Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Improve sliding performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Adhesive sheet for laser dicing and its manufacturing method

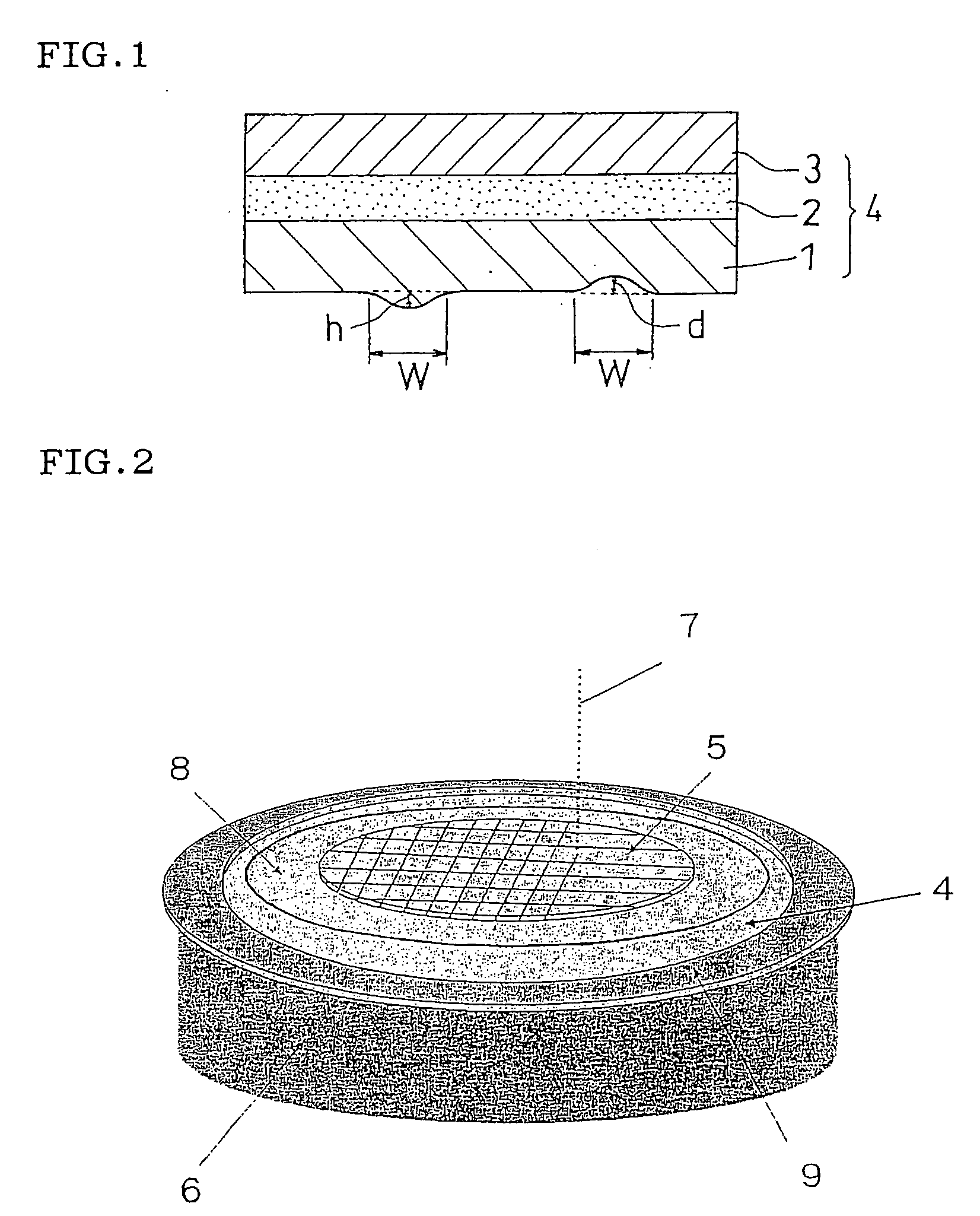

InactiveUS20050186709A1Improve production efficiencyEasy to peelSemiconductor/solid-state device detailsSynthetic resin layered productsEngineeringLaser beams

It is an object of the invention to present an adhesive sheet for laser dicing capable of dicing the workpiece into individual small pieces of element securely at high production efficiency when forming a reformed region inside the workpiece by light absorption ablation of laser beam, and its manufacturing method. It is also an object of the invention to present a method of manufacturing small pieces of element securely at high production efficiency by using this adhesive sheet for laser dicing. That is, the invention presents an adhesive sheet for laser dicing used for dicing into individual chips by forming a reformed region inside of a workpiece by light absorption ablation of laser beam, in which the adhesive sheet has an adhesive layer at least on one side of a base material, and at least the base material surface not contacting with the adhesive layer is free from convex parts of width (W) of 20 mm or less and height (h) of 1 μm or more, and concave parts of width (W) of 20 mm or less and depth (d) of 1 μm or more.

Owner:NITTO DENKO CORP

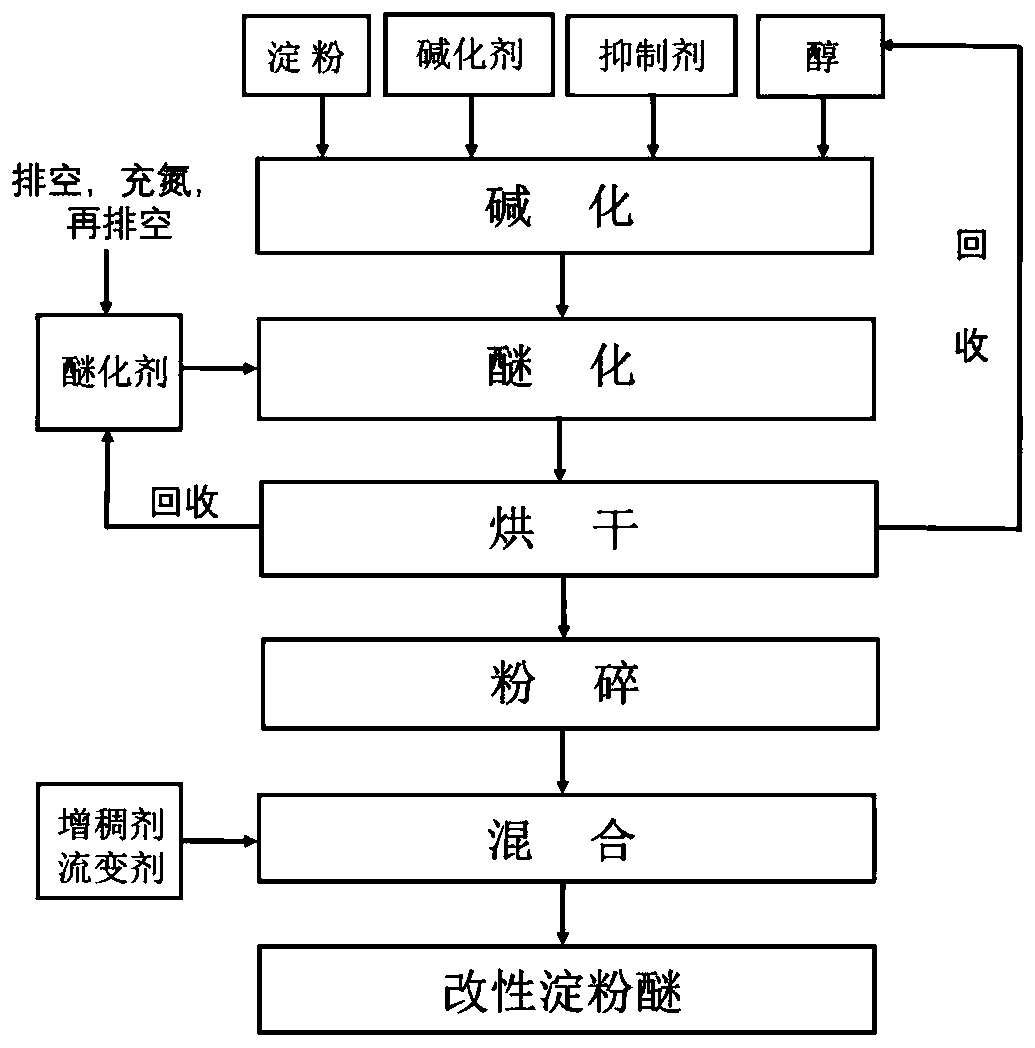

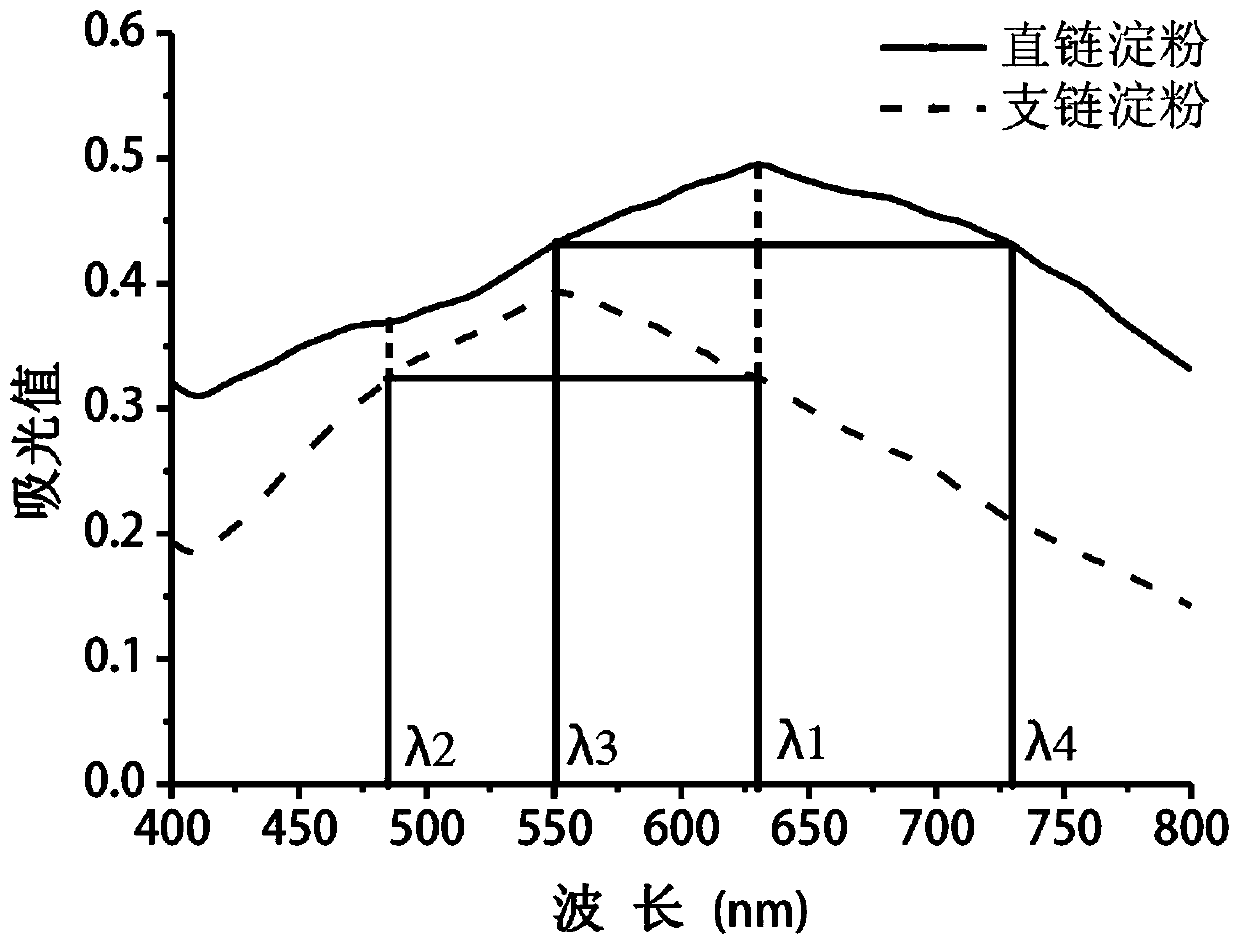

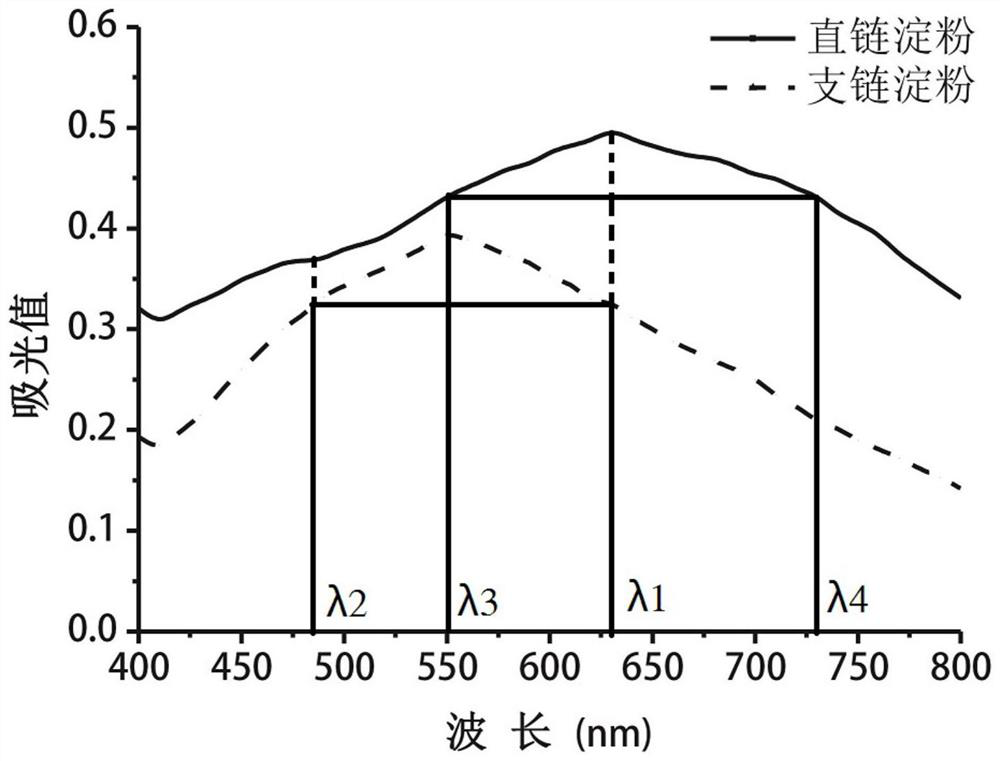

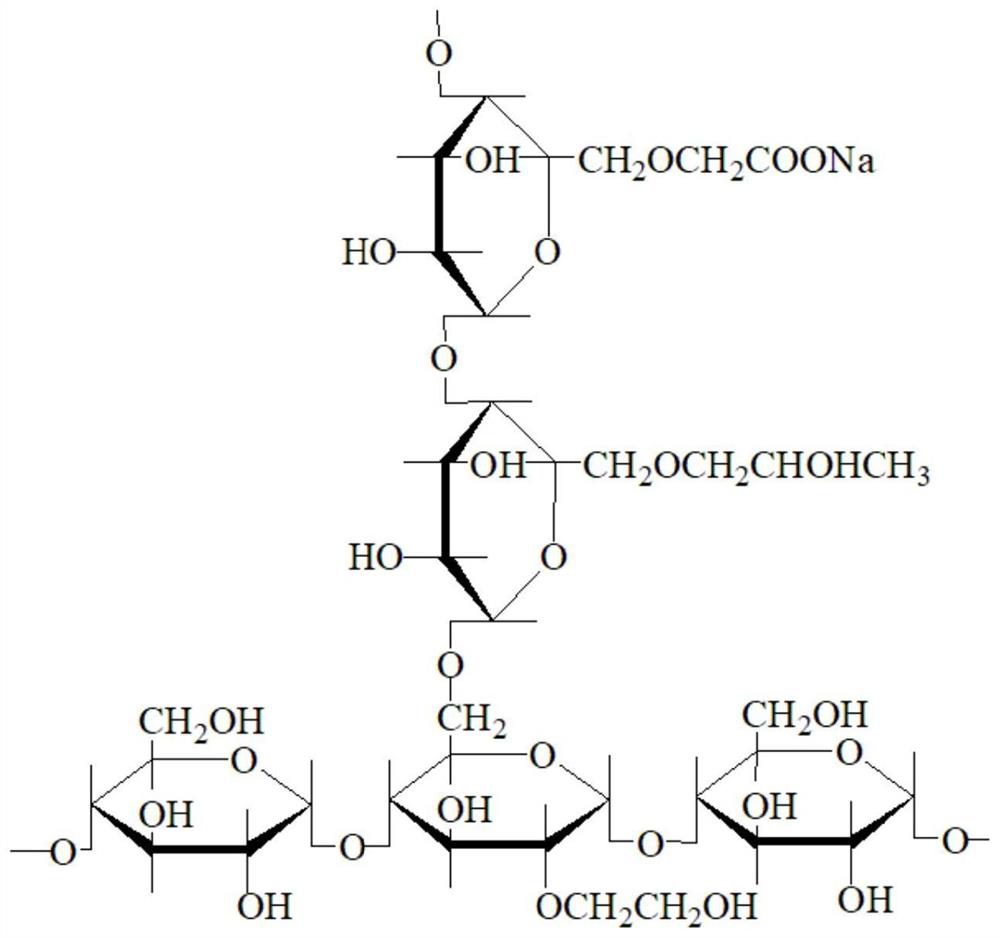

Preparation method of modified starch ether for improving slip performance of ceramic tile glue

