A kind of flexible thermal convection type acceleration sensor and preparation method thereof

An acceleration sensor, thermal convection technology, applied in the direction of acceleration measurement using inertial force, measurement of acceleration, copy/marking method, etc. The effect of improving the foldability, increasing the difference of the induction resistance, and increasing the speed of change of the thermal field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further explained below in conjunction with the accompanying drawings.

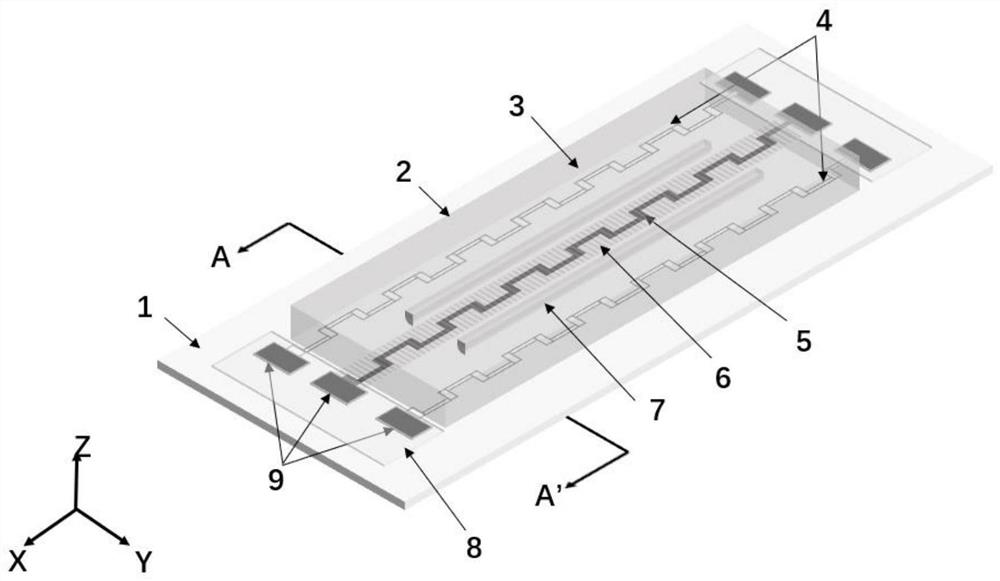

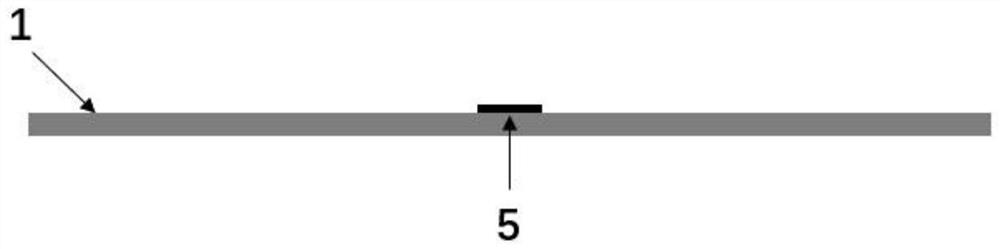

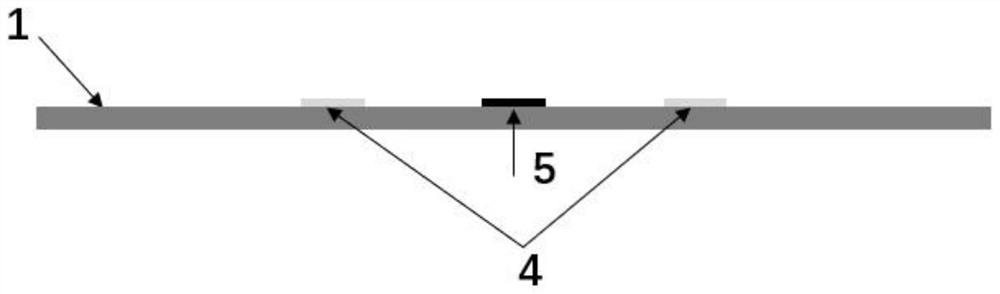

[0033] Such as Figure 1 to Figure 5 As shown, a flexible thermal convection acceleration sensor includes a flexible substrate 1 , a flexible sealing top cover 2 , an S-shaped heating element 5 , an S-shaped temperature sensing element 4 and a heat-absorbing thin layer 6 . The flexible top cover 2 is arranged on the flexible substrate 1, and a sealed cavity 3 is formed between the two, and the sealed cavity 3 is filled with air or an inert gas as a thermal fluid. The S-shaped heating element 5 is fixed in the center of the flexible substrate 1 in the sealed cavity 3 . Two S-shaped temperature sensing elements 4 are fixed on the flexible substrate 1 in the sealed cavity 3 and are symmetrically distributed on both sides of the S-shaped heating element 5 . The heat-absorbing thin layer 6 is closely attached to the S-shaped heating element 5 inside the sealed cavity 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com