Teeth part strengthening structure of spiral bevel gear

A technology of spiral bevel gear and strengthening structure, which is applied to belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problem of insufficient strength of the tooth structure of spiral bevel gears, and improve the bending resistance. and fracture strength, improve the impact resistance of the teeth, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to accompanying drawing.

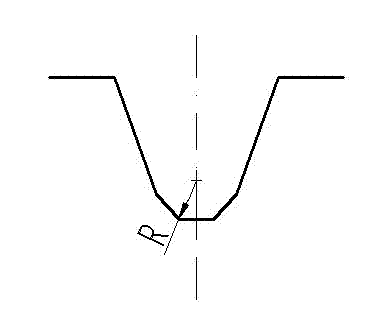

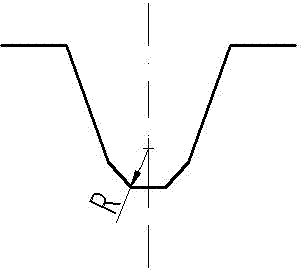

[0014] figure 1 The tooth strengthening structure of the spiral bevel gear shown is a circular transition structure formed by a circular arc located between two adjacent tooth surfaces and tangent to the tooth surfaces on both sides. The midpoint of the arc line is tangent to the dedendum circle, and the radius R value of the arc is determined by three common tangent points. This embodiment is a spiral bevel gear for Steyr heavy-duty truck drive axle. Its main structural parameters are: modulus 10.36mm, number of teeth 28, pressure angle 22.5°, tooth groove root width 4.8mm, and a radius R3.6mm fillet The diameter of the transition circle is Φ=7.2mm, which is 2.4mm larger than the root groove width. Because the tooth root is designed as a circular transition structure, the present invention has good mechanical properties. This embodiment can increase the bending resistance and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com