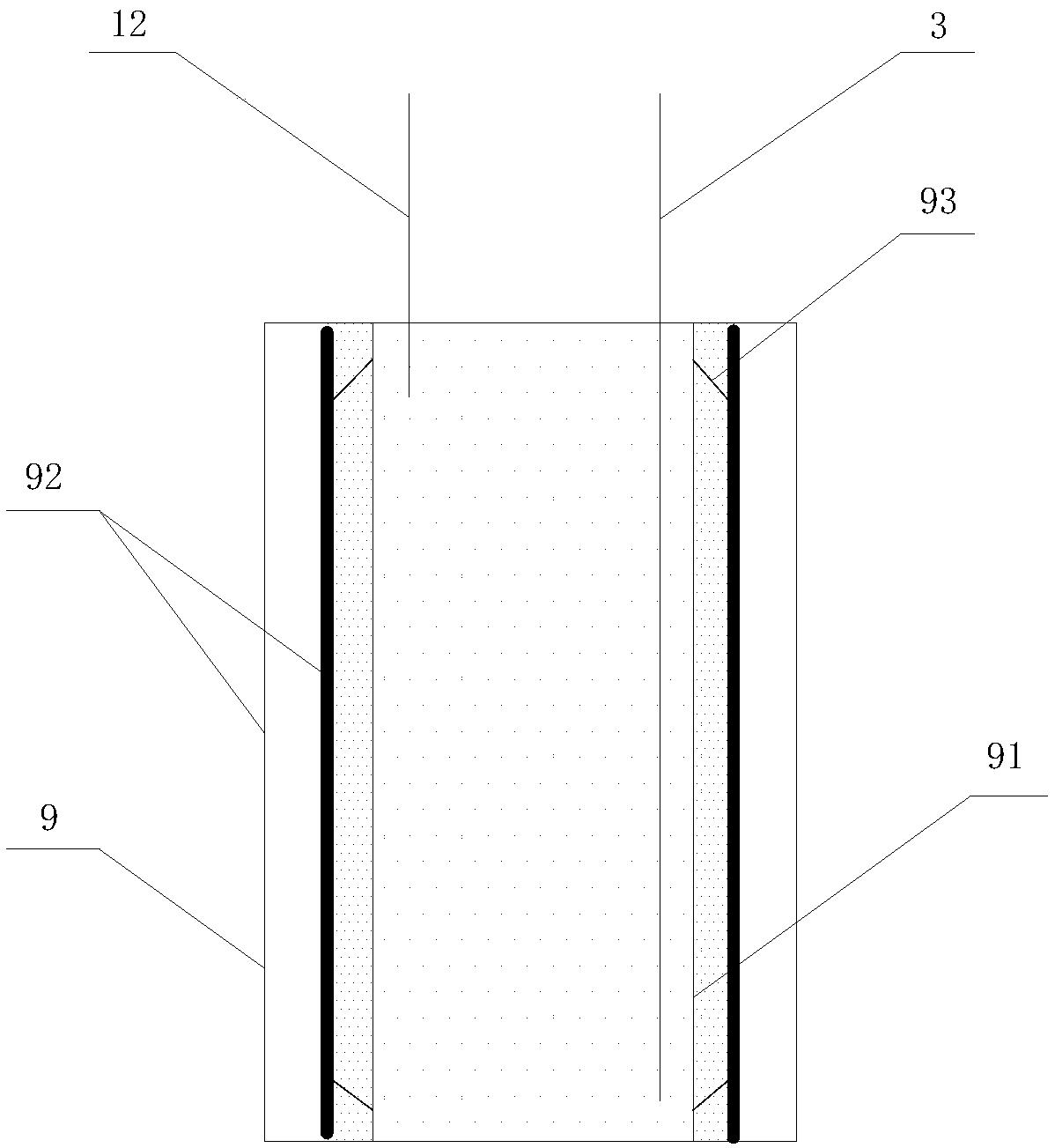

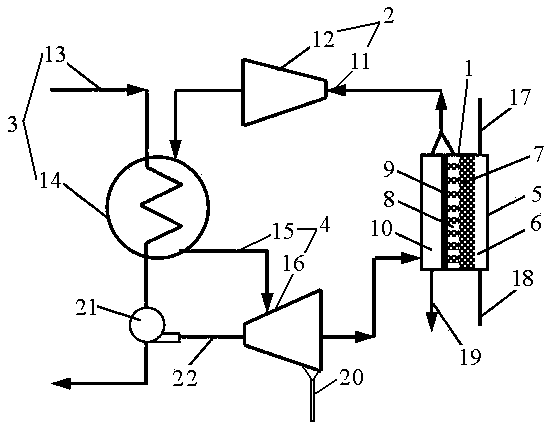

Solar refrigerating device used for manual freezing of water-rich loose and soft ground layer

InactiveCN109520148AImprove heat collection efficiencyImprove heat transfer efficiencySolar heating energyMechanical apparatusThermal energyDisease

The invention relates to a solar refrigerating device used for manual freezing of a water-rich loose and soft foundation. A heat collecting system and a steam injecting refrigerating system are included. The heat collecting system comprises a full-glass vacuum heat collecting pipe and a generator; the cylindrical generator is embedded in the tubular heat collecting pipe, and closed heating mediummedia are arranged between the two; and a gravity circulating manner is adopted for the steam injecting refrigerating system which comprises an evaporator embedded in a water-rich loose and soft ground layer, a condenser, a throttling valve, a steam injector, a one-way valve and the like, and the condenser, the throttling valve, the steam injector and the one-way valve are arranged on the ground surface. The device is vertical type refrigerating integrated machine, solar thermal energy and gravitational potential energy are combined for driving a refrigerating agent to circulate, no movement parts exist, consumption of electric energy and mechanical energy is avoided, running is reliable, and the service life is long. The device can be used for reinforcing weak cementation, large hole gapand water-rich unstable ground layers in engineering of excavating, traversing, filling and the like, and is especially suitable for preventing and controlling the hot melting disease of ice-rich foundations in linear engineering of long-distance railways, highways and power transmission lines in permafrost regions.

