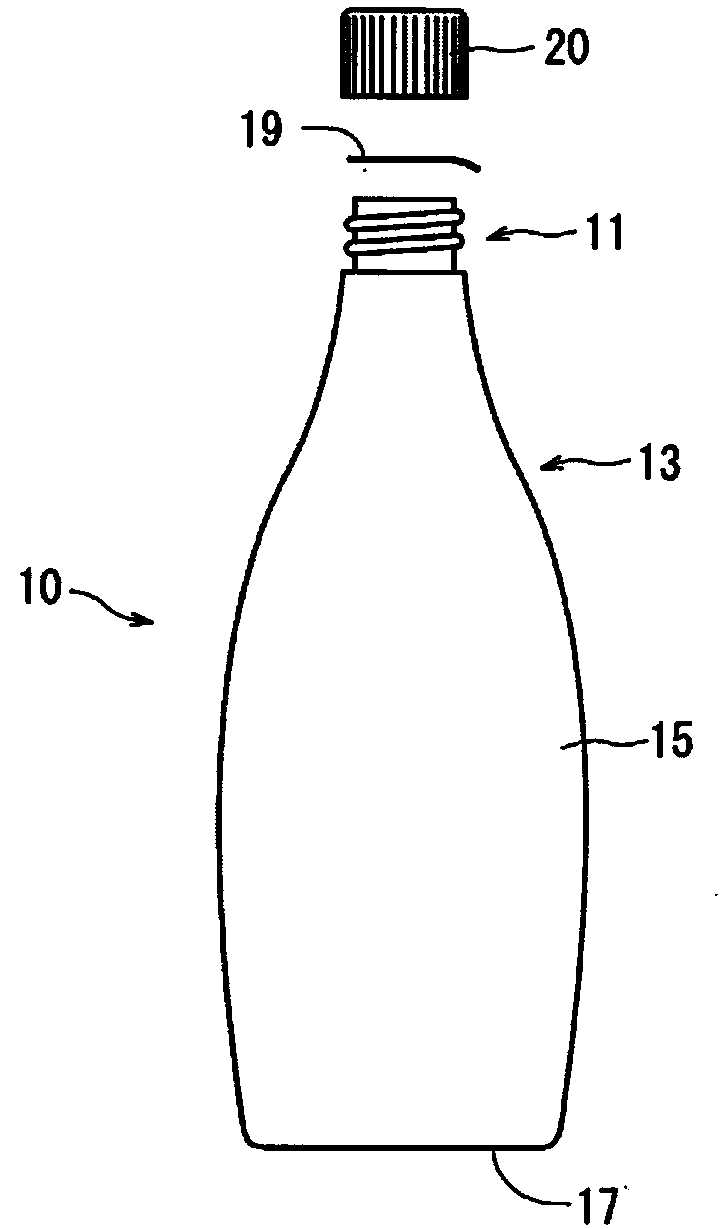

Package in which liquid contents are accommodated

一种流动性、包装体的技术,应用在容器主体的包装体领域,能够解决过量等问题,达到提高滑移性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] Hereinafter, the present invention will be described with reference to examples.

[0101] Described below are the methods for measuring various characteristics and physical properties and the container main body (bottle) employed in the following examples.

[0102]

[0103] A multilayer direct blow molded bottle having the following layer composition and a capacity of 200 ml was formed by a known method and used in the following experiments.

[0104] Bottle A: direct blow molding multilayer bottle with five types of nine layers

[0105] Layer composition: inner layer / adhesive layer / liquid diffusion inhibiting layer / adhesive layer / main layer / adhesive layer / oxygen barrier layer / adhesive layer / outer layer

[0106] Inner layer: low-density polyethylene containing 5 wt% silica (average particle diameter of silica = 5 μm)

[0107] Adhesion layer: Acid-modified polyethylene

[0108] Liquid diffusion suppression layer: Ethylene-vinyl alcohol copolymer (EVOH)

[0109] Main...

experiment example 1 to experiment example 3

[0147] Bottle A (a direct blow-molded multilayer bottle having five types of nine layers) was prepared as a container main body.

[0148] To the inner surface of bottle A, medium-chain fatty acid triglyceride as a lubricating liquid was coated in the amount shown in Table 1 by an air spray method using an air brush. A bottle having an inner surface coated with a lubricating liquid was used to confirm the pool of the above-mentioned lubricating liquid and to conduct a test of slipperiness of the fluid content. The results are shown in Table 1.

experiment example 4 to experiment example 6

[0150] Bottle B (a direct blow-molded multilayer bottle having five types of nine layers) was prepared as a container body. The amount of medium-chain fatty acid triglyceride shown in Table 1 was applied by the same method as in Experimental Example 1, followed by confirmation of a pool of lubricating liquid and a test of slipperiness of the fluid content. The results are shown in Table 1.

[0151] [Table 1]

[0152]

[0153] Table 1 shows that in Experimental Example 1 to Experimental Example 3, unevenness was formed on the inner surface of the bottle and the inner surface with unevenness was coated with a lubricating liquid. In Experimental Example 1 and Experimental Example 2, the formation of a pool of lubricating liquid was observed. In these Experimental Examples 1 and 2, the slipperiness to the contents was good. In Experimental Example 3, the formation of liquid pools was not observed, and the slipperiness to the contents was poor.

[0154] Experimental Example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com