Method for preparing combustable gas using peltate yam waste slag

A waste residue and combustible technology, applied in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve problems such as environmental pollution and energy waste, and achieve high system efficiency, continuous and stable operation, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

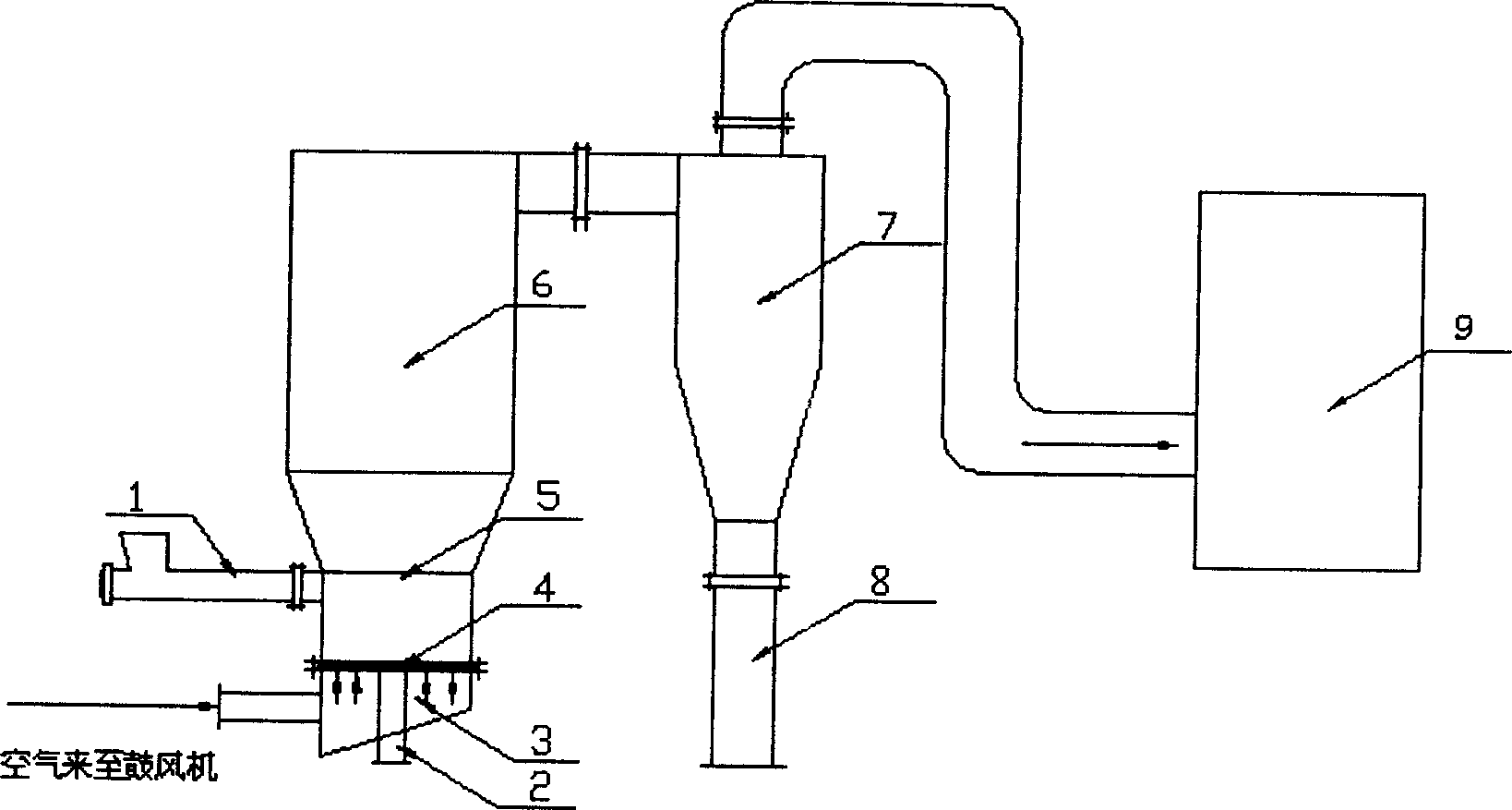

[0018] The turmeric waste residue used in the present embodiment is typical waste residue after extracting saponin from turmeric, its main components are as shown in Table 1, and its technological process is as follows figure 1 . In the figure, the turmeric waste residue is fed into the gasification device composed of the lower section 5 of the gasification device of Φ650 and the upper section 6 of the gasification device of Φ1000 in series through the Φ219 screw feeder 1. The height is 8.5 meters, and the three production process conditions are as follows: the first time, the ratio of air volume to added turmeric waste residue is 0.8Nm 3 Air / kg turmeric waste residue, the cross-sectional velocity of the air in the cold state on the air distribution plate is 0.5 m / s, the residence time of the turmeric waste residue in the gasification device is 7 seconds, and the temperature of the gasification device is controlled at 650 °C; the second time , the ratio of the amount of air t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com