Owner:SHIJIAZHUANG TIEDAO UNIV

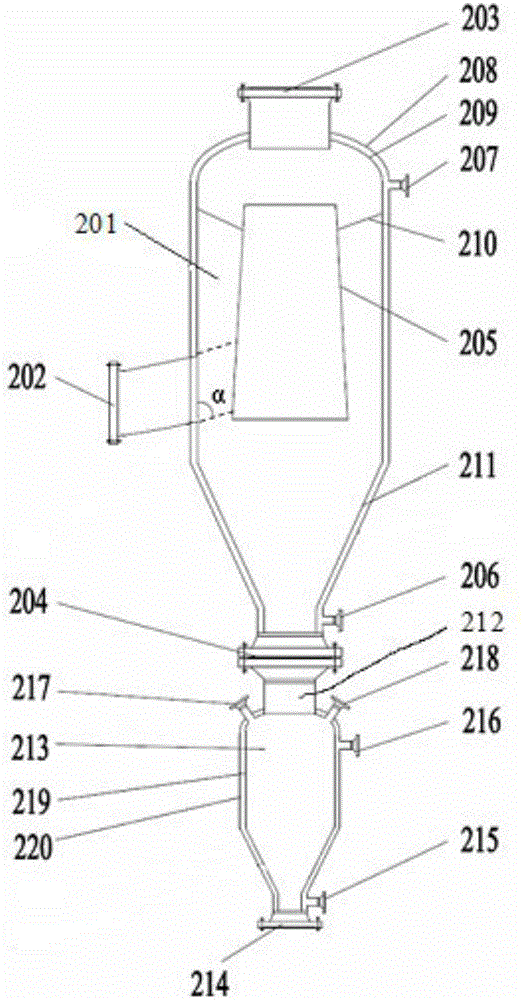

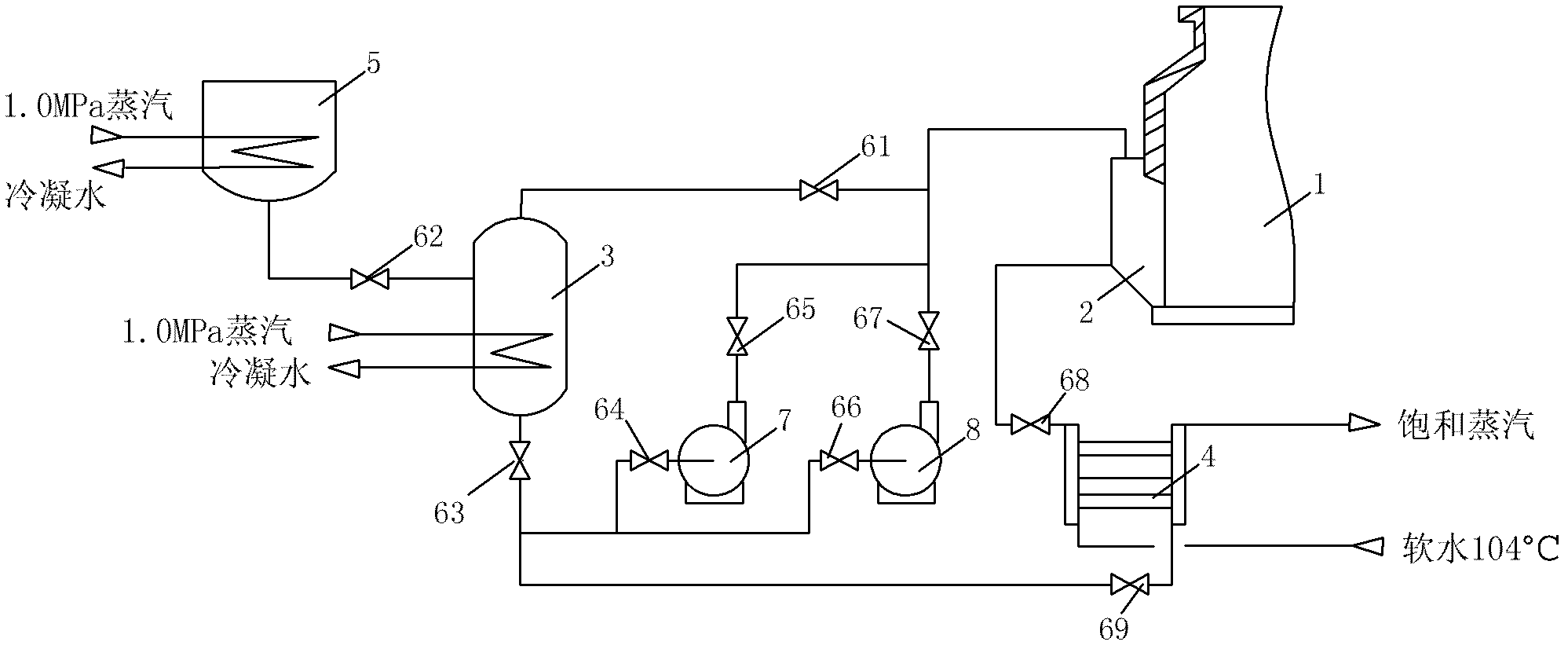

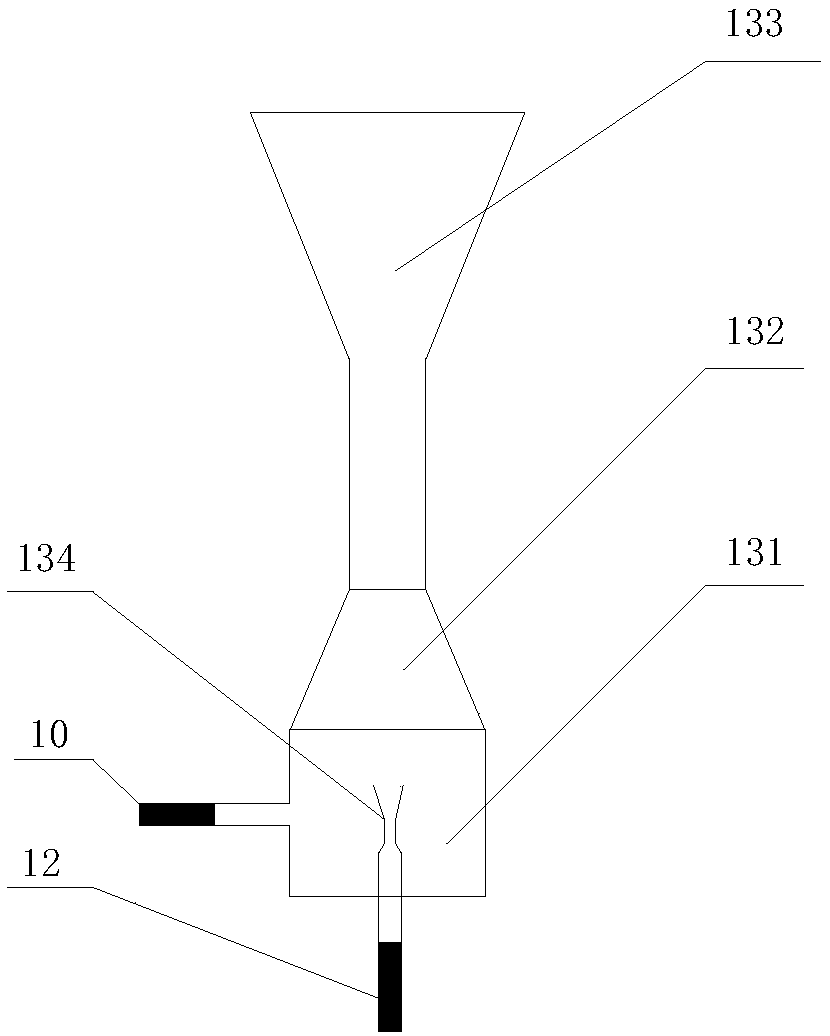

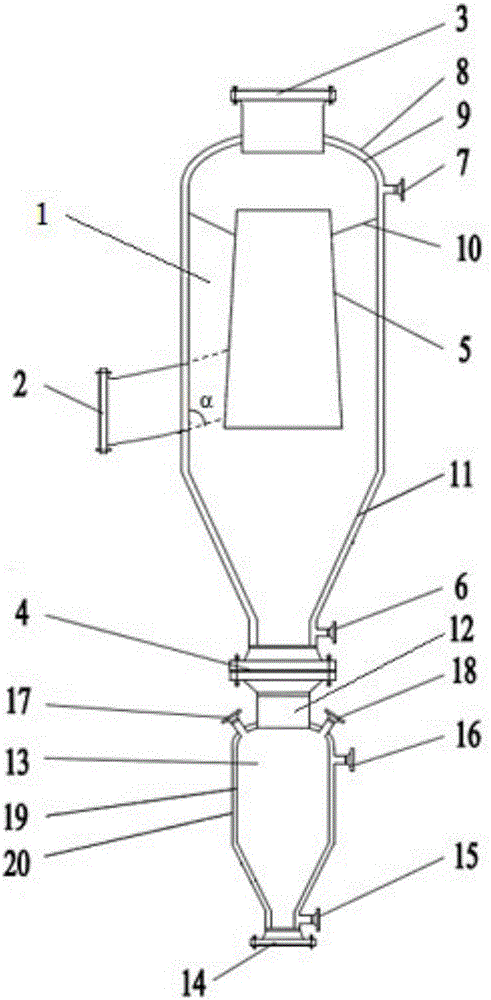

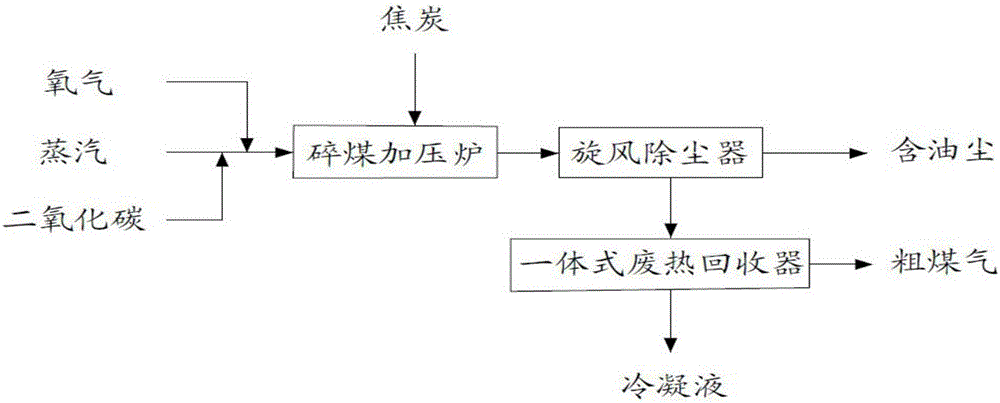

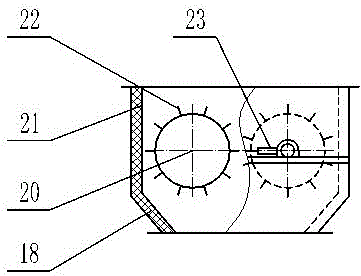

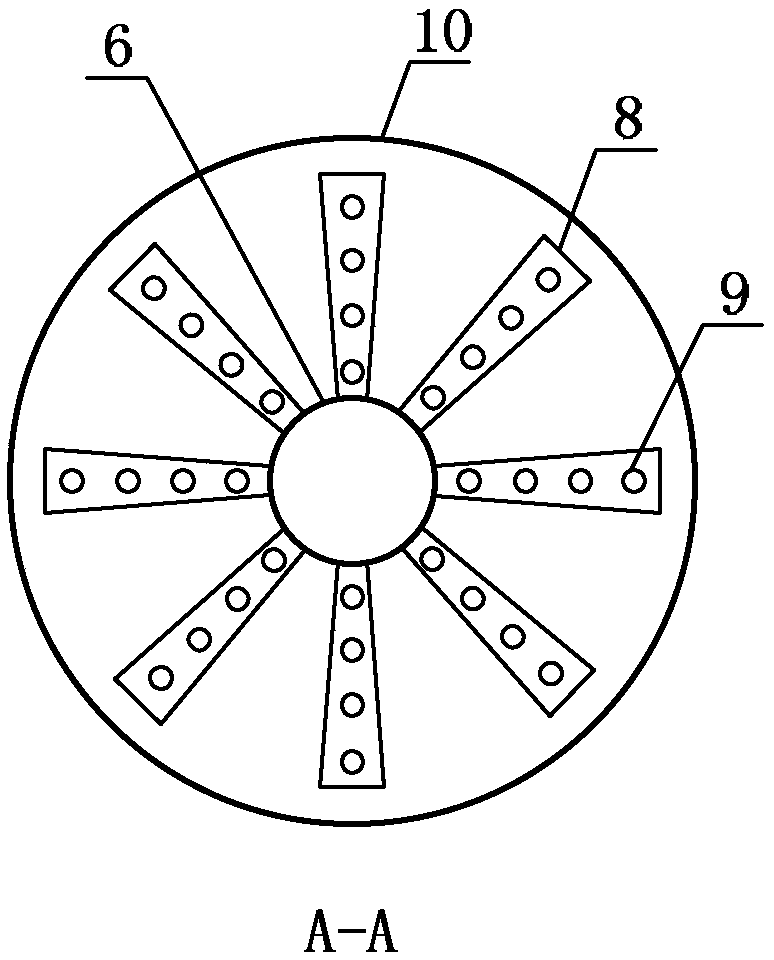

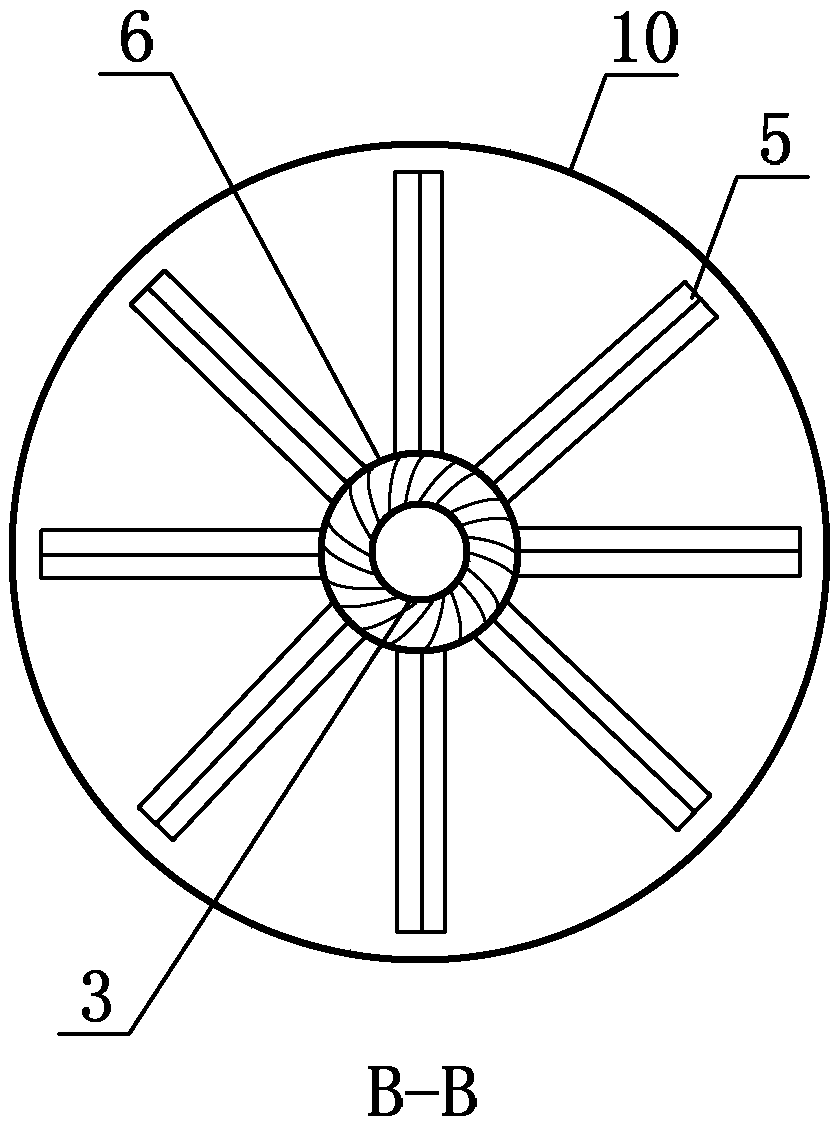

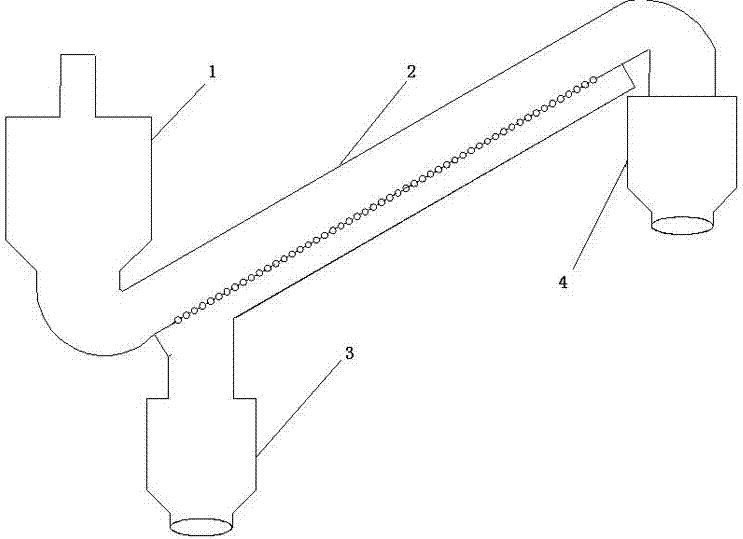

Cyclone separator for crude gas dust removal in crushed coal pressurized gasification and application

InactiveCN106190339AReduce sensible heat lossReduce resistanceGas dust removalThermodynamicsDust control

A cyclone separator for crude gas dust removal in crushed coal pressurized gasification comprises a cyclone dust collector (1) and a dust tank (13). The cyclone dust collector (1) comprises an outer cylinder (11) and an inner cylinder (5). The upper portion of the outer cylinder (11) is vertical, the lower portion of the outer cylinder (11) is conical, and the outer cylinder (11) is composed of an outer cylinder outer wall (8) and an outer cylinder inner wall (9). The inner cylinder (5) is fixed to the outer cylinder inner wall (9) through a stretching part (10). A gas inlet (2) is connected with the lower portion of the inner cylinder (5) through the outer cylinder (11), and a gas outlet (3) is located in the top end of the outer cylinder (11). A cyclone dust collector hot water outlet (7) is formed in the upper portion of the outer cylinder outer wall (8), and a cyclone dust collector hot water inlet (6) is formed in the lower portion of the outer cylinder outer wall (8). A bottom end outlet of the outer cylinder (11) is connected with the top end of the dust tank (13) through an oily dust