Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Solve the problem of thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

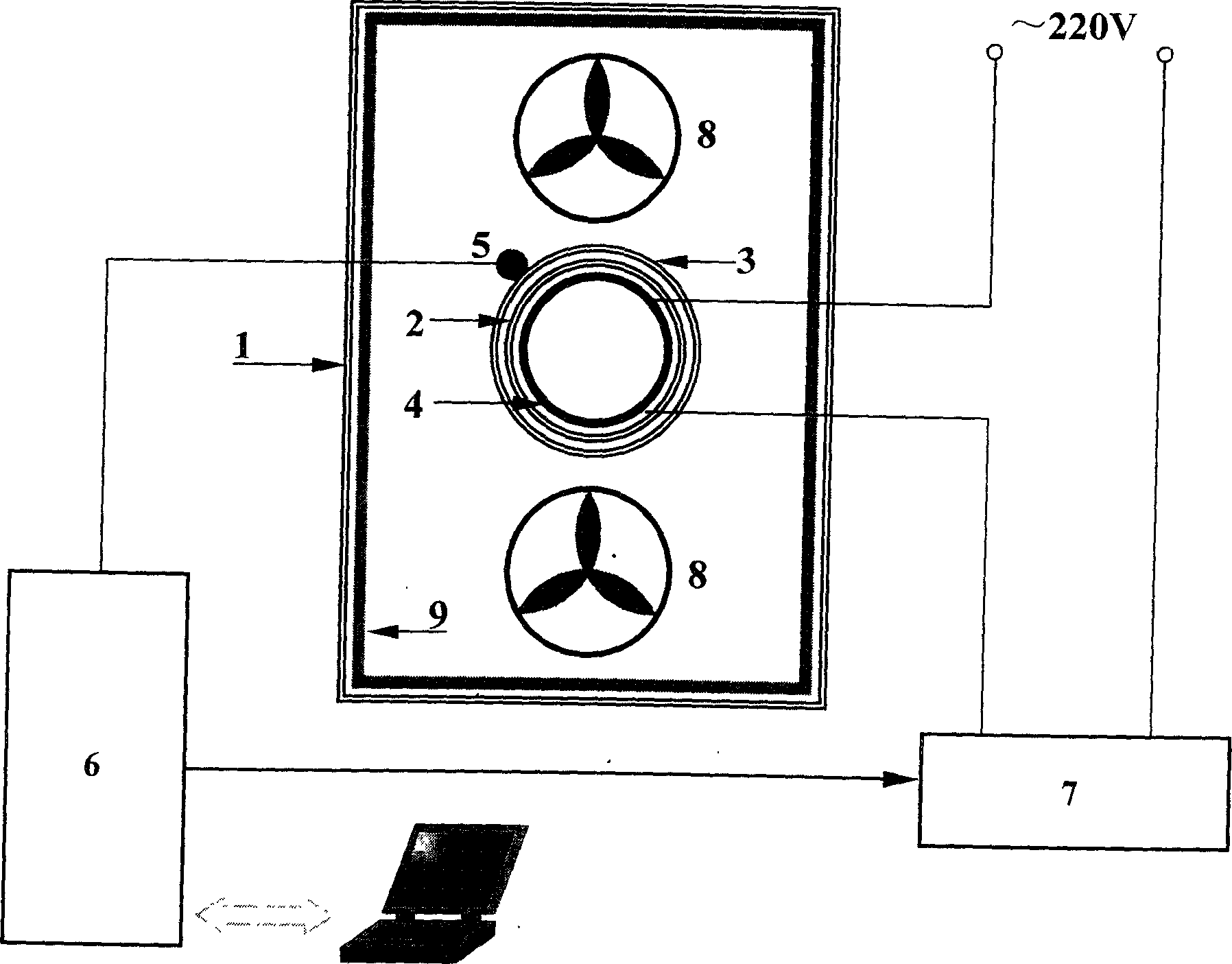

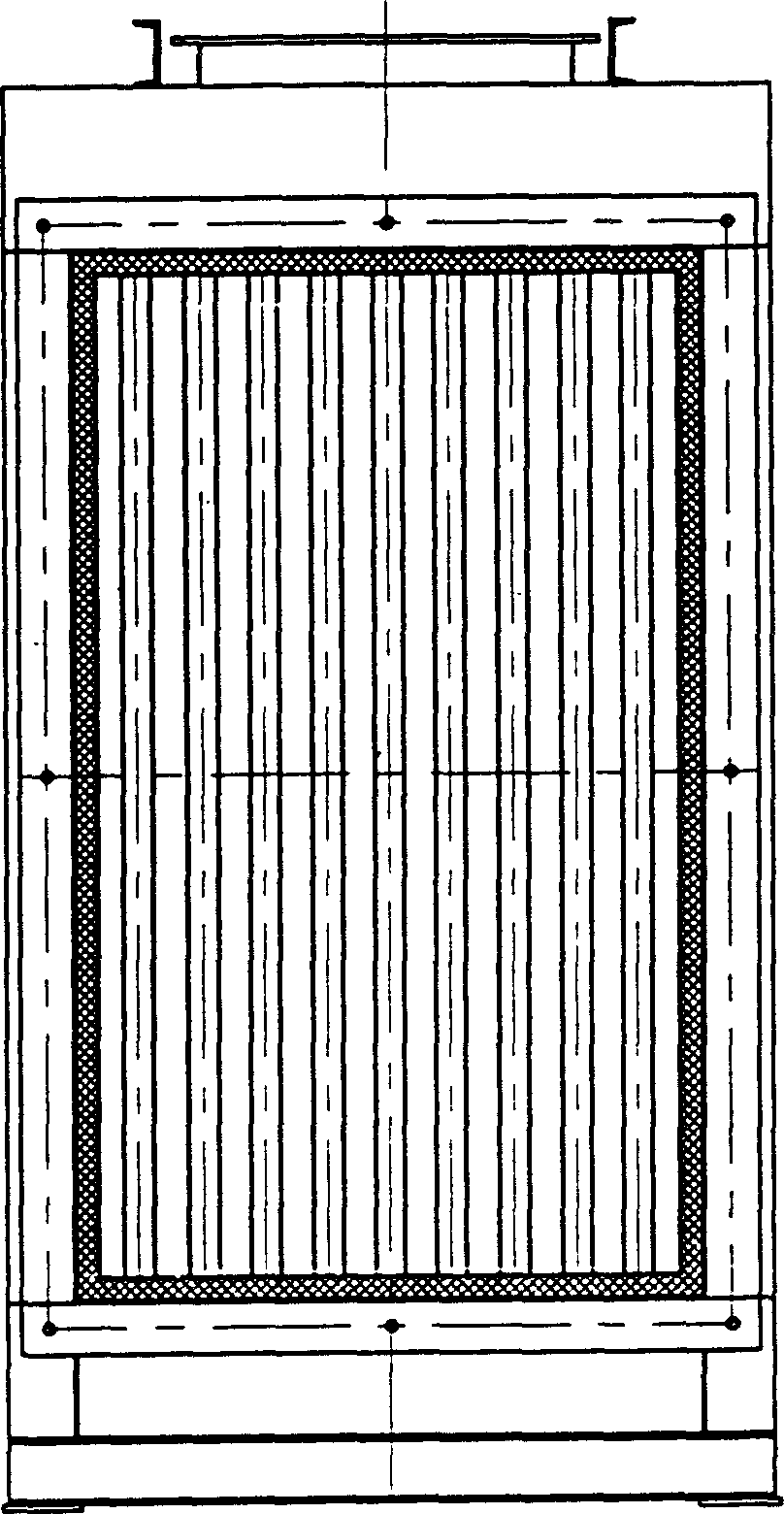

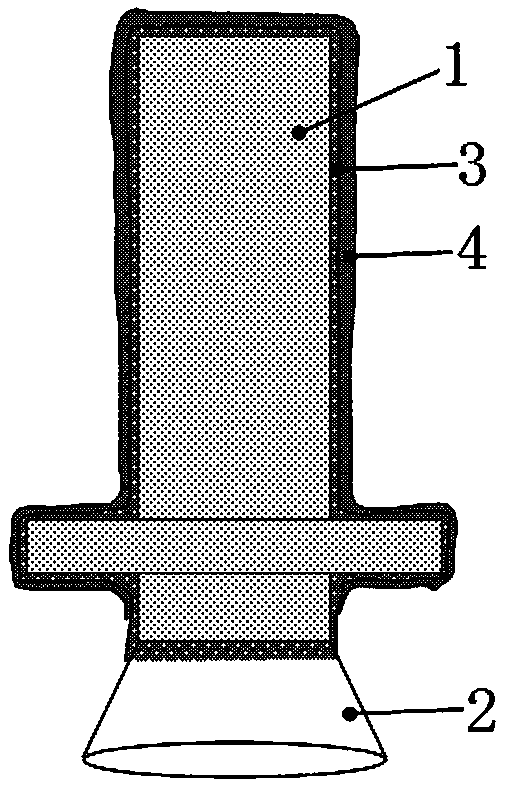

Minisize chromatographic column box with high precision temperature control system

InactiveCN1877319AImprove thermal conductivityImproved coefficient of thermal expansionComponent separationTemperatue controlTemperature controlControl system

The invention discloses a micro chromatographic column tank which comprises a tank body, capillary column heating frame set in the tank, capillary column bound around the frame, a heating device set on the inner wall of the frame, a precise thermo resistor and a temperature control system set out of the tank. The capillary column heating frame employs metal alloy material; the capillary column employs quartz material; the heating device is flexible electrical heating membrane coated on the inner wall of the frame; the temperature control system includes a temperature control module, the precise thermo resistor connects with the signal input terminal of the temperature control module, the output terminal of the temperature control module connects with the insulating single-phase alternative current modulator module of which one end of the output terminal connects with the heating device, and the other end of the output terminal connects with the input power.

Owner:张西咸 +3

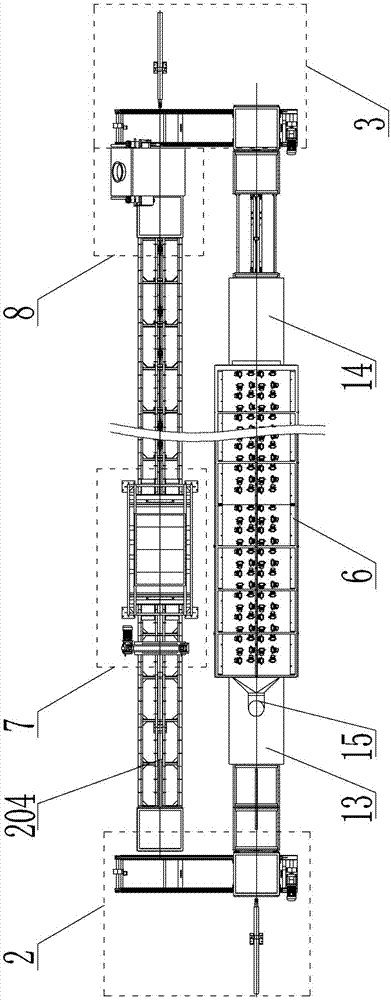

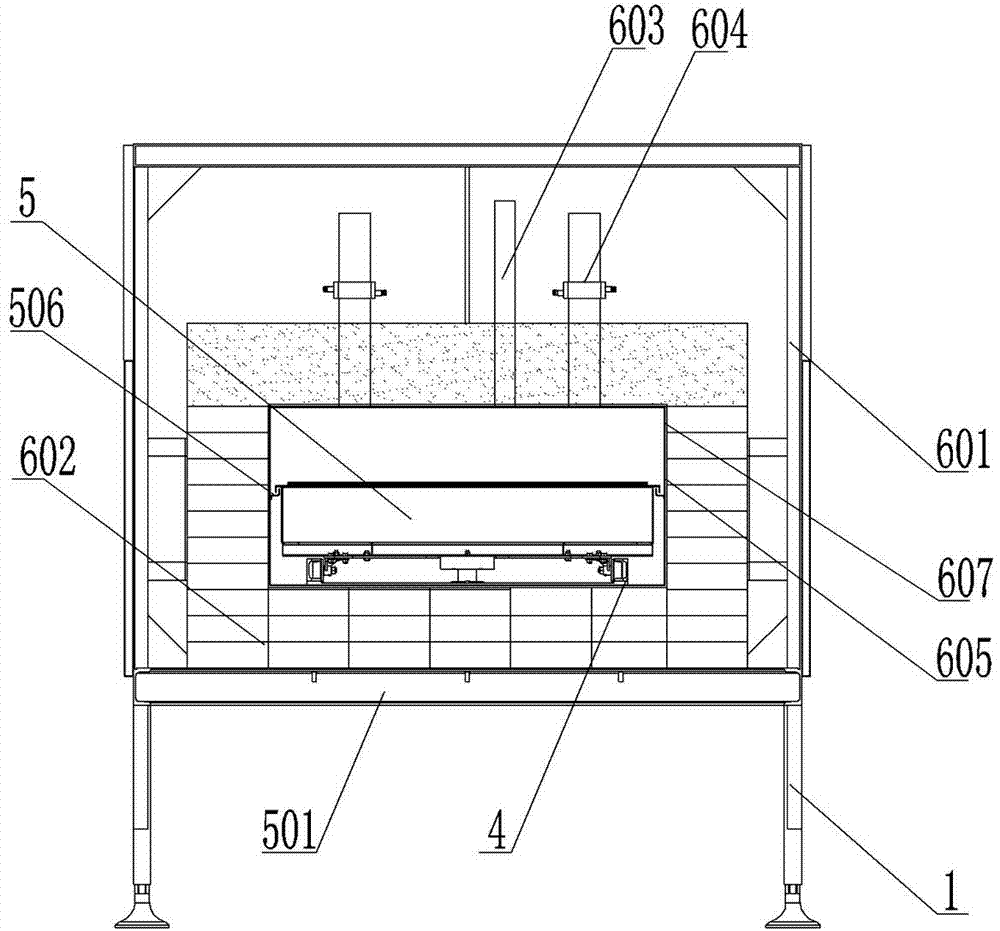

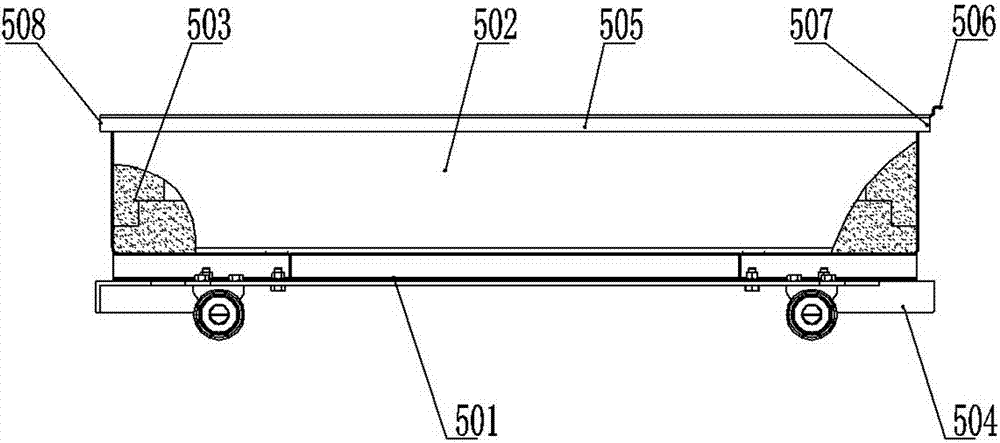

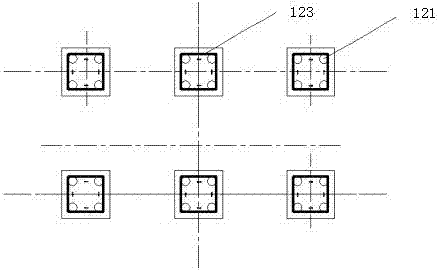

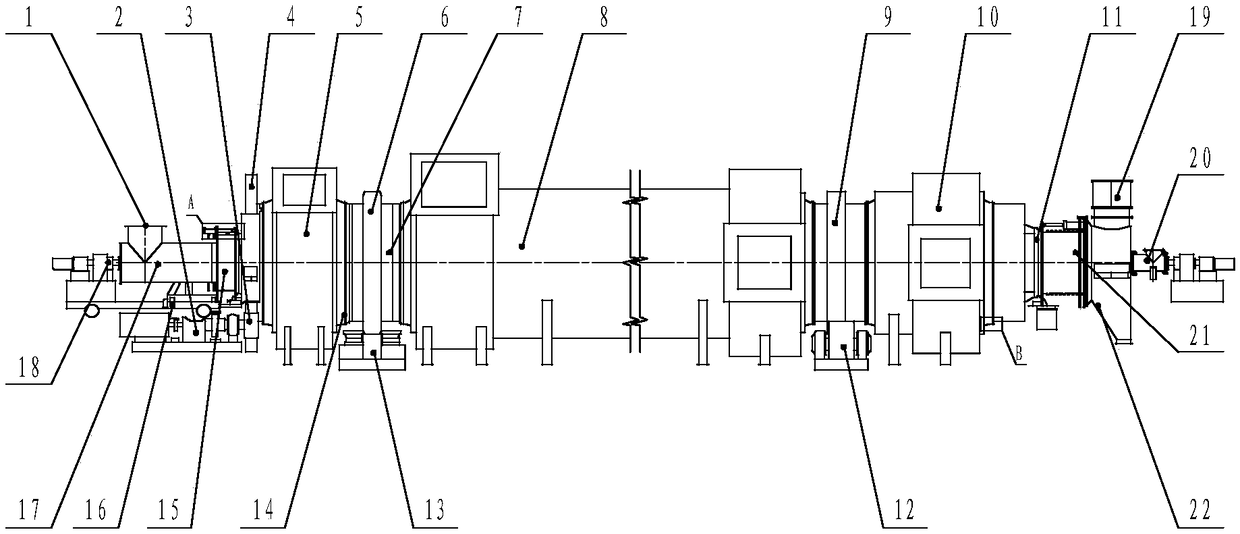

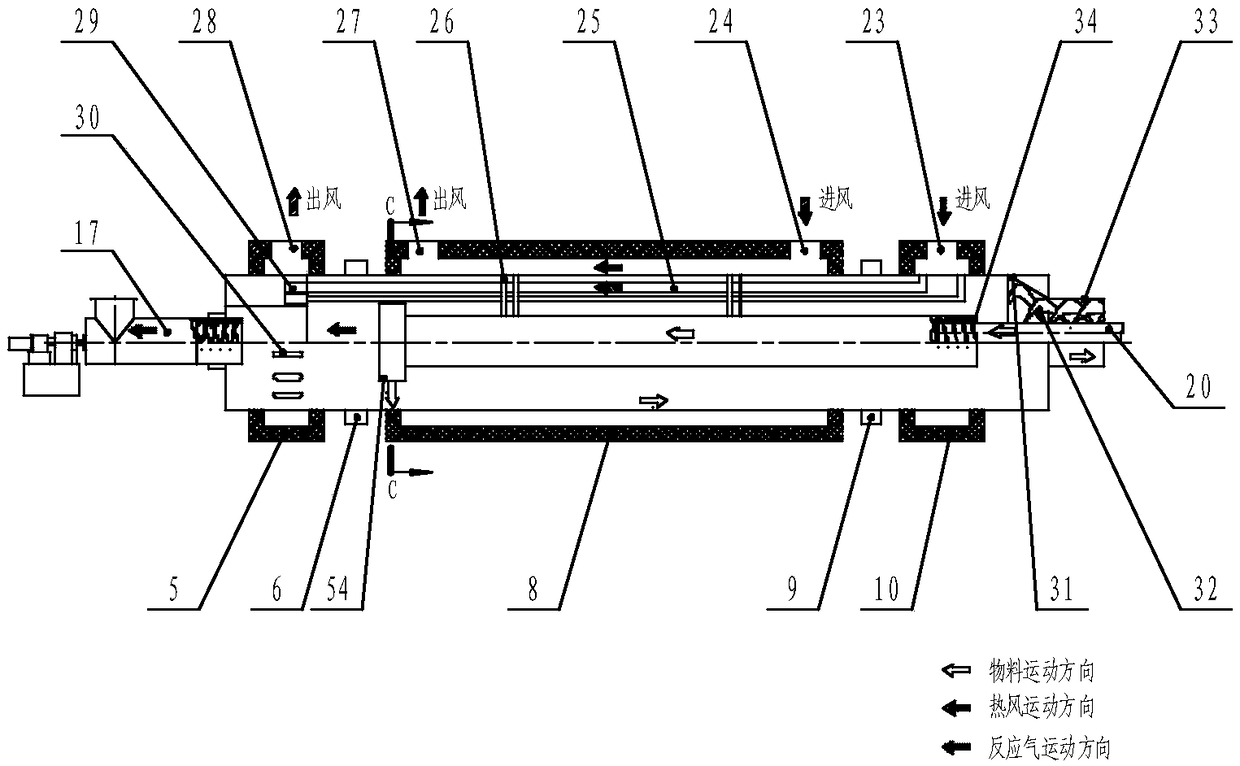

Microwave high-temperature continuous tunnel kiln

InactiveCN104501584AGuaranteed stabilityPrecise positioningFurnace typesTemperature measurementTunnel kiln

The invention relates to microwave high-temperature heating equipment, in particular to a microwave high-temperature continuous tunnel kiln. The microwave high-temperature continuous tunnel kiln comprises two bracketsarranged in parallel, an inlet-end turning device and an outlet-end turning devicewhich are arranged at the two end parts of the bracket structure respectively, kiln car traveling guide rails arranged on the brackets, a kiln car, a tunnel kiln body arranged on one bracket, a charging device and a discharging device which are arranged on another bracket, and a feeding hole inhibitor and a discharging hole inhibitor which are arranged at the two end parts of the tunnel kiln body, wherein the tunnel kiln body comprises a housing, a heat preservation layer arranged in the housing, a microwave resonance cavity body formed in the inner wall surface of the heat preservation layer, a temperature measurement device and a microwave source assembly. The microwave high-temperature continuous tunnel kiln has the advantages that the structure is compact, the automation level is high, the heating speed is high, the temperature difference of materials is low, automatic charging, discharging and heating are realized, the working environment is improved, the labor intensity is reduced, the working efficiency is improved, and the continuous material production is achieved.