ActiveCN110590966AImprove sliding performanceImprove slip resistanceStarch derivtive adhesivesMacromolecular adhesive additivesChemical treatmentEther

The invention relates to the technical field of building additives, in particular to a preparation method of a modified starch ether for improving slip performance of ceramic tile glue. The preparation method comprises the following steps: carrying out one-step etherification chemical treatment modification on starch to obtain starch ether, and carrying out physical modification treatment. According to the preparation method, the complex operation of multi-step etherification in existing modified starch ether preparation process is changed, a starch ether modified product with better performance can be obtained only by one-step simultaneous etherification, and when the obtained product is used for the ceramic tile glue, the slippage performance of ceramic tile glue can be remarkably improved because of adoption of the physical modification treatment; meanwhile, compared with the prior art, the operation conditions of one-step simultaneous etherification treatment are obviously different.

Owner:SHANDONG YITENG NEW MATERIAL CO LTD

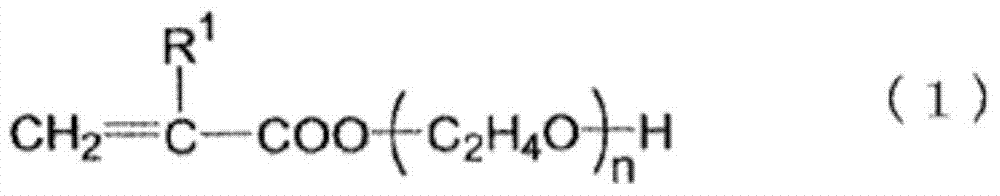

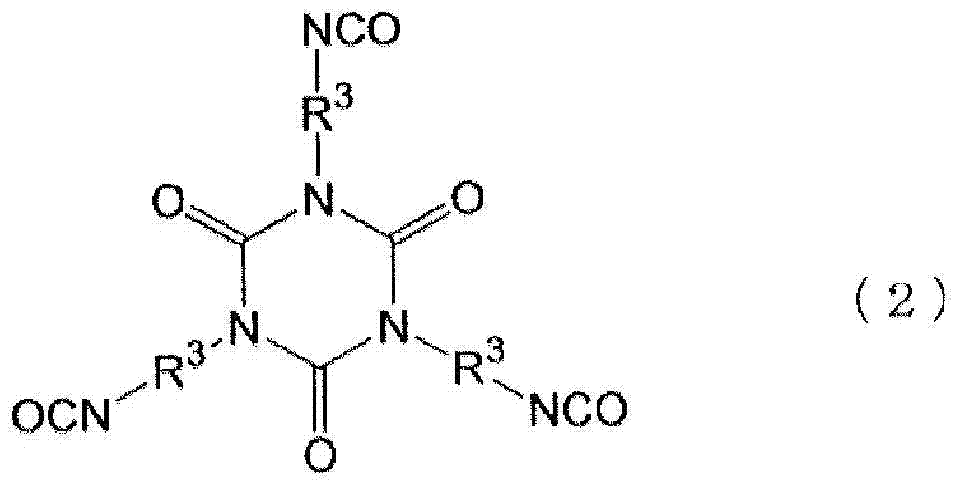

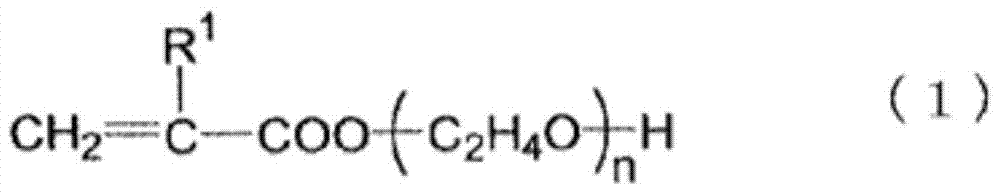

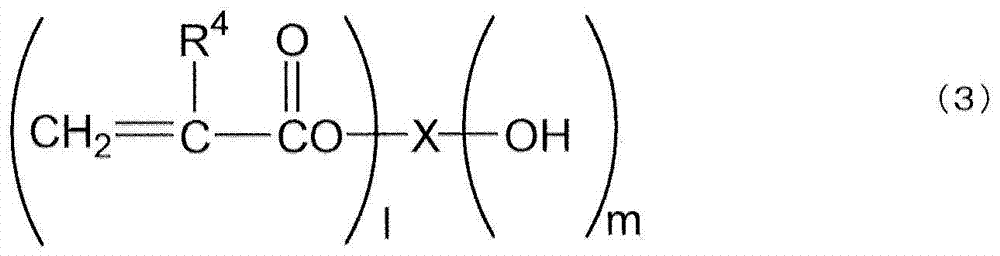

Urethane(meth)acrylate mixture and urethane(meth)acrylate composition

ActiveCN103804629AExcellent self-healing performanceImprove scratch resistancePolyurea/polyurethane coatingsCarbon numberHydrogen atom

The invention provides an urethane(meth)acrylate which can form a curing film having self-restortaion property, excellent anti-abrasion property, and low curing telescoping property, and anti-flexibility. The urethane(meth)acrylate mixture (C) is obtained through the reaction of a (A) polymeric polyoxyethylene derivative mixture and a (B) polyisocyanate compound expressed in formula (2), the (A) polymeric polyoxyethylene derivative mixture is composed of (A1) 85-95 mass% of polymeric polyoxyethylene derivative expressed in formula (1) and (A2) 5-15 mass% of (meth)hydroxyethyl acrylate. In the formula, R1 expresses hydrogen atom or methyl, n is an average addition mole number and n=3-9. In the formula, R3 respectively expresses alkylene with a carbon number in the range of 1-10.

Owner:NOF CORP

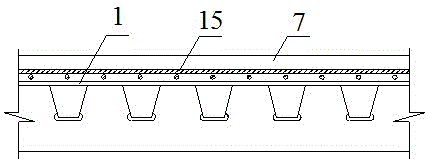

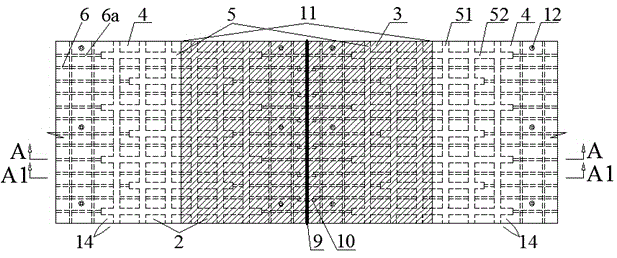

Fabricated combined bridge deck structure provided with grid type connector and construction method thereof

InactiveCN105648909AReduce adverse effectsEasy to installBridge structural detailsBridge erection/assemblyFiberButt joint

The invention discloses a fabricated combined bridge deck structure provided with a grid type connector and a construction method thereof. The combined bridge deck structure is formed by assembling at least two steel plate-fiber concrete combined type components. Each steel plate-fiber concrete combined type component comprises a steel bridge deck slab located on the lower portion and prefabricated fiber concrete pieces poured on the steel bridge deck slab. One grid type connector is arranged in the butt joint area of every two adjacent steel plate-fiber concrete combined type components. The grid type connector comprises cast-in-place fiber concrete pieces and grid reinforcement components fixedly connected to the corresponding steel bridge deck. The grid reinforcement components is completely covered with the prefabricated fiber concrete pieces located on the two sides of the butt joint area and the cast-in-place fiber concrete pieces located in the butt joint area. The prefabricated fiber concrete pieces and the cast-in-place fiber concrete pieces are connected through the grid reinforcement components, so that an integrated fiber concrete layer is formed. The two adjacent steel bridge deck slabs are fixedly connected to form an integrated steel bridge deck slab layer.

Owner:HUNAN UNIV OF TECH

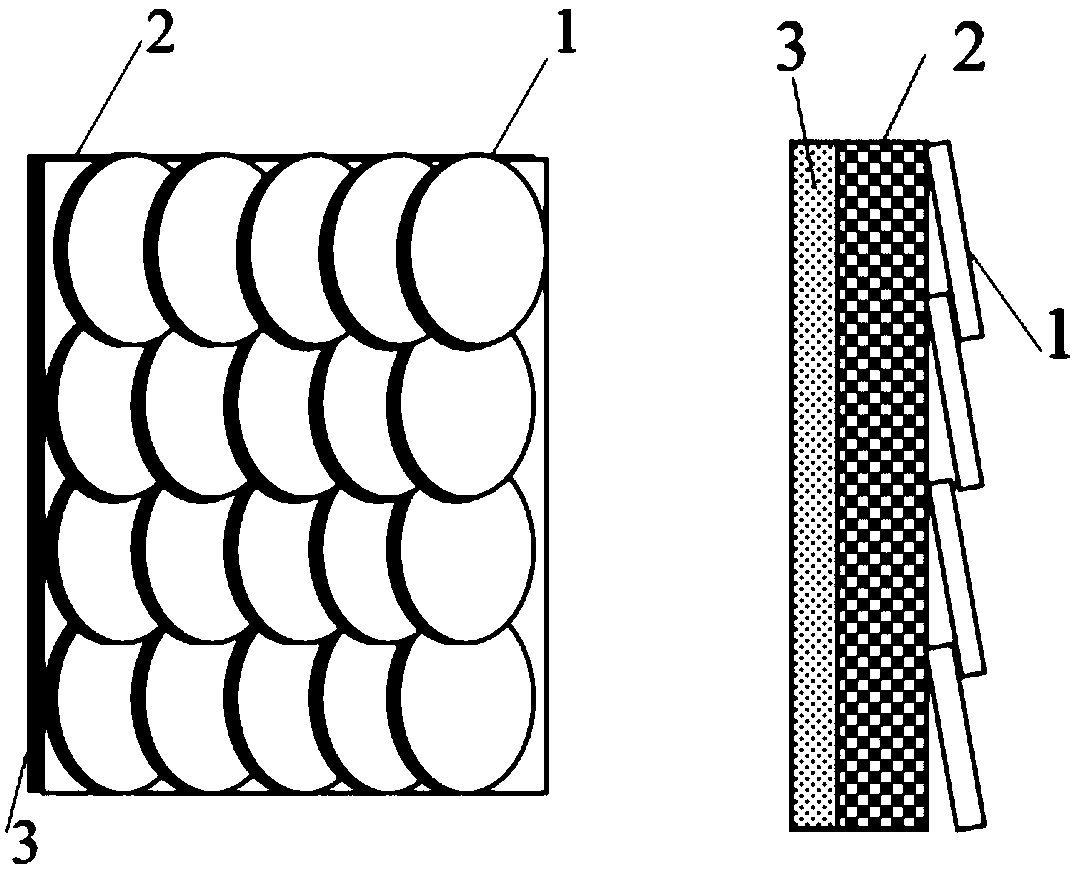

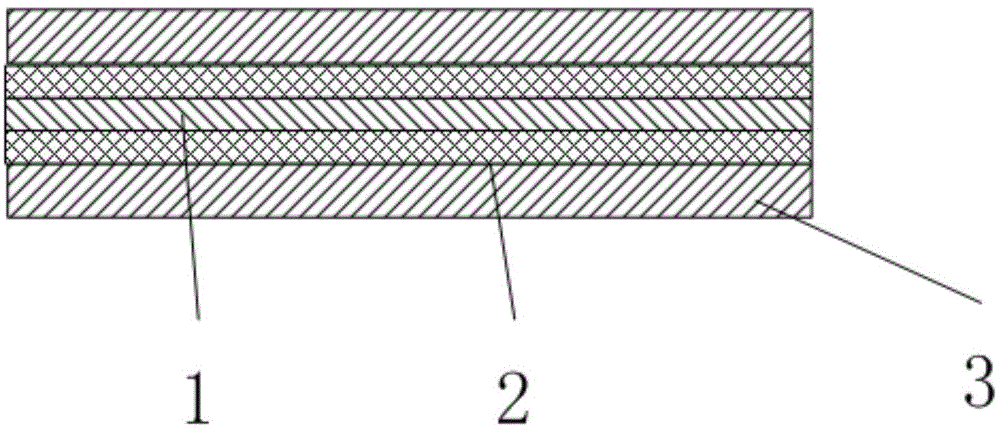

Composite bulletproof material and preparation method thereof

ActiveCN109334177AGood impact resistanceStrong resistance to bullet shear energySynthetic resin layered productsYarnAbsorbed energy

The invention discloses a composite bulletproof material and a preparation method thereof. The composite bulletproof material comprises a face layer, a middle layer and a base layer, wherein the facelayer adopts light metal armor pieces or ceramic composite armor pieces, the middle layer is a flexible high-performance fiber fabric layer, fabric comprises aramid fiber or ultra-high-molecular-weight polyethylene fiber fabric, and the base layer is high-performance fiber fabric impregnated with a shear thickening fluid. The soft and hard composite bulletproof material has good impact resistanceand high bullet shear energy, the flexible high-performance fiber fabric layer as the middle layer has the characteristics of high strength and high flexibility and has high tensile strength and slipperformance in a high-speed bullet condition, the base layer is the high-performance fiber fabric composite impregnated with the shear thickening fluid, friction performance of yarn is improved, and more energy is absorbed. Absorbed energy of the composite bulletproof material at the bullet speed of 500 m / s is 94.85 J.