discharge valve (4). The cyclone separator for crude gas dust removal in crushed coal pressurized gasification has the advantages of being high in oily dust removal efficiency, free of wastewater generation, high in treatment capacity and high in operation flexibility.

Owner:SEDIN ENG

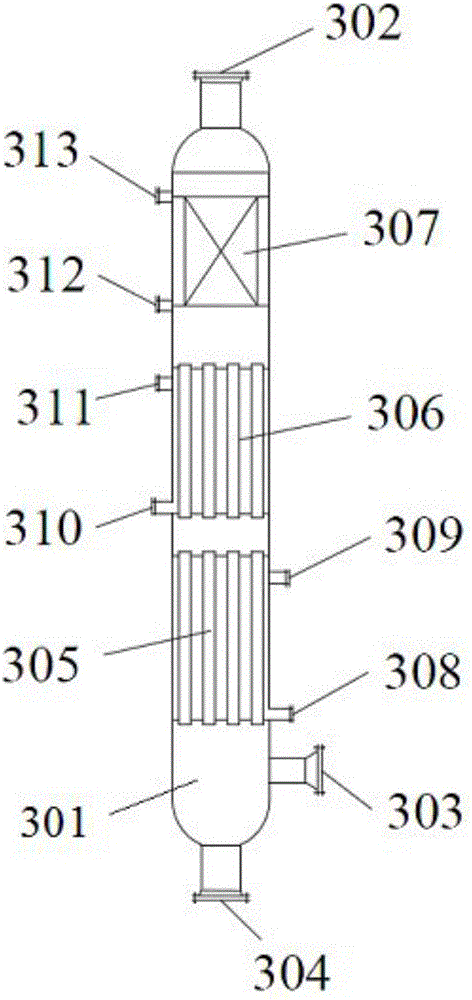

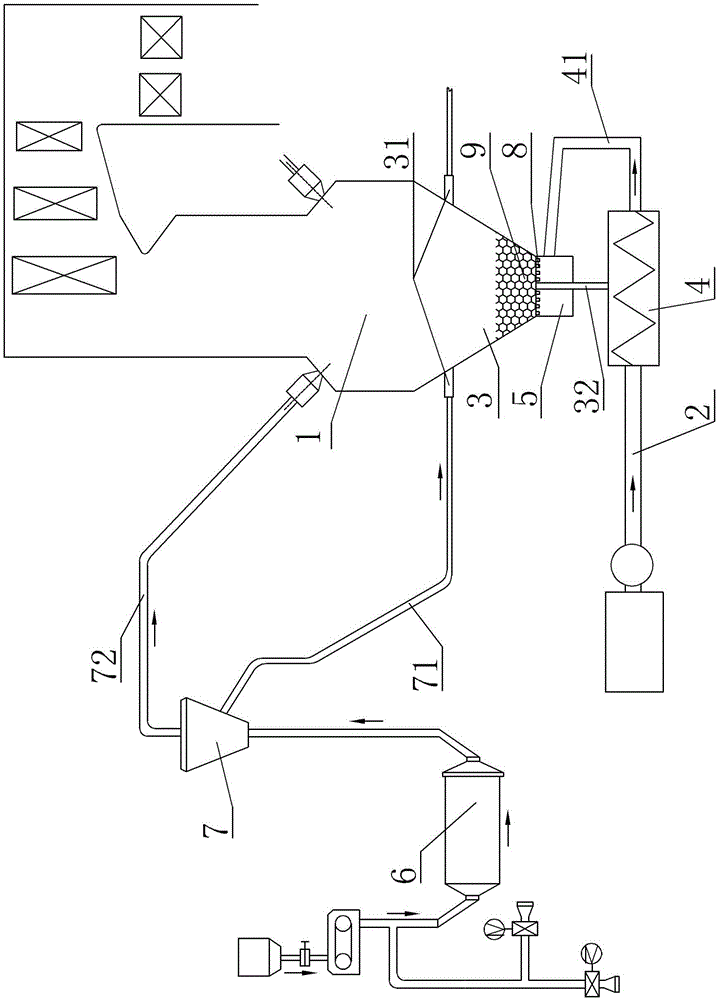

Method and equipment for producing gas by coke gasification

InactiveCN106221807AAvoid it happening againAvoid processing powerEnergy inputGasification processes detailsThermal energySuperheater

The invention discloses a method for producing gas by coke gasification. According to the method, oily dust crude gas enters a cyclone separator to be separated to obtain crude gas of which the oily dust content is 1 to 80 mg per cubic meter and oily dust; the oily dust is enriched to the bottom of the cyclone separator, an ash tank is pressurized by using the gas or an inert gas until the pressure of the ash tank is consistent with that of the cyclone separator, and an oily dust discharge valve is opened for discharging the oily dust to the ash tank; the obtained crude gas enters an integrated waste heat recovery device, heat is recovered in grades through a superheater, a heat recovery device II and a heat recovery device I, and the recovered heat generates three-grade steam of low-pressure saturated steam, medium-pressure saturated steam and superheated steam. The method and equipment for producing the gas by the coke gasification disclosed by the invention have the advantages of no gas scouring water and capabilities of carrying out grading recovery and reutilization on gas waste heat energy and further producing the steam of different grades.