Owner:HENAN BODA MICROWAVE EQUIP

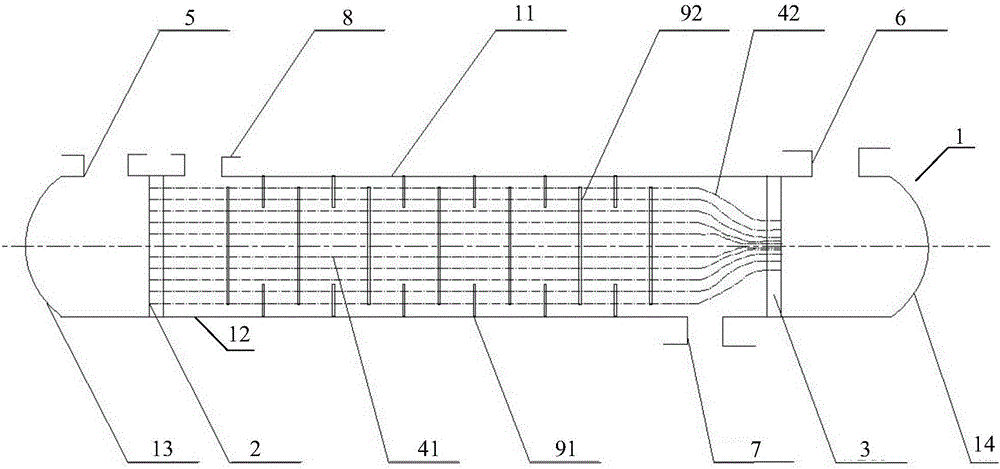

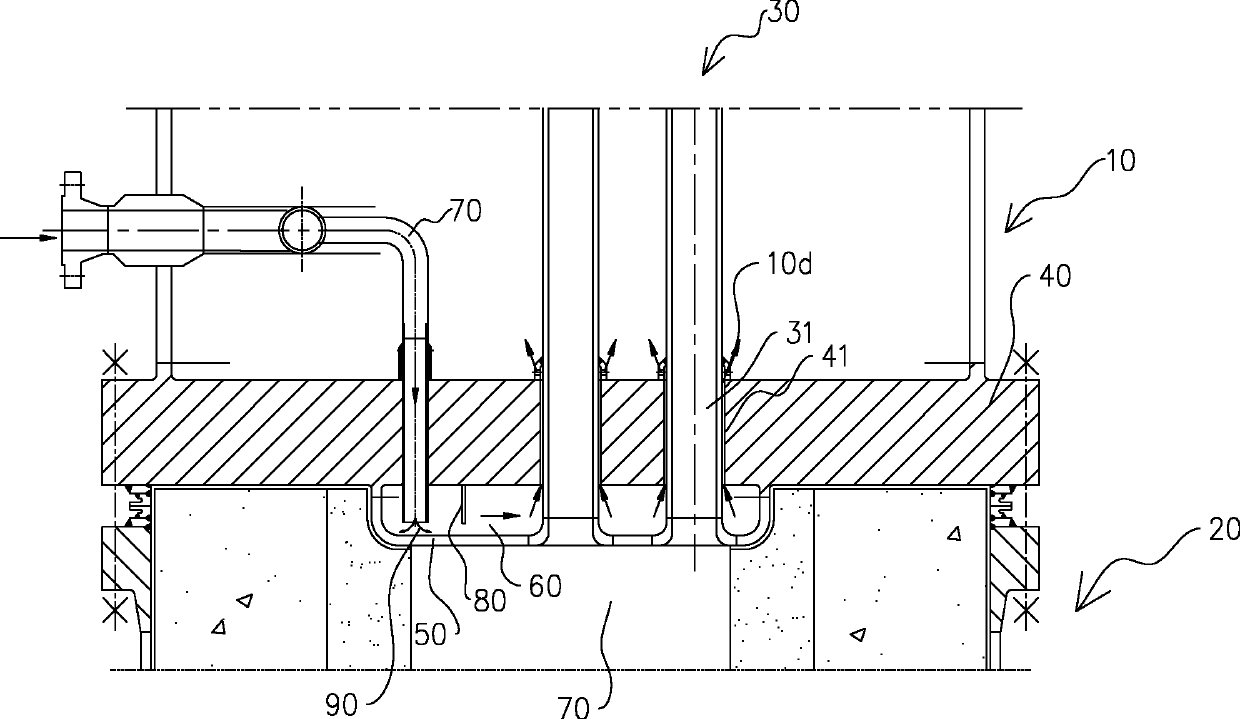

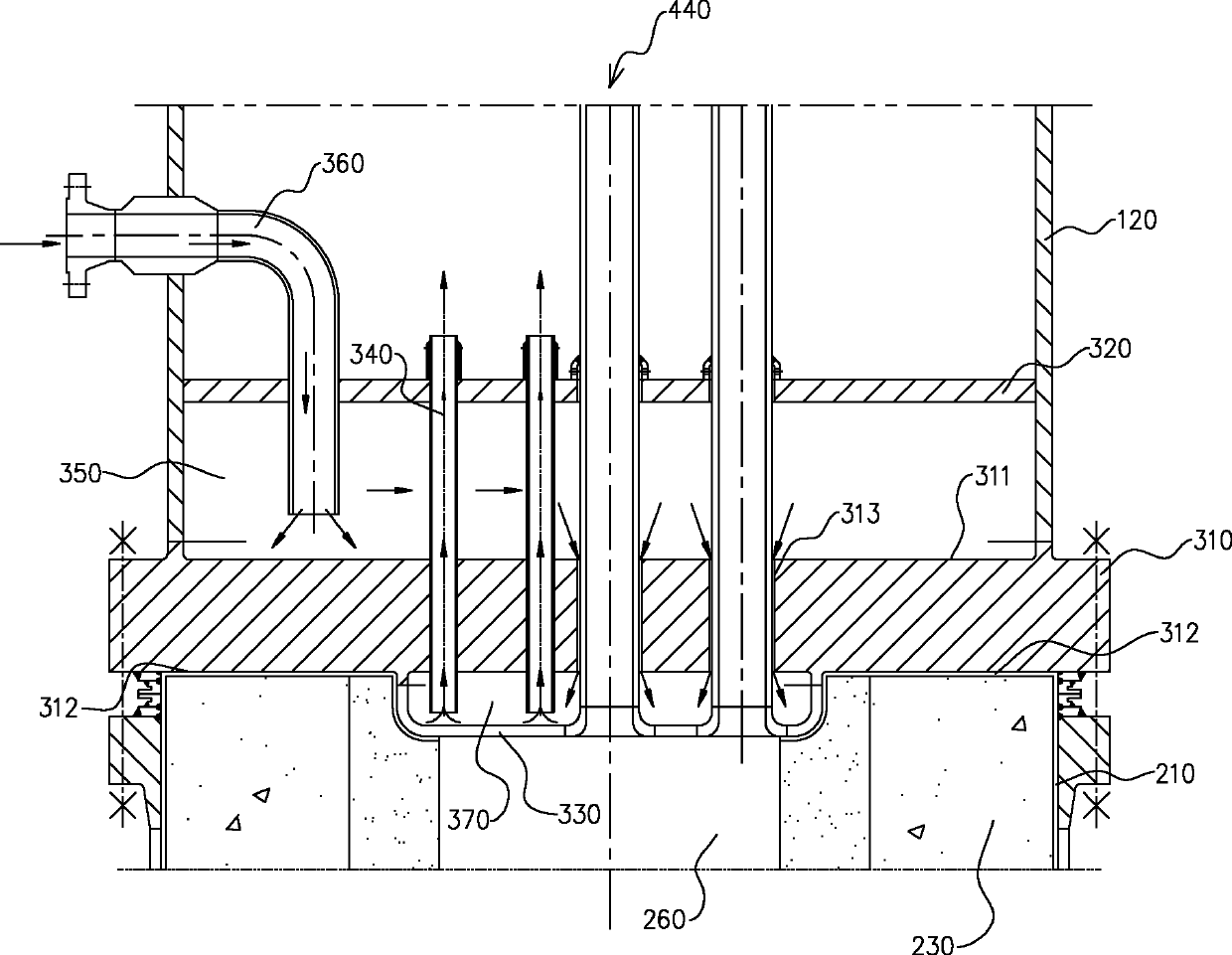

Energy-saving heating network heater

InactiveCN104864747AAvoid direct contactReduce the temperatureHeat exchanger casingsStationary tubular conduit assembliesEngineeringExpansion joint

The invention discloses an energy-saving heating network heater which belongs to heat exchangers. The structure of the energy-saving heating network heater comprises a housing, a front end channel, a back end channel and a pipe bundle. The upper portion and the lower portion of the housing are respectively provided with a steam cushioning jacket and a lyophobic storage jacket. A steam inlet pipe is arranged at the upper portion of the steam cushioning jacket; and a lyophobic outlet pipe is arranged at the lower portion of the lyophobic storage jacket. A scour-prevention plate is arranged at the lower portion of the steam inlet pipe. A split-ranging partitioning plate is arranged in the middle of the front end channel. The pipe bundle comprises a pipe plate, a support plate, a pull rod and heat-exchanging pipes. A plurality of heat-exchanging pipes is entirely distributed all over the pipe plate. An expansion joint is arranged between the housing and the back end channel. A steam stop plate is arranged inside the expansion joint. By entirely distributing the heat-exchanging pipes all over the pipe plate, the steam is prevented from directly contacting with the condensed water, and accordingly the heat-exchanging area is increased, the temperature of the condensed water is low, thereby saving the energy source. The energy-saving heating network heater is characterized in reducing the flow speed at the steam inlet, avoiding the damage to the equipment, reducing the operation noise, and being good in heat transfer effect, or the like.

Owner:SHANDONG GUOSHUN PRESSURE VESSEL

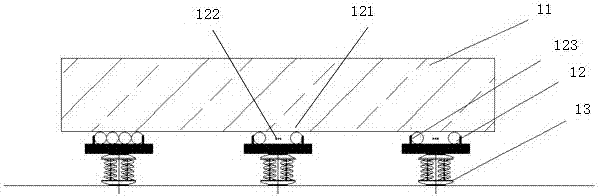

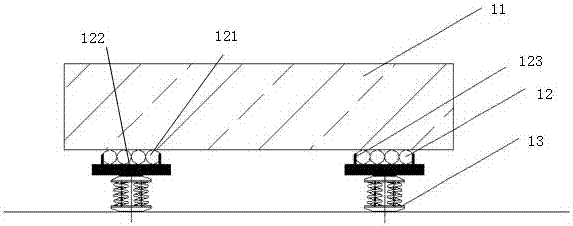

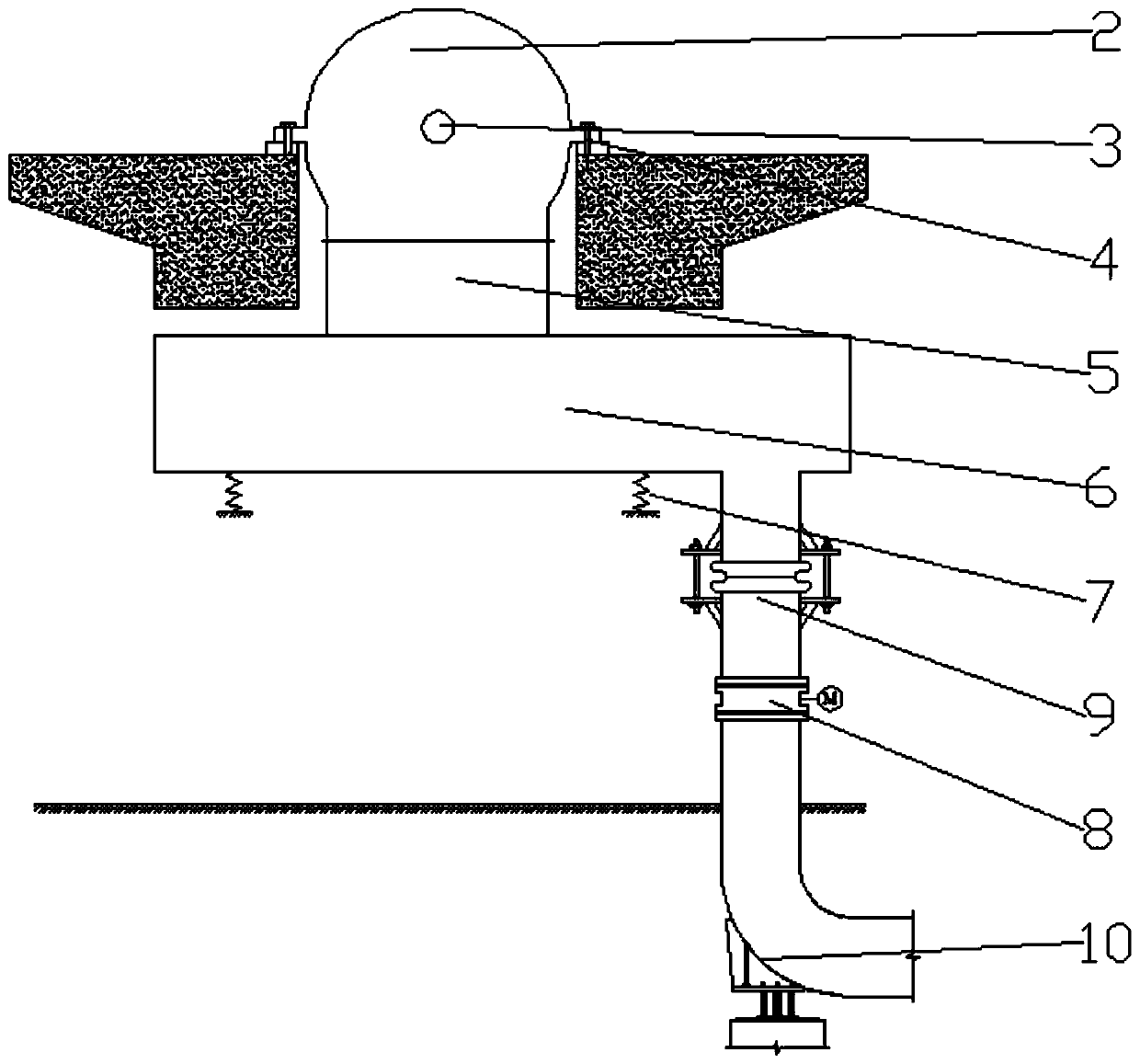

Support system of steam turbine generator unit

PendingCN106870030AReduce total pressure lossReduce heat lossMachines/enginesEngine componentsSupporting systemShortest distance

The invention discloses a support system of a steam turbine generator unit. The support system at least comprises a bedplate and a support seat, wherein the bedplate and the support seat are used for supporting the steam turbine generator unit, the support seat comprises a vibration isolation unit and a sliding unit which is located above the vibration isolation unit, the sliding unit comprises a sliding body bracket and a sliding body which is located on the bracket, the bedplate of the steam turbine generator unit is directly put on the sliding body, the sliding body bracket comprises a bottom plate and a side baffle which is perpendicular to the bottom plate and forms a sealed shape in a horizontal direction, the sliding body is located in the side baffle, and the vertical height of the sliding body is larger than the side baffle. The support system can bear the load of the steam turbine generator unit and absorb the vibration of the steam turbine generator unit and can also absorb thermal displacement in horizontal directions (X,Y) and a vertical direction (Z), the problems of thermal expansion and stress of a pipeline system for connecting a boiler with the steam turbine generator unit are solved, and the short-distance connection of the pipeline system between the boiler and the steam turbine generator unit is realized.

Owner:冯煜珵

Aluminum alloy pole material

InactiveCN103397226AAddress resource shortagesAvoid corrosionSingle bars/rods/wires/strips conductorsMetal/alloy conductorsHot meltUltimate tensile strength

The invention relates to an aluminum alloy pole material for producing electric wires and cables and belongs to the technical field of electric wires and cables. The aluminum alloy pole material comprises the following components in percentage by weight: 98.91%-99.2% of Al, 0.08%-0.1% of Si, 0.5%-0.6% of Fe, 0.2%-0.25% of Cu, 0%-0.05% of Mg, 0%-0.05% of Zn and 0.02%-0.04% of B, wherein Mg and Zn are not 0%, and the aluminum alloy pole material is prepared by adding Si, Fe, Cu, Mg, Zn and B in Al in a hot melt state in proportion. The aluminum alloy pole material provided by the invention overcomes the defects in the prior art that copper resources are in shortage and costly, and an aluminum alloy has low strength intensity and poor creep resistance. The aluminum alloy pole material has incomparable use advantages in the electric wire and cable industry.