Owner:YANCHENG INST OF TECH

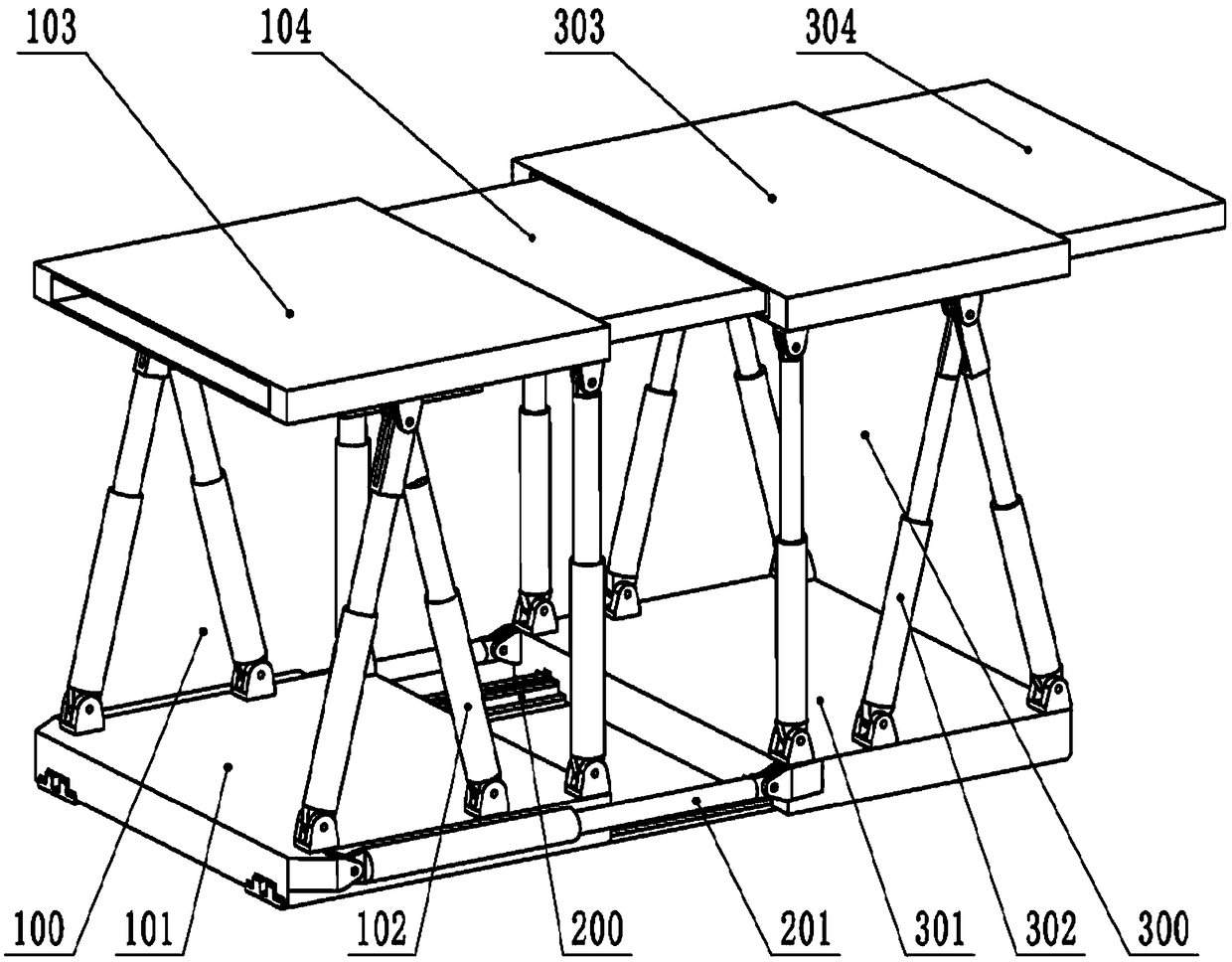

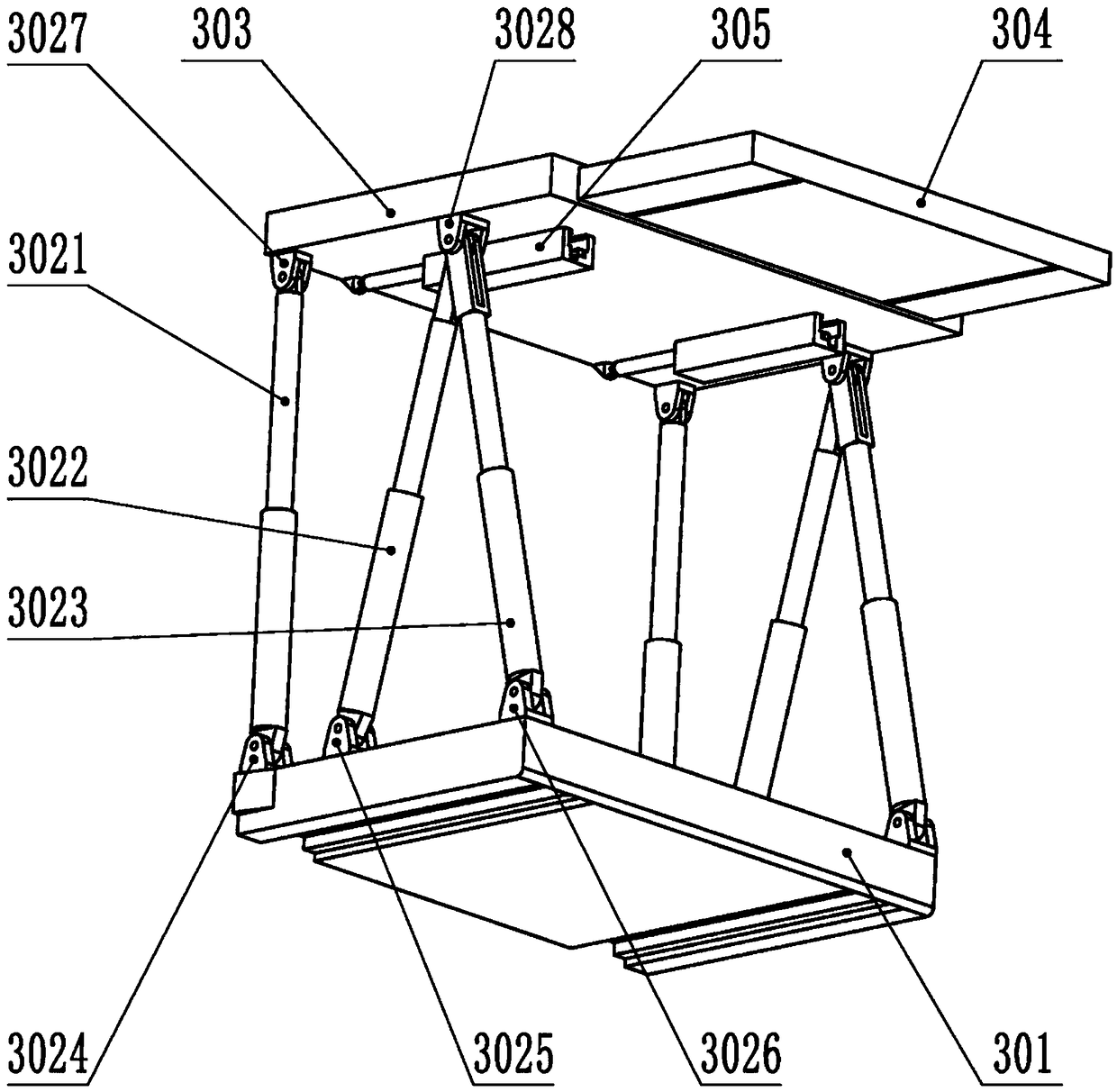

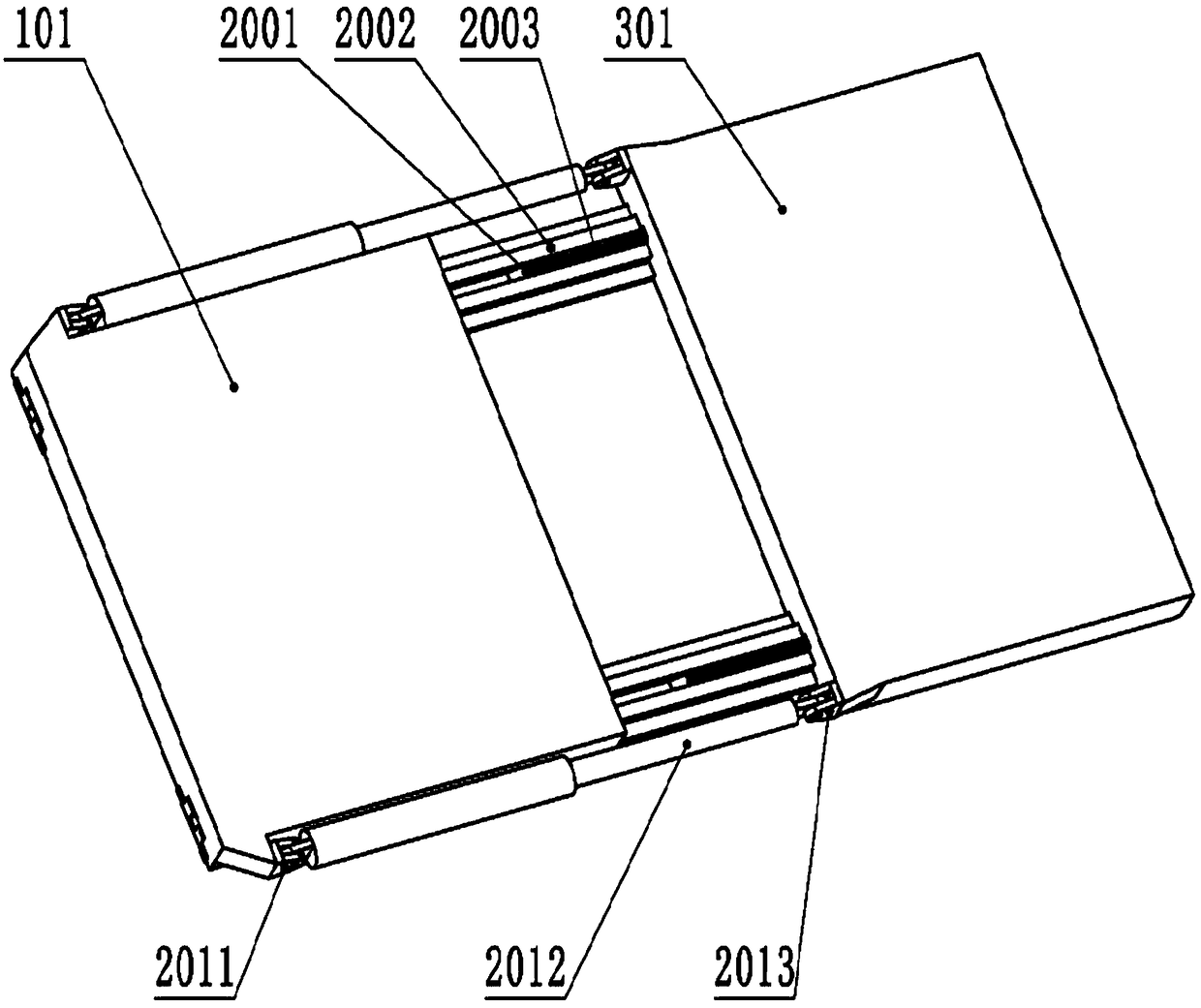

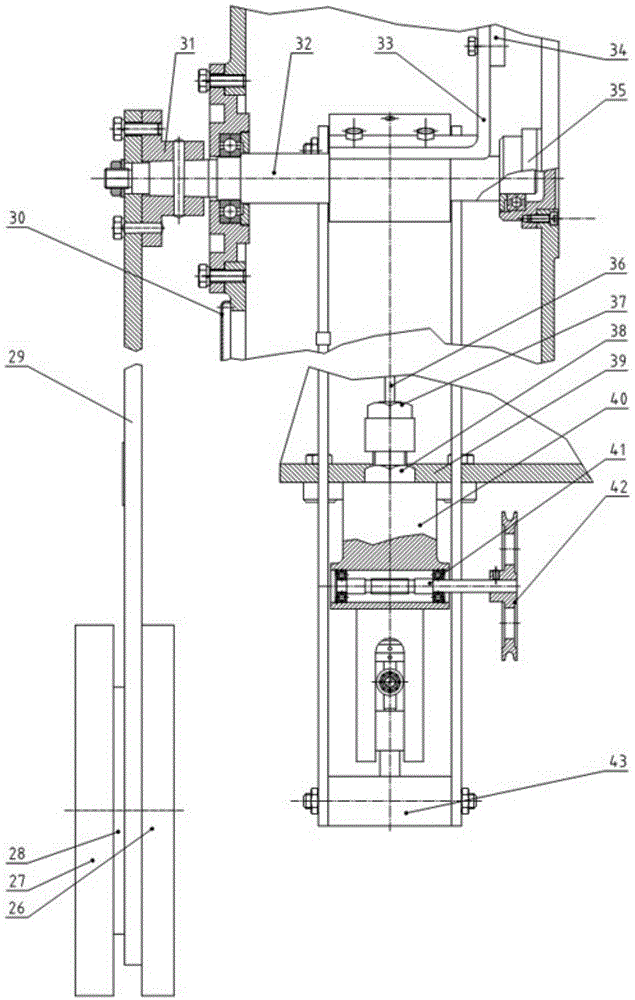

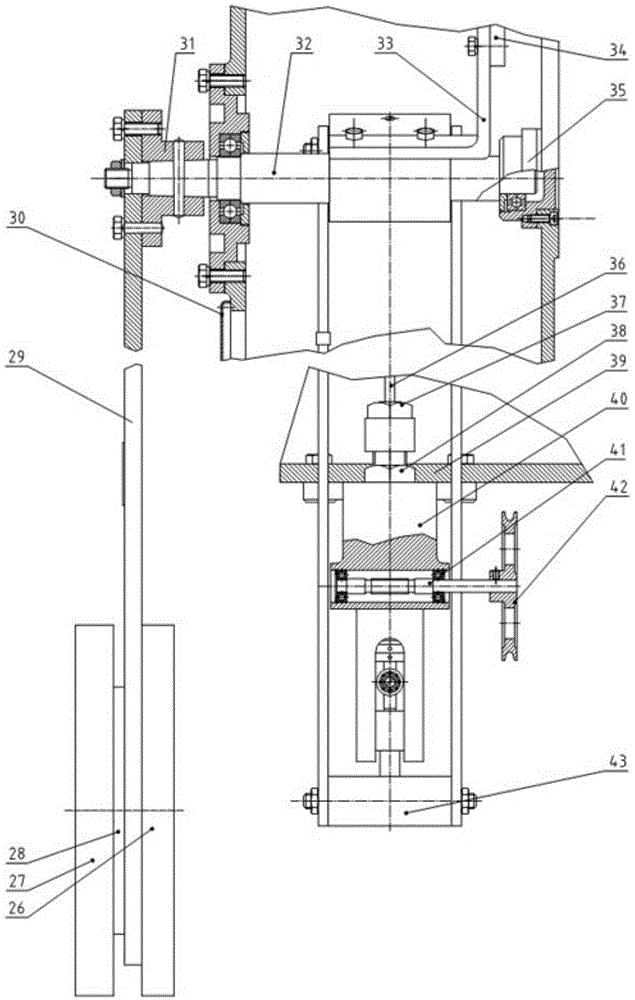

Two-degree-of-freedom sliding-type temporary supporting device and working method thereof

ActiveCN108756982AKeep people and equipment safeAvoid hurting peopleMine roof supportsHinge angleLinear drive

The invention discloses a two-degree-of-freedom sliding-type temporary supporting device and a working method thereof. The two-degree-of-freedom sliding-type temporary supporting device comprises a first supporting device, a second supporting device, a frame moving driving device and a frame moving auxiliary device. The first supporting device and the second supporting device are connected throughthe frame moving driving device and the frame moving auxiliary device. Under the joint effect of a bottom lifting device arranged at the bottom of the first supporting device and facilitating slidingand forward moving, the frame moving driving device and the frame moving auxiliary device, the sliding-type temporary supporting device automatically slides and moves forwards to the designated working position. The first supporting device and the second supporting device adopt two sets of structures which are connected and combined by three linear driving devices and hinges, so that a jacking support has two degrees of freedom. The problem that when the ground and the top face of a roadway are not parallel, the device is prone to overall skewing is solved, meanwhile, auxiliary equipment is not needed during frame moving, the pushing step pitch is large, supporting is safer and more reliable, and the two-degree-of-freedom sliding-type temporary supporting device and the working method thereof have the advantages that the work efficiency is high, the automation degree is high, and adaptability to the top face of the roadway is good.

