Method for designing fixed-geometry two-dimensional mixed-compression type supersonic velocity air inlet channel

A technology of supersonic inlet and design method, which is applied in the direction of turbine/propulsion intake, engine components, combustion air/combustion-air treatment, etc., to achieve high-efficiency combustion, simple and easy change method, and reduce the exit Mach number Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

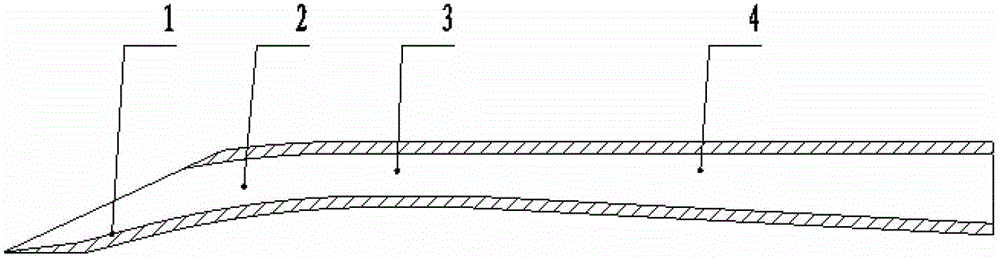

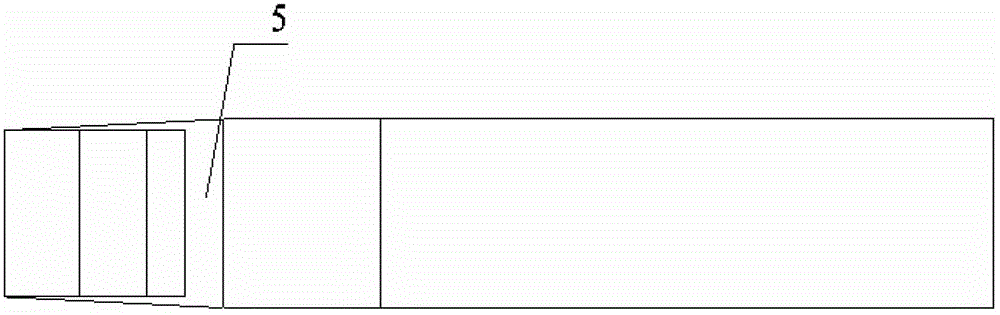

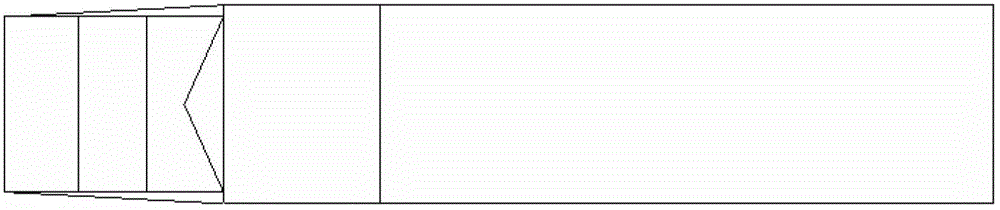

[0026] refer to figure 1 , figure 2 , image 3 , Figure 4 , the fixed geometry binary mixed-pressure supersonic inlet of the present invention comprises an external pressure section 1, an internal pressure section 2, a throat section 3, an expansion section 4, and a lip 5, and the lip 5 is a part of the internal pressure section, and is a A pointed plate structure with a certain wedge angle.

[0027] When designing the dual-pressure mixed-pressure supersonic inlet, it is necessary to select the reasonable design point, capture flow rate and starting Mach number of the inlet according to the ballistic requirements of the aircraft, and determine the capture height of the inlet and its Geometrical width; the design point of the inlet selected in this embodiment is: flight altitude 10km, design Mach number 3.0; captured flow 4kg / s; starting Mach number 2.2. According to this embodiment, the width of the air inlet is selected to be 150mm, and the capture height is 72mm. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com