Natural gas shuttle-type energy-saving kiln

A natural gas, shuttle technology, applied in the field of shuttle kiln, can solve the problem of fuel consideration, and achieve the effect of reducing energy cost, low energy consumption and low emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

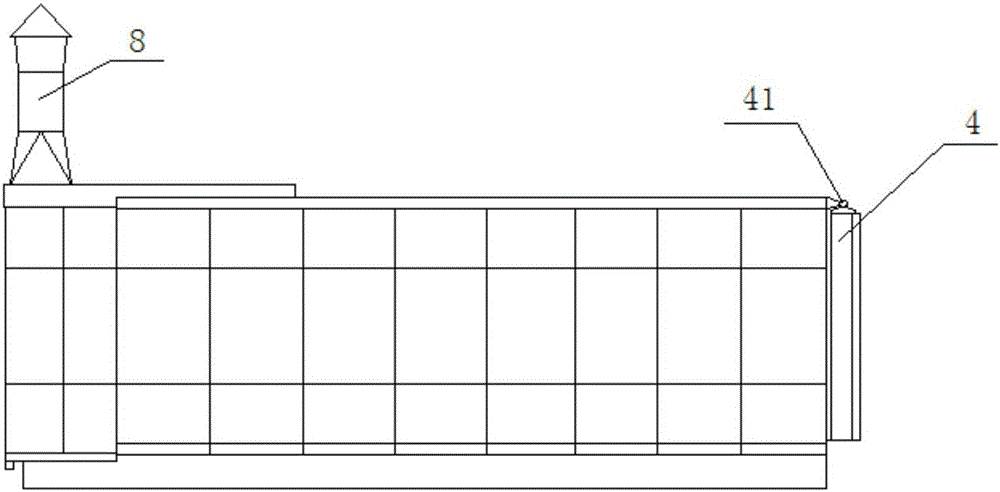

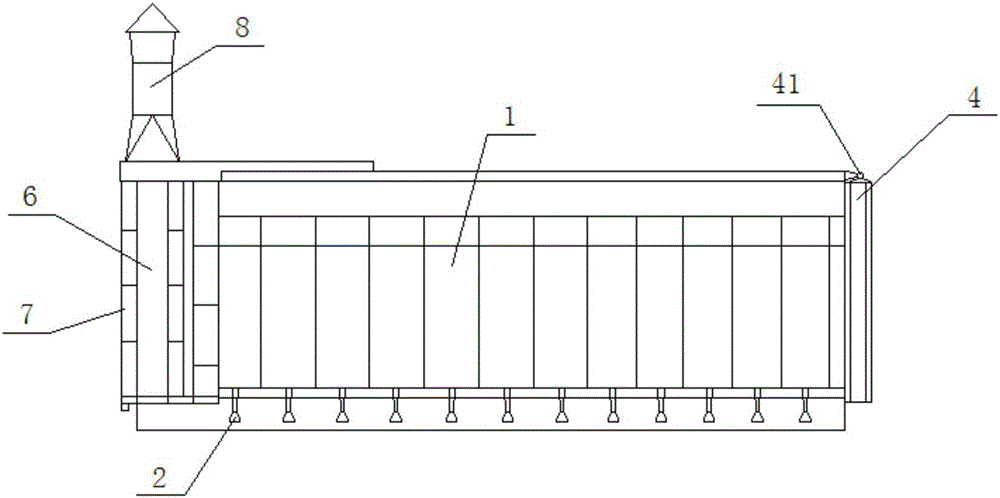

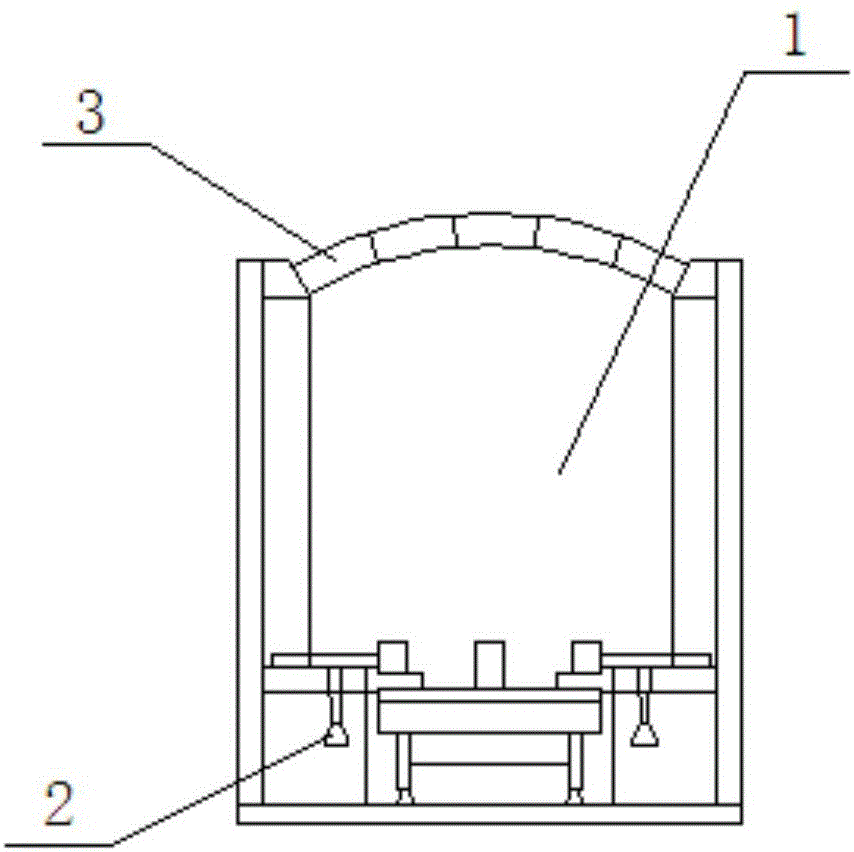

[0013] Embodiment 1, Figure 1 ~ Figure 3 Combined with a natural gas shuttle type energy-saving kiln, a natural gas shuttle type energy-saving kiln is provided, which is characterized in that it includes a kiln roof 3, the kiln roof 3 adopts a suspended micro-arc roof structure, the kiln door 4 adopts a single-arm connecting shaft rotating mechanism 41, and the entire kiln frame adopts an assembly The overall structure is sealed with baking varnish color board, the combustion system adopts the design of external mixing nozzle, and the smoke exhaust method is adopted at the kiln tail. Kiln lining materials are made of lightweight refractory materials with high thermal resistance and low heat storage. There are 50 nozzles 2, 25 on both sides of the bottom of the kiln car 1, and the nozzles 2 on each side are arranged in parallel. The flue 6 and the waste heat recovery device 8 are specifically as follows: the flue 6 and the side wall branch flue are equipped with gates 7, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com