Owner:SEDIN ENG

Coupling fixed bed oxygen-enriched continuous gasification process

InactiveCN101475839BReduce sensible heat lossReduce erosionCombined combustion mitigationCombustible gas productionFixed bedProcess engineering

The invention discloses oxygen-rich continuous gasification technology for a coupled fixed bed, wherein a solid raw material comprises coal or coke, and a gas raw material comprises oxygen, air and steam; and the oxygen can be mixed with the air into oxygen-rich air first and then is sent into a gas-making furnace, and can also be sent into the gas-making furnace in the form of single gas. The technology is characterized in that the gas-making furnace is that two common gas furnace bodies (A and B) are connected into a whole by a pipeline and a valve, two furnaces alternately upward blow to make gas, and the gas raw material can also comprise carbon dioxide; and the gas-making process comprises the step of the blowing-off of the A and B furnaces, the step of upward blowing of the A furnace, the step of secondary blowing-off of the A and B furnaces, and the step of upward blowing of the B furnace, and the steps are circulated. The gas-making furnace is that the two common gas furnace bodies are connected into a whole by the pipeline and the valve, and the two furnaces alternately upward blow to make gas, so the technology can optimize the distribution of temperature fields in the gas furnaces, reduce the sensible heat loss of semiwater gas, the erosion to pipelines in subsequent working procedures, and the quantity of carry-overs, improve the condition of gas quality, and reduce gas consumption and coal consumption.

Owner:北京名都厚德科技有限公司

High-temperature solid conveyor device

PendingCN107973086AImprove classification efficiencySimple structureSievingConveyorsThermal insulationEngineering

The invention relates to a high-temperature solid conveyor device mainly comprising an insulation tank body, anti-broken chute and a classification pore plate, wherein the top of the insulation tank body is provided with a high-temperature solid inlet, and the lateral part of the insulation tank body is provided with a high-temperature solid outlet ; the anti-broken chute is vertically arranged atthe upper part of an inner cavity of the insulation tank body, and the upper end of the anti-broken chute is located below the high-temperature solid inlet; the classification pore plate is arrangedbelow the anti-broken chute, and obliquely installed in the inner cavity of the insulation tank body; high-temperature solids are slid onto the classification pore plate through the anti-broken chute,and quickly discharged from the high-temperature solid outlet after passing through the classification pore plate. According to the conveyor device, the classification and removal treatment of powderis achieved in the material conveying process after pulverization, and the power is prevented from entering a calcium carbide furnace; meanwhile, the conveyor device has a thermal insulation function, and the sensible heat loss of the high-temperature solids is reduced; and the energy consumption in the calcium carbide production process and the carbon emission are reduced.

Owner:SHENWU TECH GRP CO LTD

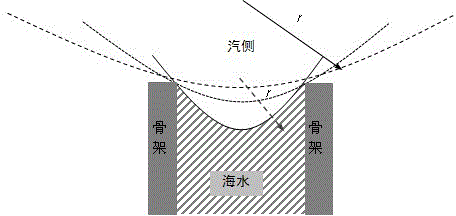

A compressed steam capillary drive seawater desalination device

InactiveCN105439223BAvoid heat lossReduce churnGeneral water supply conservationSeawater treatmentPorous mediumEngineering

The invention discloses a pressurized steam type capillary driven seawater desalination device, comprising a seawater desalination evaporator which sequentially comprises a seawater cavity, a porous medium, a desalinated steam passage, a heat conduction plate and a condensation cavity, wherein a desalinated steam outlet is formed in the seawater desalination evaporator and is communicated with the desalinated steam passage, the condensation cavity and a pressure reducing pipeline; an expansion valve and the pressure reducing pipeline are communicated with a heat exchanger; the pressure reducing pipeline comprises a heat exchanging pipeline; a heat working medium is filled into the heat exchanging pipeline; a hydraulic turbine is arranged on the heat exchanging pipeline; an outlet of the heat exchanger is connected with a pressure raising pipeline; and a compressor is arranged on the pressure raising pipeline and is connected with the hydraulic turbine by virtue of a connecting rod shaft. The pressurized steam type capillary driven seawater desalination device is characterized in that a condenser in the conventional desalination technology is abandoned to avoid the maximum heat loss-condensation heat loss in seawater desalination; and on the other hand, the desalination device disclosed by the invention makes use of capillary force to drive seawater for liquid refilling and does not need pumping work, and particularly, the used porous medium is a low-heat-conductivity material, so that the sensible heat loss brought away by discharge of concentrated brine is greatly reduced.

