A kind of thermoplastic friction stir welding device and welding method

A thermoplastic and friction stir technology, which is used in the field of plastic welding, can solve the problems of short solidification time of thermoplastics, decreased strength of welded joints, and large temperature gradient of welded parts, and achieves the advantages of improving temperature field distribution, increasing strength, and optimizing forming performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings.

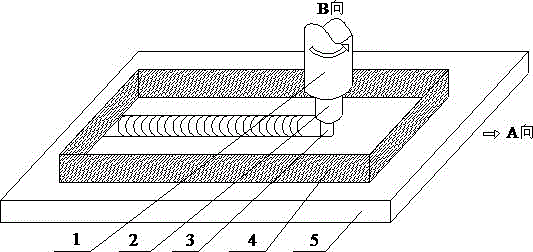

[0018] Such as figure 1 As shown, it is a diagram of the overall structure of a thermoplastic friction stir welding device, including a stirring head clamping part 1, a shaft shoulder 2, a stirring pin 3, an open container 4, and a weldment 5. The forward direction of the stirring head is A direction, The rotation direction of the stirring head is B direction. The shaft shoulder 2 and the stirring needle 3 are integrally formed to form a stirring head, the stirring head is fixed on the stirring welding machine by the holding part 1 of the stirring head, the open container 4 is fixed on the weldment 5, and the contact part between the open container 4 and the weldment 5 Seal with waterproof sealant to prevent the liquid medium contained in the open container 4 from flowing out during the welding process. The open container 4 is a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com