Special flexible cable for shield tunneling machine and manufacturing method of special flexible cable

A flexible cable and shield machine technology, applied in the direction of cable/conductor manufacturing, power cables, insulated cables, etc., can solve the problems of unusable and damaged cables, achieve increased stability, balanced force, and increased bending resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

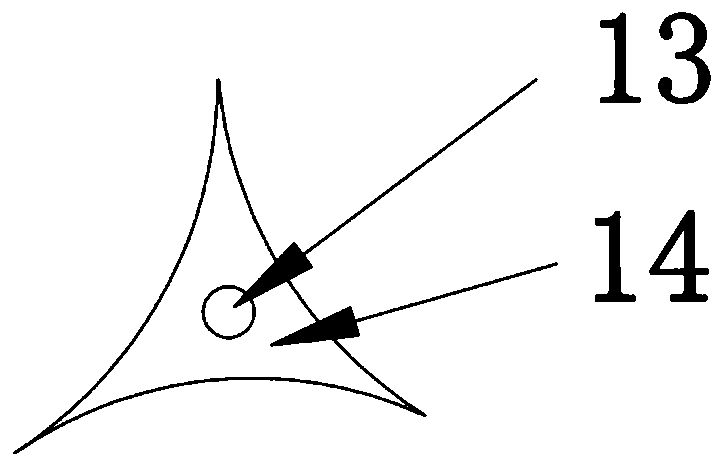

[0034] Such as Figure 1 to Figure 2 As shown, this embodiment provides a special flexible cable for shield machines. It should be noted that the serial numbers such as "first", "second", and "third" in this embodiment are only used to distinguish similar components , cannot be understood as a specific limitation on the scope of protection. In addition, directional terms such as "bottom", "top", and "side edge" in the present embodiment are described based on the drawings.

[0035] The special flexible cable for the shield machine includes a cable core, a thin non-woven fabric 12 surrounding the cable core, a reinforcing layer 11 surrounding the thin non-woven fabric 12, and an outer sheath surrounding the reinforcing layer 11 6; wherein, the cable core includes a saddle-shaped positioning cushion core 8 arranged in the center, which are respectively close to the three concave arc-shaped surfaces of the saddle-shaped positioning cushion core 8, and are three power cores arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Braiding angle | aaaaa | aaaaa |

| Braiding angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com