A compressed steam capillary drive seawater desalination system

A capillary and seawater technology, used in seawater treatment, general water supply conservation, water/sewage treatment, etc., to avoid heat loss - condensation heat loss, reduce sensible heat loss, and increase system output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

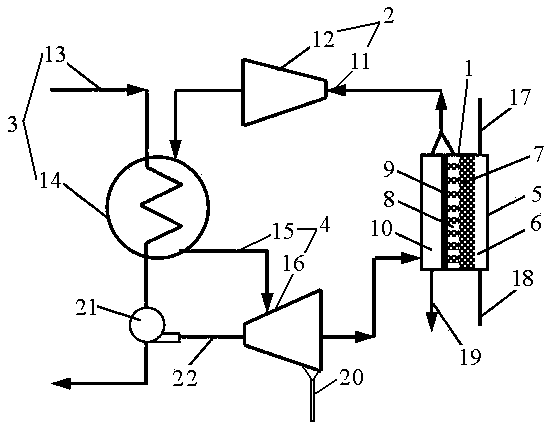

[0025] As shown in the figure, a pressure-vapor capillary-driven seawater desalination system is characterized in that it includes an evaporation-condensation module 1, a depressurization module 2, a heat exchange module 3 and a booster module 4, and the evaporation-condensation module 1 includes seawater desalination Evaporator 5, the seawater desalination evaporator 5 includes a seawater cavity 6, a porous medium 7, a desalination steam channel 8, a heat conduction plate 9 and a condensation cavity 10, the decompression module 3 includes a decompression pipeline 11 and an expansion valve 12, The heat exchange module 3 includes a heat exchange pipeline 13 and a heat exchanger 14, and the booster module 4 includes a booster pipeline 15 and a compressor 16;

[0026] The porous medium 7, the desalination steam channel 8 and the heat conducting plate 9 are sequentially arranged between the seawater cavity 6 and the condensation cavity 10, and the upper and lower ends of the seawat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com