Owner:CHINA UNIV OF MINING & TECH

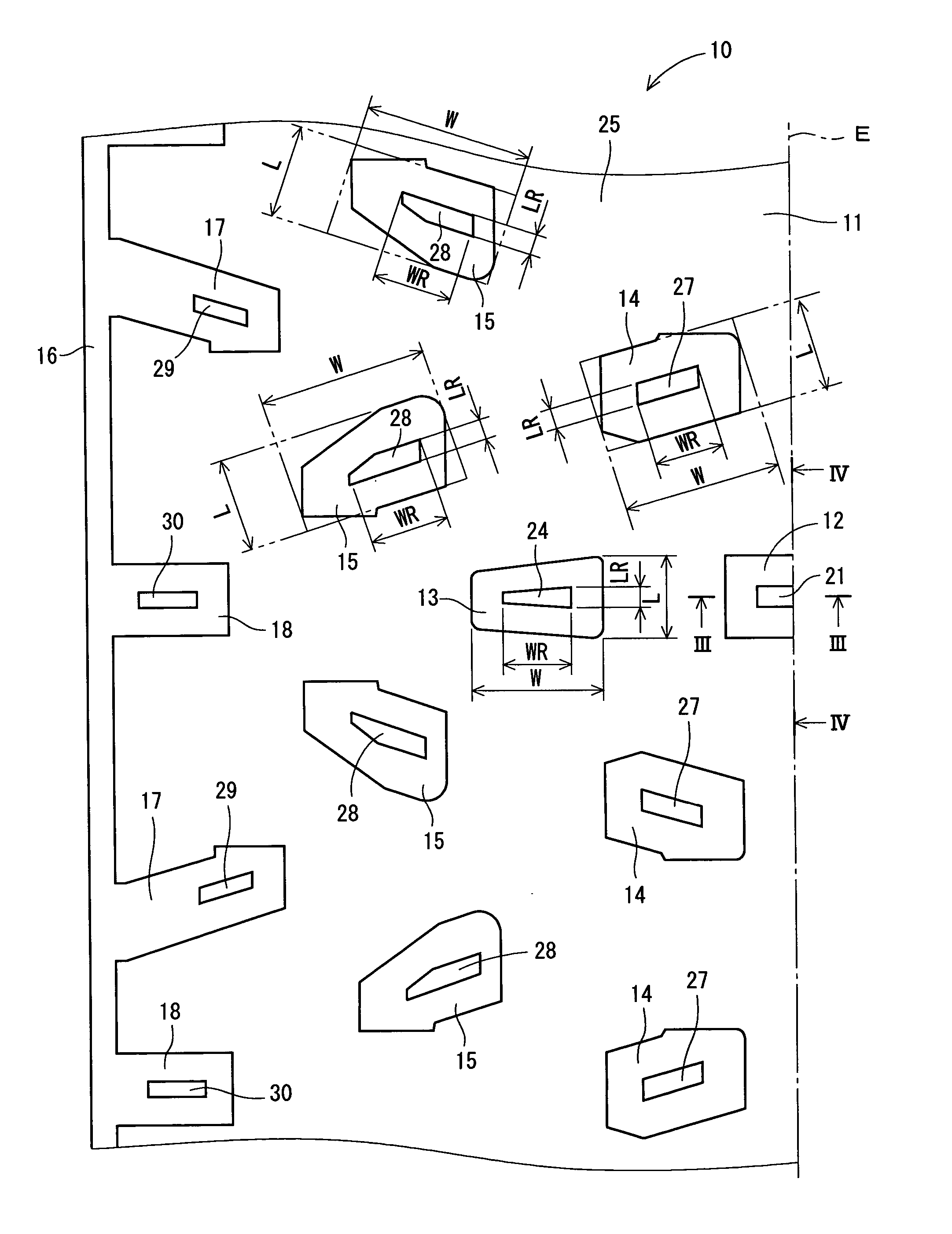

Low internal pressure pneumatic tire

InactiveUS20050139303A1Improve traction performanceImprove sliding performanceOff-road vehicle tyresMotorcycle tyresInternal pressureEngineering

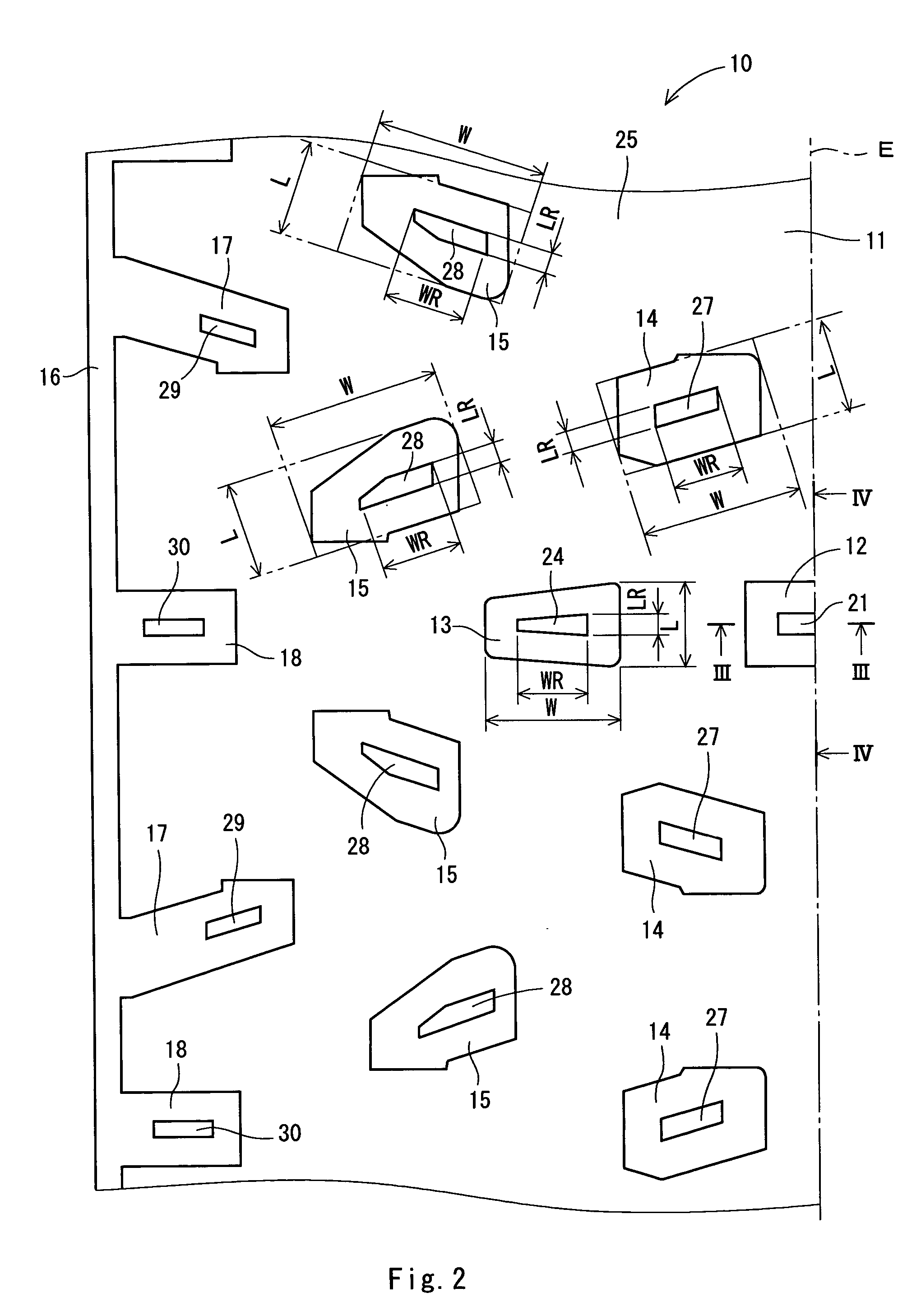

A tread (11) of a tire (10) is provided with a plurality of blocks (12) to (15). The blocks (12) to (15) are provided symmetrically about an equator plane (E). Each of the blocks (12) to (15) is provided regularly in a circumferential direction. Each of the blocks (12) to (15) is formed to take a solid shape specified by a long side dimension (W), a short side dimension (L) and a high side dimension (H). The blocks (12) to (15) include recesses (21), (24), (27) and (28) respectively. Each of the recesses (21), (24), (27) and (28) is specified by a long side dimension (WR), a short side dimension (LR) and a deep side dimension (HR). The dimensions have a relationship of WR / W=0.33 to 0.87, LR / L=0.2 to 0.8 and HR / H=0.15 to 0.85. A ratio of a block volume (BT) to a recess volume (RT) is set to be RT / BT=0.08 to 0.25.

Owner:SUMITOMO RUBBER IND LTD

High-temperature-resistant polyether-ether-ketone composite material and preparation method thereof

InactiveCN108192277AImprove uniformitySolve the problem of low interface binding forceFiberCarbon fibers

The invention discloses a high-temperature-resistant polyether-ether-ketone composite material. The composite material is prepared from the following components in parts by weight: 70-80 parts of polyether-ether-ketone, 10-20 parts of carbon fibers, 1-5 parts of nano silicon dioxide, 1-5 parts of hollow glass microspheres, 1-5 parts of hydrotalcite, and 0.5-3 parts of a titanate coupling agent. The invention also discloses a preparation method of the high-temperature-resistant polyether-ether-ketone composite material. The high-temperature-resistant polyether-ether-ketone composite material provided by the invention has the characteristics of good mechanical properties and high-temperature resistance.