Owner:ZHEJIANG KSAT CABLE

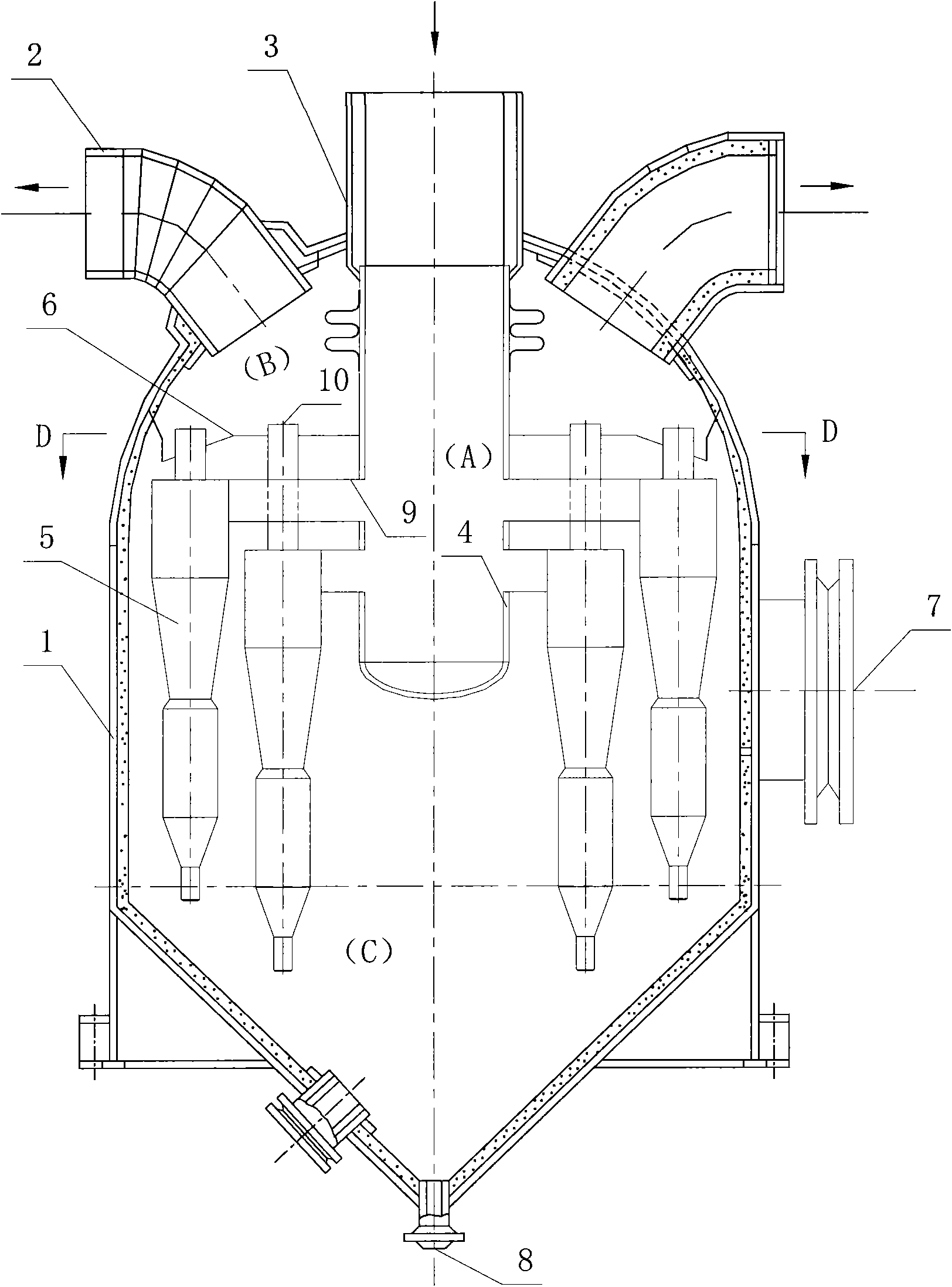

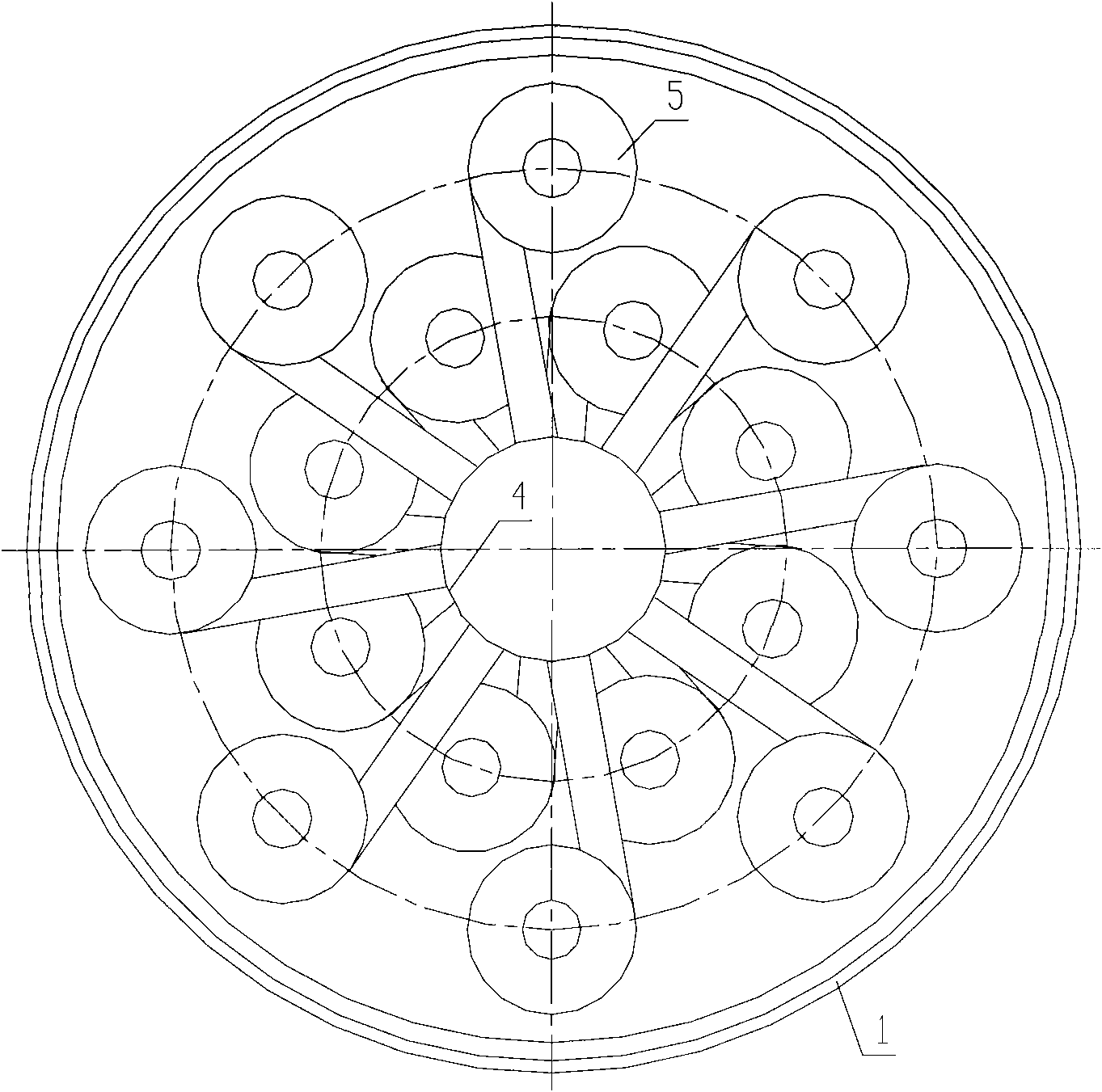

Third-level cyclone separator with large handling capacity

ActiveCN101590453AOptimize spaceReasonable arrangementReversed direction vortexPoint of entryEnergy recycling

The invention relates to a third-level cyclone separator with large handling capacity, which is mainly used in an energy recycling system of a catalytic cracking unit for refining petroleum for gas-solid separation. The separator comprise a housing, a smoke outlet, a smoke inlet, a center tube, a plurality of single cyclone separators, a hanging clapboard and the like, wherein, the internal part of the housing is divided into three relatively independent spaces of an air inlet chamber, an air collecting chamber and a dust collecting chamber; a plurality of single cyclone separators are arranged in the housing in a double-ring double-layer mode; a plurality of single cyclone separators are arranged and installed in the housing according to inner and outer rings and upper and lower layers; the arrangement ensures that each cyclone separator can keep optimum pressure balance and even distribution of air quantity so as to effectively ensure device operation stability and safe running in long period; in a plane space and vertical space which are as small as possible, the cyclone separators with large handling capacity and favorable performance are arranged as much as possible, which solves the problems of loading and thermal expansion and reduces equipment investment.

Owner:SINOPEC ENG

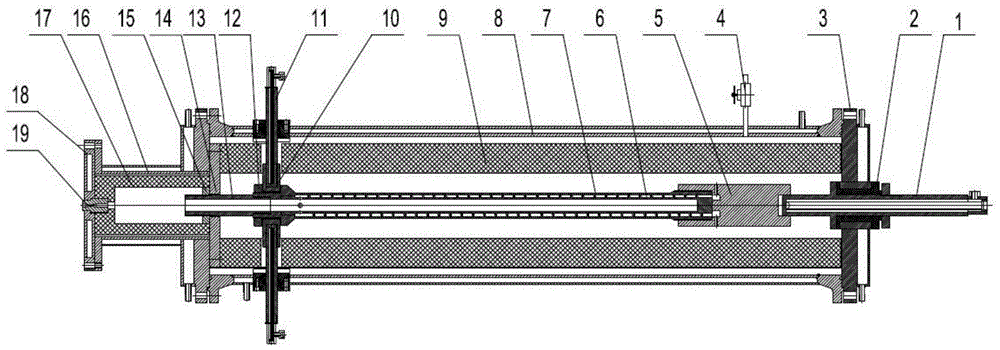

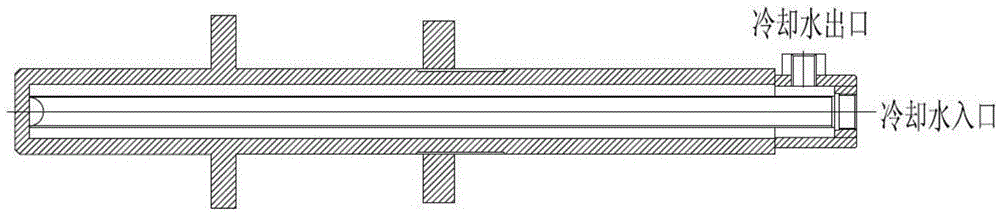

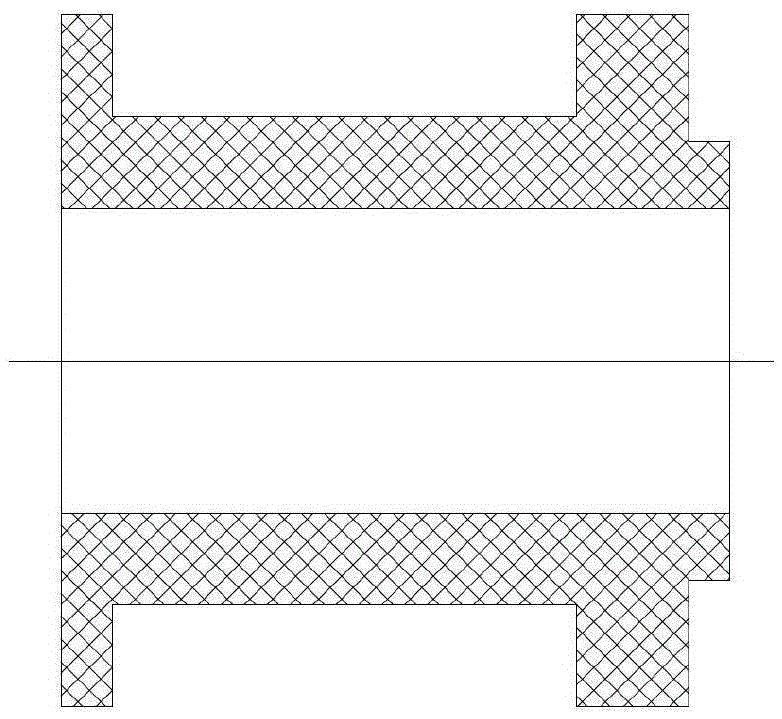

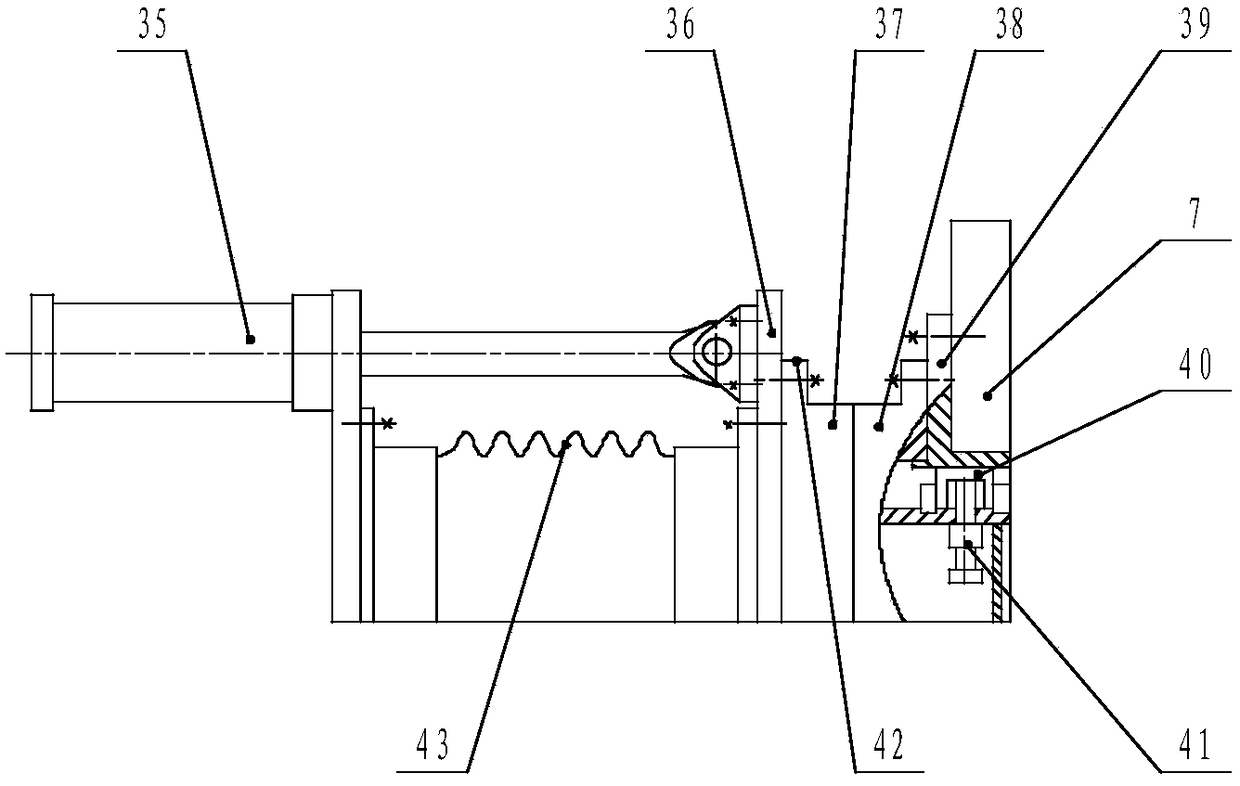

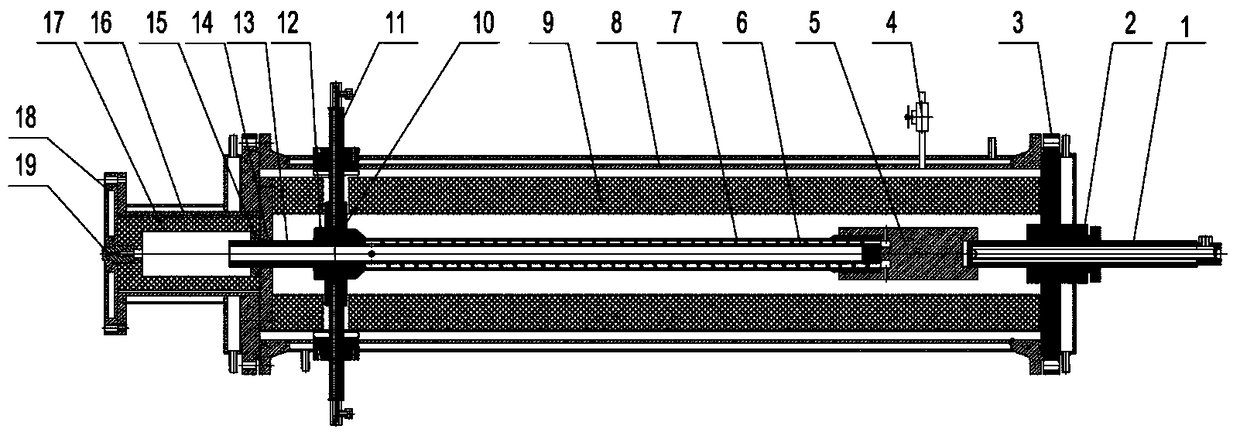

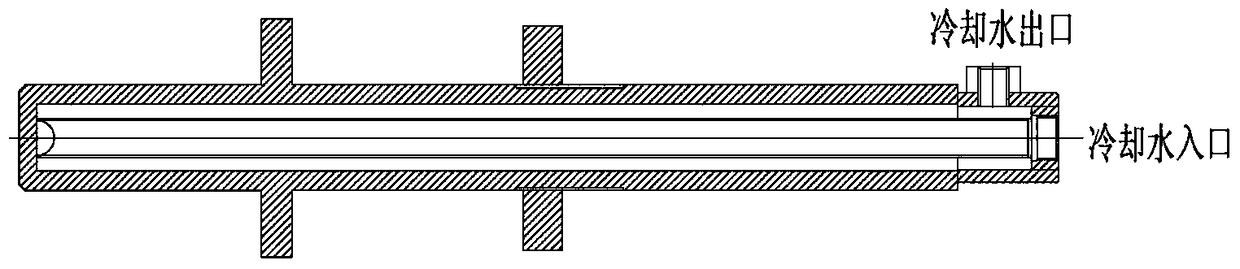

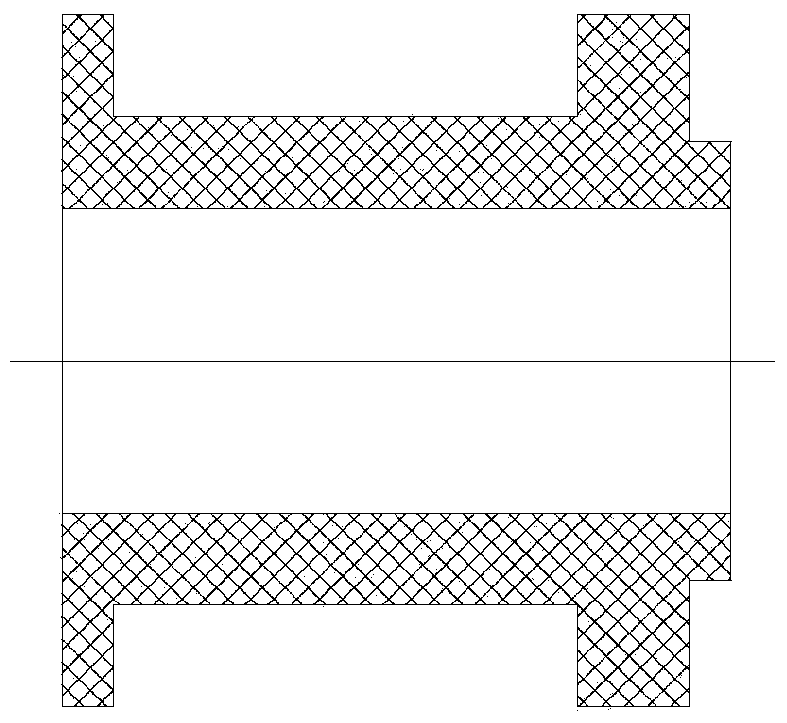

High-temperature continuous nitrogen heater

ActiveCN105627560ASolve the problem of thermal expansionSolve conductivity problemsAir heatersPower flowNitrogen

The invention provides a high-temperature continuous nitrogen heater. The high-temperature continuous nitrogen heater comprises a cylinder, a water cooling positive electrode, a water cooling negative electrode and a heating element; the heating element is mounted on the axis of the cylinder, and one end thereof is connected with the water cooling positive electrode through a slide transfer piece; the water cooling positive electrode is connected with a power supply by penetrating out of a water cooling end surface flange tightly connected to one end of the cylinder; the other end of the heating element penetrates out of a graphite baffle plate at the other end of the closed cylinder; upper and lower two water cooling negative electrodes mounted on the heating element through an electrode transfer disc are connected with the power supply after penetrating out of through holes in the wall of the cylinder; the heating element is a sandwich layer structure consisting of a graphite straight pipe on the outer layer and a graphite straight pipe with a spiral fin on the outer pipe wall on the inner layer; a spiral channel is formed between the outer-layer pipe and the inner-layer pipe through the spiral fin; and a through hole is formed in the slide transfer piece connected to one end of the heating element. The high-temperature continuous nitrogen heater solves the difficulties of thermal expansion of the heating element and high-current electric conduction, and can realize continuous heating of nitrogen currents.

Owner:BEIJING AEROSPACE YISEN WIND TUNNEL ENG TECH

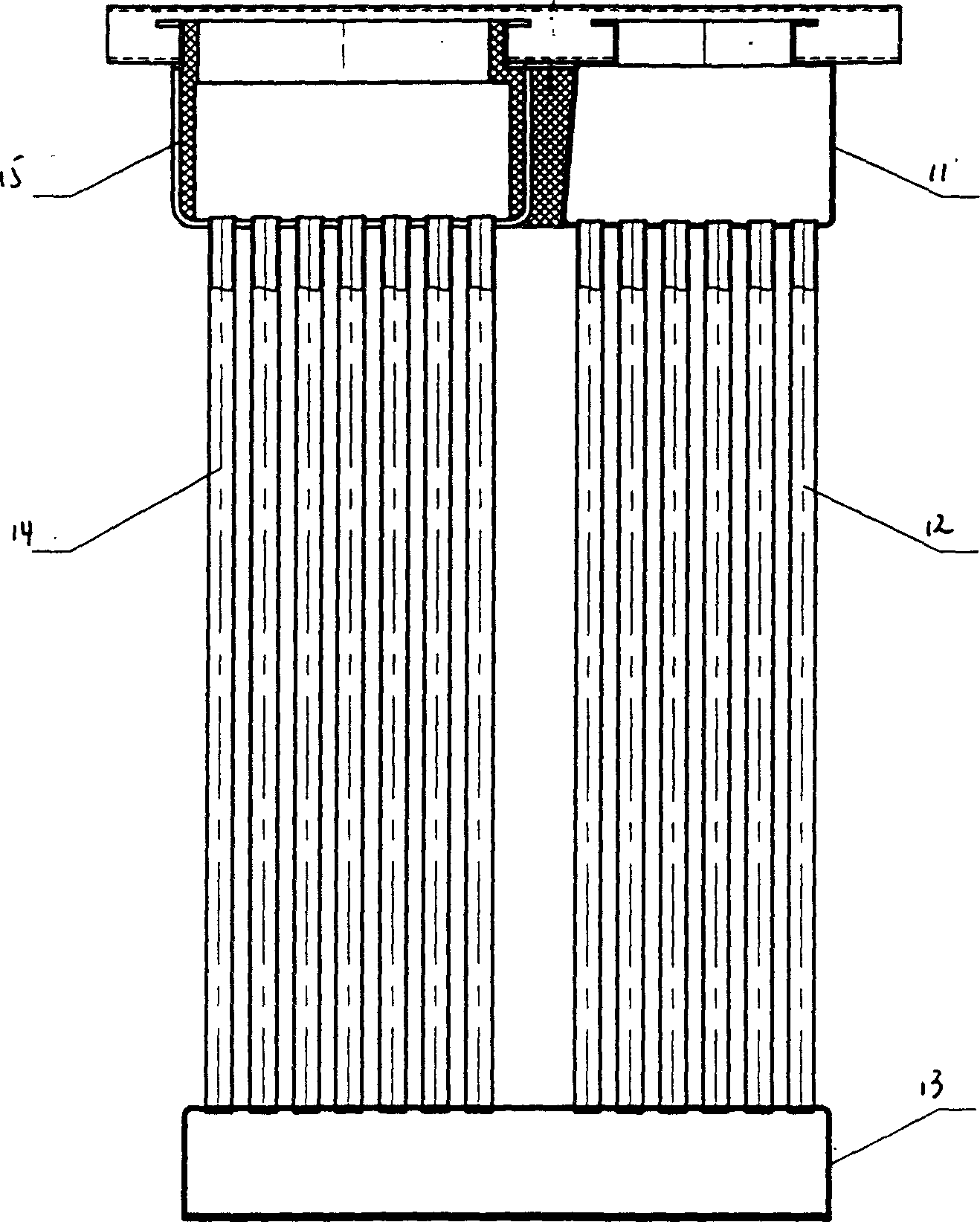

High temp, energy saving steel pipe type air preheater

InactiveCN1563802ASolve the problem of thermal expansionCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The high temperature energy saving steel pipe type air pre-heater includes casing; and return pipe bundle comprising low temperature pipe header, low temperature pipe bundle, middle pipe header, high temperature pipe bundle and high temperature pipe header. The low temperature pipe bundle has upper pipe ends connected to the low temperature pipe header; the high temperature pipe bundle has upper pipe ends connected to the high temperature pipe header; both the high temperature pipe bundle and the low temperature pipe bundle have their lower pipe ends connected to the middle pipe heater, and the said five parts constitute out U-shape. The return pipe bundle has upper part connected to the top of the casing and lower part suspended; and the caisng has right and left flue inlet and outlet and upper part as return pipe bundl installing port and air inlet and outlet. When fume temperature changes, the pipe bundles and the middle pipe header may change their length freely.