Owner:RUNHAI ENERGY TECH INC JIANGSU

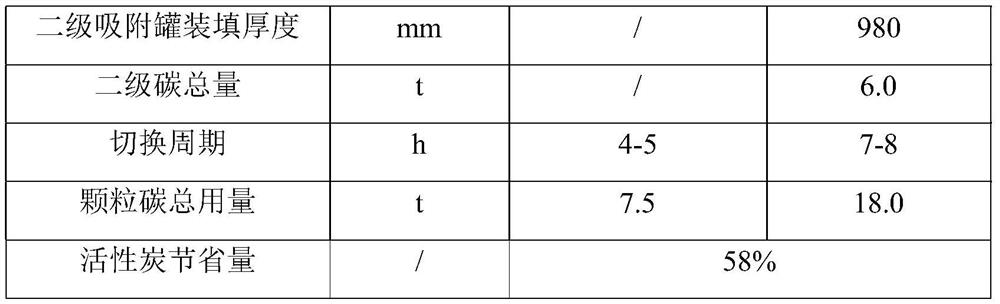

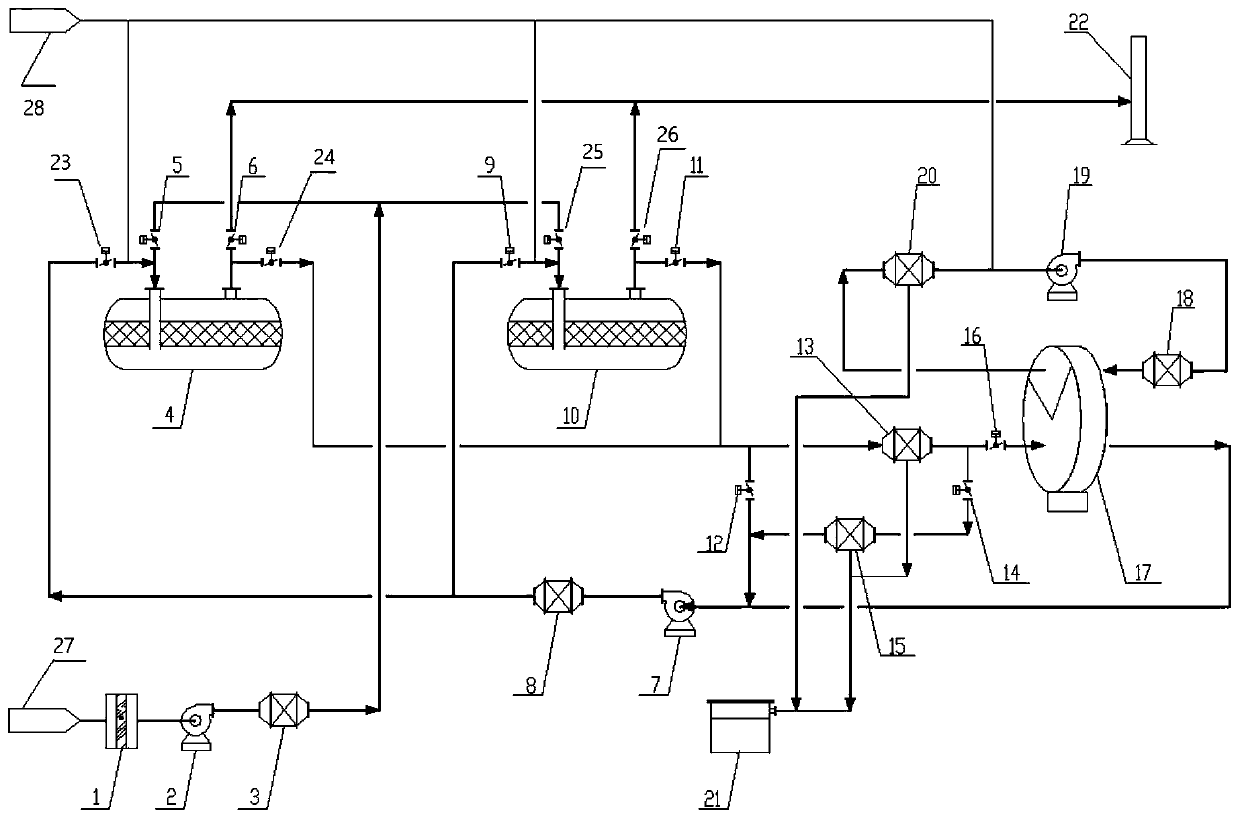

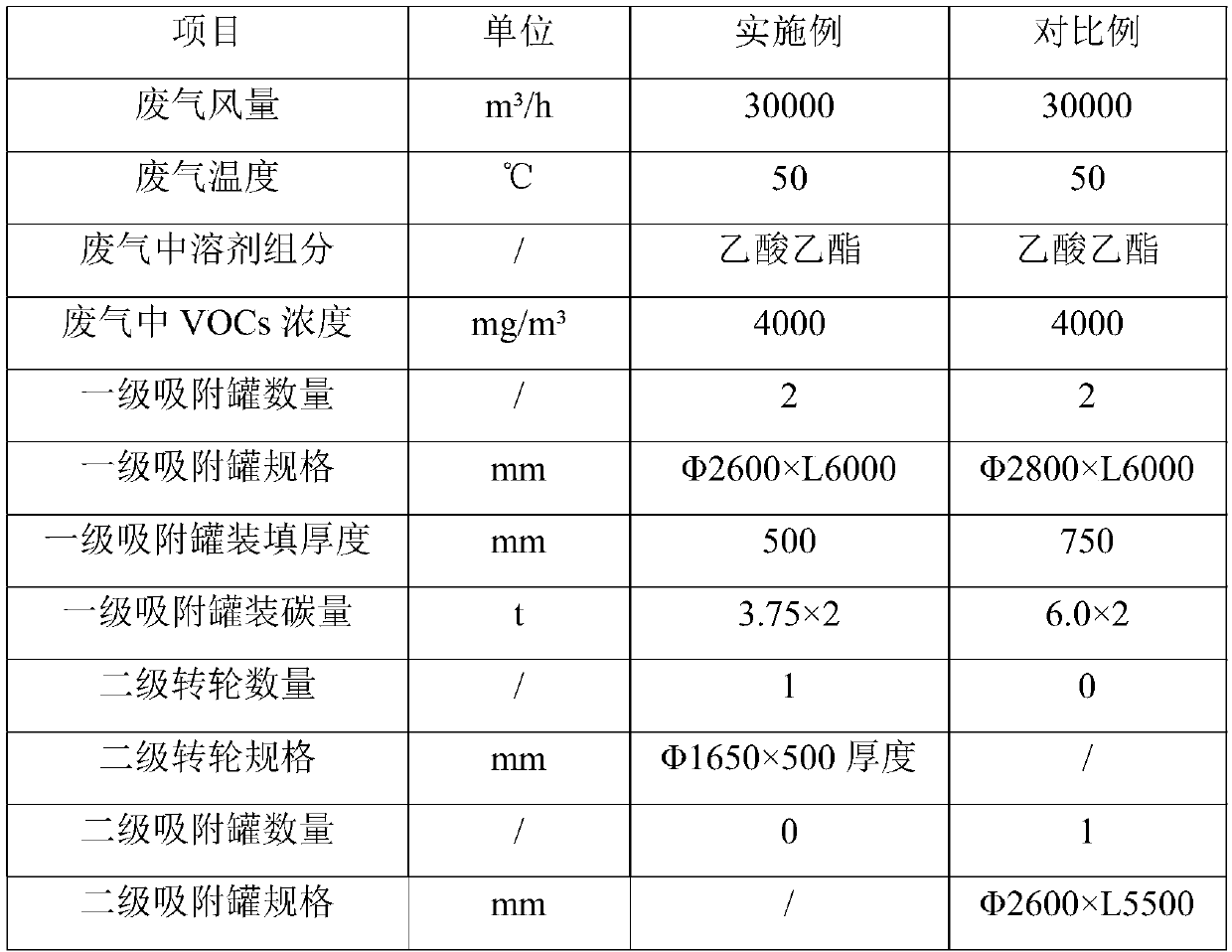

Adsorption recovery system for nitrogen regeneration and adsorption recovery method thereof

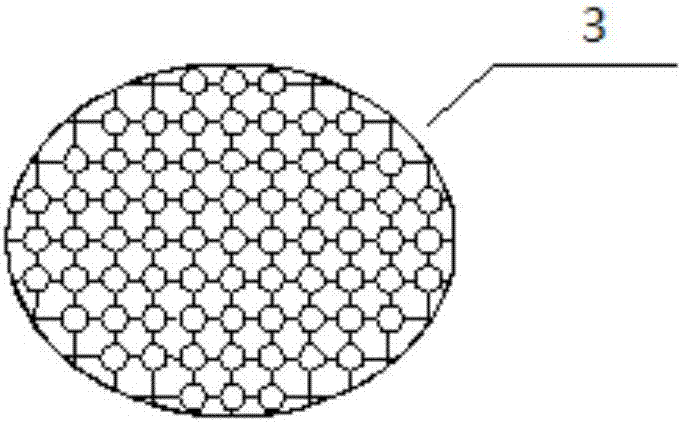

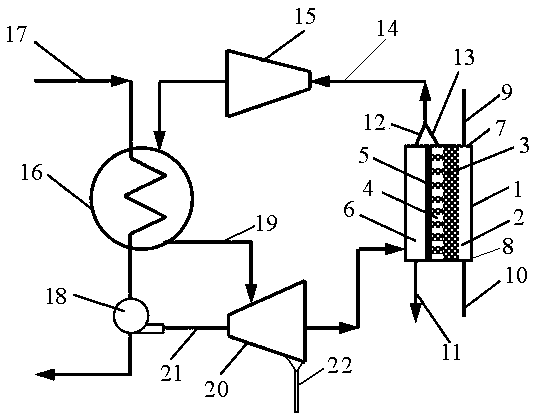

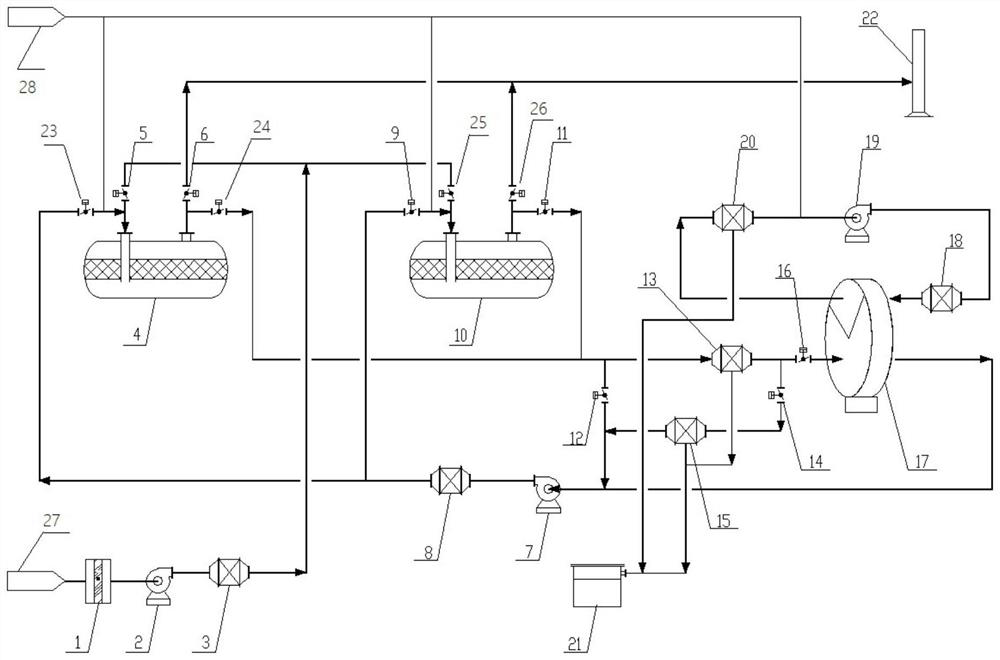

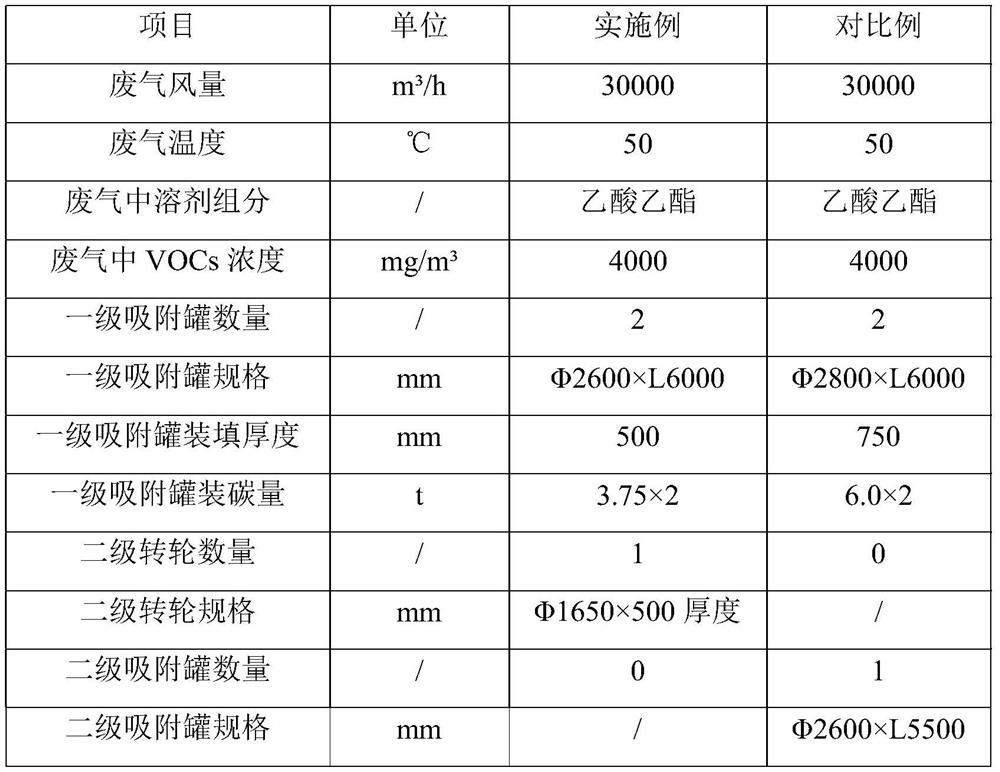

ActiveCN111318128BShort switching cycleReduce loadGas treatmentDispersed particle separationProcess engineeringNitrogen gas

The invention provides a nitrogen regeneration adsorption recovery system and an adsorption recovery method thereof, belonging to the field of adsorption recovery. The system includes exhaust gas input equipment, primary adsorption equipment and secondary adsorption equipment connected in sequence, and also includes a nitrogen replacement pipeline and a primary circulating nitrogen desorption pipeline respectively connected to the primary adsorption equipment and the secondary adsorption equipment. with the secondary circulating nitrogen desorption pipeline; the primary circulating nitrogen desorption pipeline and the secondary circulating nitrogen desorption pipeline are respectively connected with the nitrogen replacement pipeline; the primary circulating nitrogen desorption pipeline and the secondary circulating nitrogen desorption pipeline The desorption gas condensing and recovery equipment is also provided on the first-stage circulating nitrogen desorption pipeline; the first-stage adsorption device includes at least two parallel adsorption tanks, and the second-stage adsorption device is an adsorption runner. By adopting the system and method of the present application, the specification of the adsorption device can be significantly reduced, the filling amount of the adsorbent material can be greatly reduced, the switching period can be greatly shortened, the safety is high, and the energy consumption can be reduced.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD

A seawater desalination device implanted in a wind power tower

ActiveCN104528854BAvoid heat lossRaise the evaporation temperatureGeneral water supply conservationSeawater treatmentWater desalinationThermal insulation

The invention relates to a sea water desalting plant implanted into a wind power tower, and belongs to the field of sea water desalination. The sea water desalting plant comprises an evaporator. A porous barrier partitions the evaporator into an upper steam cavity and a lower sea water cavity. The porous barrier is a hydrophilic thermal insulation porous medium, the inner pore diameter is that of a micrometer hole, and the upper side of the porous barrier is coated with a heat absorption coating. The steam cavity is sequentially connected with a condenser, a condensation tank and a fresh water tank through a pipe. One end of the sea water cavity is connected with a sea water pipe to be used for water inputting, and the other end of the sea water cavity is connected with a salt pipe to be used for water outputting. Heat exchange is conducted on the sea water pipe and the salt water pipe through a heat exchanger, and an outlet of the salt water pipe is connected with a piston type water pump to pump out salt water. The center of the porous barrier and the center of the condensation tank are 10 meters away from the sea level in height. By means of the sea water desalting plant, stable and long-time sea water desalting can be achieved without inputting external power and electricity, the thermal utilization efficiency is high, and an effective path is provided for emergency water for ocean working, help seeking and the like or large-scale water contributing.