Owner:ZHANJIANG ZHENGXIN TECH SERVICE CO LTD

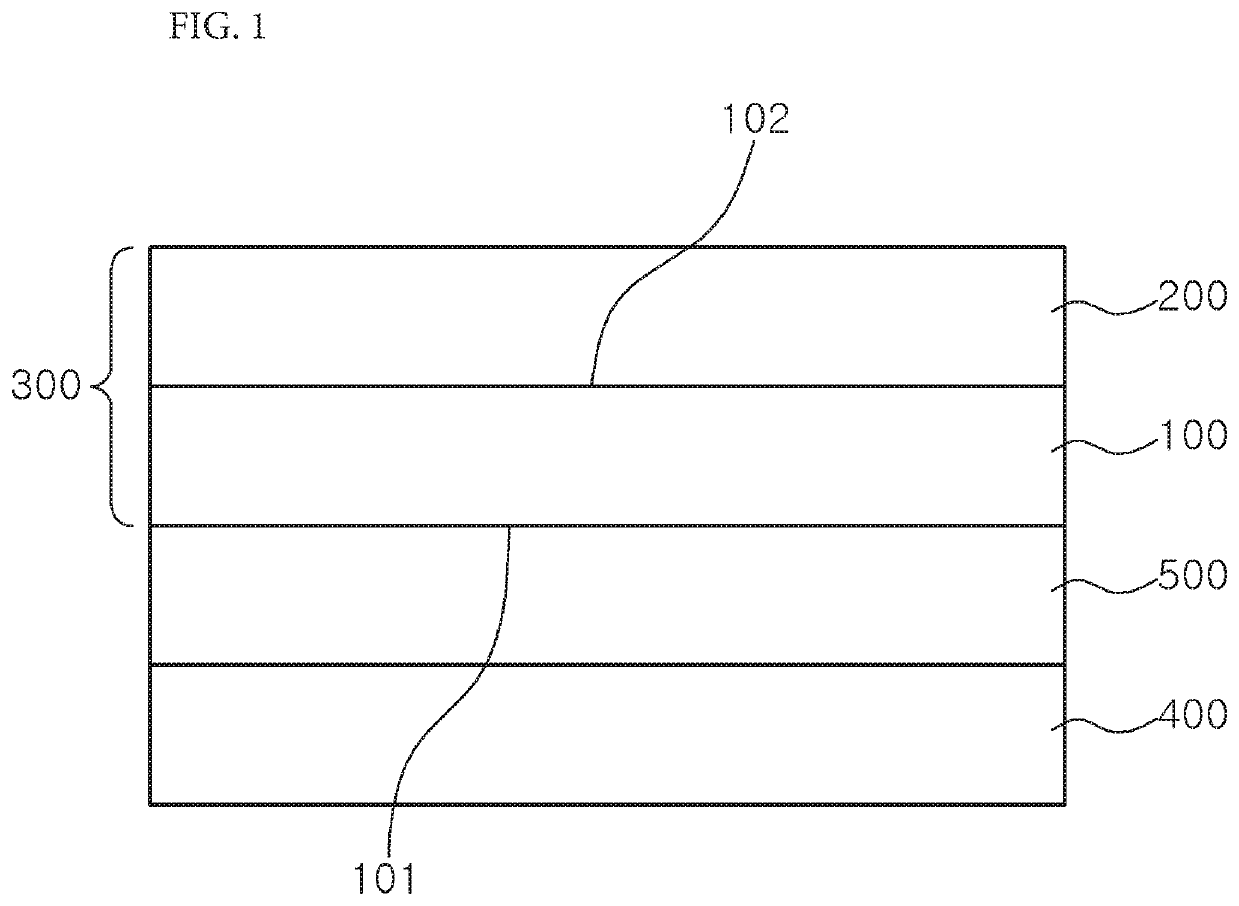

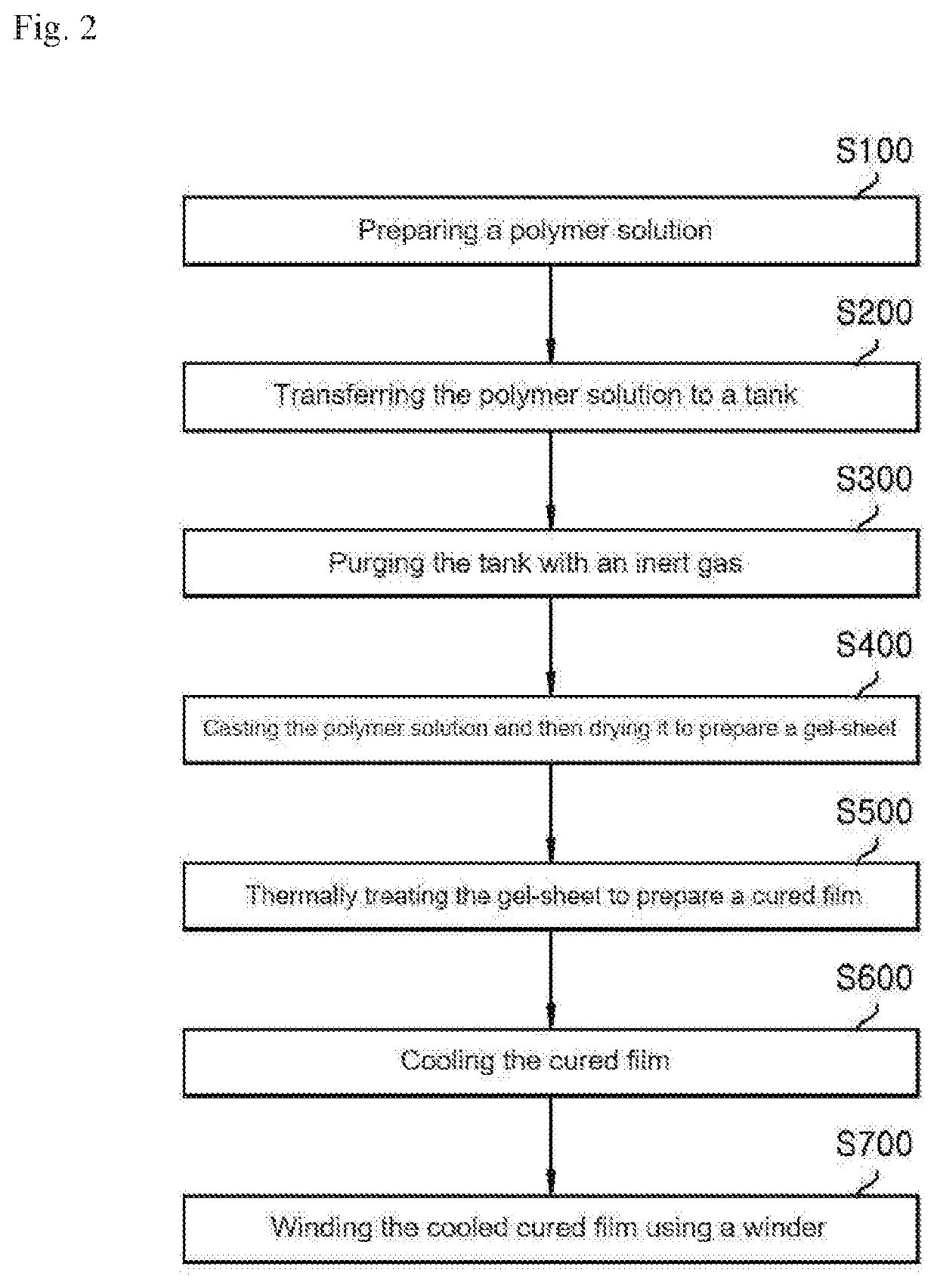

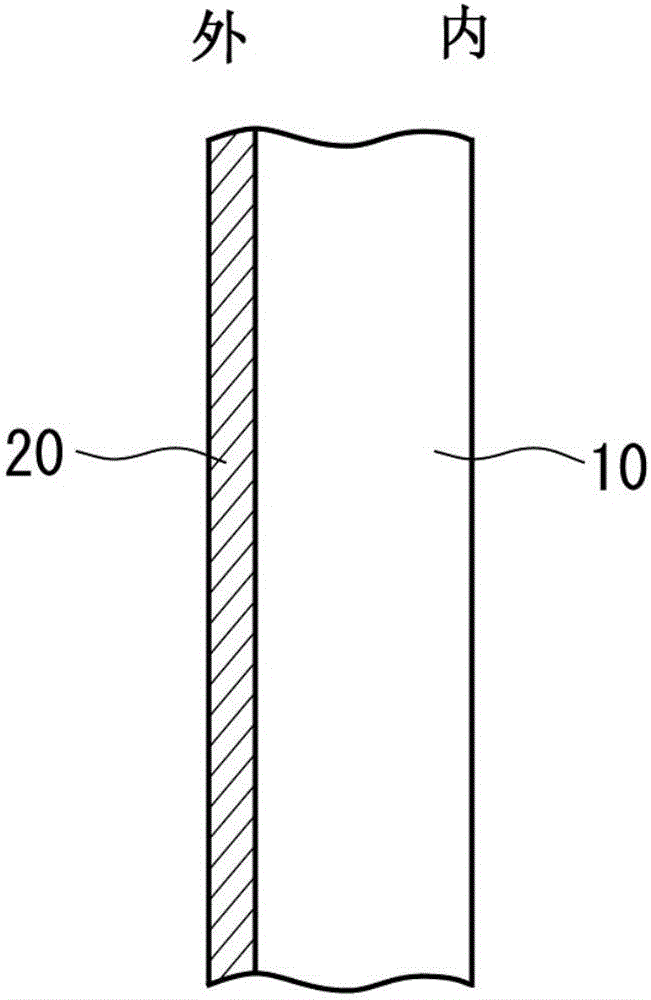

Polymer film, front plate and display device comprising same

InactiveUS20200407507A1Good anti-adhesionImprove sliding performanceDiodeFlat articlesPolymer sciencePolymer resin

Embodiments relate to a polymer film for a display that maintains a clean appearance and transparency and is excellent in antiblocking properties by securing a certain range of optical slip index (OS), a process for preparing the same, and a front panel and a display device comprising the same. The polymer film comprises a polymer resin selected from the group consisting of a polyamide-based resin and a polyimide-based resin and a filler and has an optical slip index (0.5) of less than 0.5.

Owner:SK MICROWORKS CO LTD

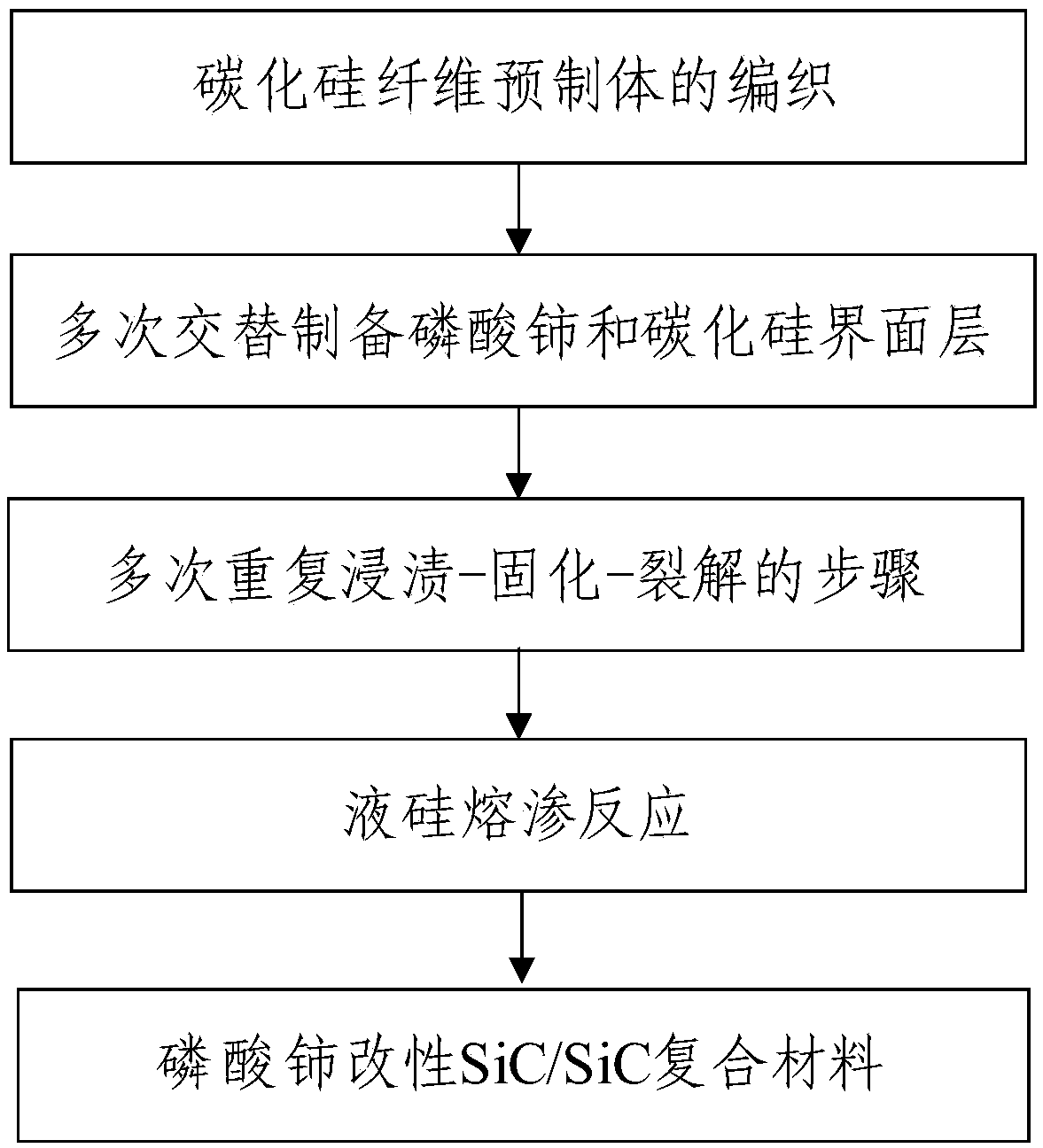

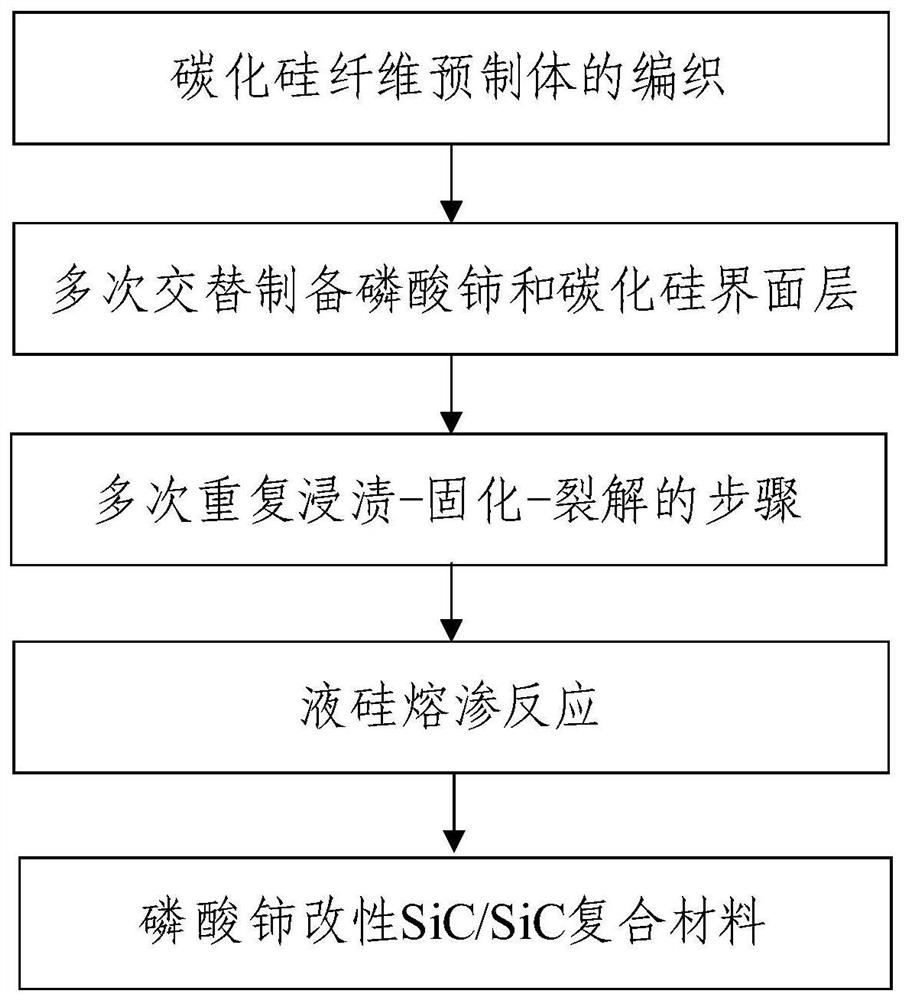

Cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material and preparation method thereof

ActiveCN109293367AHigh melting pointHigh temperature resistance and oxidation resistanceCeramicwareCerium phosphateInterface layer

The invention relates to a cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material and a preparation method thereof. The method comprises the steps: (1) alternatively preparing a cerium phosphate interface layer and a silicon carbide interface layer on the surface of silicon carbide fiber preforms until the predetermined thickness or the predetermined number of layers is reached, and thus preparing modified silicon carbide fiber preforms; (2) impregnating the modified silicon carbide fiber preforms with a carbon precursor solution, and then solidifying andsplitting the impregnated modified silicon carbide fiber preforms in turn; (3) repeating the step (2) at least once, and thus preparing porous silicon carbide fiber preforms; and (4) carrying out liquid silicon melt-infiltration reaction of the prepared porous silicon carbide fiber preforms, and thus preparing the cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material. The prepared cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material has the advantages of excellent oxidation resistance, temperature resistance andthermal shock resistance, excellent comprehensive performance at high temperature and long service life.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Rubber sealing component with low temperature resistance

The invention discloses a rubber seal with low temperature resistance, which relates to the technical field of seals and is made of the following components: EPDM rubber, natural rubber, calcium carbonate, paraffin, zinc oxide, ultrasonically modified starch, micron grade perlite, plasticizer, carbon black; the invention provides a rubber seal with low temperature resistance, which not only has good low temperature resistance, but also has good oil resistance and tear resistance.

