Device and method for preparing fuel through biomass gasification

A biomass and fuel technology, applied in the direction of biofuel, fuel, gasification process, etc., can solve the problems of tar pollution, difficult conversion of carbon dioxide, etc., achieve high utilization rate, reduce pretreatment cost, and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be further explained below.

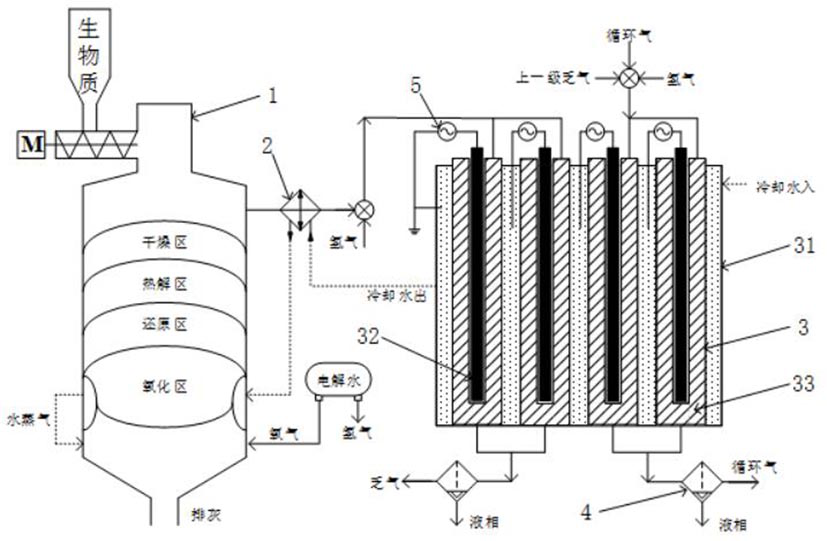

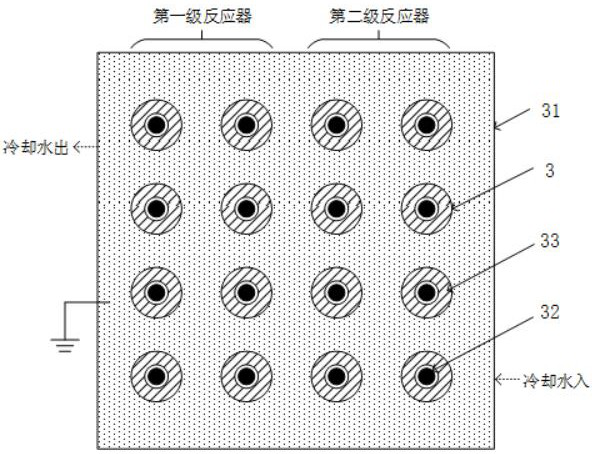

[0032] The present invention couples biomass gasification and synthesis gas to prepare liquid fuel, and its main purpose is to solve the problem that the traditional process system is too complex to realize industrialization, crude synthesis gas purification will produce a large amount of black liquor, and carbon dioxide removal will reduce the utilization rate of carbon elements, etc. question. Through the coupling of the water-cooled dielectric barrier discharge reactor and the updraft fixed-bed gasifier, the direct liquid-phase synthesis of biomass gasification gas and the utilization of all components can be realized. In the discharge reactor, high-energy electrons can directly break up tar molecules. , to reduce its poisonous effect on the synthesis catalyst; the discharge reactor adopts a water-cooled ground electrode, which can not only control the synthesis temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com