Owner:江阴市和荣燃烧设备有限公司

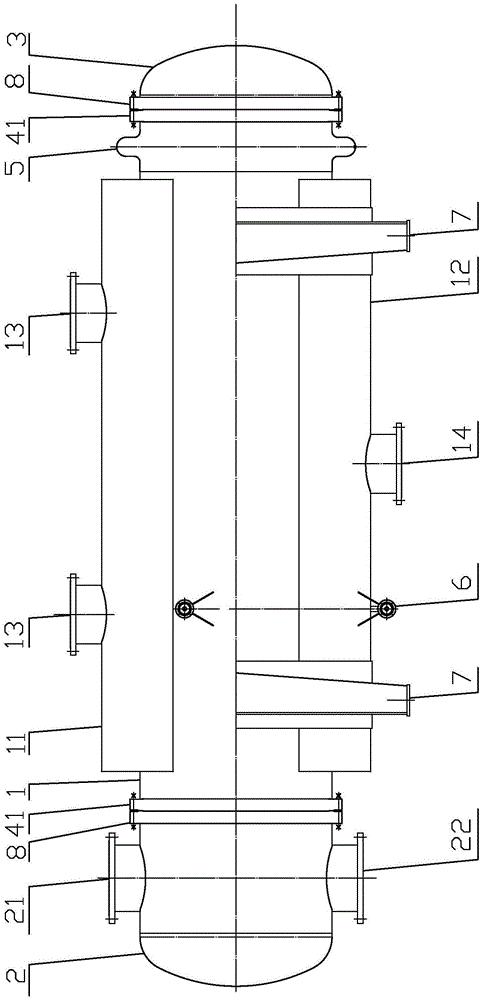

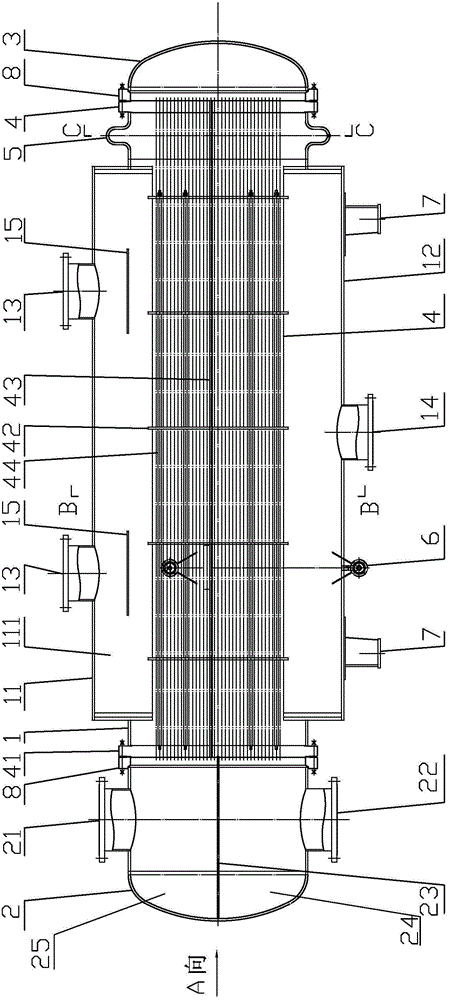

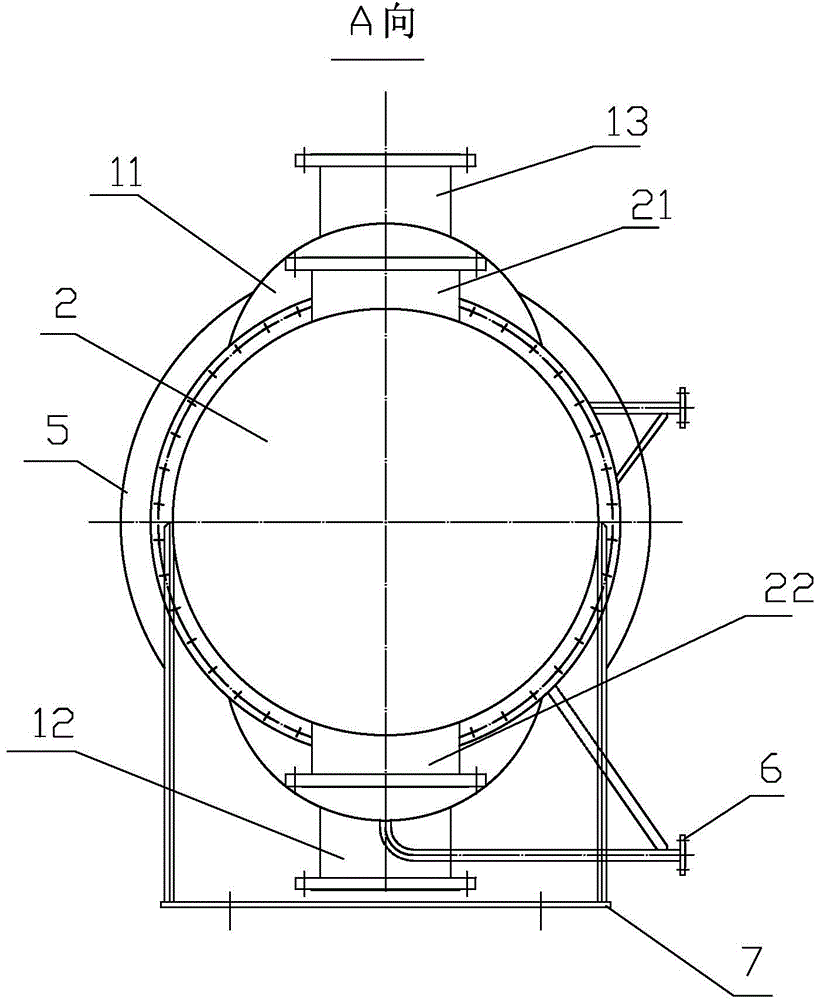

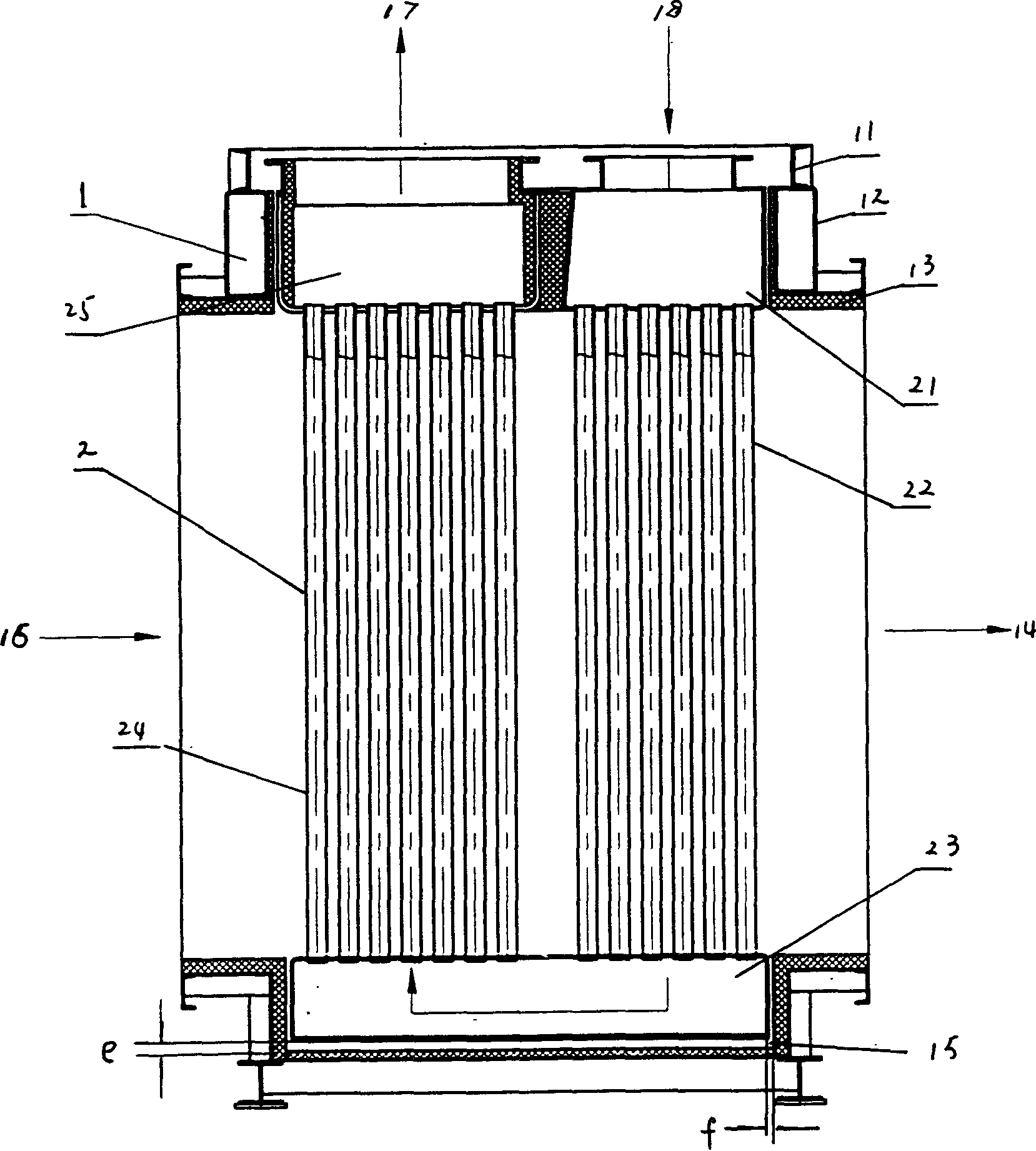

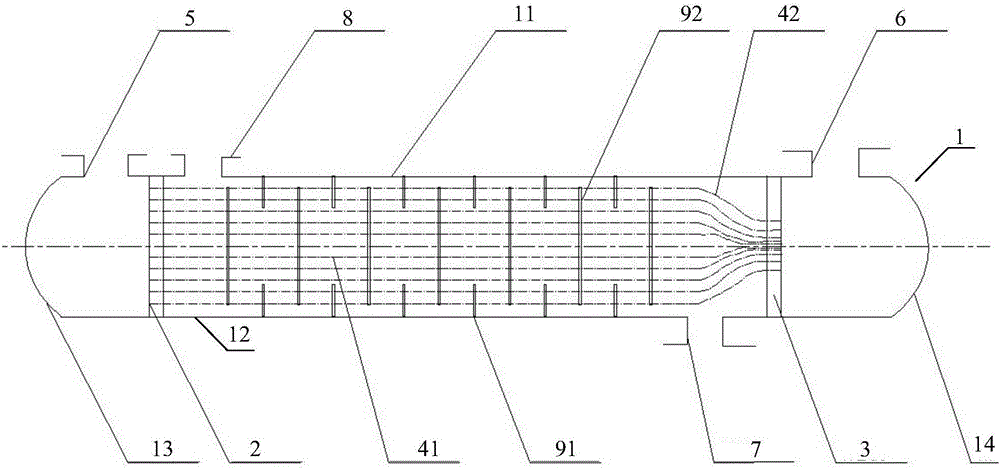

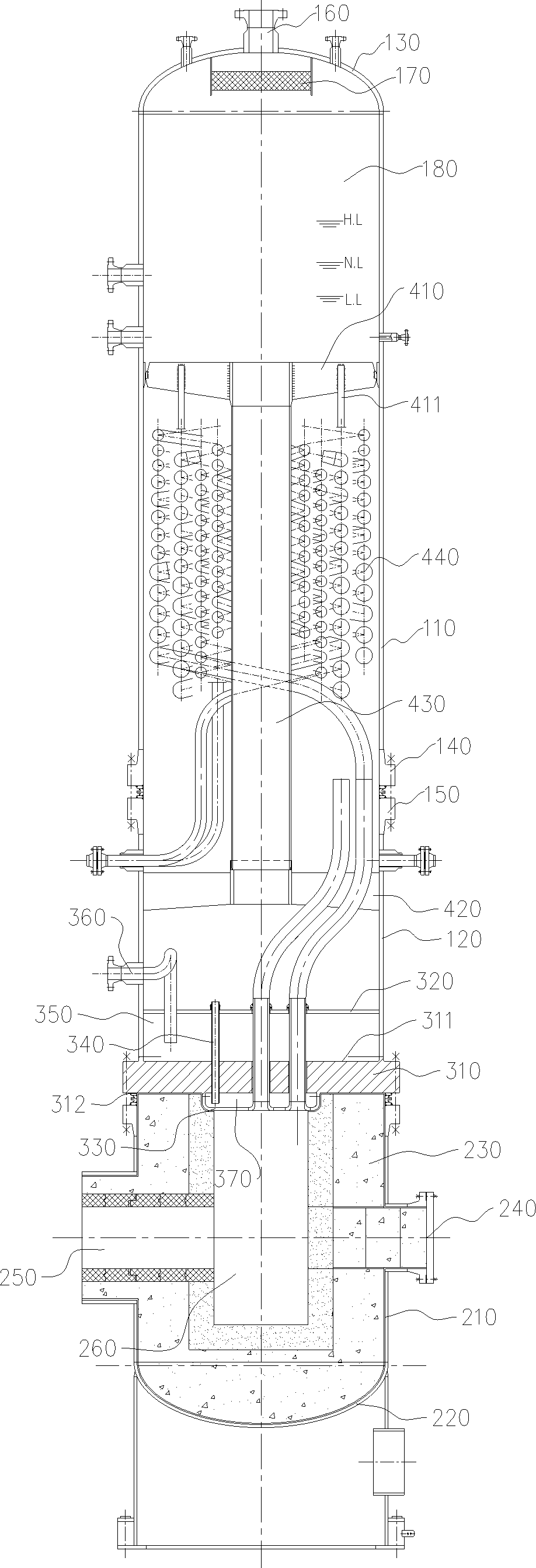

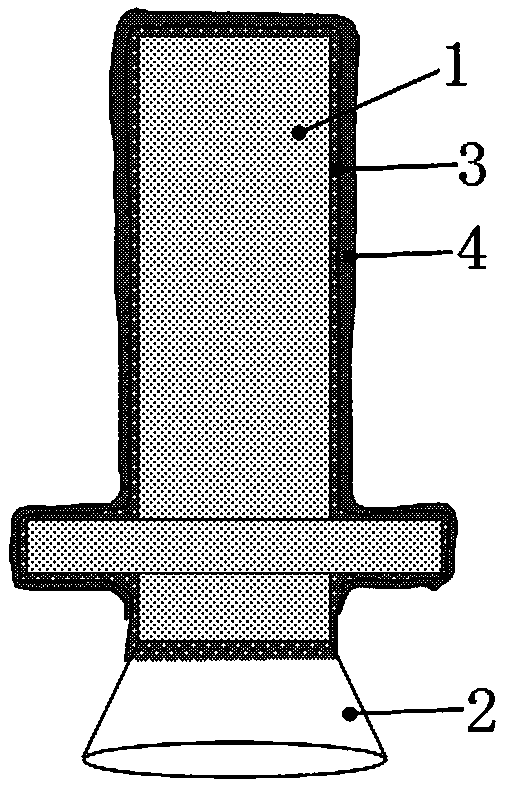

Shell and tube heat exchanger for exchanging heat of fused salts with different temperatures

InactiveCN105674770ASolve the problem of thermal expansionExtended service lifeSolar heating energySolar heat devicesPlate heat exchangerShell and tube heat exchanger

The invention provides a shell and tube heat exchanger for exchanging heat of fused salt with different temperatures. The shell and tube heat exchanger is used for exchanging heat between cold salt and hot salt and at least comprises a shell, a first tube plate and a second tube plate which are respectively mounted at both ends in the shell, and a heat exchange tube fixed between the first tube plate and the second tube plate, wherein the heat exchange tube comprises a straight tube and a spiral tube communicated with the straight tube. The shell and tube heat exchanger further comprises a hot salt inlet, a hot salt outlet, a cold salt outlet and a cold salt inlet formed in the bottom of the shell, which are formed in the top of the shell. According to the shell and tube heat exchanger, one end of the heat exchange tube is provided with the spiral tube, so that the problem of thermal expansion of the heat exchange tube due to high temperature of fused salt can be avoided, so as to prevent movement of the tube plates due to expansion pressure and prolong the service life of the shell and tube heat exchanger; and furthermore, due to the arrangement of the spiral tube, the heat exchange area can be enlarged, and thus the heat exchange effect can be greatly enhanced.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

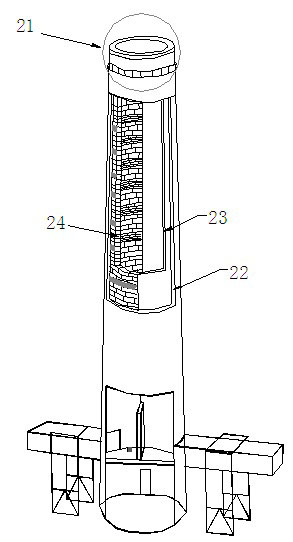

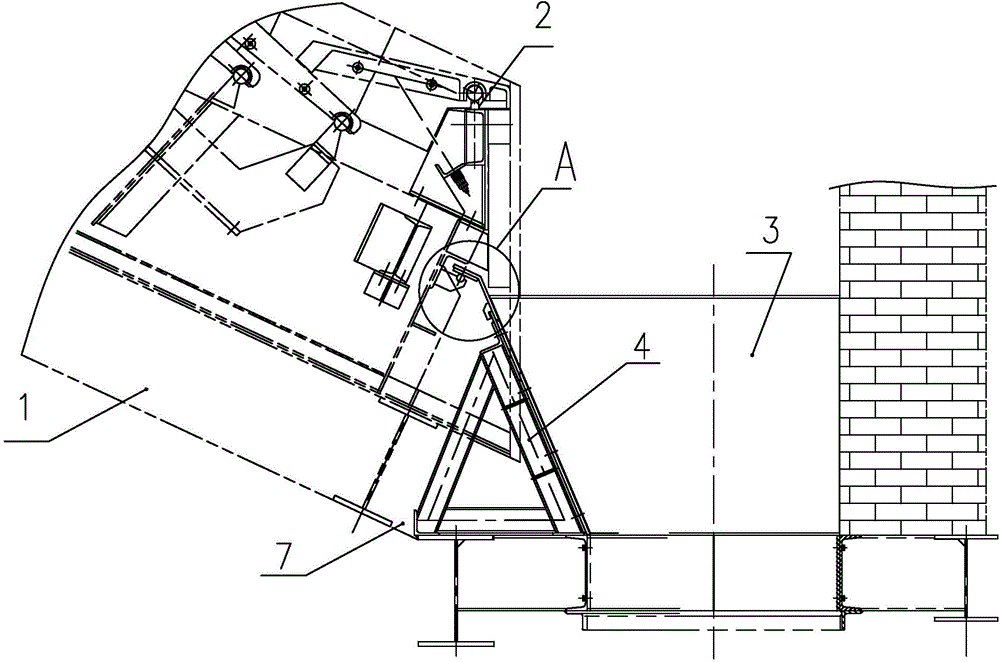

Antiseptic processing method for capping part of brick lining chimney

InactiveCN102168500AWill not cause damagePrevent leakageBuilding repairsTowersBrickThermal expansion

The invention discloses an antiseptic processing method for a capping part of a brick lining chimney, which comprises the following steps: washing a capping area at the chimney top with high-pressure water to remove impurities; repairing gaps of capping concrete bricks or locally leveling and drying; spraying, blade-coating, brush-coating or roller-coating a polyfluorine organic lining antiseptic material layer on the capping surface; and finally maintaining. In the method, antiseptic processing targeting an expansion joint part is performed by using elastic material, thereby solving the problems of leak tightness and thermal expansion at the same time. The method can perfectly eliminate thermal stress generated by fluctuation of smoke temperature, cannot damage the antiseptic layer and eradicates leakage of condensate.