Owner:宁国市润丰金属制品有限公司

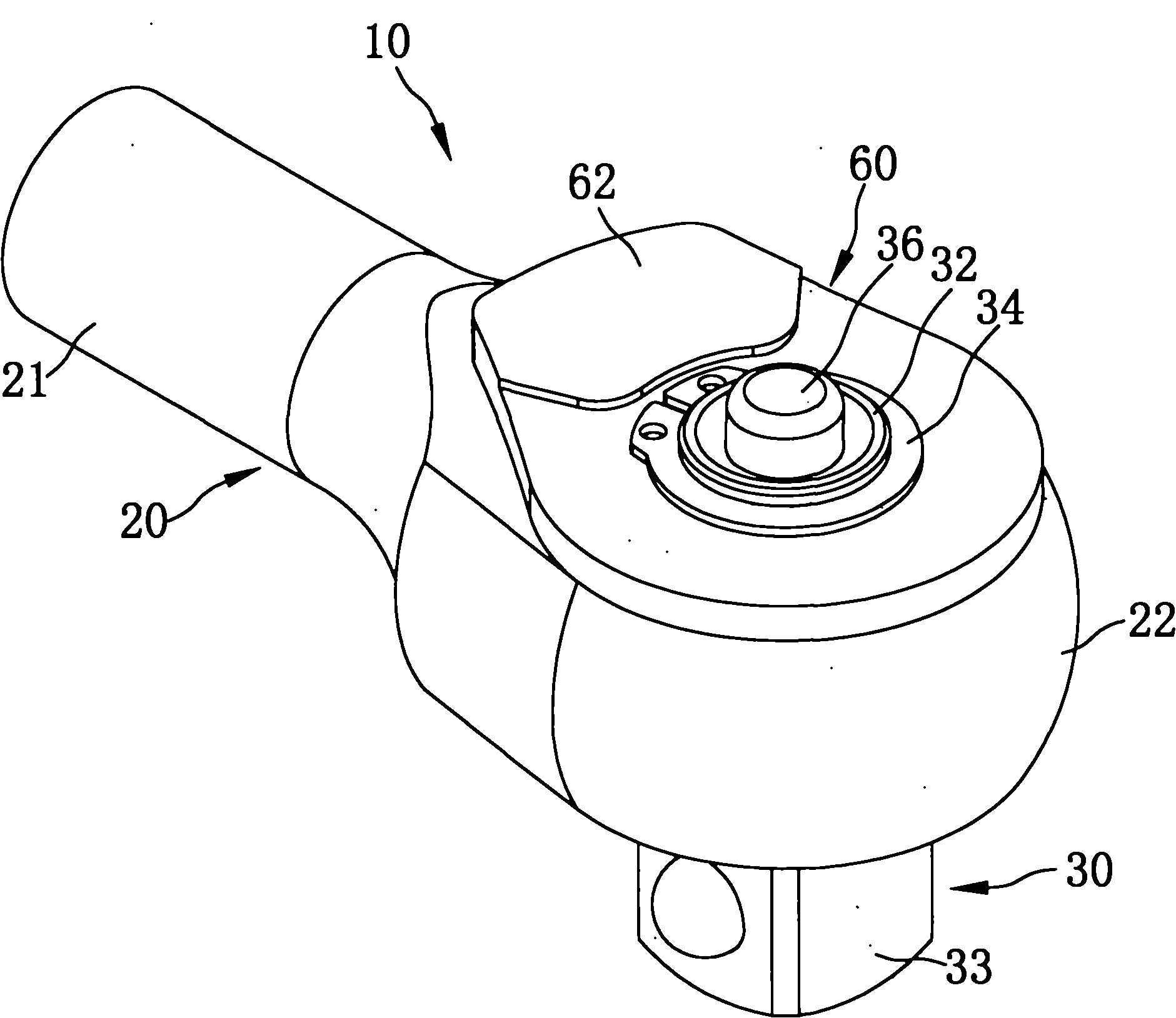

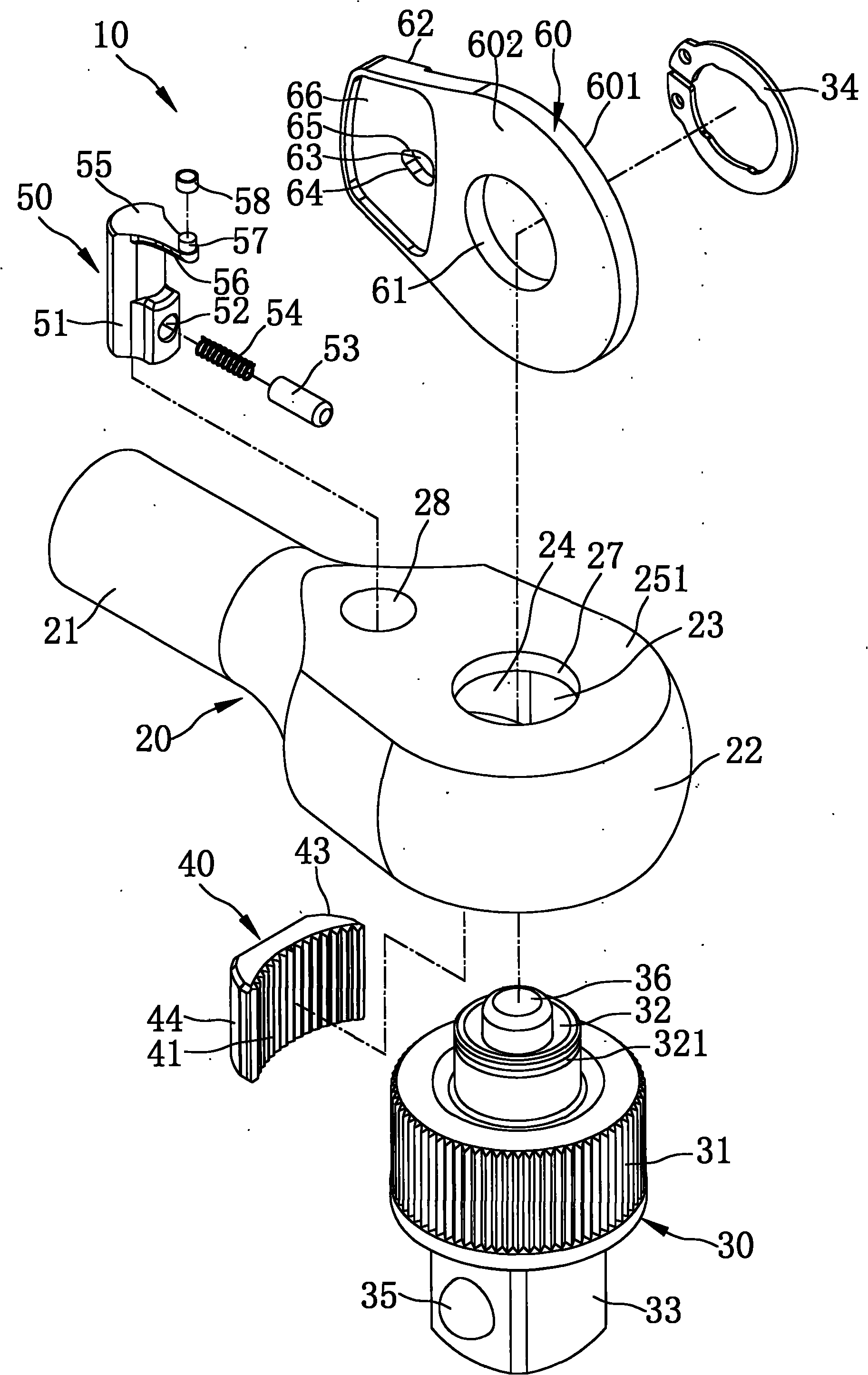

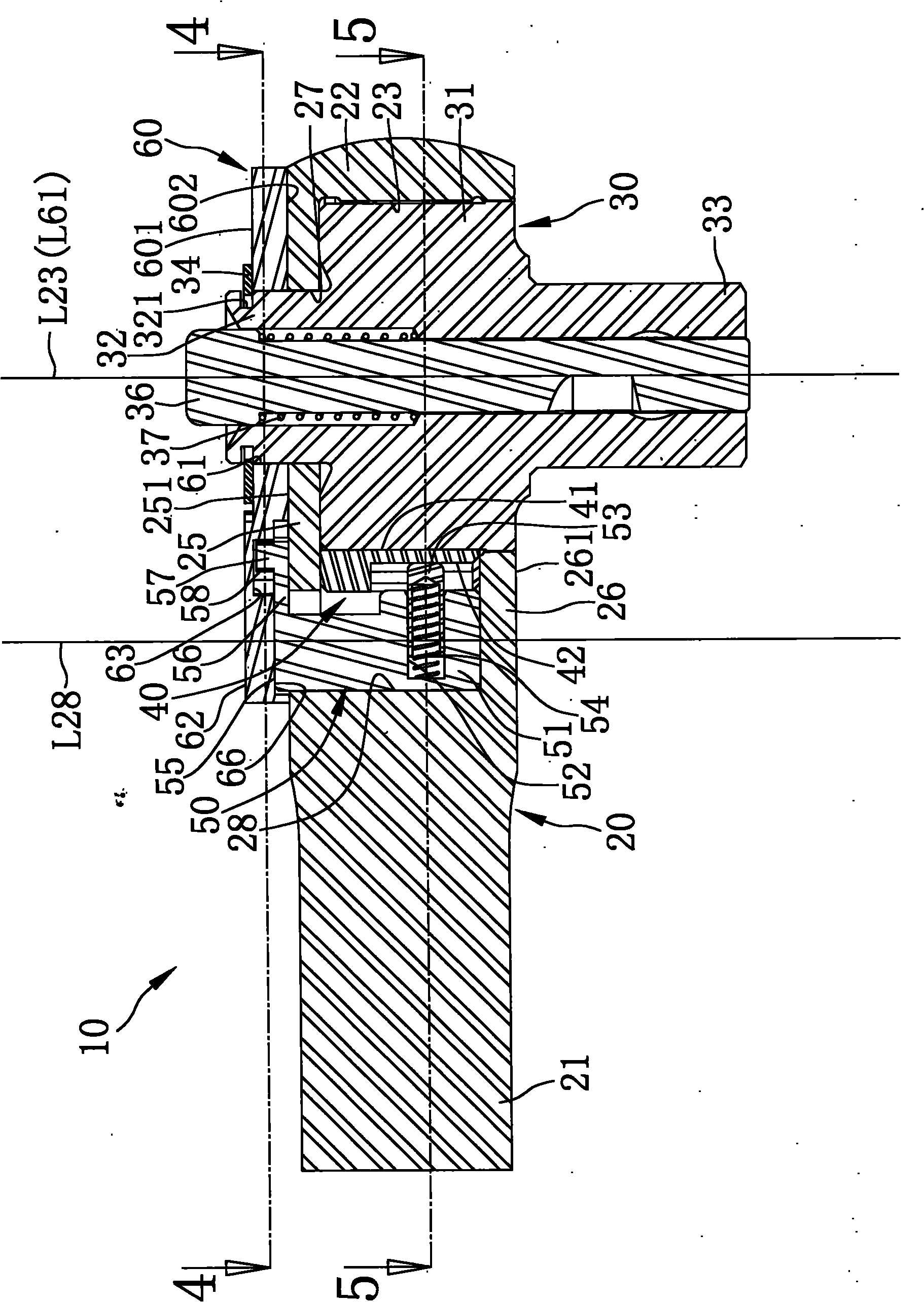

Ratchet spanner

The invention relates to a ratchet spanner for ensuring switching of a control part smoother, which adopts the following technical scheme that a first edge of a control slot is contacted with the outer periphery of a guide part of a reversing switch; and an included angle between a tangent line formed when the first edge is tangential to the guide part and a second reference line of the reversing switch is not more than 45 degrees. Therefore, if a user wants to shift the control part to a second position from a first position, most of the shifting force applied by the user to the control part can be used for pushing the guide part of the reversing switch and ensuring the reversing switch to rotate relative to a pivot slot and cannot cause the problem that the control part and the reversing switch are clamped or are not shifted to rotate smoothly. Therefore, the user can easily shift a shifting part of the control part so that the control slot drives the reversing switch to move.

Owner:胡厚飞

A wear-resistant and aging-resistant power cable sheath material and preparation method thereof

ActiveCN106366373BImprove aging resistanceAccelerated agingRubber insulatorsPlastic/resin/waxes insulatorsFiberCarbon fibers

The invention discloses a wear-resistant and aging-resistant power cable sheath material, which comprises the following raw materials in parts by weight: 30-40 parts of nitrile rubber, 20-30 parts of polyvinyl chloride, 20-30 parts of phenolic resin, and 10-30 parts of carbon fiber 18 parts, 10-15 parts of carbon black, 12-18 parts of organic montmorillonite, 10-15 parts of microcrystalline cellulose, 0.5-2 parts of N,N-phenyl-p-phenylenediamine, 1-2 parts of stearic acid , 10-15 parts of flame retardant, 3-5 parts of paraffin, 1-1.5 parts of anti-aging agent. The tensile strength of the cable sheath material is 26.4-31.5Mpa, the elongation at break is 286-310%, and it has good wear resistance, aging resistance and long service life.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

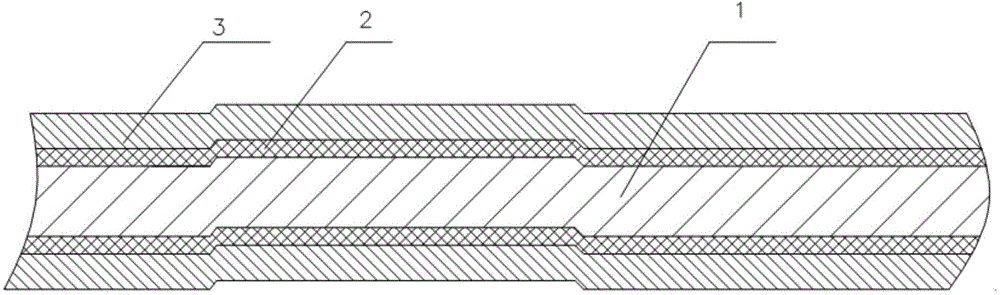

Special flexible cable for shield tunneling machine and manufacturing method of special flexible cable

PendingCN109935396AReduce relative slidingImprove stabilityPower cables with screens/conductive layersFlexible cablesShield machineSaddle shape

The invention discloses a special flexible cable for a shield tunneling machine. The special flexible cable comprises a cabling wire core, thin non-woven fabric surrounding the cabling wire core, a reinforcing layer surrounding the thin non-woven fabric, and an outer sheath surrounding the reinforcing layer, wherein the cabling wire core comprises a saddle-shaped positioning pad core arranged at the center, three power wire cores which are tightly attached to the arc-shaped surface of the saddle-shaped positioning pad core and evenly distributed in the circumferential direction, and three grounding wire cores which are arranged in three external gaps formed by the three power wire cores. The thin non-woven fabric is arranged around the three power wire cores and the three grounding wire cores. The invention further provides a manufacturing method of the special flexible cable for the shield tunneling machine. The cable has excellent tensile strength, bending resistance, extrusion resistance, wear resistance, moving torsion resistance and repeated bending and winding performance, and is long in service life.

Owner:四川川东电缆有限责任公司

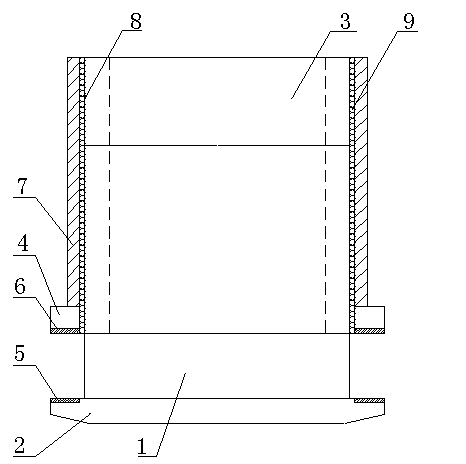

Drawer sliding mechanism of electric cabinet

InactiveCN103311836AImprove sliding performanceAvoid getting stuckSwitchgear with withdrawable carriageEngineeringMechanical engineering

The invention relates to an electric cabinet and in particular to a drawer sliding mechanism of an electric cabinet. The drawer sliding mechanism comprises a drawer, a panel, an electric cabinet box body and an insertion cavity, wherein the panel is positioned at the front side of the drawer, the insertion cavity is formed on the electric cabinet box body, and the drawer is positioned in the insertion cavity and is matched with the insertion cavity to slide. The drawer sliding mechanism is characterized in that the mechanism further comprises supports positioned at two sides of the insertion cavity; the supports form a sealing surface with the panel at the front side of the drawer; tracks are arranged on side faces, opposite to the drawer, of the insertion cavity; and balls are arranged in the tracks. Compared with the prior art, the drawer sliding mechanism enables the sliding performance of the drawer to be improved, can avoid the phenomenon that the drawer cannot be closed after long-time use and enables the service life of the drawer to be prolonged.

Owner:SHANGHAI XINLAI IND

High tensile resin-based traffic guardrail structure composite material dedicated resin

The invention proposes a high tensile resin-based traffic guardrail structure composite material dedicated resin, aiming to providing a high tensile resin-based traffic guardrail structure composite material dedicated resin featuring high yielding elongation, excellent tenacity, high intensity, satisfaction of collision, anti-ageing and installation properties. The invention comprises products obtained by the following chemical reaction: (A) high tenacity resin synthesized by adding 1000 parts of flexible resin to 1000 parts of unsaturated polyester base stock; (B) a novel unsaturated polyester synthesized by introducing a longer aliphatic chain or adding divalent alcohol containing ether linkage; (C) polyurethane modified unsaturated polyester prepared by adding a certain amount of diisocyanate monomer to react with unsaturated polyester, the products (A), (B) and (C) are mixed following a certain proportion to combine the products into modified and unsaturated polyester tenacity base material, then 2-500 parts of filler is fully kneaded to prepare dedicated resin. The resin of the invention can be used to produce low-cost and high-intensity traffic guardrail.

Owner:周志亮

Package in which liquid contents are accommodated

ActiveCN108137218AAvoid changes in thickness etc.Keep stableLinings/internal coatingsCoatingsMechanical engineeringLiquid content

A package comprising a container body 1 in which liquid contents 3 are accommodated such that a headspace 7 remains, wherein the package is characterized in that: protrusions and recesses are formed along the entirety of an inner surface 1a of the container body 1; the inner surface 1a of the container body 1 comprising the protrusions and recesses is covered by a lubricating liquid 30 that is immiscible with the liquid contents 3; a covering layer of the lubricating liquid 30 is interposed between the inner surface 1a and the liquid contents 3; and, with the container body 1 being held erect,a reservoir 31 of the lubricating liquid 30 that forms the covering layer is formed at a peripheral edge part of the upper-end surface of the liquid contents 3 accommodated within the container body1.

Owner:TOYO SEIKAN GRP HLDG LTD +1

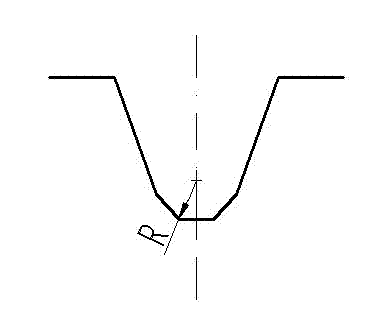

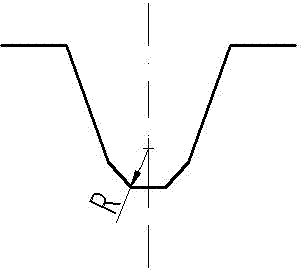

Teeth part strengthening structure of spiral bevel gear

InactiveCN102359569AImprove bending resistanceHigh strengthPortable liftingGearing elementsFiberStress concentration

The invention discloses a teeth part strengthening structure of a spiral bevel gear. The strengthening structure is a circle transition structure which is formed by tangency of a circular arc arranged between two adjacent tooth faces and the tooth faces at the two sides. The strengthening structure is characterized in that the midpoint of a circular arc line is tangent to a root circle, and the semidiameter R value of the circular arc is determined by three common tangency points; and the circle transition structure is designed at the tooth root position and has good mechanical property, thereby promoting strengths of bending resistance and cracking resistance of the tooth root and obviously reducing the stress concentration degree. According to the strengthening structure provided by the invention, a strengthening measure can be further implemented from the other two aspects besides the technology effect: firstly, the circle transition structure at the tooth root position provides convenience for adoption of a refined forging shaping process when forging and pressing are carried out, metal fibres are continuously distributed along the height direction of a tooth form, and the tooth part is of a longitudinal metal fibre structure, thereby effectively improving the gliding property of the tooth face and the shock resistance of the tooth part; and secondly, the circle transition structure at the tooth root position has no dead angles so as to conveniently carry out the shot peening strengthening on the tooth part. The strengthening structure provided by the invention has the advantages of reasonable structure and high strength, and is particularly suitable for being matched with a main reduction gear in a heavy vehicle driving axle.

