Double-beam swing welding method for inhibiting high-strength titanium alloy welding cracks

A welding crack and welding method technology is applied in the field of dual-beam laser swing welding for suppressing welding cracks in high-strength titanium alloys. Effects of small joint stress and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The conventional oscillating laser welding and the method of the present invention are respectively used to weld a 2mm thick titanium alloy butt joint. The specific experimental method is as follows:

[0041] Conventional swing laser welding welds 3mm thick titanium alloy butt joints:

[0042] Step 1: process the parts to be welded of the workpiece to the required accuracy as required, and grind or clean the surfaces on both sides of the workpiece after processing;

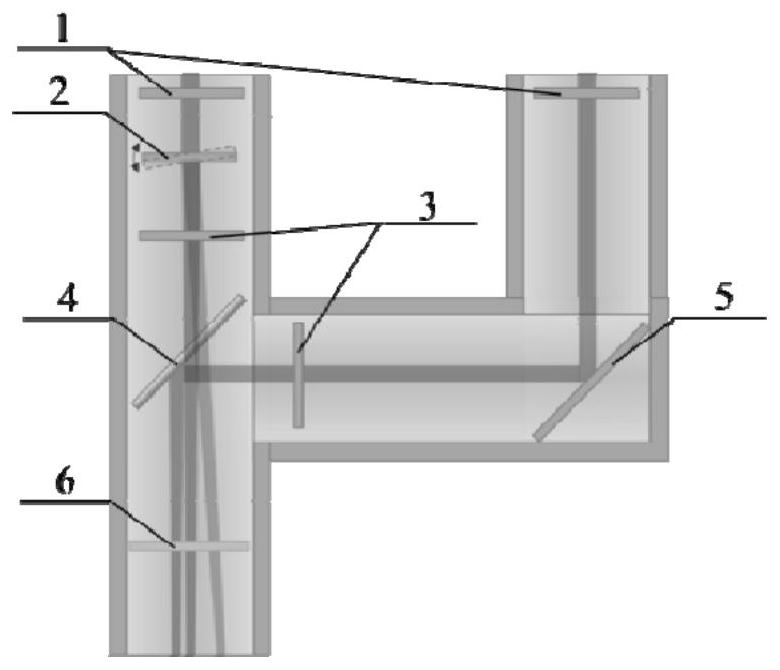

[0043] Step 2: fixing the workpiece to be welded after grinding or cleaning on the welding fixture;

[0044] Step 3: The laser defocus is ﹢5mm, the laser power is 2100W, the welding speed is 1.0m / min, the swing trajectory is circular swing, the swing frequency is 150Hz, the swing amplitude is 3mm, the shielding gas is Ar gas, and the flow rate is 30L / min;

[0045] Step 4: In the actual welding process, the robot integrated system is used to control the welding process parameters. First, the laser is con...

Embodiment 2

[0047] The method of the present invention welds a 2mm thick titanium alloy butt joint:

[0048] Step 1: process the parts to be welded of the workpiece to the required accuracy as required, and grind or clean the surfaces on both sides of the workpiece after processing;

[0049] Step 2: fixing the workpiece to be welded after grinding or cleaning on the welding fixture;

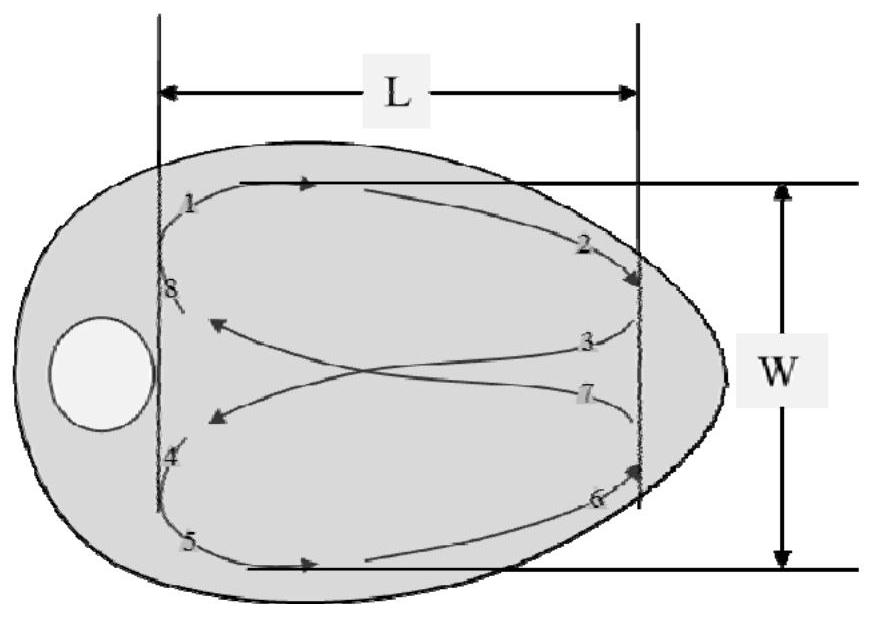

[0050] Step 3: Set up double-beam lasers, wherein one laser light source is located at the front end of the welding pool, and the other laser light source periodically swings at the rear part of the welding pool to form a movement path; wherein, the movement path is "8" type path;

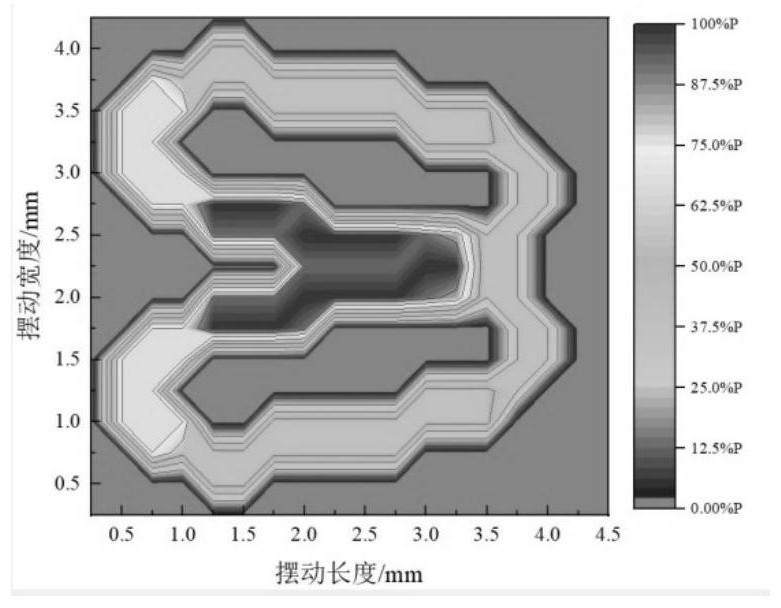

[0051] Select two points in the upper half of the 10-20% length area of the "8"-shaped path near the front of the welding pool, marked as P1 and P 8, and select two points in the lower half, marked as P 4 and P 5; close to the welding pool Select two points in the upper half of the 10-20% length area of the "8"-shaped path ...

Embodiment 3

[0060] The difference between this embodiment and embodiment 2 is: the laser defocus is ﹢15mm, the fixed laser power is 5000W, and the swing laser peak power P is 2500W; both P1 and P5 are 60%P, and both P2 and P6 are 40%P , P3 and P7 are all 100% P, P4 and P8 are both 75% P; the welding speed is 5m / min, the laser swing frequency is 400Hz, the swing length is 5mm, the swing width is 5mm, and the shielding gas adopts Ar gas and inert gas The mixed gas flow rate is 60L / min. Others are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com