Plastic container having excellent scratch resistance and antifouling properties

A technology for plastic containers, metallic pigments, applied in the direction of chemical instruments and methods, coverings/exterior coatings, synthetic resin layered products, etc., which can solve the problems of reduced transparency, no improvement in scratch resistance and anti-fouling properties, etc., Achieves scratch or abrasion inhibition, excellent scratch and stain resistance, and adhesion avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108]

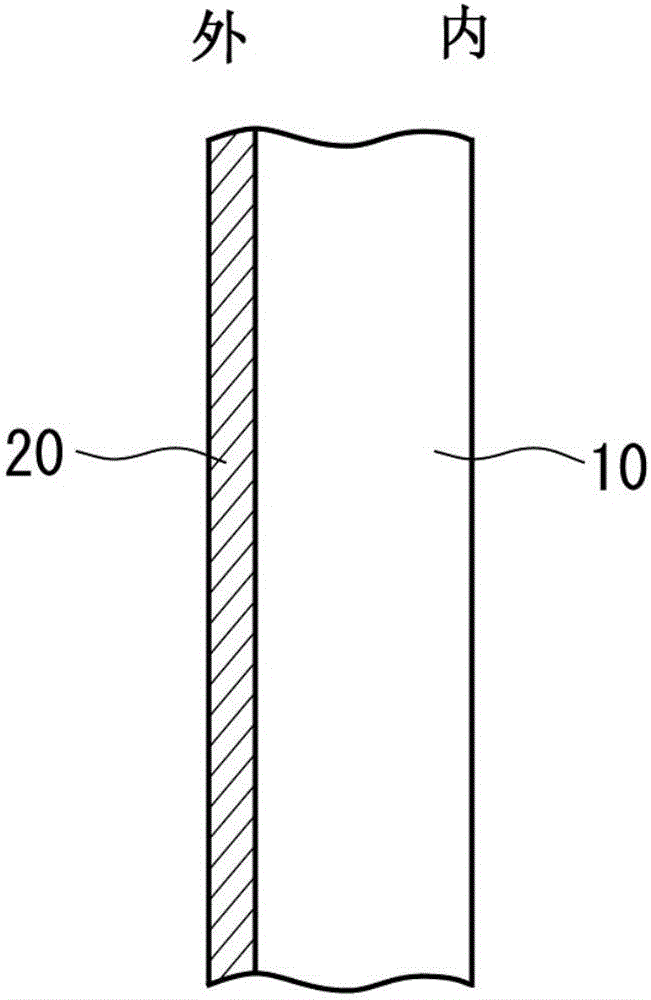

[0109] The following resins are respectively filled in four extruders, and each resin is plasticized and kneaded under heating and extruded, thereby forming a multilayer parison composed of four layers by using a multilayer head, the four layers From the outside, there are a transparent polyester-based resin outer layer, a transparent adhesive resin layer, a colored polyolefin-based resin layer containing a gloss pigment, and a colored polyolefin-based resin layer not containing a gloss pigment. Next, the parison is clamped between molds having a cavity, and compressed air is blown into the parison, thereby producing four cylindrical cylinders with a capacity of 500 ml, a height of 200 mm, and a barrel diameter of 70 mm. A multilayer plastic bottle composed of layers. The details of the resin are as follows.

[0110] Transparent polyester resin outer layer:

[0111] Transparent Amorphous Cyclohexanedimethanol (CHDM) Copolymerized Polyethylene Terephthalate Resin ...

Embodiment 2

[0124] In addition to mixing 96 parts by mass of water, 0.08 parts by mass of dimethyl silicone, and 3.92 parts by mass of a nonionic surfactant under agitation to prepare an emulsion-based coating liquid (protective liquid) for a protective film, with Plastic bottles were produced and evaluated in the same manner as in Example 1.

[0125] The content of the nonionic surfactant was 5,000 parts by mass based on 100 parts by mass of dimethyl silicone in the dry solid content of the protective film. Table 1 shows the specifications and evaluation results of the protective film.

Embodiment 3

[0127] In addition to mixing 96 parts by mass of water, 2.7 parts by mass of dimethyl silicone, and 1.3 parts by mass of a nonionic surfactant under stirring to prepare an emulsion-based coating liquid (protective liquid) for a protective film, with Plastic bottles were produced and evaluated in the same manner as in Example 1.

[0128] The content of the nonionic surfactant was 50 parts by mass based on 100 parts by mass of dimethyl silicone in the dry solid content of the protective film. Table 1 shows the specifications and evaluation results of the protective film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com