Preparation and defocusing forming method of low-cost ceramic powder for selective laser melting

A laser selective melting and ceramic powder technology, applied in the field of additive manufacturing, can solve the problems that ceramic materials are sensitive to stress and cracks, cannot completely suppress cracks, and the performance of formed parts is not good, so as to reduce the dependence on harsh conditions and optimize The effect of uniform distribution of temperature field, reduction of processing cost and threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

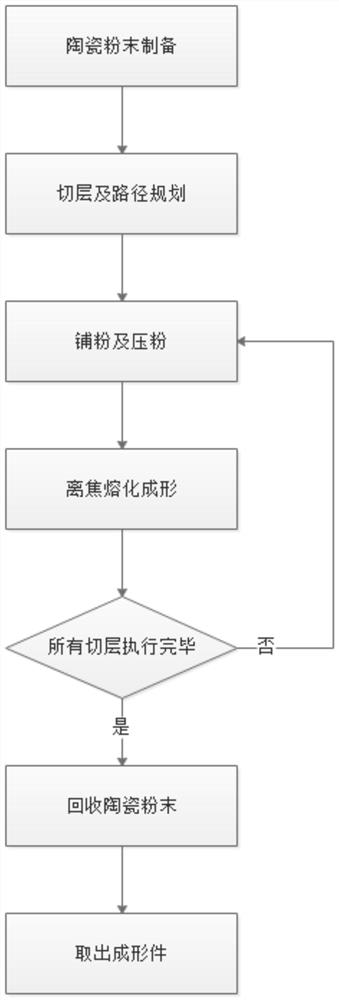

[0046] combine figure 1 As shown, the specific preparation process is:

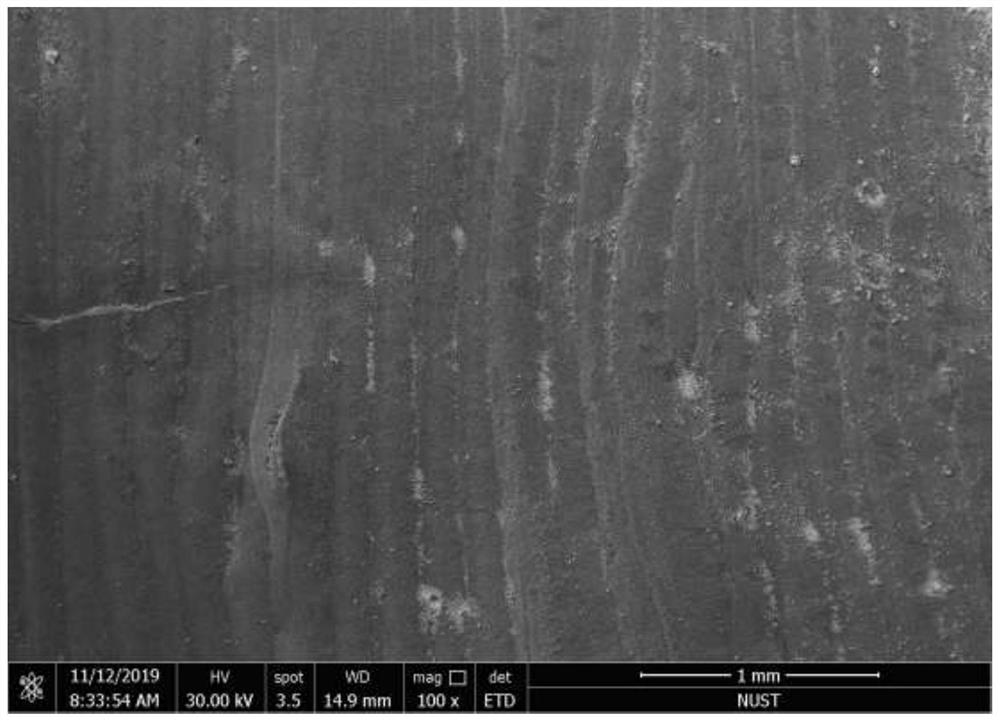

[0047] Aluminum oxide and zirconium oxide with a purity of 99.5% are selected as raw material powders to prepare small cubes with a size of 8×8×8 mm by selective laser melting. The median particle size of alumina powder is 0.78 μm, and the powder presents an irregular flake shape; the median particle size of zirconia powder is 1 μm, and the powder presents an irregular polyhedral shape. Select the mass ratio of alumina and zirconia as 61.5:38.5, select alumina balls so that the mass ratio of balls to materials is 3:1, and use alcohol as the medium to mix evenly at 200r / min, take the ceramic slurry obtained by high-energy ball milling at 100 After drying for 2 hours under the environment of ℃ and 10KPa, sieve the powder, place the sieved powder in an argon atmosphere for annealing treatment, the heating temperature is 700 ℃, the holding time is 72h, and air cooling after holding the heat. A 99.9% dense f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com