Gas base shaft-furnace direct reduction method for strengthening iron ore pellets

A gas-based shaft furnace and oxidizing pellet technology, which is applied to shaft furnaces, furnaces, furnace types, etc., can solve the problems of reduced efficiency, deteriorated adhesion, material layer permeability, uneven temperature distribution of the shaft furnace, and affecting the normal operation of the shaft furnace. , to achieve the effect of alleviating the material and speeding up the reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

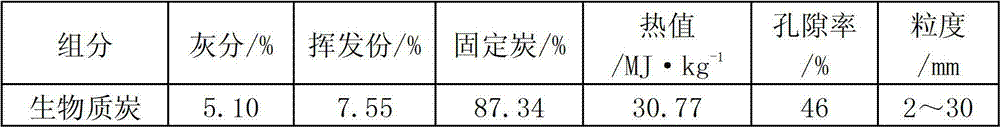

Examples

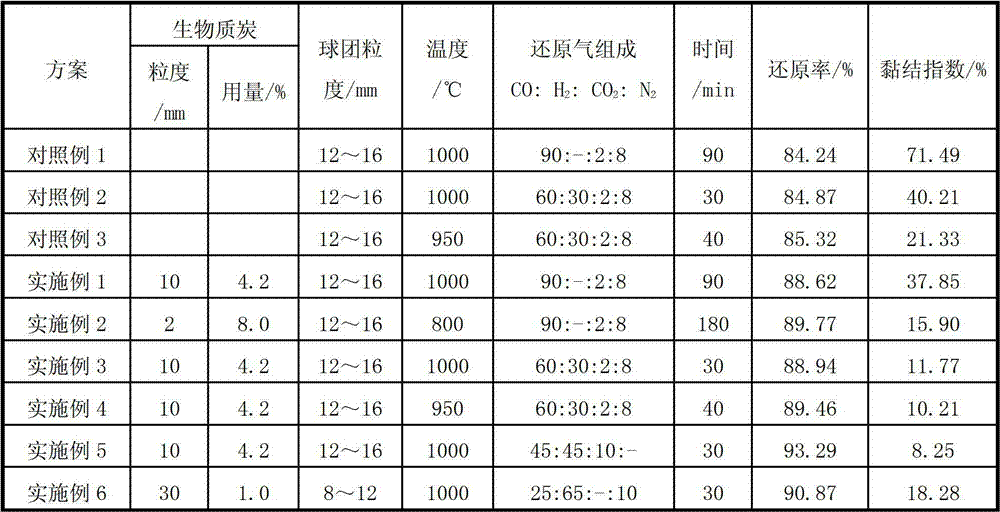

Embodiment 1

[0029] Example 1: Mix 500g iron ore oxidized pellets (12mm~16mm) with 22.1g (accounting for 4.2% of the total amount of the mixture) of biochar (average particle size 10mm) and mix them evenly, then add them to the shaft furnace, and heat them at a temperature of 1000°C , the atmosphere is 90% CO, 2% CO 2 , 8%N 2 (Volume percent) The reduction rate of the metallized pellet sample obtained after reduction for 90 minutes was 88.62%, and the cohesion index was 37.85%.

Embodiment 2

[0030] Example 2: Take 460g of iron ore oxidized pellets (12mm-16mm) and 40g (accounting for 8% of the total amount of the mixture) of biochar (average particle size 2mm) and mix them evenly, then add them to the shaft furnace, at a temperature of 800 ° C, The atmosphere is 90%CO, 2%CO 2 , 8%N 2 (Volume percent) The reduction rate of the metallized pellet sample obtained after reduction for 180 minutes was 89.77%, and the cohesion index was 15.90%.

Embodiment 3

[0031] Example 3: Mix 500g iron ore oxidized pellets (12mm~16mm) with 22.1g (accounting for 4.2% of the total amount of the mixture) of biochar (average particle size 10mm) and mix them evenly, then add them into the shaft furnace, and heat them at a temperature of 1000°C , the atmosphere is 60%CO, 30%H 2 , 2%CO 2 , 8%N 2 (Volume percent) The reduction rate of the metallized pellet sample obtained after reduction for 30 minutes was 88.94%, and the cohesion index was 11.77%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com