Owner:深圳润德工程有限公司

Coal gas production method and device using high-temperature rich oxygen and high temperature steam as gasification agent

ActiveCN103525465BReduce loadIncrease concentrationCombustible gas productionFixed bedControl valves

The invention belongs to the technical field of chemical coal made gas, and particularly relates to a coal gas production method and device using high-temperature rich oxygen and high temperature steam as a gasification agent. The coal gas production method and device adopt oxygen-enriched air with the oxygen concentration of 25 ~ 30% and with the oxygen temperature of 120 ~ 220 DEG C and the high temperature steam with the temperature of 120 ~ 220 DEG C as the gasification agent for coal gas production; and accordingly, an oxygen-enriched air source and related a heat exchanger, a control valve and pipelines are additionally arranged in an original coal gas production device. The coal gas production method and device well overcome the technical defects of coal gas production by use of a traditional atmospheric-pressure fixed bed gas producer, increase the coal gas producer yield and the coal gas calorific value, reduce the carbon content of ash, and reduce sensible heat loss, and the coal gas unit consumption is reduced by 10 ~ 30%.

Owner:上海穗杉实业股份有限公司

W-type flame boiler combustion and pulverizing system

ActiveCN104061569BLarge emissionsReduce sensible heat lossFluidized bed combustionApparatus for fluidised bed combustionAir preheaterSlag

The invention discloses a W-shaped flame boiler combustion and pulverization system, which includes a furnace, a hot air pipe drawn from the outlet of an air preheater, a cold ash hopper arranged at the bottom of the furnace, a pulverized coal separator, and a pulverized coal separator. The device includes a powder return pipe. The system also includes a slag cooler and an air chamber installed at the bottom of the cold ash hopper. There are several powder feeding inlets on the front and rear walls of the cold ash hopper. There is an air distribution plate, on which bed material is loaded, the cold ash hopper is connected to the slag cooler through a hot slag pipe through the air distribution plate and the air chamber, and the hot air pipe is connected to the air inlet of the slag cooler , the air outlet of the slag cooler is connected to the air chamber through a hot air pipe, and the powder return pipe is connected to the powder feeding inlet to form a bubbling fluidized bed combustion. The invention couples the bubbling fluidized bed combustion technology and the slag cooler to the existing W flame boiler to further burn the slag, recover the waste heat of the slag, reduce the unit consumption of pulverizing and steel ball wear, and improve the combustion stability of the main combustion zone.

Owner:STATE GRID CORP OF CHINA +2

a closed thermal 2 Thermal insulation red coke crushing, screening and pre-storage method and device

ActiveCN104646100BReduce sensible heat lossAvoid explosionGasification processes detailsSpecial form destructive distillationTemperature controlCombustion

The invention discloses a method and a device for crushing, screening and prestoring red coke in a closed hot N2 heat preservation condition, namely a method and a device developed for high-temperature pyrolysis of the red coke by directly employing pulverized coal. The method comprises the following steps: unloading a high-temperature pyrolysis product, namely the red coke of the pulverized coal at 950-1050 DEG C in 0.1MPa in the hot N2 heat preservation condition into a red coke hopper from a red coke tank; uniformly conveying to a crusher for crushing through a feeding machine; regulating, screening and then conveying to an afterheat recovery temperature-control red coke product cabin for prestoring; conveying into a fluidized bed and a mobile bed red coke boiler for combusting and / or a fluidized bed or a fixed bed red coke gasifier for gasifying through a red coke material cup at 350-850 DEG C; and removing dust through a dust remover, and introducing tail gas into a hot N2 heat preservation circulating system. The method and the device disclosed by the invention can meet the requirements of the red coke combustion boiler and / or the red coke gasifier on particle size in the method for the high-temperature pyrolysis of the red coke by directly employing the pulverized coal; the sensible heat loss of the red coke is reduced; the explosion caused by over-high dust concentration is effectively prevented; the dust pollution is solved from the source; and the environment benefits are obviously significant.

Owner:太原理工大学建筑设计研究院有限公司 +1

Mixed-flow moving bed high-temperature gas filtration and purification device and method

ActiveCN105331394BOverall uniform cross-street areaImprove filtration efficiencyDispersed particle filtrationGas purification with selectively adsorptive solidsMixed flowProcess engineering

The invention discloses a mixed-flow type moving bed high-temperature gas filtering and purifying device and a method. The device comprises an inner body shell and an outer body shell. A first chamber is formed in the inner body shell, a raw gas inlet is formed in the inner body shell, and the first chamber is communicated with a raw gas conveying pipeline through the raw gas inlet. The inner body shell is sleeved with the outer body shell to form an inner body cavity, the inner body cavity is filled with a filter material layer, the first chamber is communicated with the inner body cavity through the raw gas inlet formed in the inner body shell to form a raw gas even distributing channel, a purified gas outlet is formed in the position, away from the raw gas inlet, of the outer body shell, and the inner body cavity is communicated with a purified gas conveying pipeline through the purified gas outlet to form a purified gas even distributing channel. The device and the method have the advantages that the gas filtering efficiency is high; operating cost is low; the sensible heat loss of hot gas is small; operating is continuous, and the filtering effect is good; during feeding, purified gas is not leaked.