Owner:重庆大众防腐股份有限公司

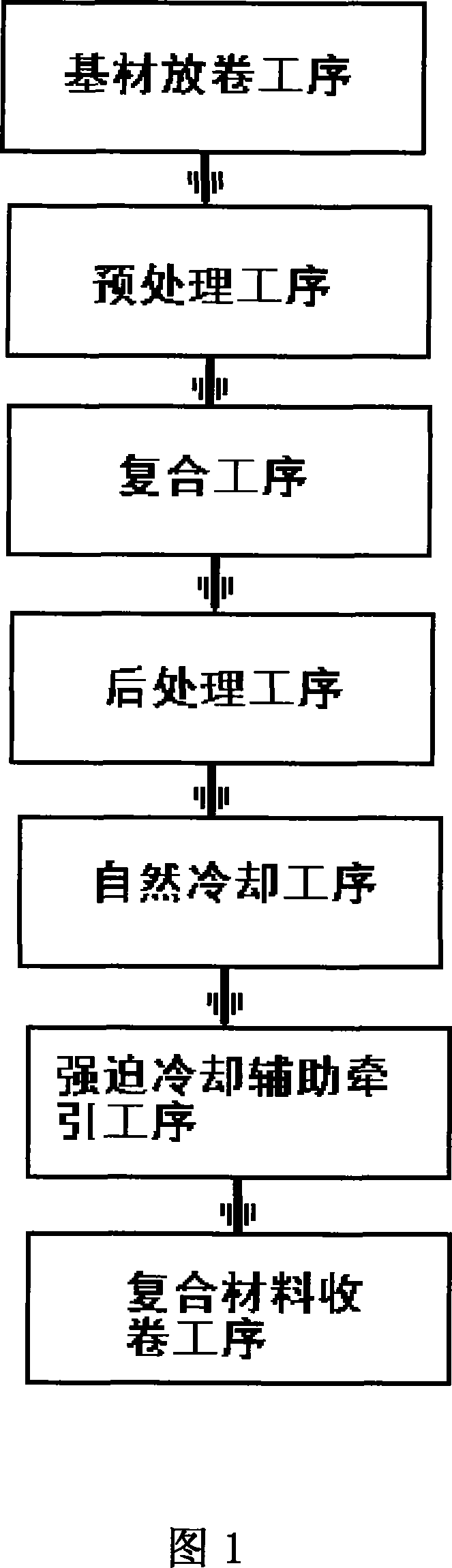

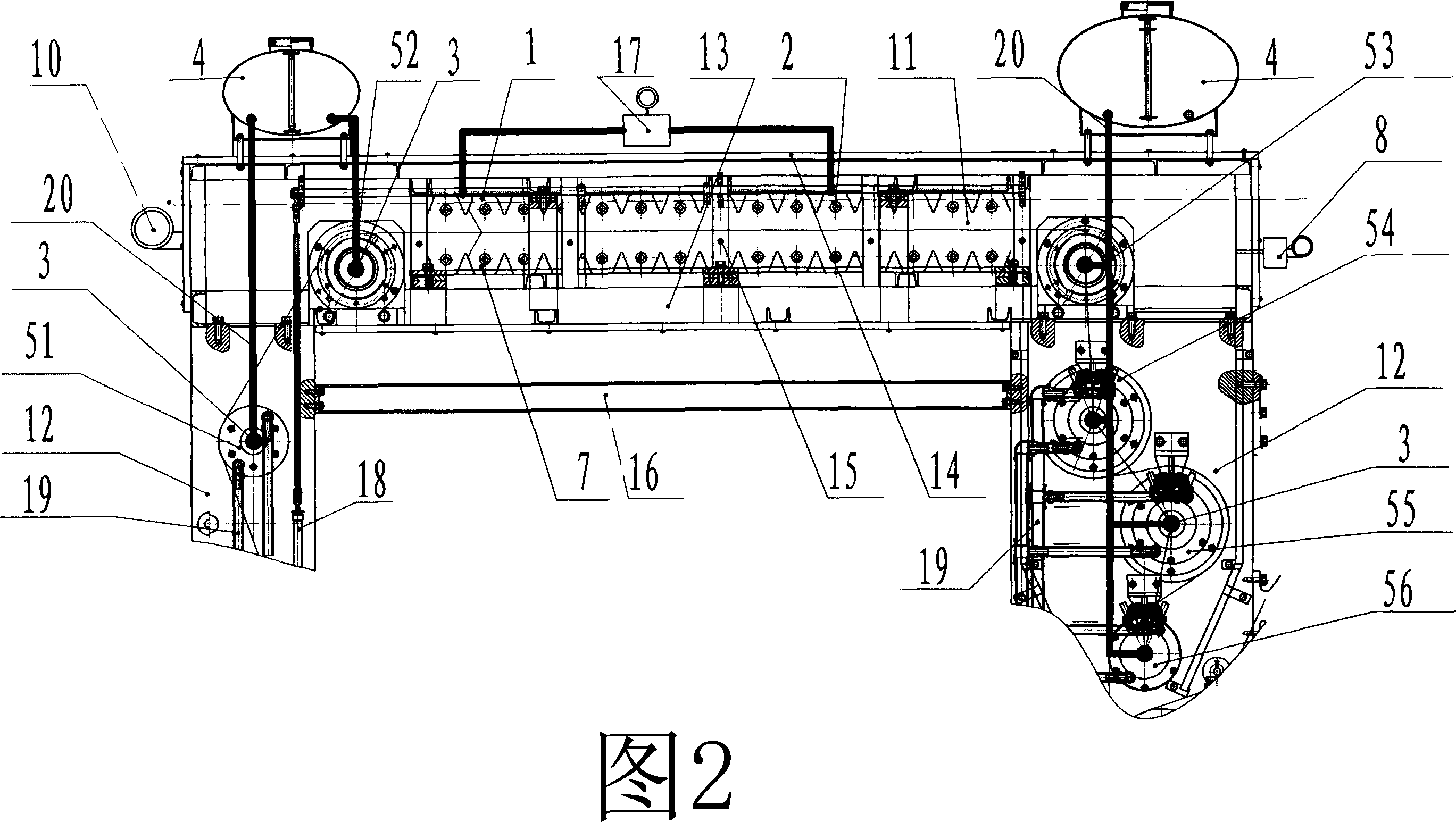

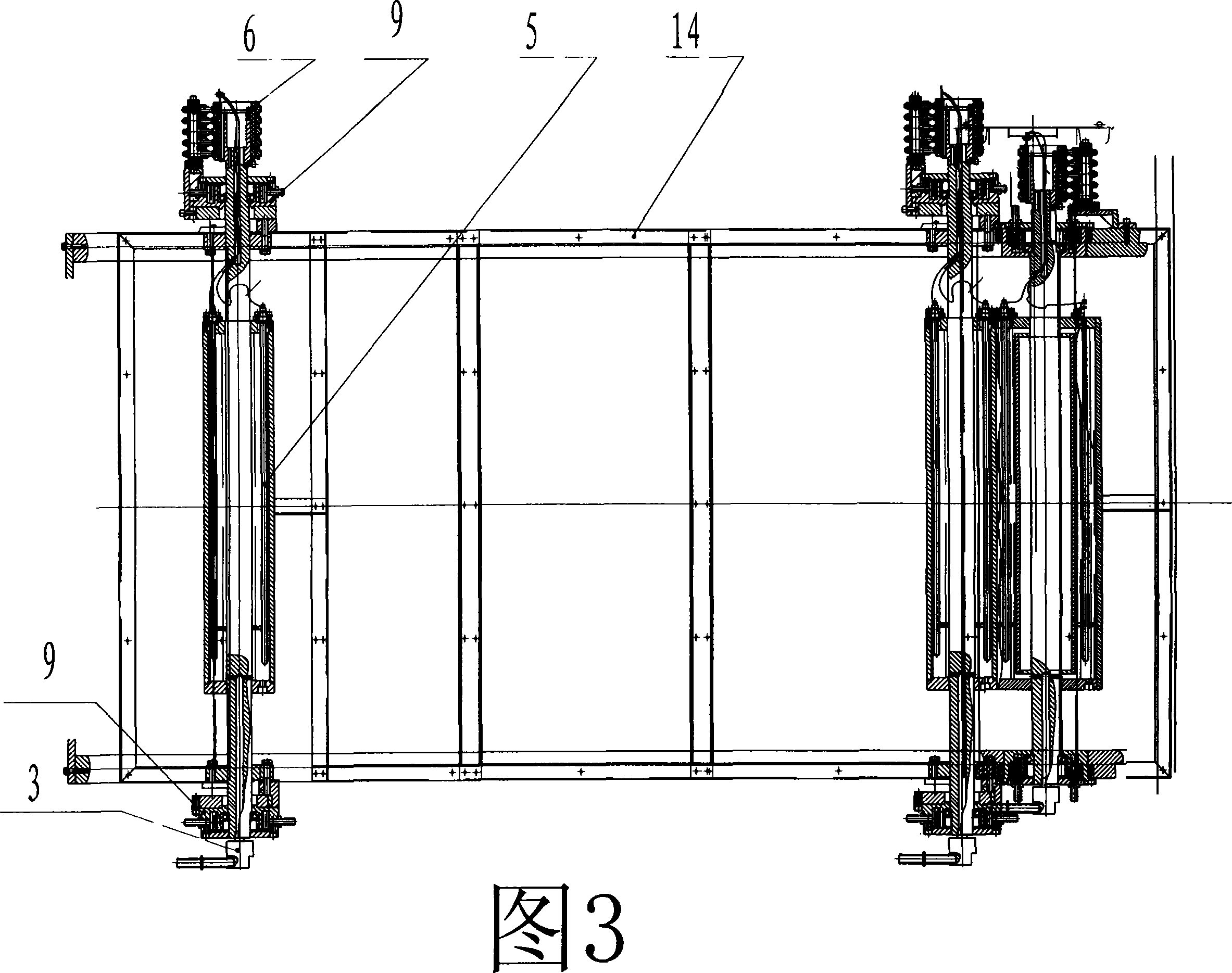

Apparatus for pretreating composite material metal base material and pretreating method

ActiveCN101134997AImprove efficiencyEven heat dissipationFurnace typesHeat treatment furnacesPre treatmentMetal substrate

The present invention relates to pre-treating apparatus and process for composite metal base material. The pre-treating apparatus includes one combined portal frame, heating guide rollers, one guide unit, one energy accumulator, one air blowing unit, heat collecting boxes and one hot blast circulator. During pre-treatment, the composite metal base material is made to pass through the heating guide rollers and the boxes separately in specific temperatures successively in certain linear speed. The present invention has the composite metal base material possess homogeneous heating, less heat deformation and no destruction of mechanical performance.

Owner:上海网讯新材料科技股份有限公司

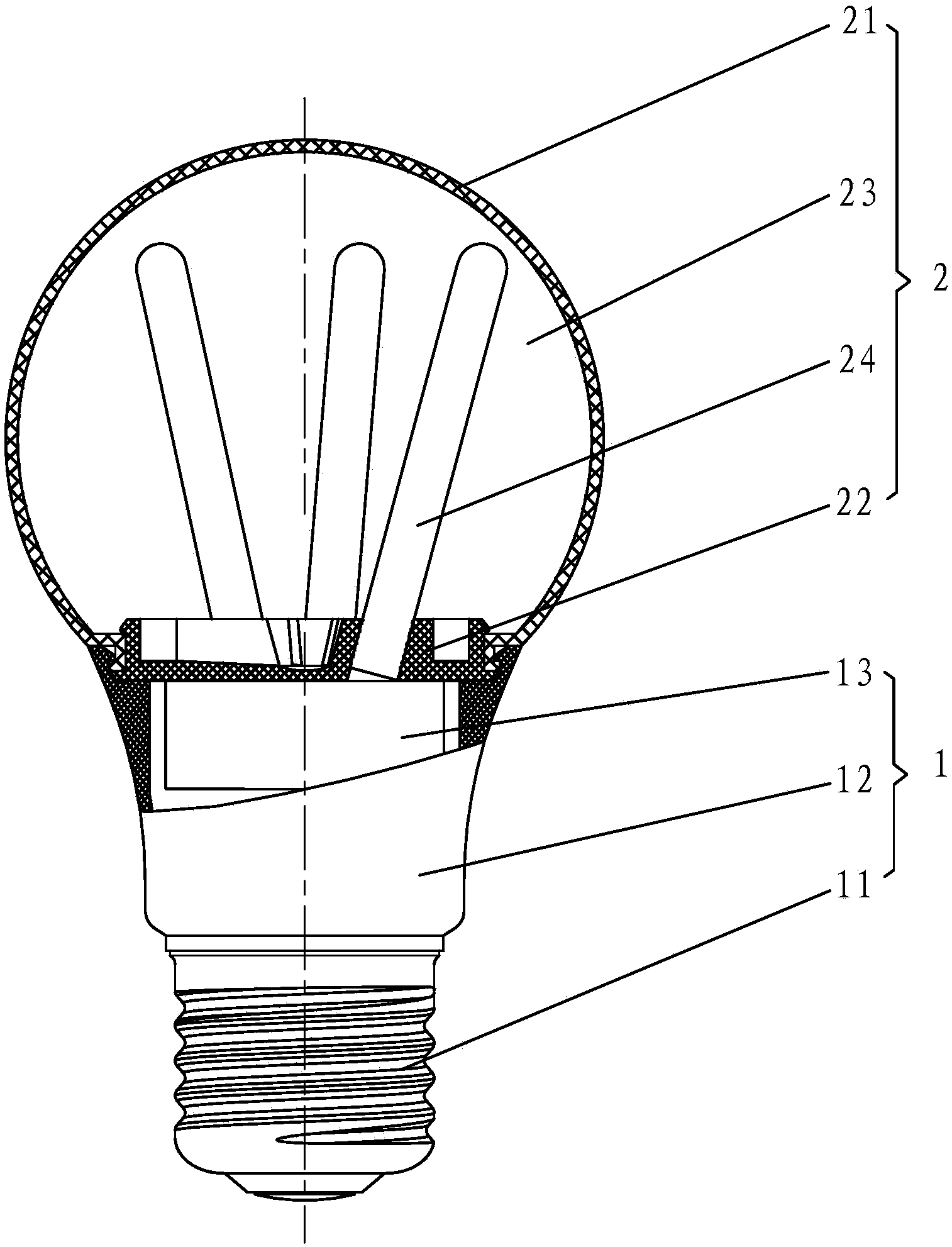

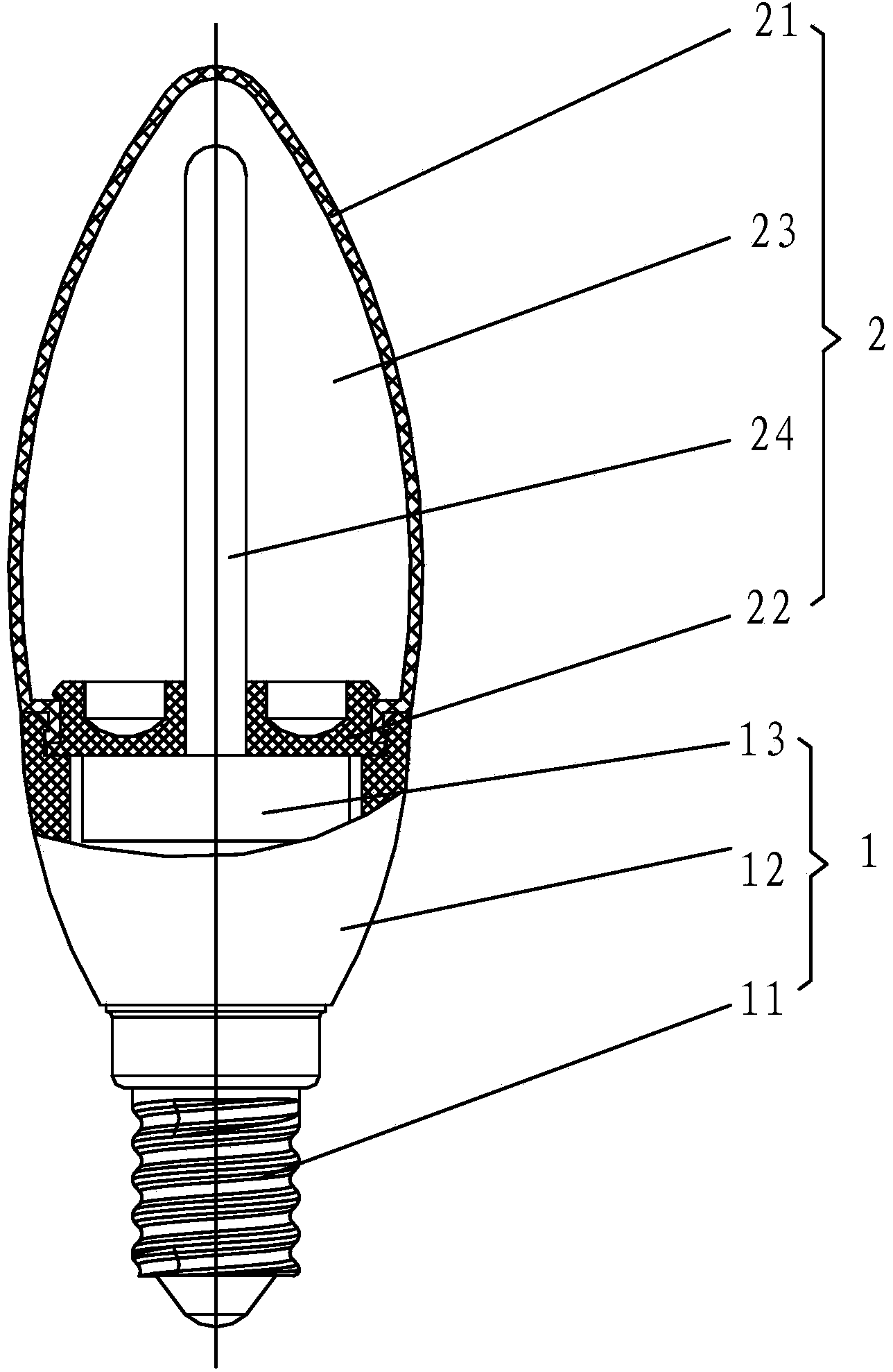

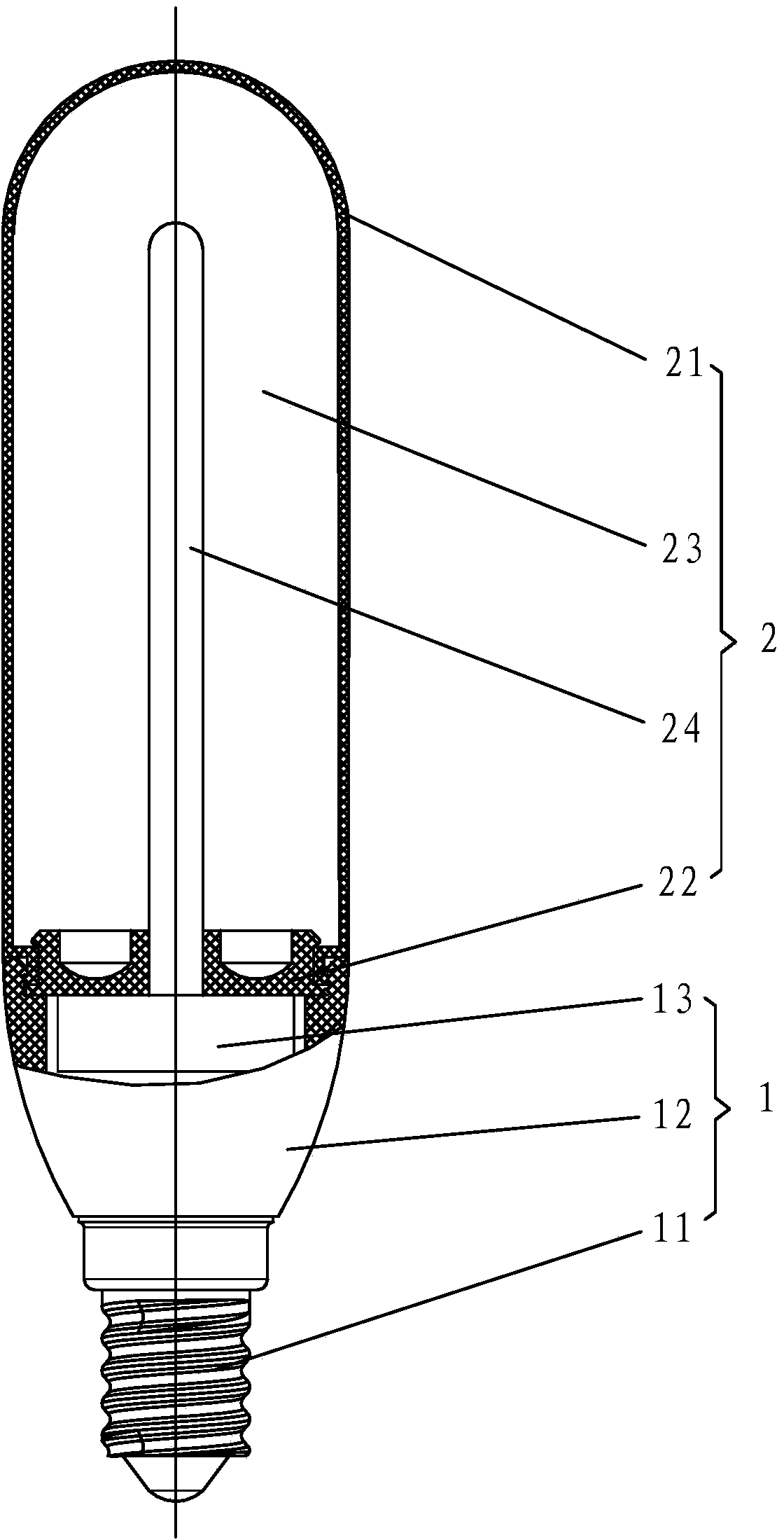

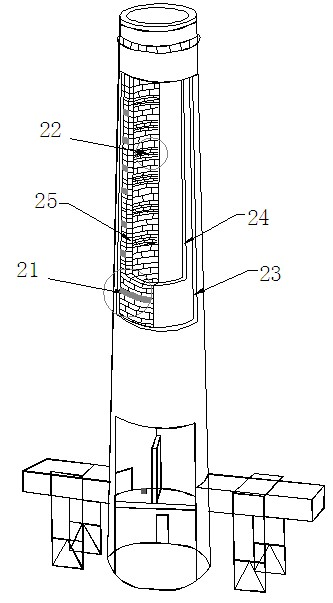

LED (light emitting diode) illumination light source

InactiveCN103867943ALight evenlyRealize omni-directional heat conductionPoint-like light sourceLighting heating/cooling arrangementsHeat conductingLight transmission