Owner:JIANGSU AIRSHIP GEAR

Mining fluorescence cable for coal mining machine

InactiveCN105719744ASolve the problem of bent broken coreImprove sliding performanceDetails of conductive coresFlexible cablesPower cableFluorescence

The invention discloses a mining fluorescence cable for a coal mining machine, which comprises a ground cable core, three power cable cores, three control cable cores and a first sheath. Three control cable cores are in parallel mutually and are arranged in a rectangular shape; the peripheries of the three control cable cores are coated with a second sheath; a peripheral diameter of the second sheath is equal to that of each power cable core; the second sheath and three power cable core are tightly attached to form a square arrangement; the ground cable core is arranged at a middle gap of the square arrangement; a torsion resistance braid is arranged between the square arrangement and the first sheath; and fluorescence color strips are respectively arranged on the surfaces of the first sheath, outer shielding layers and second insulating layers. According to the mining fluorescence cable for the coal mining machine, which is disclosed by the invention, the problem of bending breakage of the control cable cores is fundamentally solved; arrangement of gliding increasing layers reinforces the gliding property among the control cable cores; the cable is more stable in structure, the sheaths are difficult to wrinkle, and under the reinforcing action of the torsion resistance braid, the mechanical property of the sheaths is greatly improved; and the fluorescence color strips are arranged reasonably and comprehensively.

Owner:ANHUI HUAYU CABLE GRP

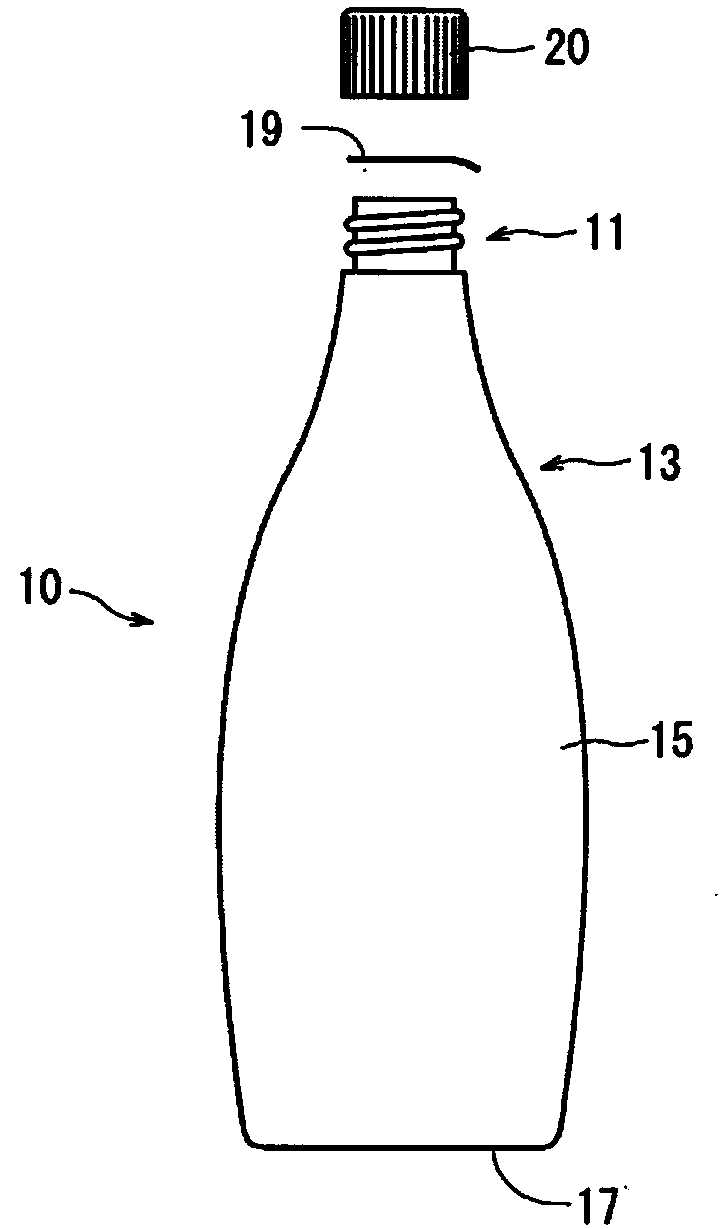

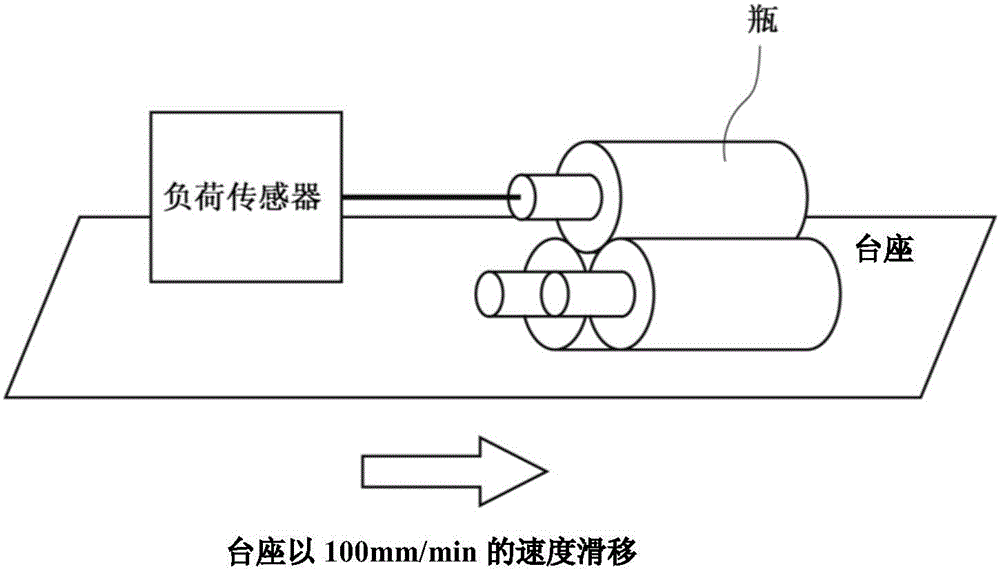

Plastic container having excellent scratch resistance and antifouling properties

InactiveCN106687382AImprove scratch resistanceImprove sliding performanceSynthetic resin layered productsCoverings/external coatingsTectorial membraneSurface layer

This plastic container is characterized in that: at least an outer surface layer is formed of a transparent resin layer that is formed from a transparent resin or a colored resin layer that is obtained by blending a coloring agent in the transparent resin; and a protective film that contains 100 parts by mass of a silicone oil and 50-5,000 parts by mass of a surfactant is formed on the outer surface layer. This plastic container exhibits excellent scratch resistance and antifouling properties without being covered with a label such as a shrink film.

Owner:TOYO SEIKAN KAISHA LTD

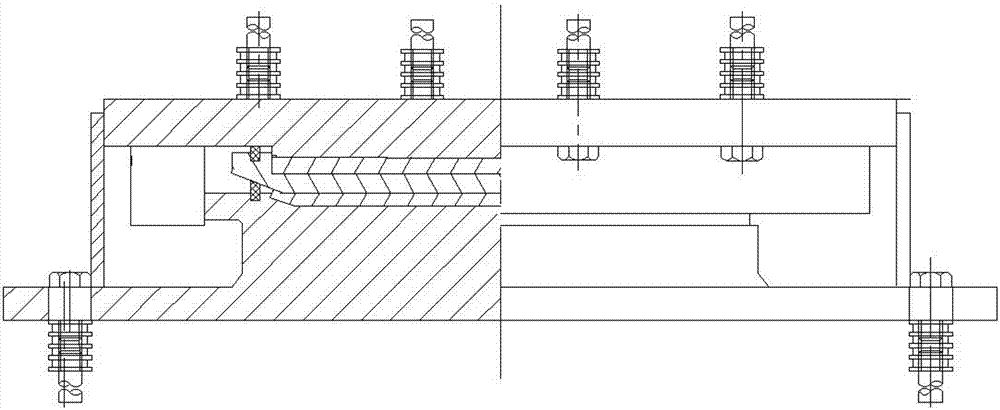

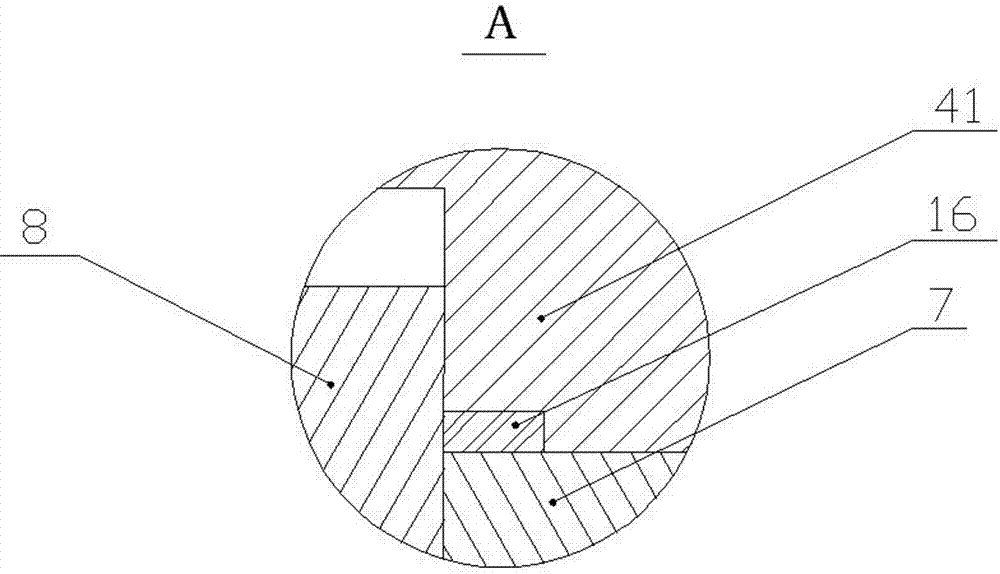

Die and covered edge press fit mechanism thereof

The invention discloses a die and a covered edge press fit mechanism thereof. The covered edge press fit mechanism comprises a covered edge driving cylinder installed on a fixed plate through a cylinder barrel of the covered edge driving cylinder, a telescopic rod of the covered edge driving cylinder penetrates a cylinder rod through hole in the fixed plate, the tail end of the telescopic rod is fixedly connected to an installing plate, and the installing plate is fixedly connected to a covered edge knife block. The fixed plate is installed on an installing base, and the lateral end face of the installing base is rotatably connected with a telescopic rod of a switchover cylinder through a driving shaft. The bottom end face of the installing base is rotatably connected with an installing support through a rotating shaft, the installing support is fixedly connected to a die body, and the rotating shaft is parallel to the driving shaft. A first control valve for controlling the covered edge driving cylinder to extend and a second control valve for controlling the switchover cylinder to extend are installed on the die body. The covered edge press fit mechanism is simple in structure and high in stability.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

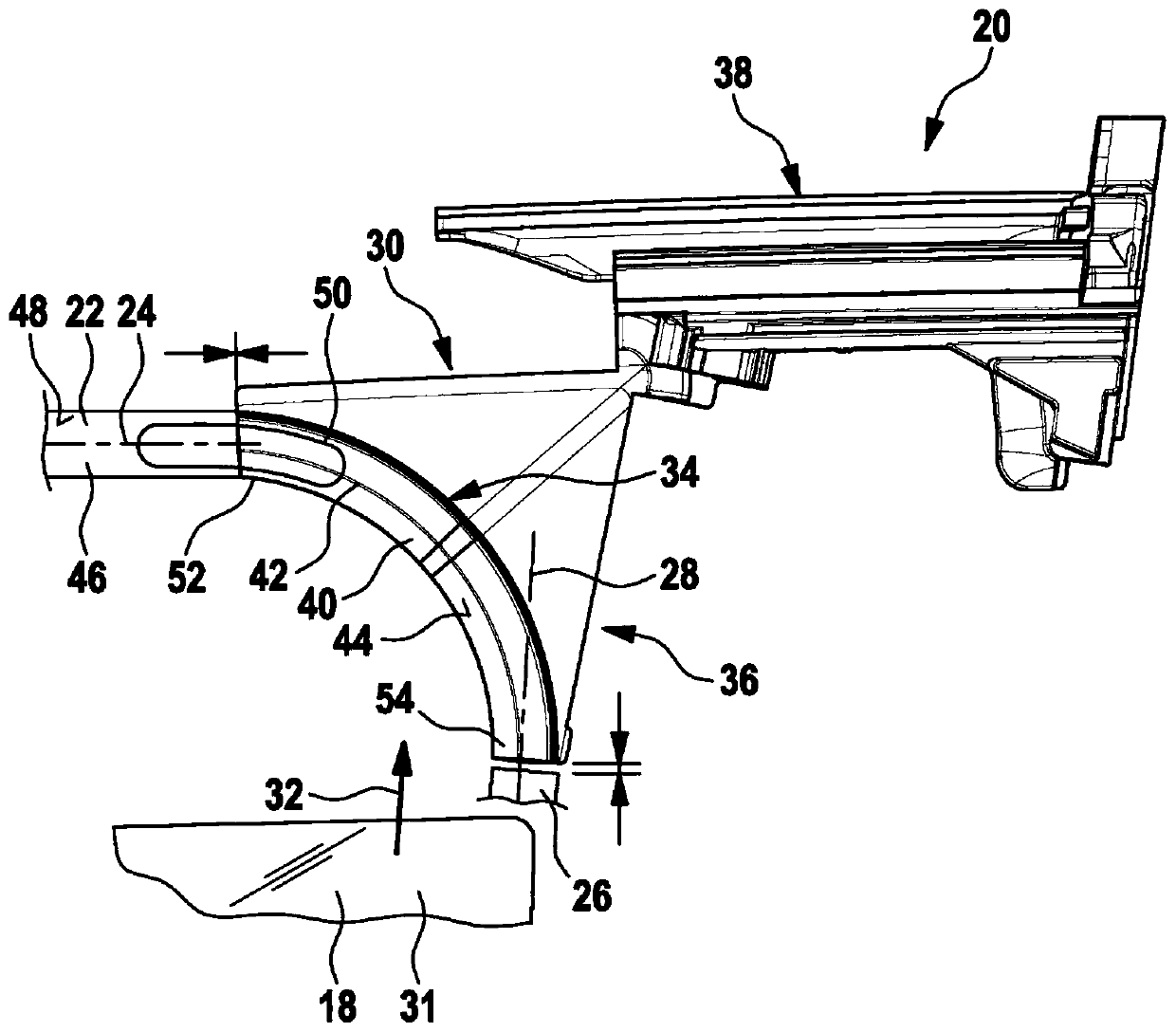

Sealing arrangement for a motor vehicle window, composite seal, and method for producing composite seal

ActiveCN109715425AExcellent surface appearanceImprove Noise PerformanceEngine sealsVehicle sealing arrangementsStructural engineeringMechanical engineering

Owner:COOPER STANDARD

A kind of preparation method of the modified starch ether that improves the sliding performance of tile adhesive

ActiveCN110590966BImprove sliding performanceImprove slip resistanceStarch derivtive adhesivesMacromolecular adhesive additivesChemical treatmentPolymer science

The invention relates to the technical field of building additives, in particular to a preparation method of modified starch ether for improving the sliding performance of tile adhesives. The preparation method comprises the steps of carrying out one-step etherification chemical treatment modification on starch to obtain starch ether, and continuing physical modification treatment. This preparation method has changed the cumbersome operation of multi-step etherification in the preparation of existing modified starch ethers. Only one step of simultaneous etherification can obtain starch ether modified products with better performance, and because the physical modification steps continue to be added, The obtained product can significantly improve the sliding performance when used in tile adhesives; at the same time, the operating conditions of one-step simultaneous etherification treatment are significantly different from those of the prior art.