Owner:舒瑞 +1

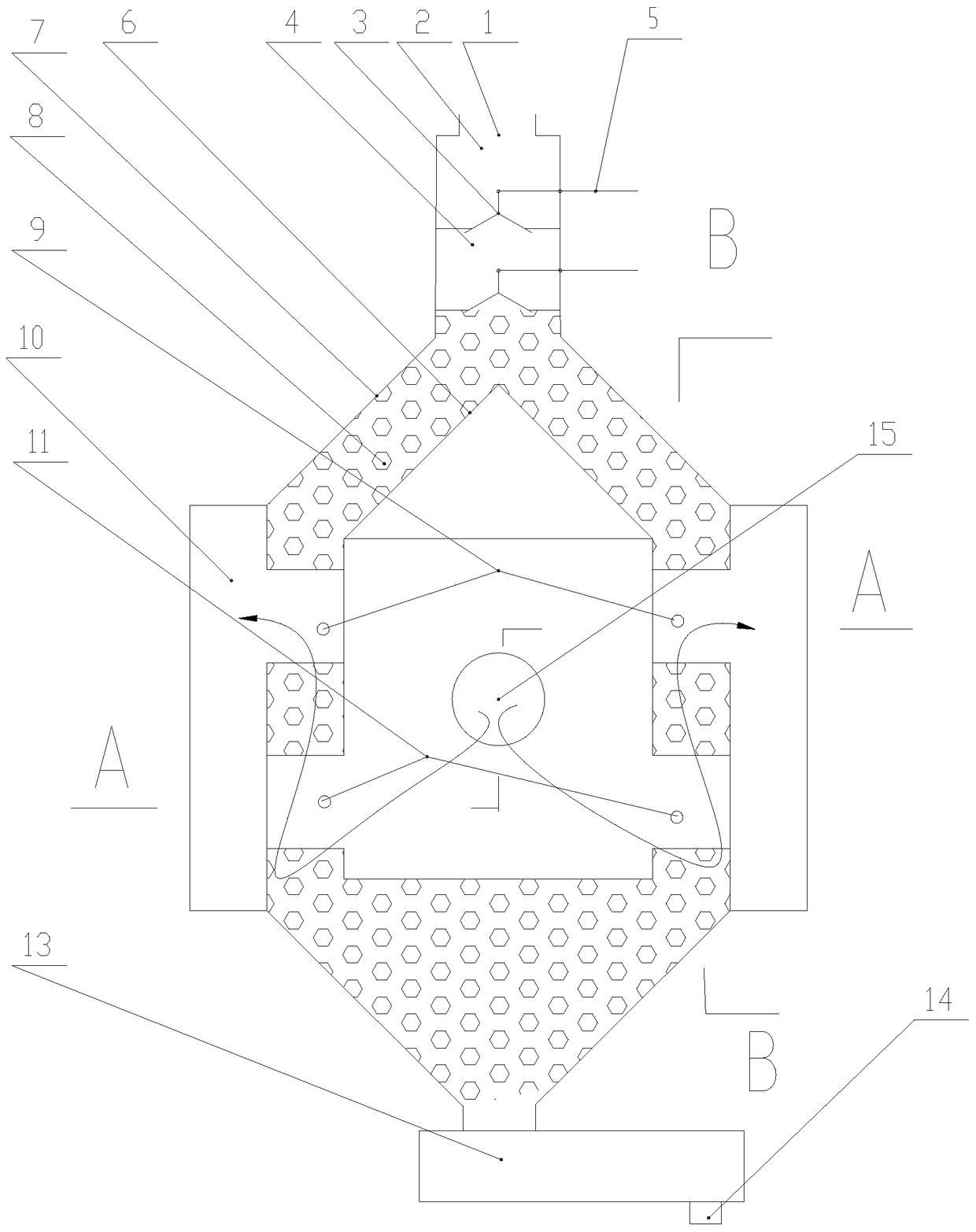

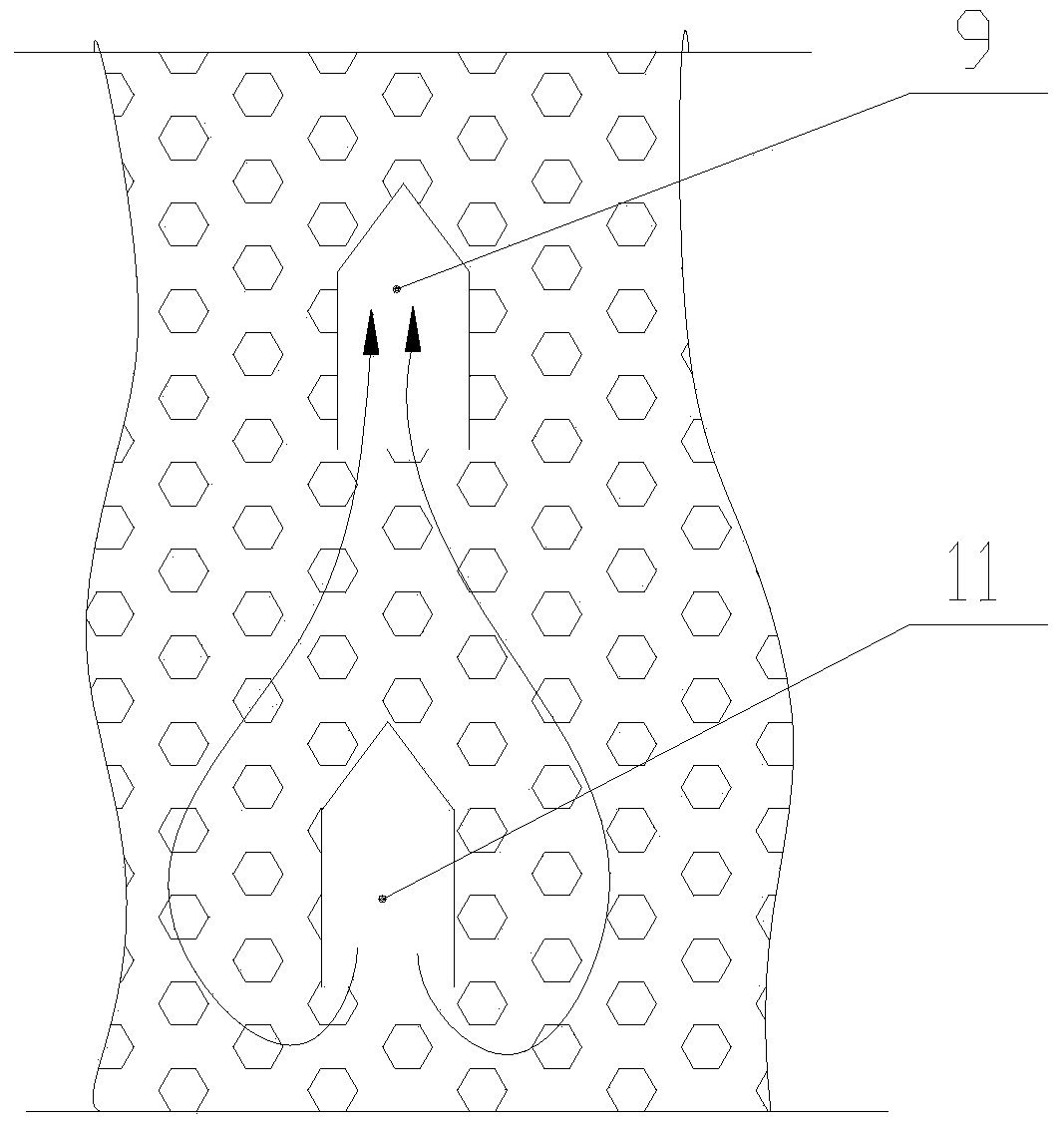

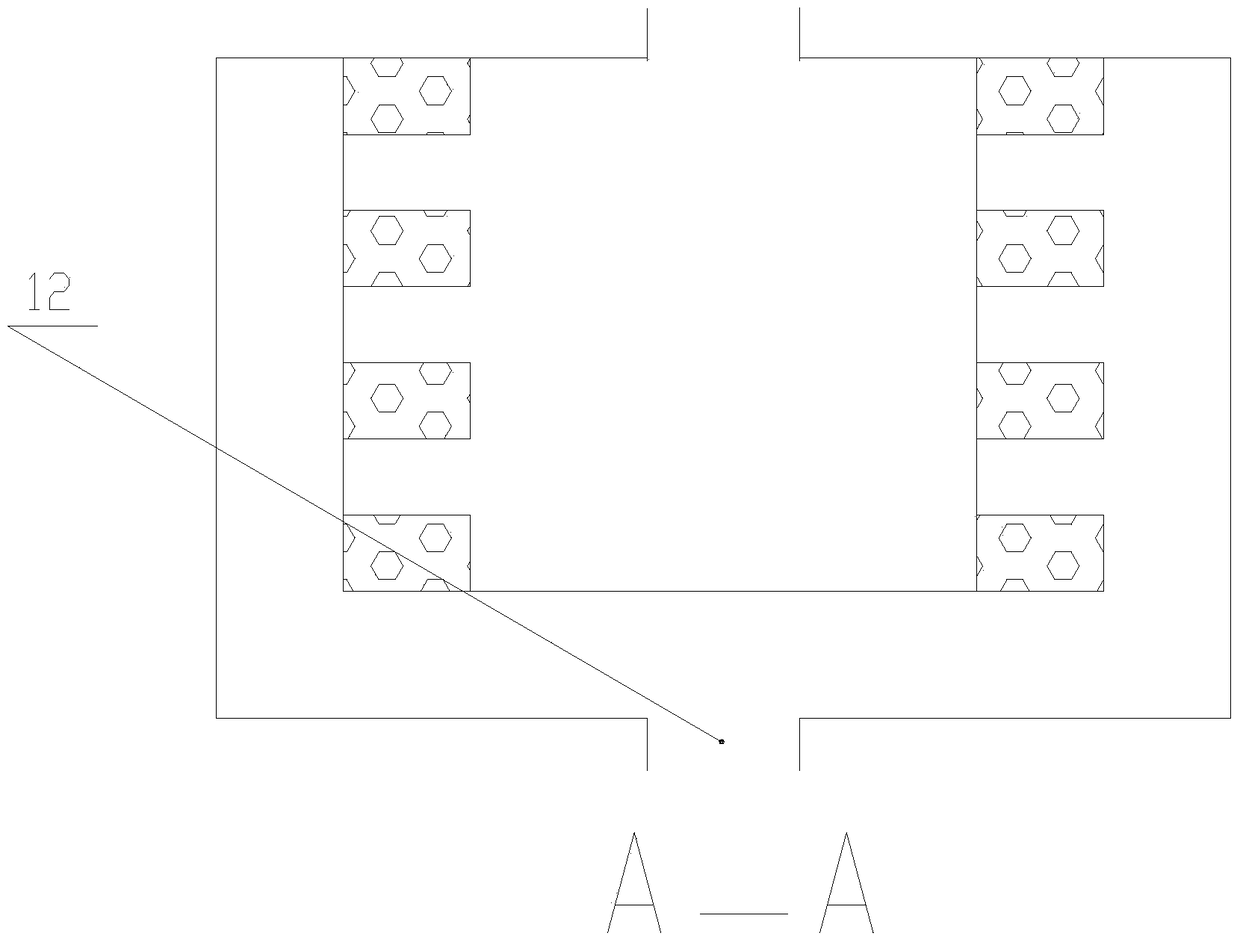

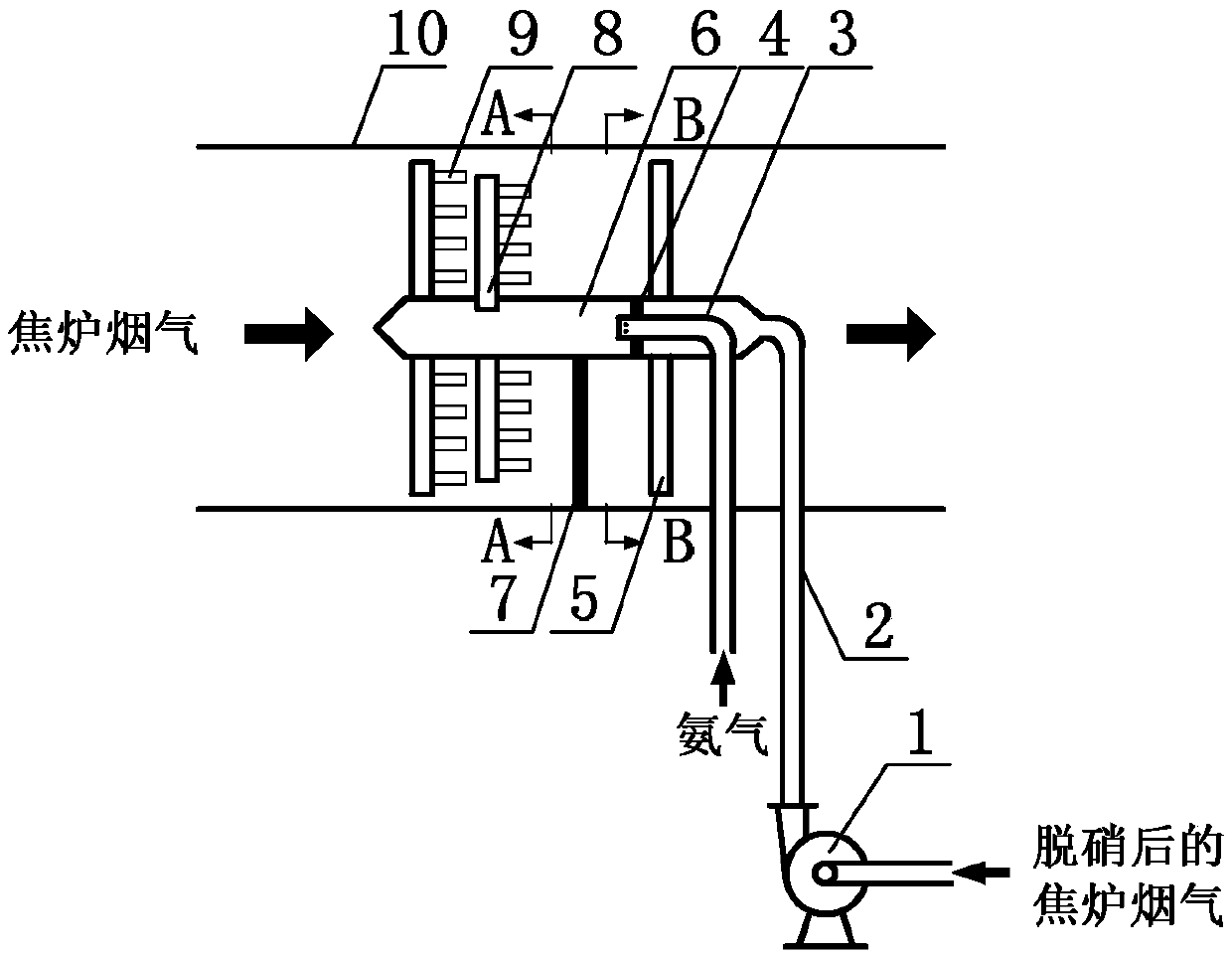

A petal-shaped ammonia injection device for coke oven flue gas denitrification

ActiveCN106390708BFlexible control of ammonia injection volumeReduce sensible heat lossGas treatmentDispersed particle separationFlue gasPetal

The invention discloses a petal-shaped ammonia spray device used for coke oven flue gas denitration. The device comprises a circulating fan, a flue gas feeding tube, an ammonia gas feeding tube, a spiral flow plate, a flow disturbing member, a mixer, a tube holder, secondary ammonia spraying tubes, primary ammonia spraying tubes and a flue. Denitrated flue gas goes through the circulating fan and enters the mixer together with ammonia gas, the denitrated flue gas and the ammonia gas are fully mixed in a spiral flow entrainment manner, the obtained mixture sequentially goes through two layers of the primary ammonia spraying tubes and the secondary ammonia spraying tubes to form micro-scale rapid jet flow, the micro-scale rapid jet flow interacts with mainstream coke oven flue gas, and the micro-scale rapid jet flow and the mainstream coke oven flue gas go through the annular flow disturbing member and then are further fully mixed. The denitrated coke oven flue gas goes through the built-in spiral flow mixer and dilutes ammonia gas, and micro-scale rapid crossbar jet flow is fully mixed with the mainstream flue gas, so the device has the advantages of compact system, high efficiency energy saving and accurate ammonia control.