The invention belongs to the technical field of an LED (light emitting diode), and particularly relates to an LED illumination light source, which comprises a light transmission lamp shade, an elastic sealing cover, heat conduction light transmission cooling liquid and an LED luminous element, wherein the light transmission lamp shade and the elastic sealing cover are connected in a sealed way for forming a sealed space, the LED luminous element is arranged in the light transmission lamp shade and is fixedly arranged on the elastic sealing cover, and heat conducting light transmission cooling liquid is filled in the sealed space. The invention aims at solving the technical problems to provide the LED illumination light source with the advantages of heat conducting light transmission cooling liquid cooling, all-direction heat conduction and all-direction uniform light outlet.

Owner:FUJIAN YDJ LIGHT

Corrosion-resistant treatment method of corbel part of brick lining chimney

The invention provides a corrosion-resistant treatment method of a corbel part of a brick lining chimney. The method comprises the following steps of: firstly cleaning a substrate; then digging a corbel joint seam, wherein the depth of the seam is larger than or equal to 100mm; pouring the seam by using polyurethane sealing cream and silicon rubber type high-temperature elastic adhesive sealing material; then coating polyfluorine organic lining corrosion-resistant material at the upper and lower sides of the seam, and building vitrified ceramic tiles for protection; if a drainboard exists, performing sloping processing on the drainboard; and maintaining according to the maintaining conditions of the material. The method employs the elastic materials to perform corrosion-resistant processing on the chimney corbel at the retractable seam part of the corbel, so as to excellently and simultaneously solve the problems of sealing performance and thermal swelling. According to the method of the invention, the thermal stress generated through smoke temperature waving is excellently eliminated; the corrosion-resistant layer is prevented from being corroded, and the leakage of condensate can be avoided.

Owner:重庆大众防腐股份有限公司

Airtight external thermal type rotary furnace with same-side feed and discharge functions

PendingCN109269294AFree from pollutionReduce pollutionRotary drum furnacesProcess engineeringRotary furnace

The invention discloses an airtight external thermal type rotary furnace with same-side feed and discharge functions. The airtight external thermal type rotary furnace comprises a furnace and three jackets. The jackets are arranged on the outer wall of the furnace, and a support wheel device for supporting the furnace is arranged between the jackets; an inner cavity of the furnace is provided withtube bundles which are axially distributed along the furnace, independent heat-carrying gas channels inside the furnace are formed by tube nest air inlet jackets and tube nest air outlet jackets in the three jackets and the tube bundles, and independent heat-carrying gas channels outside the furnace are formed by intermediate jackets and the outer wall of the furnace; the various jackets are sealed by flexible jacket seals; a gas outlet device and power mechanisms are arranged at the front of the furnace, the furnace can be in linkage with the power mechanisms to rotate, feed and discharge devices which are arranged on the same side are arranged at the tail of the furnace, and sealing structures are arranged on the furnace and are positioned on the gas outlet device and the feed and discharge devices. The airtight external thermal type rotary furnace has the advantages that materials in the furnace can be simultaneously indirectly heated by the heat-carrying gas channels formed by thetube bundles inside the furnace and the external jackets and accordingly can be efficiently heated; environmental pollution and energy consumption can be reduced by equipment, the heat exchange efficiency can be improved, and the operation safety of the equipment can be guaranteed.

Owner:西安三瑞实业有限公司

Molten salt heat exchanger for intelligently controlling heat exchange flowing speed

InactiveCN105841522ASolve problems that don't match wellRealize intelligent controlHeat exchanger casingsStationary tubular conduit assembliesMolten saltEngineering

The invention provides a molten salt heat exchanger with intelligent control of heat exchange flow rate, which is used for heat exchange between cold salt and hot salt. The molten salt heat exchanger at least includes: an outer shell; The first tube sheet and the second tube sheet at both ends; the heat exchange tube fixed between the first tube sheet and the second tube sheet, the heat exchange tube includes a straight tube and a spiral tube communicating with the straight tube ; The hot salt inlet, hot salt outlet and cold salt outlet arranged on the top of the shell; there are also cold salt inlets arranged at the bottom of the shell, several cold salt passages arranged between the cold salt inlet and the cold salt outlet, and the Intelligent control valves at both ends of each cold salt channel and temperature sensing devices arranged on the cold salt channel and heat exchange tubes. The molten salt heat exchanger of the present invention can realize intelligent control through an intelligent control valve and a temperature sensing device, and can well match the heat exchange flow rate of hot salt and cold salt to achieve better heat exchange effect.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

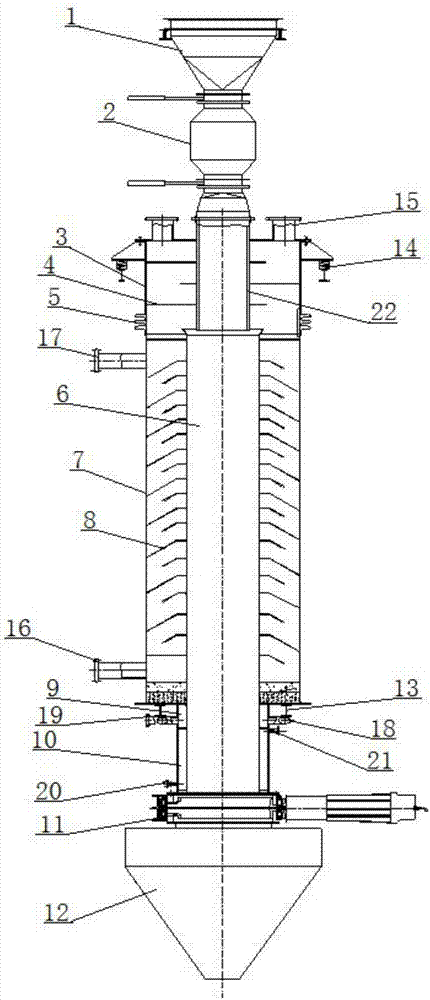

High-efficiency biomass treatment tar poly-generation pyrolysis furnace

InactiveCN107267176AReduce coking rateRealize gas-solid separationBiofuelsGasification processes detailsCooling chamberTar

A high-efficiency biomass treatment tar poly-generation pyrolysis furnace comprises a feed bunker (1), a lock bucket (2), a settling chamber (3), a reaction chamber, a cooling chamber and a discharged charcoal bunker (12), the lower end of the settling chamber (3) is connected with the reaction chamber, the lower end of the reaction chamber is connected with the cooling chamber, the bottom end of the cooling chamber is connected with the discharged charcoal bunker (12), a feed hose tube (22) is arranged in the settling chamber (3), the top end of the lock bucket (2) is connected with the outlet of the feed bunker (1), the bottom end of the lock bucket (2) is connected with the inlet of the feed hose tube (22) of the settling chamber (3), the inner wall of the settling chamber (3) is provided with a deflector separator (4), the deflector separator (4) is connected with the outer wall of the feed hose tube (23), and the top of the settling chamber (3) is provided with a pyrolysis gas outlet (15). The deflector separator (4) realizes gas-solid separation, so dusts in combustible gas are separated, the combustible gas is purified, and the coking rate of a purification system is reduced.

Owner:武汉光谷蓝焰新能源股份有限公司

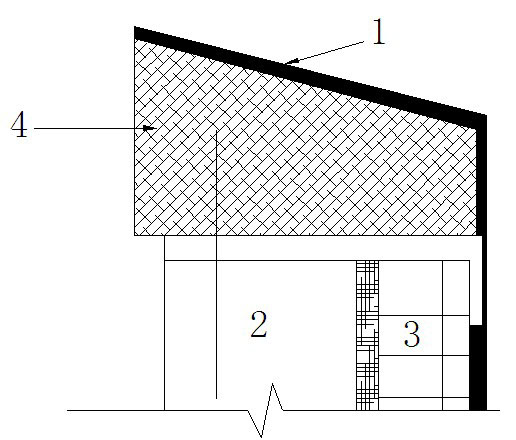

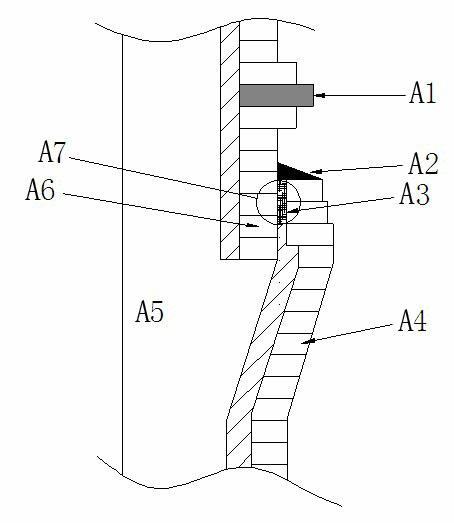

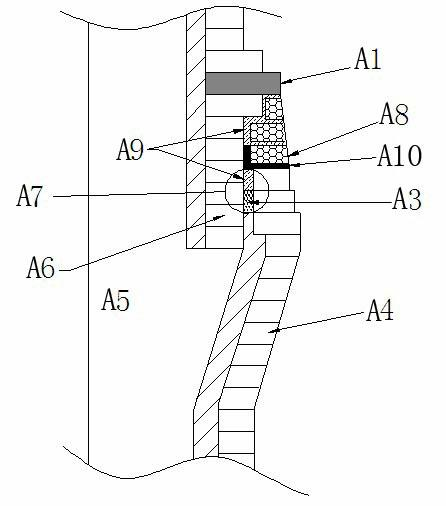

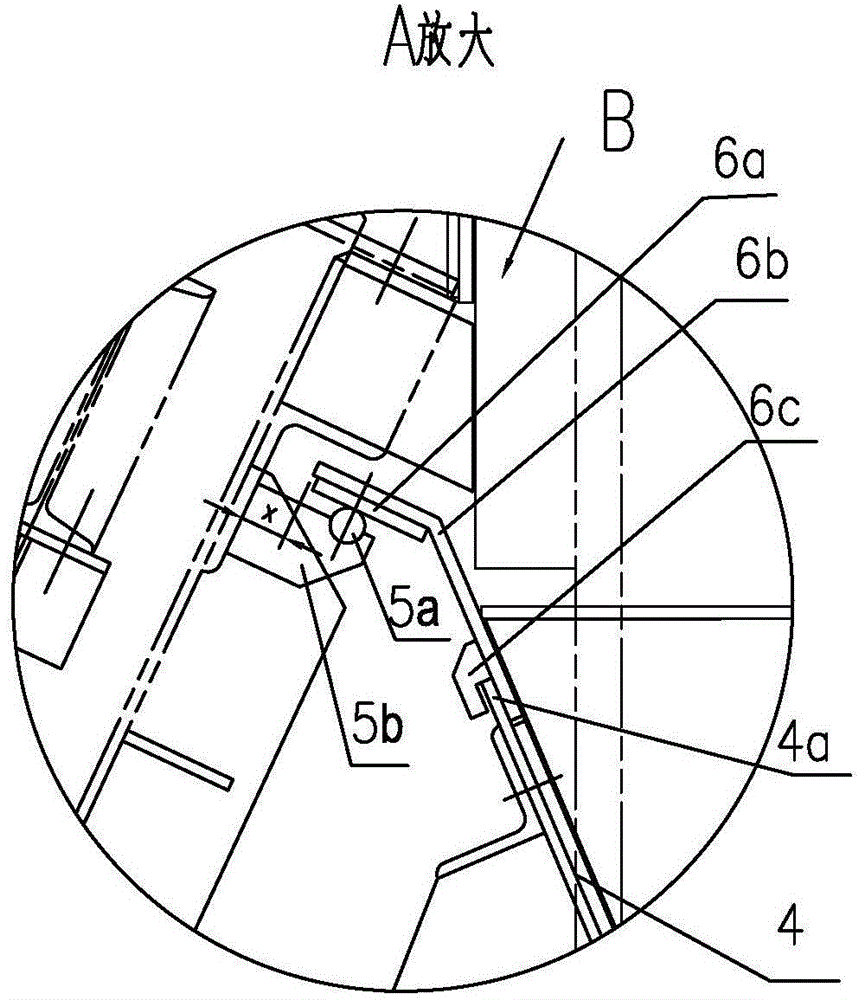

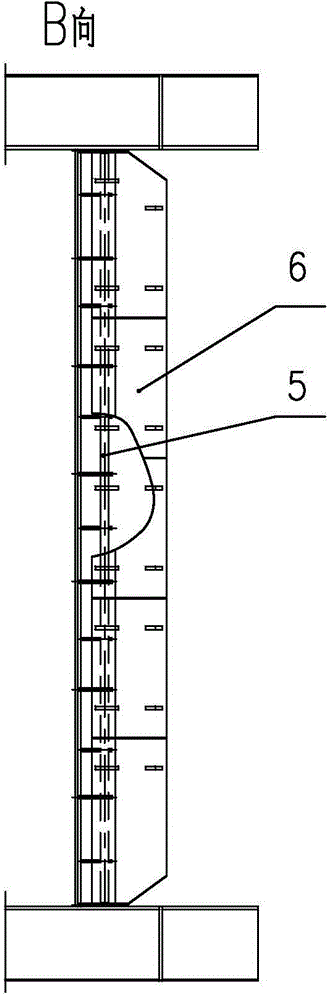

Thermal expansion structure of joint part of garbage incinerator

The invention relates to a thermal expansion structure of a joint part of a garbage incinerator. The structure is adaptable to the joint part between a fixed end and a thermal expansion end. By the adoption of the structure, all components of the garbage incinerator can slide down freely without interference within a certain temperature range during operation, and sealing performance can be guaranteed. According to the technical scheme, the structure comprises a steel frame, a thermal expansion component, a fixed component and a heat insulating and sealing structure, the thermal expansion component and the fixed component are supported by the steel frame, and the heat insulating and sealing structure is arranged on the joint part between the thermal expansion component and the fixed component. The structure is characterized in that a shelf is fixed to the thermal expansion component, round steel is arranged on the top of the shelf, a cover plate is installed on the fixed component, the bottom surface of the front portion of the cover plate is in contact with the round steel, and the front end of the cover plate is spaced from the thermal expansion component.

Owner:HANGZHOU NEW CENTURY ENERGY ENVIRONMENTAL PROTECTION ENG CO LTD

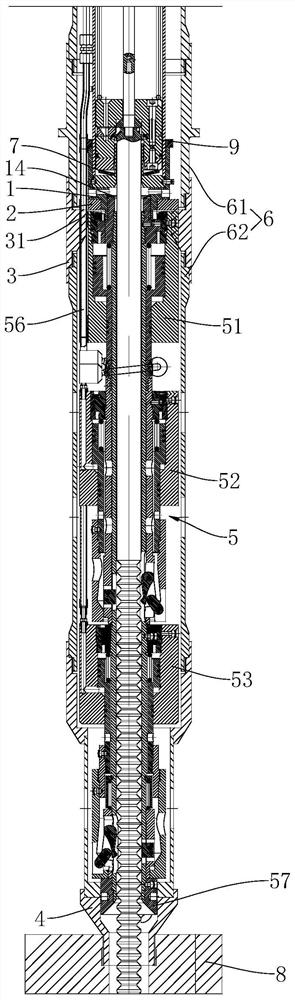

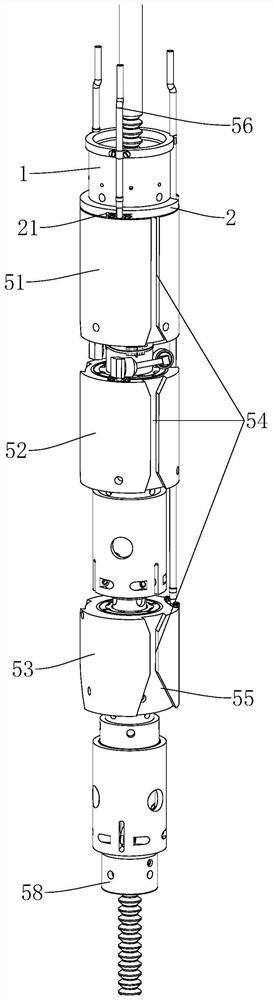

Special vertical lower cantilever hollow screw rod vacuum pump for pharmaceutical chemical engineering

InactiveCN105626522AEliminate cloggingSolve the problem of thermal expansionRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsGear transmissionAirflow

The invention relates to a special vertical lower cantilever hollow screw rod vacuum pump for pharmaceutical chemical engineering. The screw rod vacuum pump comprises a pump shell, an upper bearing box, a lower bearing box, a driving screw rod, a driven screw rod and a motor; the lower bearing box is arranged between the pump shell and the upper bearing box; spiral rotors of the driving screw rod and the driven screw rod are vertically arranged in a pump cavity side by side; shaft rods of the driving screw rod and the driven screw rod penetrate in a cavity formed by closing the lower bearing box and the upper bearing box up and down; synchronous gears engaged with each other are respectively mounted on the shaft rods of the driving screw rod and the driven screw rod; a gear transmission mechanism is arranged in the upper bearing box; a motor is mounted on the upper bearing box; and the gear transmission mechanism is respectively engaged with a driving gear on a main shaft of the motor and the synchronous gear on the driving screw rod. The screw rod vacuum pump realizes support of a lower cantilever structure by single end of screw rods, and enables a working airflow direction to be consistent with a gravity direction, so that such impurities as dust entering the pump cavity are easy to be discharged from an exhaust port in the lower part of the pump shell along with suction of working airflow of the vacuum pump, the blockage is eliminated, and the cleaning of the pump cavity is convenient.

Owner:HEBEI WEIPU VACUUM EQUIP CO LTD

High-temperature vertical waste heat boiler with coil pipes

ActiveCN102705801BWide range of applicable parametersSolving Recycling ProblemsHeat exchanger casingsSteam boilersDraining tubeWater source

Owner:SHANGHAI INT ENG CONSULTING

Ceramic shell dewaxing method

ActiveCN108246976AReduce the probability of crackingImprove pass rateFoundry mouldsFoundry coresWaxMetallurgy

The invention discloses a ceramic shell dewaxing method. The method includes the steps that (1) before a ceramic shell with a wax mould enters a dewaxing procedure, a heat resisting layer which differs from thin to thick is disposed outside the ceramic shell with a dewaxing opening serving as the starting point; (2) the ceramic shell with the wax mould and the heat resisting layer are put in dewaxing equipment, the dewaxing opening in the ceramic shell faces downwards, the thinnest area of the heat resisting layer outside the ceramic shell is located in the undermost position in the vertical direction, and the thickest area of the heat resisting layer is located in the uppermost position in the vertical direction; and (3) after the ceramic shell with the wax mould and the heat resisting layer enters the dewaxing procedure, the heat resisting layer outside the ceramic shell controls the wax mould in the ceramic shell from bottom to top to gradually change and absorb dewaxing heat, the wax mould in the ceramic shell uses the dewaxing opening as the melting starting point, and sequential dewaxing is achieved from outside to inside and from bottom to top. By means of the ceramic shelldewaxing method, auxiliary dewaxing openings in the ceramic shell can be reduced or directly omitted, and the qualified rate and quality of dewaxing and forming of the ceramic shell can be guaranteedeffectively and reliably.