Owner:SHANDONG YITENG NEW MATERIAL CO LTD

A kind of cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material and preparation method thereof

ActiveCN109293367BHigh melting pointHigh temperature resistance and oxidation resistanceCeramicwareCerium phosphateCarbide silicon

The invention relates to a cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material and a preparation method thereof. The method: (1) alternately prepare cerium phosphate interface layers and silicon carbide interface layers on the surface of the silicon carbide fiber preform until reaching a predetermined thickness or predetermined number of layers to obtain a modified silicon carbide fiber preform; (2) use carbon The precursor solution is impregnated with the modified silicon carbide fiber preform, and then the impregnated modified silicon carbide fiber preform is sequentially subjected to a curing step and a cracking step; (3) repeating step (2) at least once to prepare a porous silicon carbide fiber preform and (4) subjecting the prepared porous silicon carbide fiber preform to liquid silicon infiltration reaction to obtain a cerium phosphate modified silicon carbide fiber reinforced silicon carbide composite material. The cerium phosphate modified silicon carbide fiber-reinforced silicon carbide composite material prepared by the invention has excellent oxidation resistance, temperature resistance, thermal shock resistance, etc., excellent comprehensive performance at high temperature, and long service life.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Bridge support

ActiveCN107354864AIncrease heightDoes not increase heightBridge structural detailsStructural engineeringBlind hole

The invention discloses a bridge support which comprises a lower support plate, a steel liner plate and an upper support plate. A protruding part is arranged in the middle of a lower spherical surface. A first spherical crown protruding upwards is arranged at the top end of the protruding part, the steel liner plate is a second spherical crown with the upper surface being a cut plane, a central blind hole is formed in the middle of the crown part of the second spherical crown, the hole type of the central blind hole is a spherical hole and the central blind hole is provided with an upper spherical surface. The spherical surface of the crown part of the second spherical crown is matched with the lower spherical surface to form a first spherical surface friction structure. The upper spherical surface is matched with the first spherical crown to form a second spherical surface friction structure. The lower surface of the upper support plate is matched with the cut plane. The bridge support is strong in slipping capacity and high in stability.

Owner:山东龙祥新材料科技有限公司

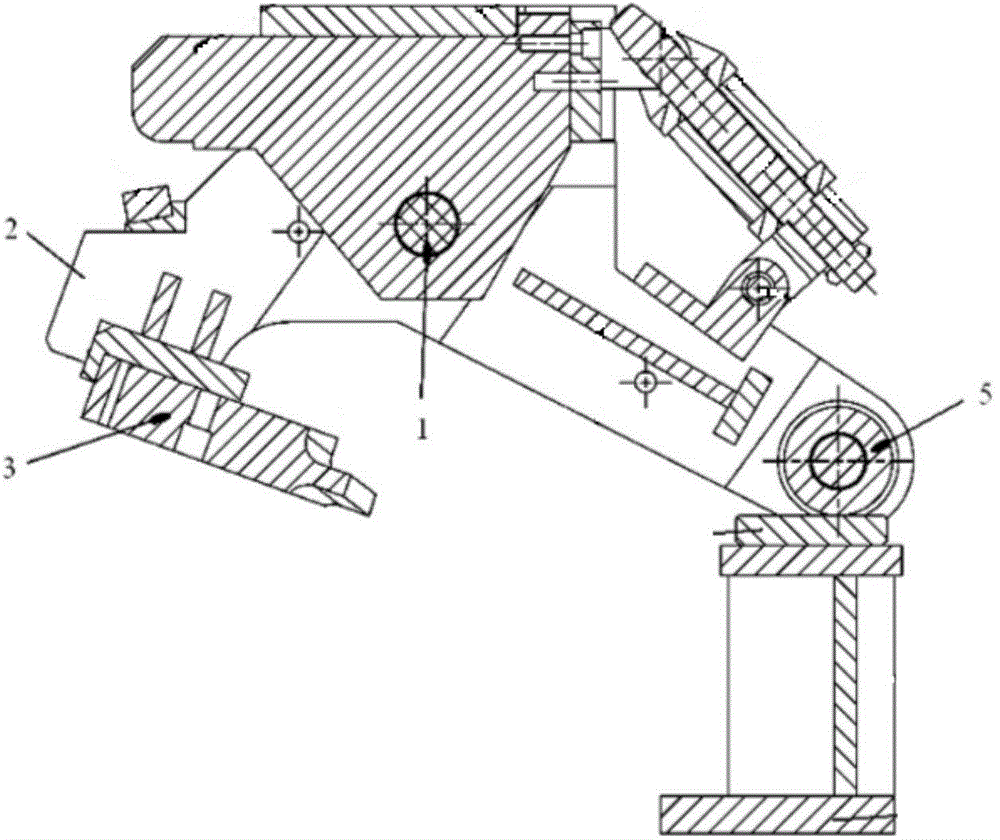

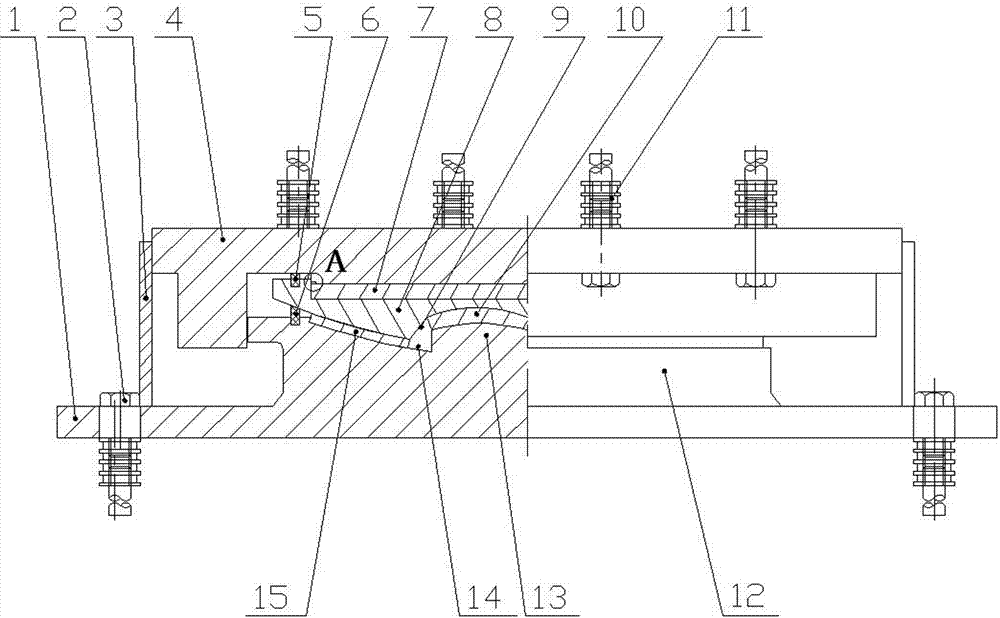

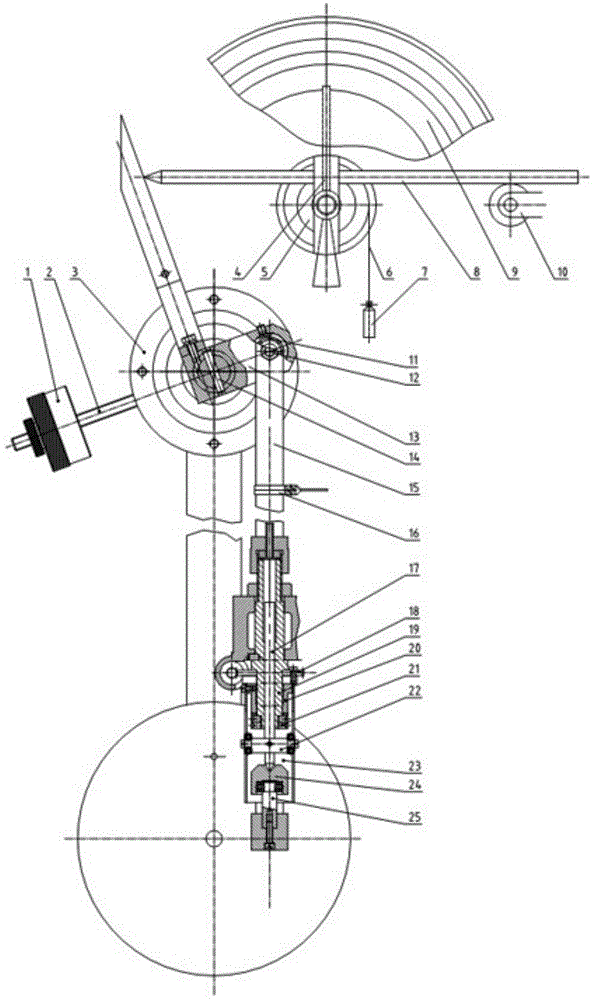

Hydraulic pendulum force measuring mechanism

ActiveCN103604532BImprove sliding performanceIngenious structureForce measurement using counterbalancing forcesStrength propertiesDynamometerEngineering

The invention belongs to the technical field of a measuring device and relates to a hydraulic pendulum bob force measuring mechanism used for detecting pressure strength of a cement test block. The force measuring mechanism comprises an upper box body, wherein a pendulum rod shaft is rotatably arranged on the upper box body, a front end of the pendulum rod shaft penetrates through an outer side of the upper box body, a shaft diameter is fixed with a pendulum rod flange seat, a pendulum rod is fixed on the pendulum rod flange seat through a fastening bolt, the pendulum rod shaft is arranged on a shaft in the upper box body and is fixedly connected with a pendulum rod shaft seat through a taper bolt, two ends of a connection rod shaft are rotatably arranged on the pendulum rod shaft seat through a bearing respectively, two ends of an outer side of the connection rod shaft corresponding to the pendulum rod shaft seat are respectively provided with a pull board, each pull board is respectively arranged along a length direction of the upper box body and penetrates through the outer side of the upper box body, and end portions of the pull boards which penetrate through the outer side of the upper box body are fixed with the pendulum rod shaft seat. Through the force measuring mechanism, a largest force is enabled to change according to weight change of a pendulum bob, the force measuring mechanism is converted to a load indication mechanism through calculation to acquire a measurement result, and an upper limit of measurement can reach above kilotons.

Owner:WUXI JIANYI INSTR & MACHINERY

Hydraulic pendulum bob force measuring mechanism

ActiveCN103604532AImprove sliding performanceIngenious structureForce measurement using counterbalancing forcesStrength propertiesCircular coneEngineering

The invention belongs to the technical field of a measuring device and relates to a hydraulic pendulum bob force measuring mechanism used for detecting pressure strength of a cement test block. The force measuring mechanism comprises an upper box body, wherein a pendulum rod shaft is rotatably arranged on the upper box body, a front end of the pendulum rod shaft penetrates through an outer side of the upper box body, a shaft diameter is fixed with a pendulum rod flange seat, a pendulum rod is fixed on the pendulum rod flange seat through a fastening bolt, the pendulum rod shaft is arranged on a shaft in the upper box body and is fixedly connected with a pendulum rod shaft seat through a taper bolt, two ends of a connection rod shaft are rotatably arranged on the pendulum rod shaft seat through a bearing respectively, two ends of an outer side of the connection rod shaft corresponding to the pendulum rod shaft seat are respectively provided with a pull board, each pull board is respectively arranged along a length direction of the upper box body and penetrates through the outer side of the upper box body, and end portions of the pull boards which penetrate through the outer side of the upper box body are fixed with the pendulum rod shaft seat. Through the force measuring mechanism, a largest force is enabled to change according to weight change of a pendulum bob, the force measuring mechanism is converted to a load indication mechanism through calculation to acquire a measurement result, and an upper limit of measurement can reach above kilotons.

Owner:WUXI JIANYI INSTR & MACHINERY

Urethane (meth)acrylate blends and urethane (meth)acrylate compositions

ActiveCN103804629BExcellent self-healing performanceImprove scratch resistancePolyurea/polyurethane coatingsMeth-Carbamate

The present invention provides a urethane (meth)acrylate capable of forming a cured film with self-healing properties, excellent scratch resistance, low curing shrinkage, and flex resistance. The urethane (meth)acrylate mixture (C) of the present invention is obtained by reacting (A) a polymerizable polyoxyethylene derivative mixture with (B) a polyisocyanate compound represented by formula (2) The (A) polymerizable polyoxyethylene derivative mixture is composed of 85-95% by mass of the polymerizable polyoxyethylene derivative represented by (A1) formula (1) and 5-15% by mass of (A2) (meth) hydroxyethyl acrylate; in the formula, R1 represents a hydrogen atom or a methyl group, n is the average number of moles added, n=3-9. In the formula, R3 each independently represents an alkylene group having 1 to 10 carbon atoms.

Owner:NOF CORP

High-temperature high-pressure resistant air exhaust sealing gasket of diesel engine and manufacturing method of high-temperature high-pressure resistant air exhaust sealing gasket

InactiveCN104553141AHigh strengthIncrease the compression ratioLaminationLamination apparatusEngineeringHigh pressure

The invention provides a high-temperature high-pressure resistant air exhaust sealing gasket of a diesel engine. The high-temperature high-pressure resistant air exhaust sealing gasket is composed of a high-temperature resistant steel sheet of a middle layer and flexible graphite sheets on both side of the high-temperature resistant steel sheet, wherein the high-temperature resistant steel sheet and the flexible graphite sheets are bonded together by bonding layers; and the bonding layers are 704 silicone rubbers. The high-temperature resistant steel sheet is provided with a heave formed through punching, and the heave goes around a to-be-sealed channel. Compared with the prior art, the air exhaust sealing gasket has the advantages that the flexible graphite is good in compression rate and resilience rate and is applied to a sealing position of an air exhaust pipe of the diesel engine to effectively solve the problem of great clearance difference with multiplesurface seal, and the pressed high-temperature resistant steel sheet is adopted to be bonded with the flexible graphite through a silicon rubber material so that the high-temperature resistant steel sheet is high in strength and good in sealing effect and the defect of detachment of the flexible graphite layers and a metal net can not occur simultaneously.

Owner:CHINA NORTH ENGINE INST TIANJIN

A kind of composite bulletproof material and preparation method thereof

ActiveCN109334177BImprove impact resistanceGuaranteed flexibilitySynthetic resin layered productsYarnCeramic composite

The invention discloses a composite bulletproof material and a preparation method thereof. The composite bulletproof material comprises a face layer, a middle layer and a base layer, wherein the facelayer adopts light metal armor pieces or ceramic composite armor pieces, the middle layer is a flexible high-performance fiber fabric layer, fabric comprises aramid fiber or ultra-high-molecular-weight polyethylene fiber fabric, and the base layer is high-performance fiber fabric impregnated with a shear thickening fluid. The soft and hard composite bulletproof material has good impact resistanceand high bullet shear energy, the flexible high-performance fiber fabric layer as the middle layer has the characteristics of high strength and high flexibility and has high tensile strength and slipperformance in a high-speed bullet condition, the base layer is the high-performance fiber fabric composite impregnated with the shear thickening fluid, friction performance of yarn is improved, and more energy is absorbed. Absorbed energy of the composite bulletproof material at the bullet speed of 500 m / s is 94.85 J.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com