Flexible organic light emitting diode

A light-emitting diode, organic technology, applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of flexibility limitation, light-emitting color coordinate shift, unfavorable device large area, etc., to solve the square resistance Large and weak microcavity effects, avoiding the effect of strong microcavity effects in devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

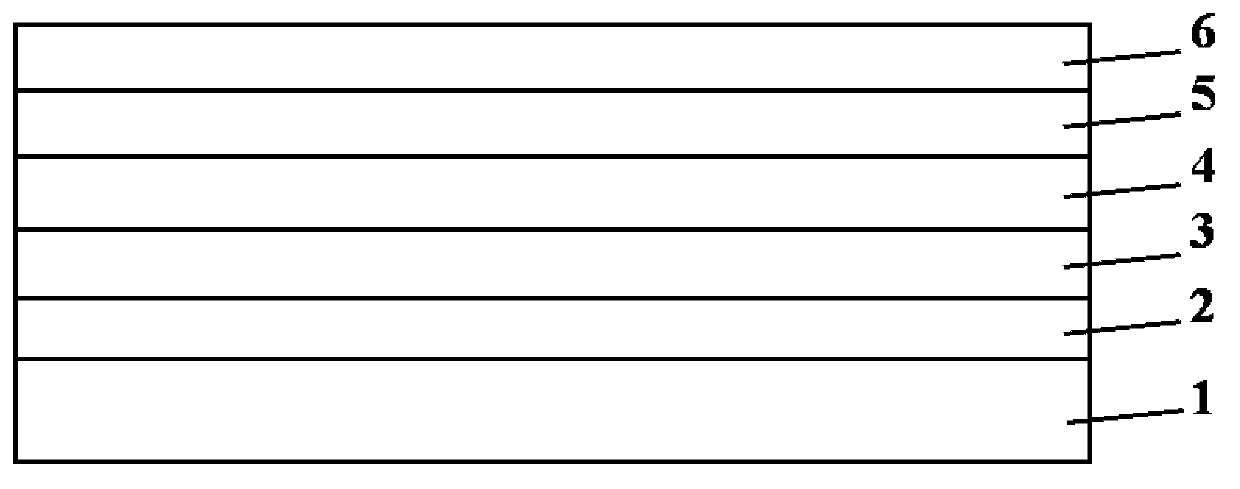

[0072] A flexible organic light emitting diode device includes: a flexible substrate 1, a graphene composite anode 2, a hole injection layer 3, an organic functional layer 4, an electron injection layer 5, and a cathode 6. figure 1 It is a cross-sectional structure diagram of a flexible organic light-emitting diode single-pixel device based on a graphene composite anode.

[0073] The manufacturing process of the flexible organic light emitting diode mainly includes the following steps:

[0074] (1) Clean the flexible substrate;

[0075] (2) Fabricate and pattern a graphene composite anode on the substrate;

[0076] (3) Depositing the hole injection layer material on the composite anode;

[0077] (4) Depositing an organic functional layer on the hole injection layer;

[0078] (5) Depositing an electron injection layer on the organic functional layer;

[0079] (6) Depositing the cathode on the electron injection layer;

[0080] (7) Perform flexible packaging on the device. ...