Owner:DONGFANG TURBINE CO LTD

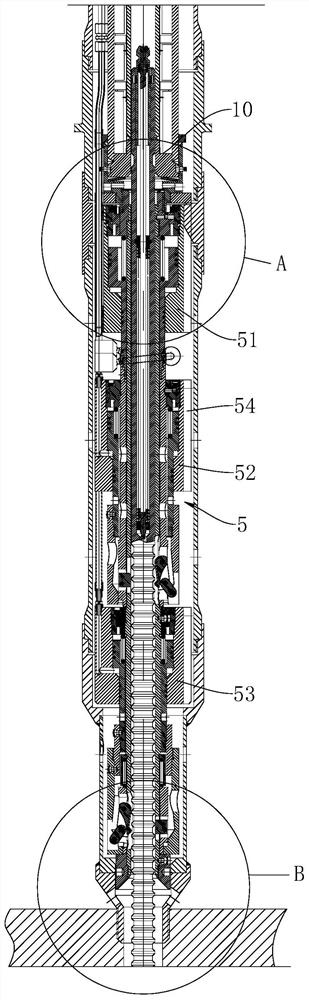

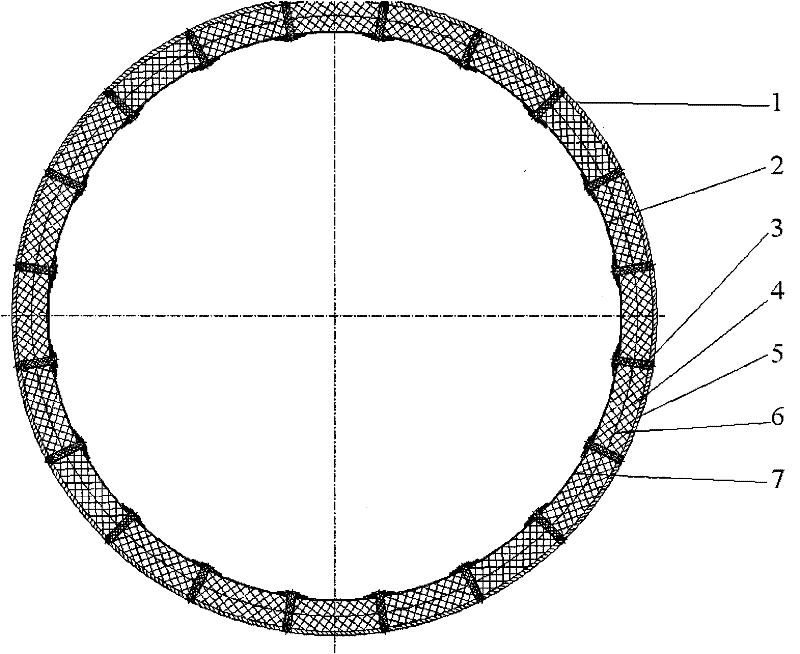

Driving mechanism support structure and control rod driving wire

ActiveCN111968761AImprove performanceImprove reliabilityNuclear energy generationNuclear reaction controlStructural engineeringWater pressure

The invention provides a driving mechanism support structure and a control rod driving wire. The driving mechanism support structure comprises a bearing piece, a supporting ring, a ring supporting piece and a lower end hole shrinkage piece, a supporting part is arranged on the inner wall of the annular supporting piece, the lower side of the supporting ring abuts against the supporting part, the upper side of the supporting ring abuts against the bearing piece, the lower portion of the bearing piece penetrates through a center hole of the supporting ring and is detachably connected with the upper end of the driving mechanism, and the upper end of the bearing piece abuts against a component which is arranged in the guide cylinder and is axially fixed, the upper end of the lower-end hole shrinkage piece is fixedly connected with the guide cylinder, the lower end is mounted on the reactor core supporting plate, the lower-end hole shrinkage piece sleeves the outer side of the lower end ofthe driving mechanism, and a gap is formed between the lower-end hole shrinkage piece and the lower end of the driving mechanism. Enough space is reserved for operation of the water pressure cylinderand the pin claw mechanism, the problem that the water pressure cylinder and the pin claw mechanism are unreasonable in stress in the working state is solved, a water diversion pipe of the driving mechanism is not interfered, and the performance and reliability of the driving mechanism are improved.

Owner:TSINGHUA UNIV

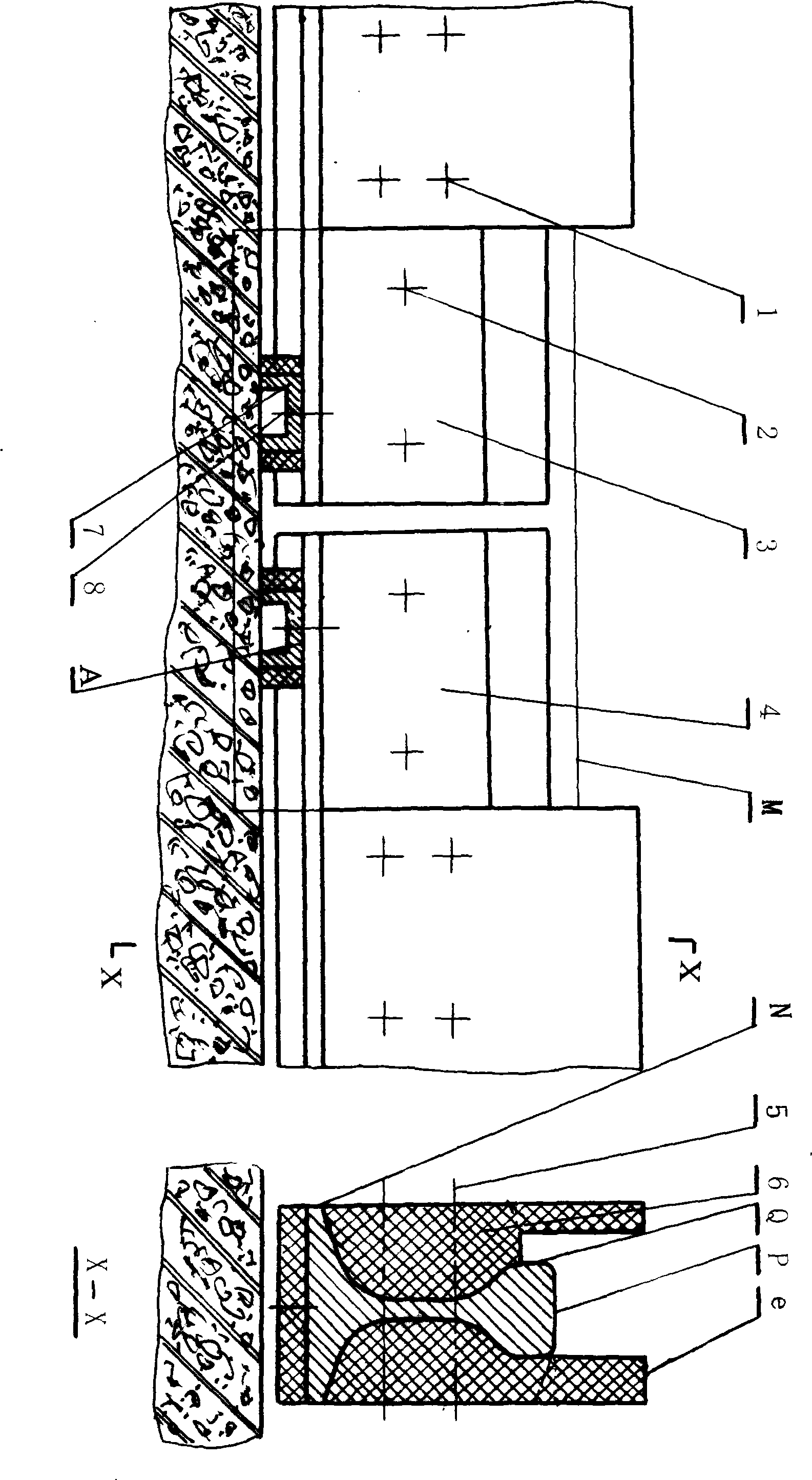

White synchronization railway

InactiveCN101381976ASmall temperature rangeSolve the problem of thermal expansionRailsBallastwayReinforced concreteIsolation layer

The invention relates to a technology for white synchronous railroad, which uses a glabrous white heat isolation layer to be coated on a railroad. A sleeper, in particular a steel sleeper, is coated with the glabrous white heat isolation layer, thereby substantially shortening the range of temperature change of the railroad, realizing the synchronous thermal expansion between the railroad and a roadbed, just like the synchronous thermal expansion between steel reinforcement and concrete in reinforced concrete, and completely solving the problem of the thermal expansion of the railroad.

Owner:张世俊

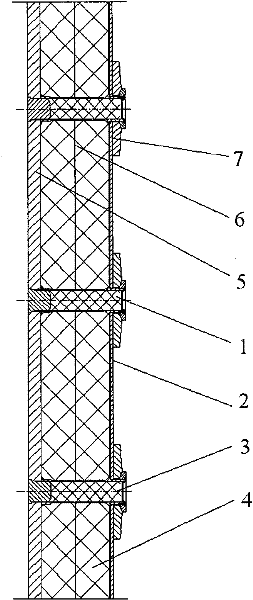

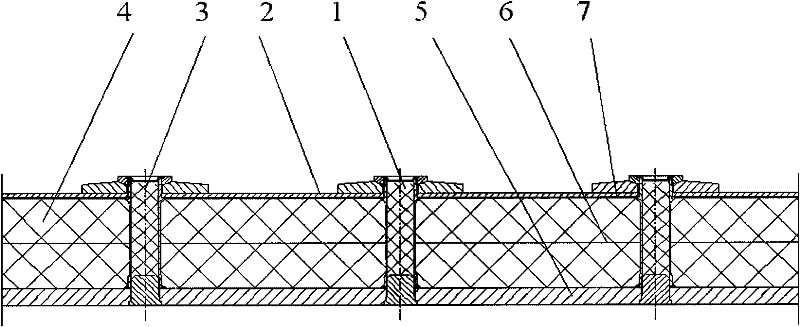

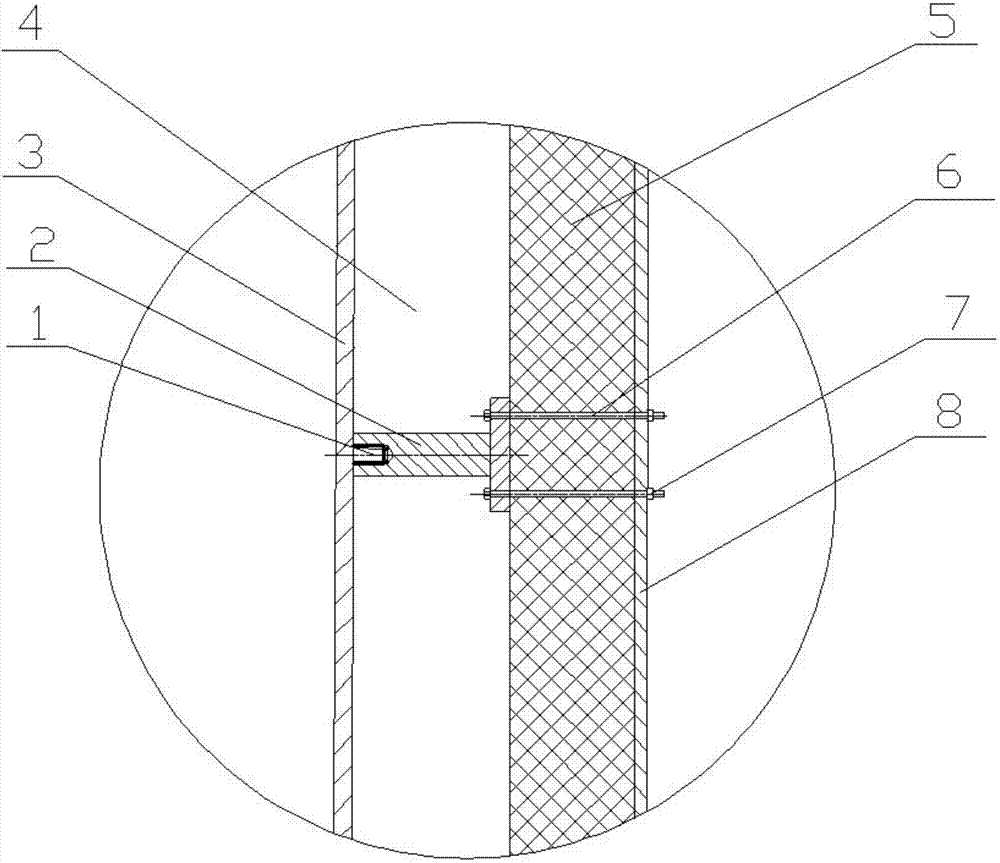

Heat insulation layer structure

ActiveCN101832448BReduce heat transferSolve the problem of thermal expansionThermal insulationPipe protection by thermal insulationInsulation layerBiochemical engineering

The invention discloses a heat insulation layer structure which comprises a fixing plate (5) and a covering plate (2), wherein the covering plate (2) is fixed and connected with the fixing plate (5) through a primary fixing piece (1) and a secondary fixing piece (3); heat insulation material (4) is paved between the covering plate (2) and the fixing plate (5); a sealing film (7) is arranged on the heat insulation material (4); the primary fixing piece (1) is positioned in the middle of the covering plate (2); and the secondary fixing piece (3) is positioned on the periphery of the covering plate (2). The invention breaks through the limitation of the application field of the common heat insulation structure, can be applied to large-scale heat insulation of gas media of high temperature, high speed and high pressure, and solves the problem of the heat expansion generated on both sides of the heat insulation layer due to different temperatures.

Owner:CHINERGY CO LTD

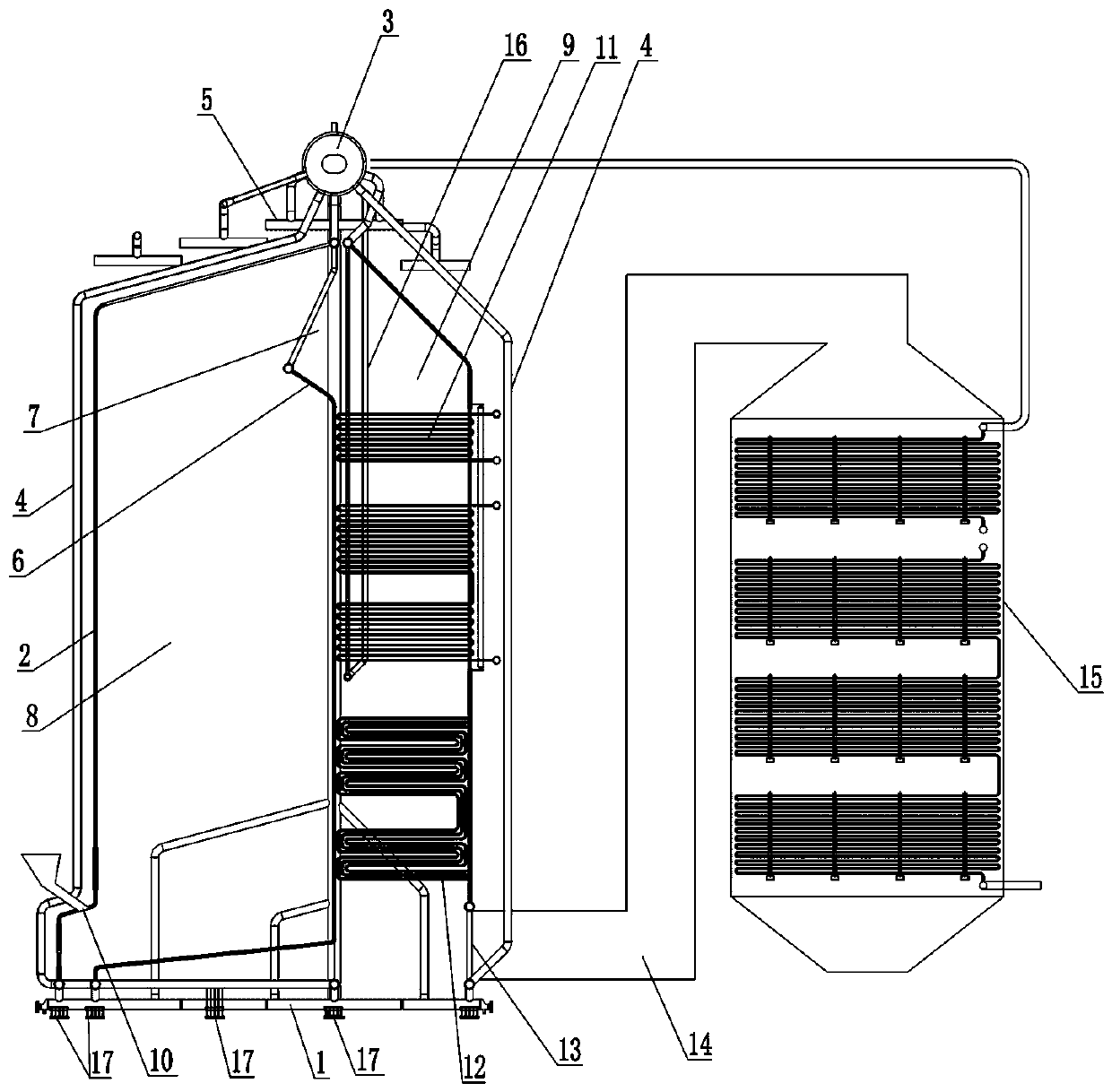

Vertical type angular-tube type bubbling bed boiler

PendingCN107654990ASmall footprintReduce use costBoiler drums/headersIncinerator apparatusEngineeringSuperheater

The invention discloses a vertical type angular-tube type bubbling bed boiler comprising a boiler bottom support seat formed by a plurality of lower collecting boxes and middle connecting tubes. A boiler body defined by a film-type water cooling wall is placed on the boiler bottom support seat, and a steam drum is arranged above the boiler body and supported by falling tubes arranged outside the boiler body. The upper ends of the falling tubes communicate with the steam drum, and the lower ends of the falling tubes communicate with the lower connecting boxes. The lower connecting boxes communicate with an upper connecting box through the film-type water cooling wall, and the upper connecting box communicates with the steam drum. A partition plate is arranged in the boiler body, the film-type water cooling wall of a front cavity is provided with a feeding port, and the film-type water cooling wall of the bottom of the front cavity is provided with a plurality of air inlets. A superheater and an evaporator are arranged in a rear cavity, the superheater communicates with the steam drum, and the evaporator communicates with the film-type water cooling wall of the rear side of the rearcavity. The film-type water cooling wall of the rear cavity is provided with a smoke outlet communicating with an economizer of the exterior of the boiler body, and the economizer communicates with the steam drum. The vertical type angular-tube type bubbling bed boiler has the advantages that the combustion efficiency is high, and the occupied area is small.

Owner:SUZHOU HAILU HEAVY IND

Novel heat preserving layer structure

InactiveCN104500921ASolve non-detachableSolve the creepThermal insulationPipe protection by thermal insulationRadiation lossVacuum pumping

The invention relates to a novel heat preserving layer structure. The novel heat preserving layer structure comprises a screw, a T-shaped vacuum main rib, a heat preserving container wall, a vacuum heat insulating layer, a heat preserving layer, bolts, nuts and a protective reflecting layer. The heat preserving layer is connected with the heat preserving container wall through the T-shaped vacuum main rib, and the T-shaped vacuum main rib is connected with the heat preserving layer through special bolts, so that convenience is brought to maintenance and overhauling; through design of the special bolts, creepage is prevented; vacuum pumping is performed between the heat preserving layer and the container wall, so that a good heat preserving effect is achieved; through the protective reflecting layer made of an iron sheet, the heat preserving layer can be protected, and external radiation loss can be reduced; the heat preserving layer is filled with a foam polymer, so that a remarkable heat insulating effect and outstanding economical benefit are achieved.

