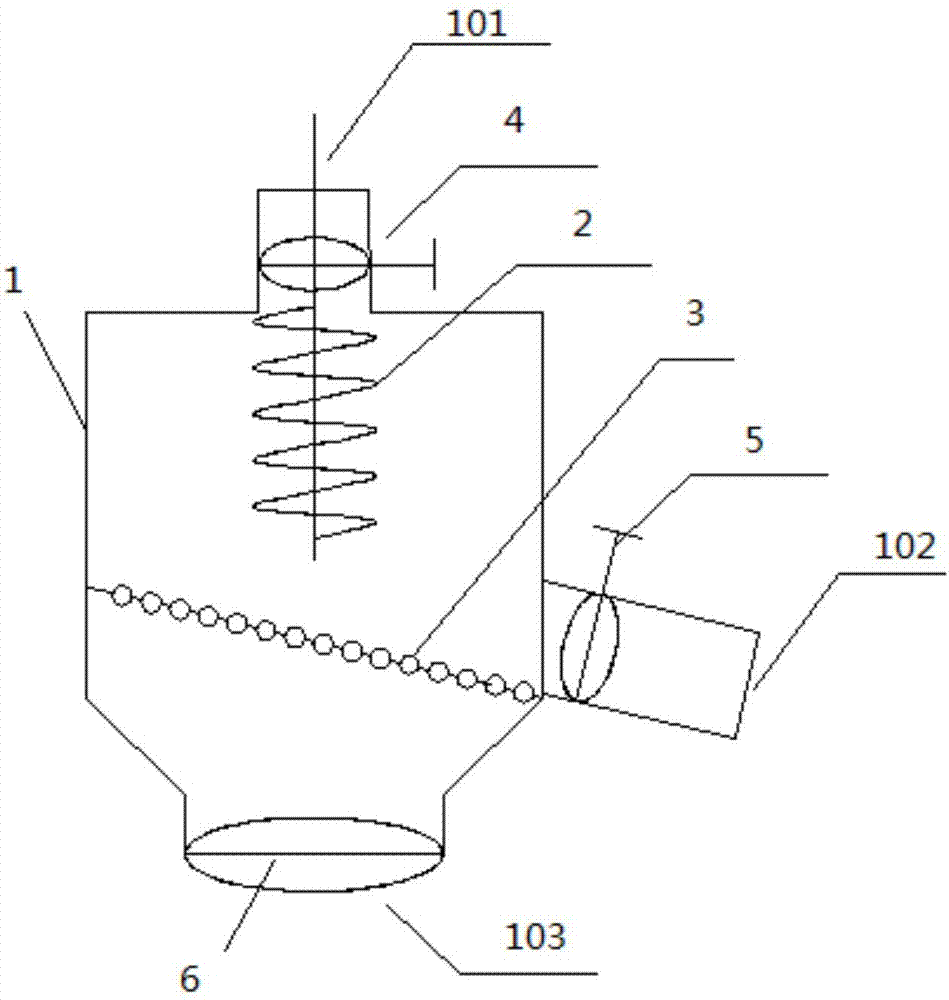

High-temperature solid conveyor device

A technology of high-temperature solids and conveying device, applied in the field of conveying, can solve the problems of heat loss, pulverization, affecting the normal operation of calcium carbide production units and the risk of safe operation, and achieves the effect of reducing carbon emissions, reducing sensible heat loss and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Embodiment: the specific technological process of this embodiment is as follows.

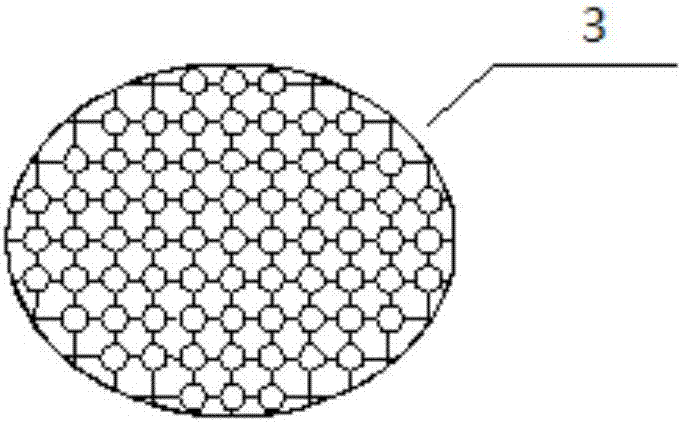

[0030] The diameter of the high-temperature solid inlet is 40mm: it is set directly above the heat preservation tank, and the feeding process is controlled by the feed control valve; The upper surface is at the same level, and high-temperature solids enter the insulation tank through the anti-breakage chute, which can reduce the breakage caused by collision and drop during the feeding process. The pulverization rate of the feeding process is 0.1%; Inside the body, the aperture is 5mm, the opening rate is 20%, the distance from the bottom of the insulation tank is 30cm, and the angle with the vertical tank wall is 80°, the effective classification efficiency of powder is 98%; the high temperature solid outlet is set On the side wall of the thermal insulation tank, the lower side wall of the high-temperature solid outlet is connected to the lowest point of the grading orifice plate, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com