Embodiment 2

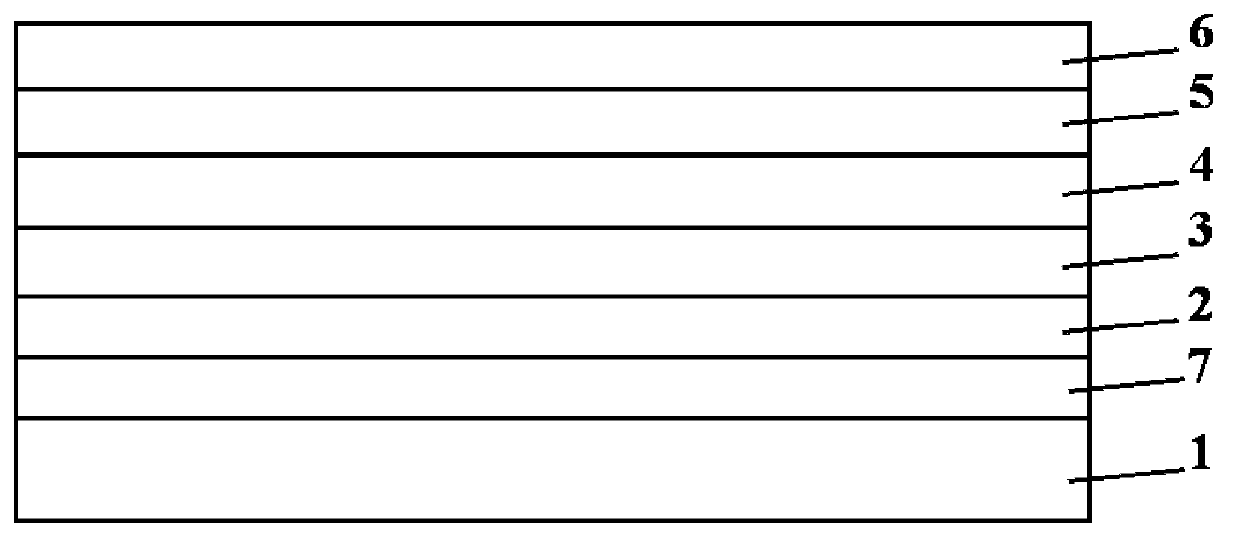

[0089] On the basis of the structure of the flexible organic light-emitting diode provided in Example 1, an internal light extraction layer 9 is added. The extraction layer can be made of materials such as tantalum oxide, molybdenum oxide, tungsten oxide, and vanadium oxide. deposited on flexible substrates. figure 2 It is a schematic cross-sectional structure diagram of the flexible organic light emitting diode device described in Example 2, and its specific implementation method is as follows:

[0090] (1) Clean the flexible substrate;

[0091] (2) Depositing an internal light extraction layer on a flexible substrate;

[0092] (3) Fabricate and pattern the graphene composite anode on the inner light extraction layer;

[0093] (4) Depositing the hole injection layer material on the composite anode;

[0094] (5) Depositing an organic functional layer on the hole injection layer;

[0095] (6) Depositing an electron injection layer on the organic functional layer;

[0096] (...

Embodiment 3

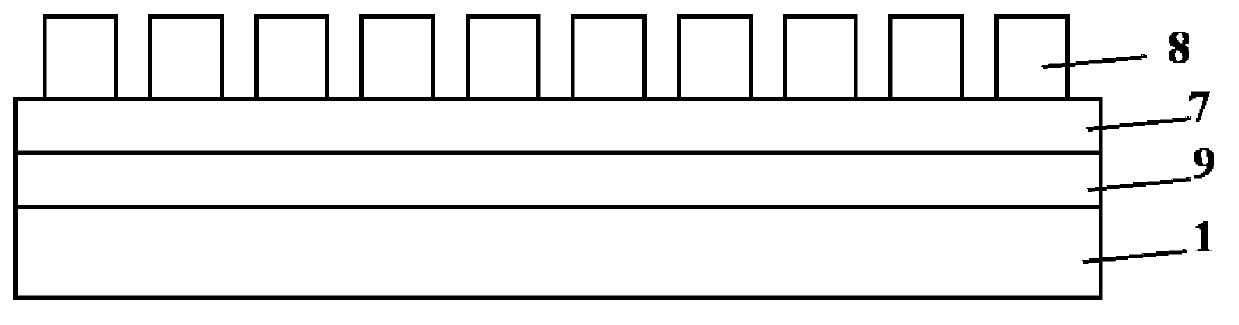

[0100] image 3 A cross-sectional structure diagram of an organic light-emitting diode display device integrating a single-chip capacitive touch screen for a flexible substrate. This device structure enables good touch performance to be achieved after the flexible light-emitting device is fabricated. The electrode can be made of materials such as graphene, carbon nanotubes, metal nanowires, conductive polymers, etc., and its processing method can be yellow light process or laser etching. The method of laser etching is preferred. The specific The implementation process is as follows:

[0101] (1) Clean the flexible substrate;

[0102] (2) Fabricate the touch sensing layer on the substrate;

[0103] (3) Depositing an internal light extraction layer on the touch sensing layer;

[0104] (4) Fabricate and pattern the graphene composite anode on the inner light extraction layer;

[0105] (5) Depositing the hole injection layer material on the composite anode;

[0106] (6) Depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com