a closed thermal 2 Thermal insulation red coke crushing, screening and pre-storage method and device

A closed, red coke technology, used in coke ovens, special forms of dry distillation, gasification processes, etc., can solve the problems of gasification raw material particle size and temperature and environmental pollution, achieve simple purification process and sewage treatment, and avoid environmental pollution. , the effect of low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

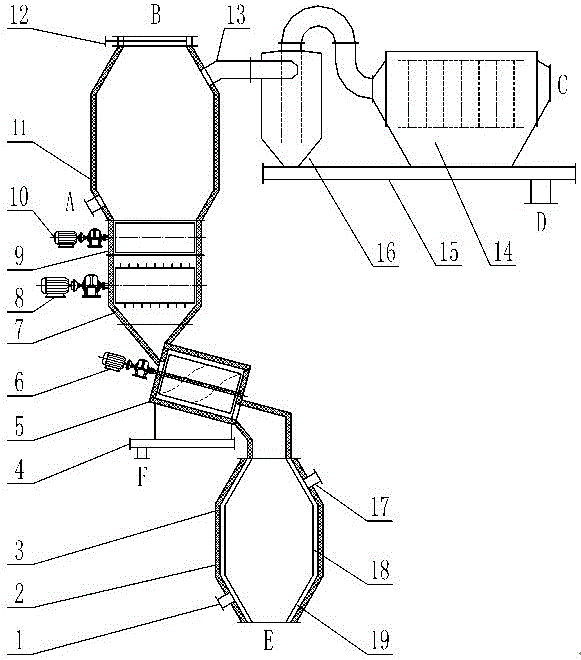

[0028] Implement a closed thermal N 2The thermal insulation red coke crushing, screening and pre-storage method, this method is to unload the red coke, the high-temperature pyrolysis product of pulverized coal at 950°C to 1050°C, from the red coke tank into the red coke silo 11, and then use the drum feeder 9 to discharge the red coke The coke is evenly sent to the red coke roller crusher 7 for crushing, and then enters the roller coke grain adjusting and sieving machine 5 to be screened, and then sent to the waste heat recovery and temperature-controlled red coke finished product warehouse 2 for pre-storage, and is processed by red coke at a temperature of 350°C to 850°C. The coke material cup is sent to the fluidized bed and moving bed red coke boiler for combustion and / or the fluidized bed and fixed bed red coke gasifier for gasification. Entire closed heat N 2 When the thermal insulation red coke crushing, screening and pre-storage device is connected to the method of dir...

specific Embodiment approach 2

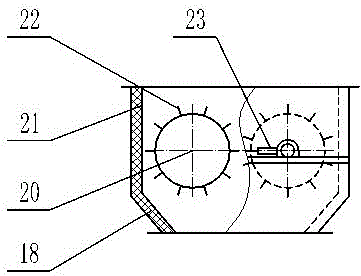

[0029] Such as figure 1 shown: implementing a closed thermal N 2 The device of thermal insulation red coke crushing, screening and pre-storage method, the device of the present invention is sequentially composed of red coke silo 11, drum feeder 9, red coke pair roller crusher 7, drum coke particle adjusting sieve machine 5 and waste heat recovery The temperature-controlled red coke finished product bin 2 is connected, and is provided with a primary cyclone dust collector 16 and a secondary electrostatic precipitator connected with 14 red coke bins 11 to form. Among them, the inner wall of the red coke silo 11, the drum feeder 9, the red coke roller crusher 7 and the drum coke particle adjusting screen 5 is fixed with a high temperature and wear-resistant lining plate, and the material of the lining plate is ZG3Cr7Si2. The space is filled with heat-insulating refractory materials to ensure that each equipment can operate normally at a temperature of <1050°C, and at the same ti...

Embodiment 1

[0038] In the method of directly using pulverized coal at high temperature to pyrolyze red coke, red coke is used in moving bed red coke combustion boilers and / or normal pressure, pressurized fixed bed red coke gasifiers

[0039] The red coke, the high-temperature pyrolysis product of pulverized coal, is unloaded into the red coke tank at a temperature of 950°C to 1050°C, and 2 It is transported to the upper part of the red coke silo under heat preservation, the outlet of the red coke tank is connected with the inlet of the red coke silo, the outlet valve of the red coke tank and the inlet valve of the red coke silo are opened at the same time, the red coke is unloaded into the red coke silo, and then the red coke is closed. Coke silo inlet valve, remove the red coke tank. The drum feeder rotates under the drive of the power device to send the red coke evenly into the red coke roller crusher. After the red coke is crushed, it becomes 7mm on the sieve are sent to the waste heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com