Owner:SOUTHEAST UNIV

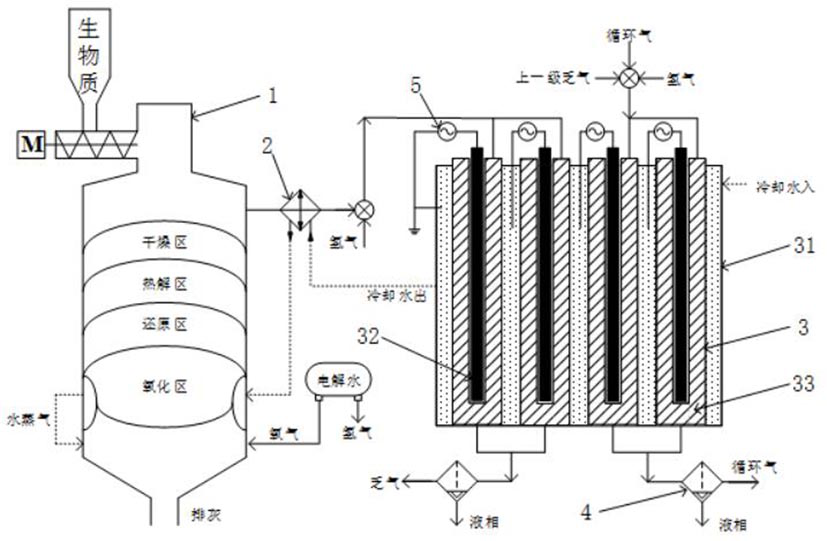

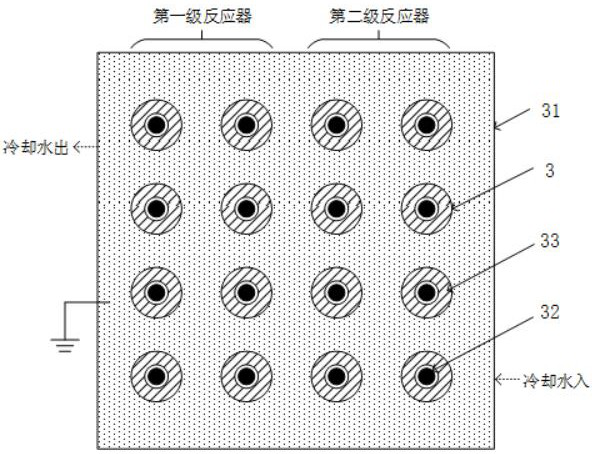

Device and method for preparing fuel through biomass gasification

InactiveCN112322354AEasy to implement distributed utilizationEasily brokenBiofuelsGasification processes detailsSyngasFluid phase

The invention discloses a device and method for preparing fuel through biomass gasification, and the device comprises a gasification furnace which is provided with a biomass inlet, a water vapor inlet, an oxygen inlet and a crude synthesis gas outlet, and biomass reacts with oxygen and water vapor in the gasification furnace to generate crude synthesis gas, the dielectric barrier discharge reactoris provided with a first-stage liquid-phase synthesis reactor, and the first-stage liquid-phase synthesis reactor is used for reacting the crude synthesis gas generated by the gasification furnace togenerate gas fuel. The dielectric barrier discharge reactor is also provided with a secondary liquid-phase synthesis reactor, and the secondary liquid-phase synthesis reactor is used for reacting theexhaust gas generated by the primary liquid-phase synthesis reactor to generate gas fuel. The device disclosed by the invention is simple, does not need a complex synthesis gas purification system, and is easier to realize distributed utilization of biomass, all components of the biomass gasified gas can be utilized, a carbon dioxide removal reaction is not needed, the energy consumption of the device is reduced, and the utilization rate of a carbon element is improved.

Owner:SOUTHEAST UNIV

A compressed steam capillary drive seawater desalination system

InactiveCN105439224BAvoid heat lossReduce churnGeneral water supply conservationSeawater treatmentWater desalinationSaline water

Owner:RUNHAI ENERGY TECH INC JIANGSU

Adsorption recovery system for nitrogen regeneration and adsorption recovery method thereof

ActiveCN111318128AShort switching cycleReduce loadGas treatmentDispersed particle separationPhysical chemistryNitrogen gas

The invention provides an adsorption recovery system for nitrogen regeneration and an adsorption recovery method thereof, which belong to the field of adsorption recovery. The system comprises waste gas input equipment, primary adsorption equipment and secondary adsorption equipment which are connected in sequence, and further comprises a nitrogen replacement pipeline, and a primary circulating nitrogen desorption pipeline and a secondary circulating nitrogen desorption pipeline which are connected with the primary adsorption equipment and the secondary adsorption equipment respectively, the primary circulating nitrogen desorption pipeline and the secondary circulating nitrogen desorption pipeline are respectively communicated with the nitrogen replacement pipeline; desorption gas condensation recovery equipment is arranged on each of the primary circulating nitrogen desorption pipeline and the secondary circulating nitrogen desorption pipeline; wherein the primary adsorption equipmentcomprises at least two adsorption tanks which are connected in parallel, and the secondary adsorption equipment is an adsorption rotating wheel. By adopting the system and the method provided by theinvention, the specification of the adsorption device can be obviously reduced, the filling amount of the adsorption material is greatly reduced, the switching period is greatly shortened, the safetyis high, and the energy consumption is reduced.

Owner:QINGDAO HSJ ENVIRONMENTAL PROTECTION TECH CO LTD

Fixed bed gasifier, production system and production method thereof

InactiveCN113416580AIncrease heightGreat tasteChemical industryCombustible gas productionProcess engineeringEnvironmental geology

The invention provides a fixed bed gasifier, a production system and a production method thereof, and relates to the technical field of coal gas manufacturing equipment. The fixed bed gasifier provided by the invention comprises a furnace body with a feed inlet, a feeding mechanism connected with the furnace body, a fire grate mechanism horizontally and rotatably arranged in the furnace body and a transmission device for driving the fire grate mechanism to rotate. The gasifier has the advantages of efficient and energy-saving structure, convenient transportation and installation, reasonable height-diameter ratio, helps to increase the height of a material layer, not only reduces the sensible heat loss, but also improves the steam taste. The invention further provides a production system which comprises the fixed bed gasifier and other auxiliary purification equipment. The discharge amount of dust, suspended solids and steam in the coal gas is reduced, so that the temperature of a coal gas outlet is very low, and the subsequent coal gas treatment pressure is reduced. The invention also provides a production method for producing coal gas by using the production system, so that the effective gas in the coal gas can reach more than 90%, the steam decomposition rate reaches more than 85%, the residual carbon content is about 2%, and the gasification intensity reaches more than 2000m <3> / m<2>.h.

Owner:陈松涛

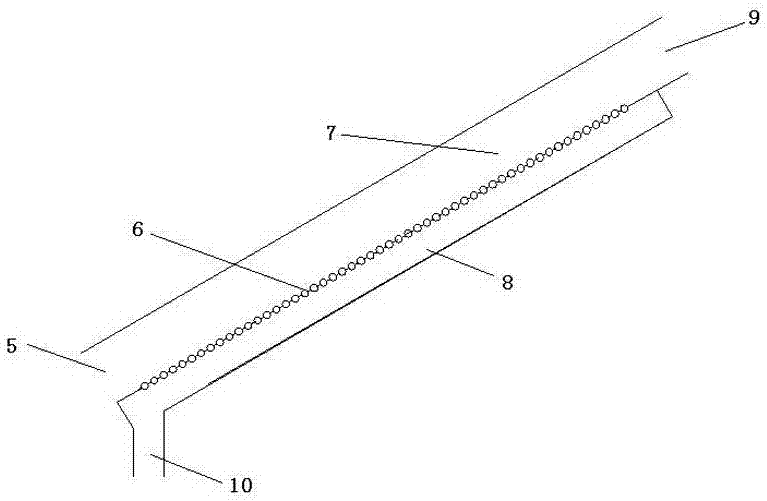

High-temperature solid conveyor device

PendingCN107973087AReduce sensible heat lossReduce energy lossSievingConveyorsThermal insulationSolid particle

The invention provides a high-temperature solid conveyor device comprising a feeding machine, an insulation conveyor chute, a powder bin and a high-temperature solid bin. High-temperature solid particles are screened through a material conveying plate in the insulation conveyor chute, and the solids therein enter the high-temperature solid bin; the powder enters the powder bin through a powder outlet; not only the classification and removal treatment of the power can be achieved in the material conveying process, and the power is prevented from entering a calcium carbide furnace, thereby affecting the operation of the calcium carbide furnace, but also the conveyor device has a thermal insulation function, and the sensible heat loss of the high-temperature solids is reduced; and the energyconsumption in the calcium carbide production process and the carbon emission are reduced.

Owner:SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com