Owner:天津深蓝宇节能减排技术有限公司

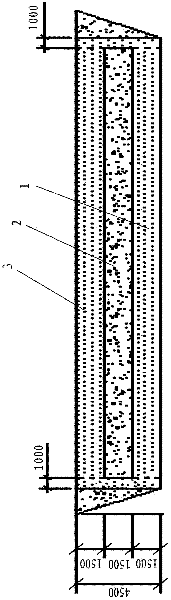

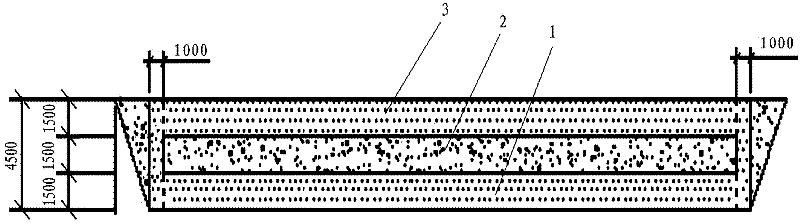

Blast furnace slag replacement method for high-fill steel slag foundation

ActiveCN102518111ASolve the problem of thermal expansionResolve lateral pressureEmbankmentsSoil preservationSlagThermal expansion

The invention discloses a blast furnace slag replacement method for high-fill steel slag foundation, which comprises the following steps of: superimposing a first blast furnace slag cushion layer (1), a graded gravel cushion layer (2) and a second blast furnace slag cushion layer (3) sequentially from bottom to top in a steel slag foundation pit, respectively compacting the first blast furnace slag cushion layer, the graded gravel cushion layer and the second blast furnace slag cushion layer, setting up a through groove around the first blast furnace slag cushion layer, the graded gravel cushion layer and the second blast furnace slag cushion layer, and filling blast furnace slag into the groove. By adopting the blast furnace slag replacement method, the problem of thermal expansion of the high-fill steel slag foundation can be solved. The invention has the advantages that the method can be easily mastered and has practicality, the quality requirements can be satisfied, the construction period can be shortened, and the construction cost can be reduced. Therefore, the method has good promotion prospects.

Owner:PANGANG GRP ENG TECH

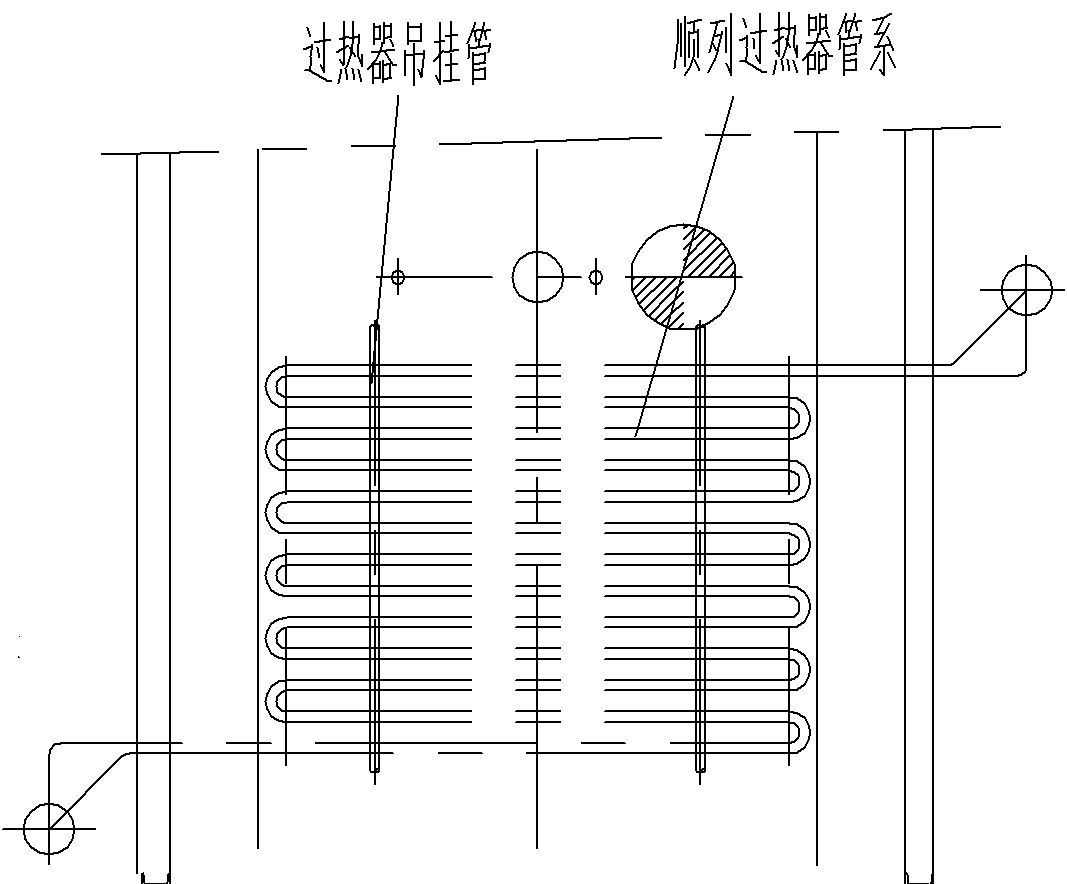

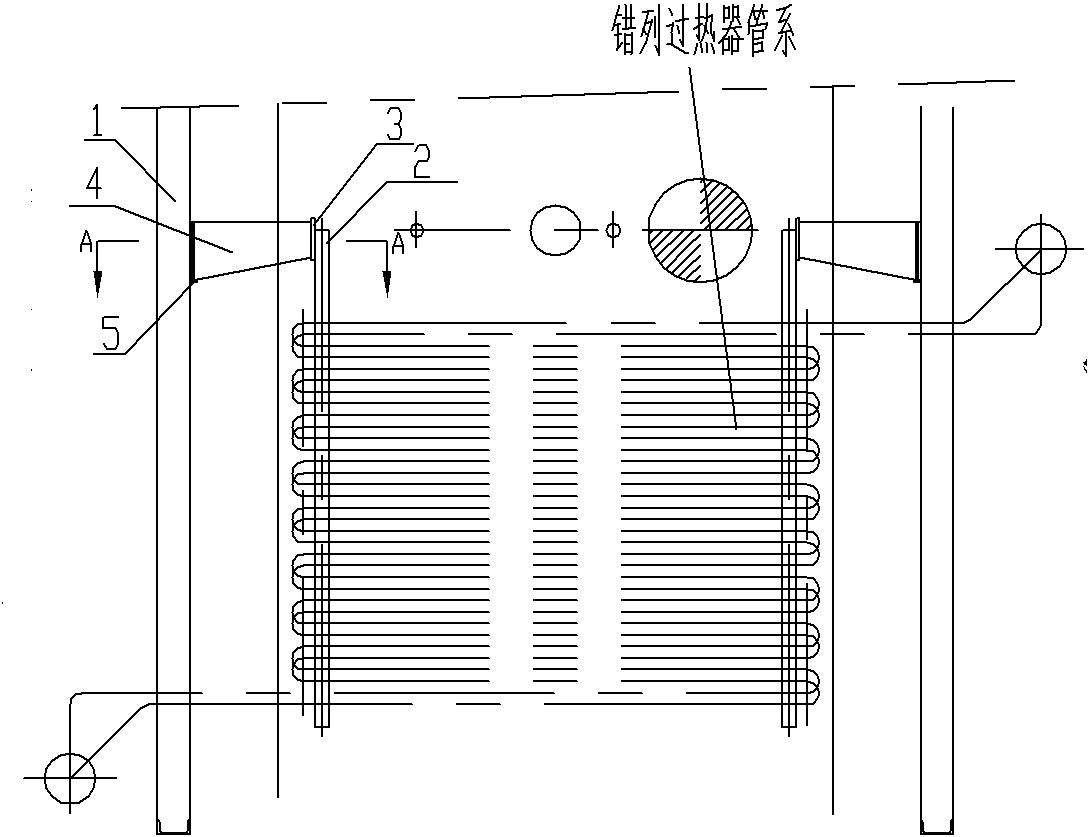

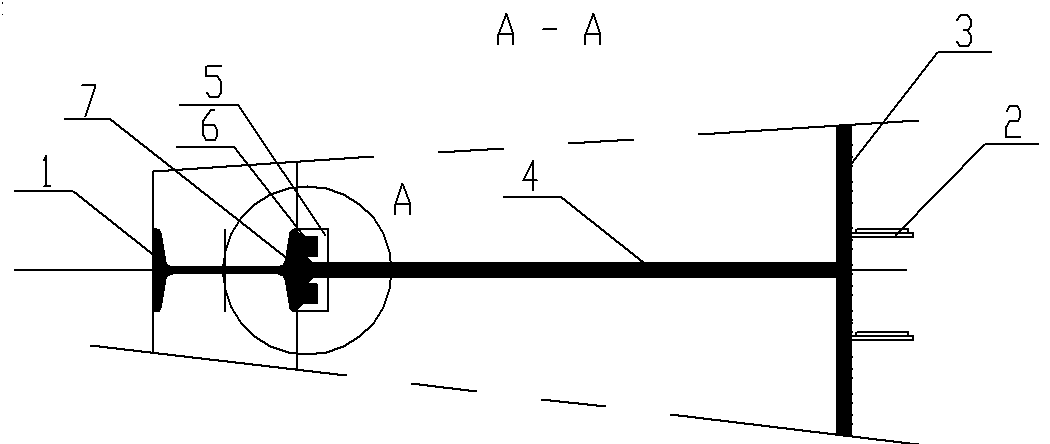

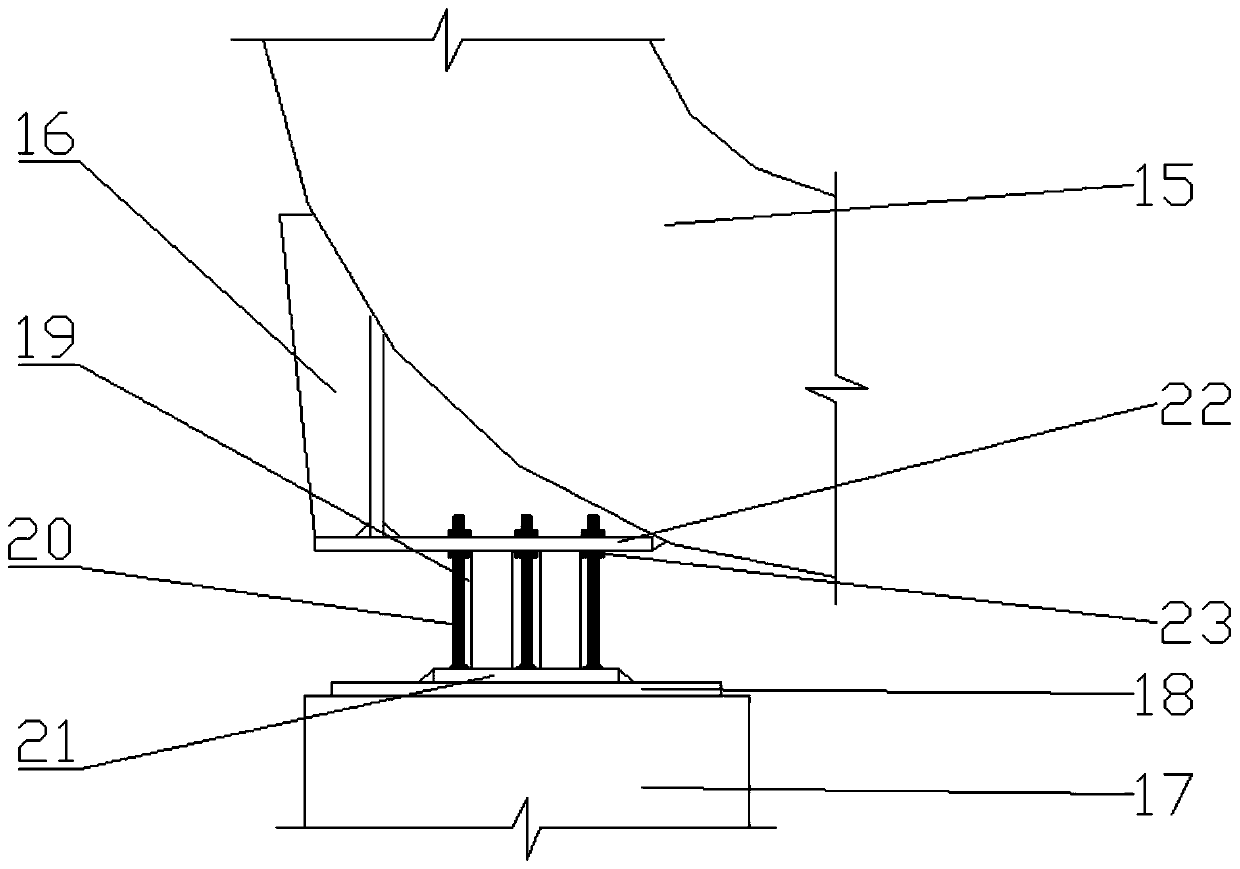

A hanger structure for boiler superheater

ActiveCN105937757BEasy to fixHeat transferBoiler supporting/setting arrangementsSuperheaterEngineering

The invention relates to the technical field of pipe hanging of a boiler superheater, and in particular to a hanging clamping frame structure for a boiler superheater. The hanging clamping frame structure can solve the problems of heat transfer due to connection and heat expansion and guarantee normal operation. The hanging clamping frame structure comprises a protection plate and a superheater pipe clamp, and is characterized in that the superheater pipe clamp is connected to one end of a supporting rib plate; the other end of the supporting rib plate is a T-shaped head; a bottom plate is mounted on the protection plate; a side surface of the T-shaped head end of the supporting rib plate clings to a vertical reinforcement of the protection plate closely; a bottom surface of the supporting rib plate is supported on an upper end face of the bottom plate; two angular septum plates which are arranged at two sides of the T-shaped head and closely cling to the T-shaped head are also mounted on the bottom plate.

Owner:WUXI HUAGUANG BOILER

A kind of dewaxing method of ceramic shell

ActiveCN108246976BReduce the probability of crackingImprove pass rateFoundry mouldsFoundry coresThermal insulationCeramic

The invention discloses a method for dewaxing a ceramic mold, which includes: -before the ceramic mold with a wax pattern enters the dewaxing process, setting a thickness ranging from thin to Thick, differentiated thermal barrier;‑Place the ceramic mold with the wax pattern and thermal barrier in the dewaxing equipment, with the dewaxing port on the ceramic mold facing down, and the thermal barrier on the outside of the ceramic mold The thinnest area is at the bottom of the vertical, and the thickest area is at the top of the vertical; - After the ceramic shell with wax pattern and heat-resistant layer enters the dewaxing process, the heat-resistant layer outside the ceramic shell Control the gradual change of the wax pattern inside the ceramic shell to absorb the heat of dewaxing in the order from bottom to top, so that the wax pattern inside the ceramic shell takes the dewaxing port as the starting point of melting, and realizes the sequence from bottom to top in the order from outside to inside. Dewaxing. It can reduce or directly cancel the auxiliary dewaxing port on the ceramic shell, effectively and reliably guarantee the qualified rate and quality of the dewaxing molding of the ceramic shell.

Owner:DONGFANG TURBINE CO LTD

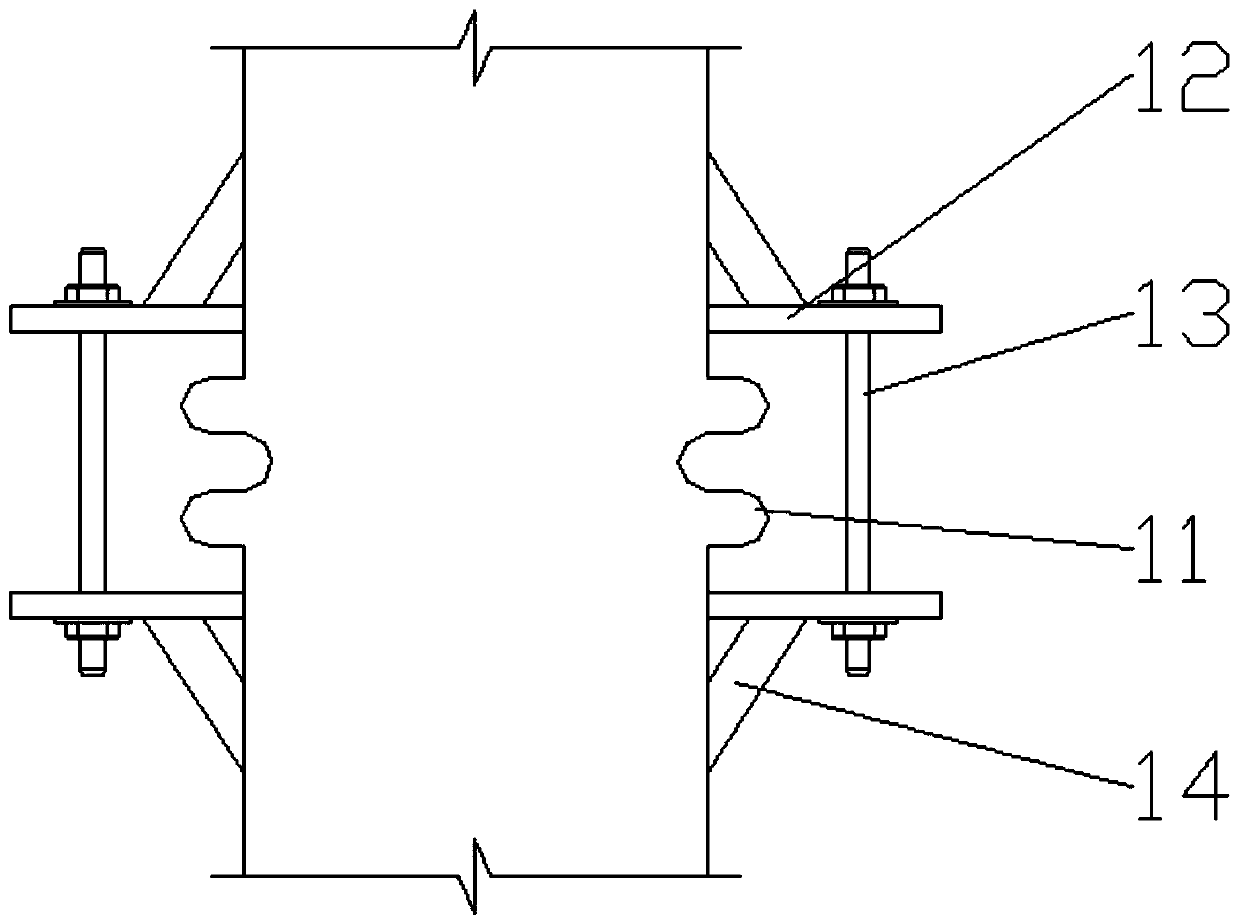

Device for reducing operation vibration of steam turbine

PendingCN111140294AGuaranteed stabilityReduce contact stiffnessMachines/enginesEngine componentsThermodynamicsEngineering

The invention discloses a device for reducing the operation vibration of a steam turbine. The device comprises a steam turbine body; condenser spring support seats for supporting a condenser are arranged on the lower surface of the condenser; a circulating water pipe expansion part comprises an expansion joint connected onto a circulating water pipe; and an elbow joint part comprises a water pipeelbow and a support frame fixedly connected to the outer side of the water pipe elbow. Pull plates and pull rods are arranged at the expansion joint of the circulating water pipe of the steam turbine,water pipes at two ends of the expansion joint are fixedly connected together through the pull plates and the pull rods, and then the expansion joint is turned into a rigid whole; and when circulating water generates a blind plate force at the expansion joint, the extension of the circulation water pipe at the expansion joint is not caused, therefore, the problem of the rise of the condenser caused by the extension of the circulating water pipe can be avoided, and a thrust on a rear cylinder is not generated, so that the balanced stress on the cylinder is realized, the vibration generated dueto the stress imbalance is further avoided, and the operation stability of the steam turbine is ensured.

Owner:中安联合煤化有限责任公司

High temperature continuous nitrogen heater

ActiveCN105627560BSolve the problem of thermal expansionSolve conductivity problemsAir heatersPower flowNitrogen

The invention provides a high-temperature continuous nitrogen heater. The high-temperature continuous nitrogen heater comprises a cylinder, a water cooling positive electrode, a water cooling negative electrode and a heating element; the heating element is mounted on the axis of the cylinder, and one end thereof is connected with the water cooling positive electrode through a slide transfer piece; the water cooling positive electrode is connected with a power supply by penetrating out of a water cooling end surface flange tightly connected to one end of the cylinder; the other end of the heating element penetrates out of a graphite baffle plate at the other end of the closed cylinder; upper and lower two water cooling negative electrodes mounted on the heating element through an electrode transfer disc are connected with the power supply after penetrating out of through holes in the wall of the cylinder; the heating element is a sandwich layer structure consisting of a graphite straight pipe on the outer layer and a graphite straight pipe with a spiral fin on the outer pipe wall on the inner layer; a spiral channel is formed between the outer-layer pipe and the inner-layer pipe through the spiral fin; and a through hole is formed in the slide transfer piece connected to one end of the heating element. The high-temperature continuous nitrogen heater solves the difficulties of thermal expansion of the heating element and high-current electric conduction, and can realize continuous heating of nitrogen currents.

Owner:BEIJING AEROSPACE YISEN WIND TUNNEL ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com