Cyclone separator for crude gas dust removal in crushed coal pressurized gasification and application

A crushed coal pressurized gasification and cyclone separator technology, which is applied in gas dust removal, combustible gas purification, combustible gas purification/transformation, etc., can solve problems affecting stable operation, crude gas outlet temperature, tar condensation, slag outlet blockage, etc. problem, to achieve the effect of less sensible heat loss of gas, small equipment amplification effect, and large operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

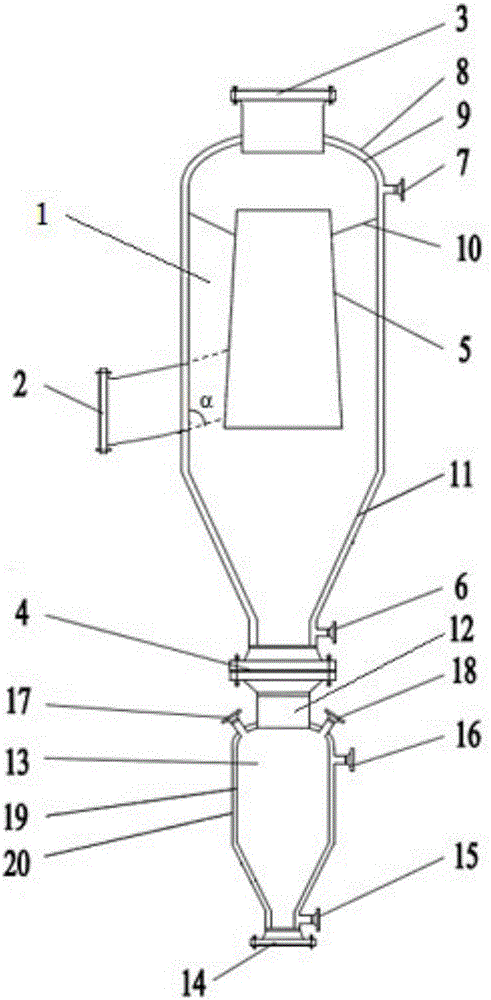

[0030] A cyclone separator for dust removal of crushed coal pressurized gasification crude gas, which includes a cyclone dust collector 1 and an ash tank 13, characterized in that the cyclone dust collector 1 includes an outer cylinder 11 and an inner cylinder 5, and an outer cylinder The upper part of 11 is vertical and the lower part is tapered. The outer cylinder body 11 is composed of the outer cylinder outer wall 8 and the outer cylinder inner wall 9 and forms a jacket structure. The inner cylinder body 5 is fixed to the outer cylinder inner wall by a tensile member 10 9, the gas inlet 2 communicates with the lower part of the inner cylinder 5 through the outer cylinder 11, and the gas outlet 3 is located at the top of the outer cylinder 11. The upper part of the outer cylinder wall 8 has a cyclone dust collector hot water outlet 7, and the lower part has a cyclone dust collector heat The water inlet 6 and the bottom outlet of the outer cylinder 11 are connected to the top ...

Embodiment 2

[0045] Crude gas produced by pressurized gasification of crushed coal has a temperature of 640°C and a pressure of 4.0 MPa. The crude gas contains 13.5 grams of oil dust per cubic meter of crude gas. The crude gas is driven at a speed of 25m / s.

[0046] After the oil dust is removed, the oil dust content per cubic meter of crude gas is 75mg.

[0047] The angle α between the gas inlet 2 and the inner wall 9 of the outer cylinder is 76 degrees.

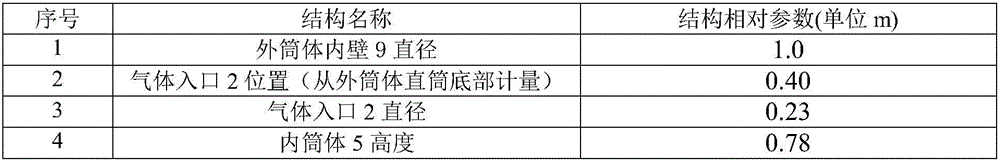

[0048] The 1m diameter of the inner wall 9 of the cylinder outside the cyclone dust collector 1 of the present invention is taken as a reference, and the relative parameters of other structures are shown in Table 3. The rest is the same as in Example 1.

[0049] Table 3 Design structure parameters of cyclone dust collector

[0050] Serial number

Embodiment 3

[0052] Crude gas produced by pressurized gasification of crushed coal has a temperature of 550°C and a pressure of 2.5MPa. The crude gas contains 0.15 grams of oil dust per cubic meter of crude gas. The crude gas is at a speed of 21m / s.

[0053] After the oil dust is removed, the oil dust content per cubic meter of crude gas is 1.2mg.

[0054] The angle α between the gas inlet 2 and the inner wall 9 of the outer cylinder is 85 degrees.

[0055] The 1m diameter of the inner wall 9 of the cylinder outside the cyclone dust collector 1 of the present invention is taken as a reference, and the relative parameters of other structures are shown in Table 4. The rest is the same as in Example 1.

[0056] Table 4 Design structure parameters of cyclone dust collector

[0057]

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com